ECU NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2912 of 4801

BODY SIDE TRIMINT-21

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

K L

M A

B

INT

N

O P

FRONT PILLAR FINISHER : Removal and InstallationINFOID:0000000009461348

REMOVAL

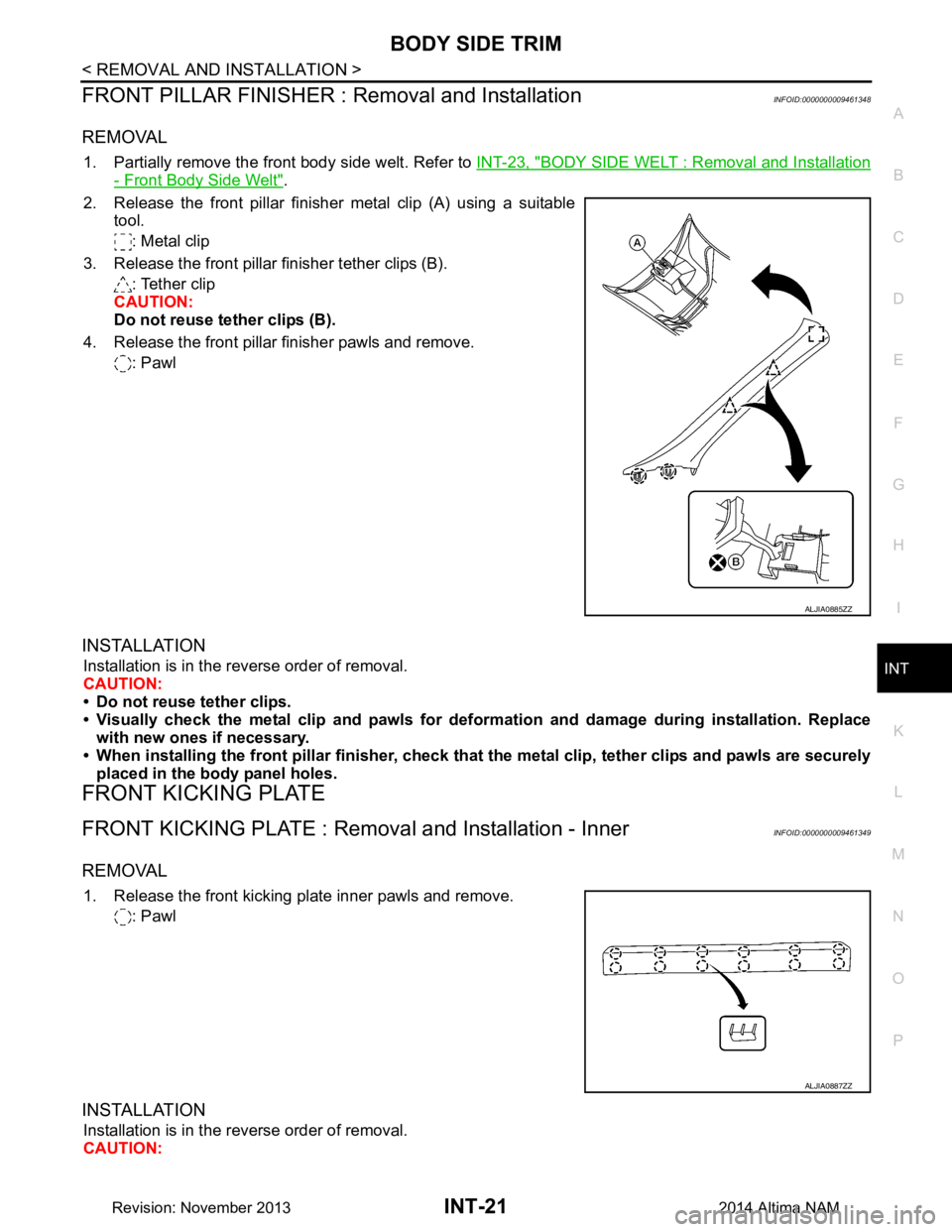

1. Partially remove the front body side welt. Refer to INT-23, "BODY SIDE WELT : Removal and Installation

- Front Body Side Welt".

2. Release the front pillar finisher metal clip (A) using a suitable tool.

: Metal clip

3. Release the front pillar finisher tether clips (B). : Tether clip

CAUTION:

Do not reuse tether clips (B).

4. Release the front pillar finisher pawls and remove. : Pawl

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse tether clips.

• Visually check the metal clip and pawls for defo rmation and damage during installation. Replace

with new ones if necessary.

• When installing the front pillar finisher, check that the metal clip, tether clips and pawls are securely

placed in the body panel holes.

FRONT KICKING PLATE

FRONT KICKING PLATE : Remova l and Installation - InnerINFOID:0000000009461349

REMOVAL

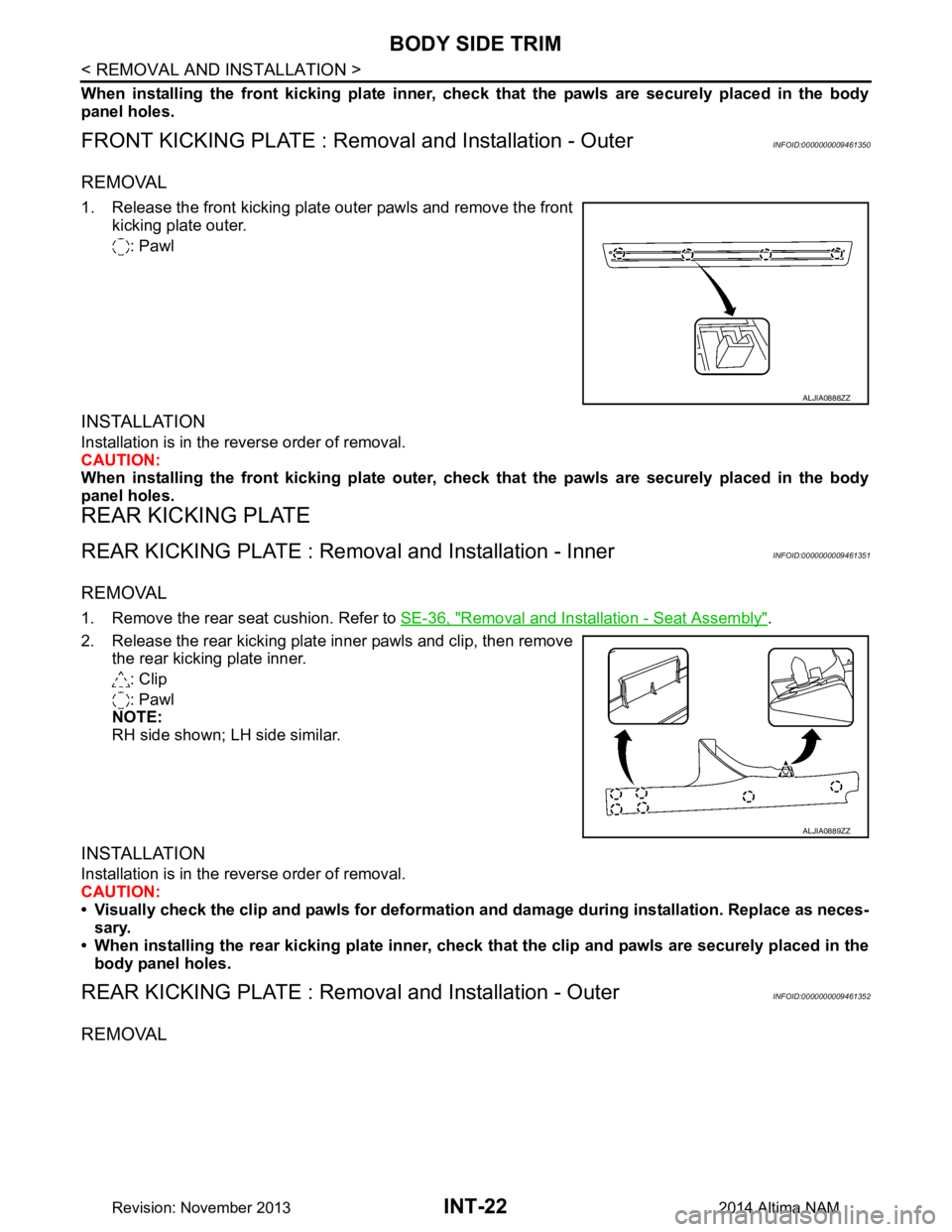

1. Release the front kicking plate inner pawls and remove.

: Pawl

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

ALJIA0885ZZ

ALJIA0887ZZ

Revision: November 20132014 Altima NAM

Page 2913 of 4801

INT-22

< REMOVAL AND INSTALLATION >

BODY SIDE TRIM

When installing the front kicking plate inner, check that the pawls are securely placed in the body

panel holes.

FRONT KICKING PLATE : Remova l and Installation - OuterINFOID:0000000009461350

REMOVAL

1. Release the front kicking plate outer pawls and remove the front

kicking plate outer.

: Pawl

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When installing the front kicking plate outer, ch eck that the pawls are securely placed in the body

panel holes.

REAR KICKING PLATE

REAR KICKING PLATE : Remova l and Installation - InnerINFOID:0000000009461351

REMOVAL

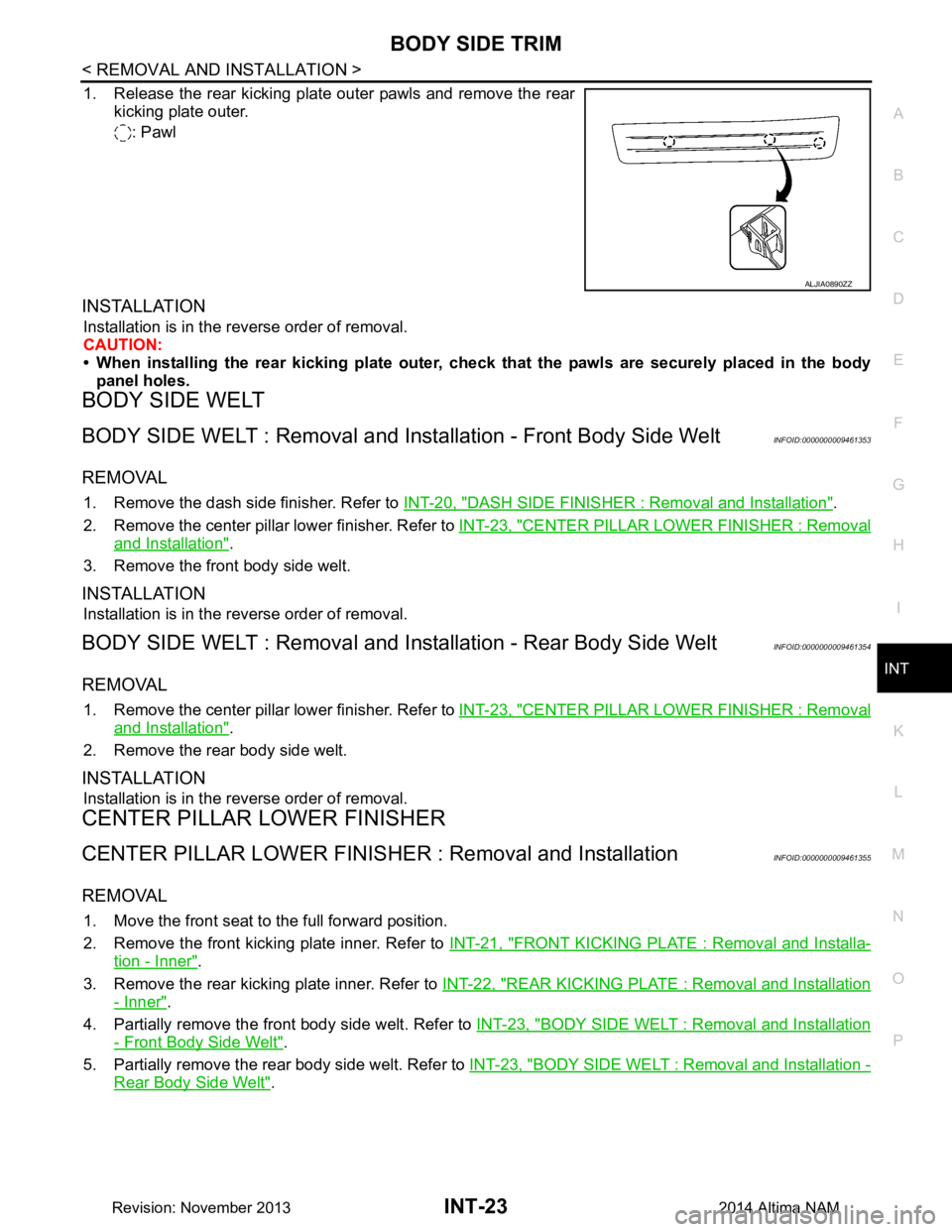

1. Remove the rear seat cushion. Refer to SE-36, "Removal and Installation - Seat Assembly".

2. Release the rear kicking plate inner pawls and clip, then remove the rear kicking plate inner.

: Clip

: Pawl

NOTE:

RH side shown; LH side similar.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the clip and pawls for deformation and damage during installation. Replace as neces-

sary.

• When installing the rear kicking plate inner, check that the clip and pawls are securely placed in the

body panel holes.

REAR KICKING PLATE : Remova l and Installation - OuterINFOID:0000000009461352

REMOVAL

ALJIA0888ZZ

ALJIA0889ZZ

Revision: November 20132014 Altima NAM

Page 2914 of 4801

BODY SIDE TRIMINT-23

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

K L

M A

B

INT

N

O P

1. Release the rear kicking plate outer pawls and remove the rear kicking plate outer.

: Pawl

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When installing the rear kicking plate outer, ch eck that the pawls are securely placed in the body

panel holes.

BODY SIDE WELT

BODY SIDE WELT : Removal and Inst allation - Front Body Side WeltINFOID:0000000009461353

REMOVAL

1. Remove the dash side finisher. Refer to INT-20, "DASH SIDE FINISHER : Removal and Installation".

2. Remove the center pillar lower finisher. Refer to INT-23, "CENTER PILLAR LOWER FINISHER : Removal

and Installation".

3. Remove the front body side welt.

INSTALLATION

Installation is in the reverse order of removal.

BODY SIDE WELT : Removal and In stallation - Rear Body Side WeltINFOID:0000000009461354

REMOVAL

1. Remove the center pillar lower finisher. Refer to INT-23, "CENTER PILLAR LOWER FINISHER : Removal

and Installation".

2. Remove the rear body side welt.

INSTALLATION

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER

CENTER PILLAR LOWER FINISHER : Removal and InstallationINFOID:0000000009461355

REMOVAL

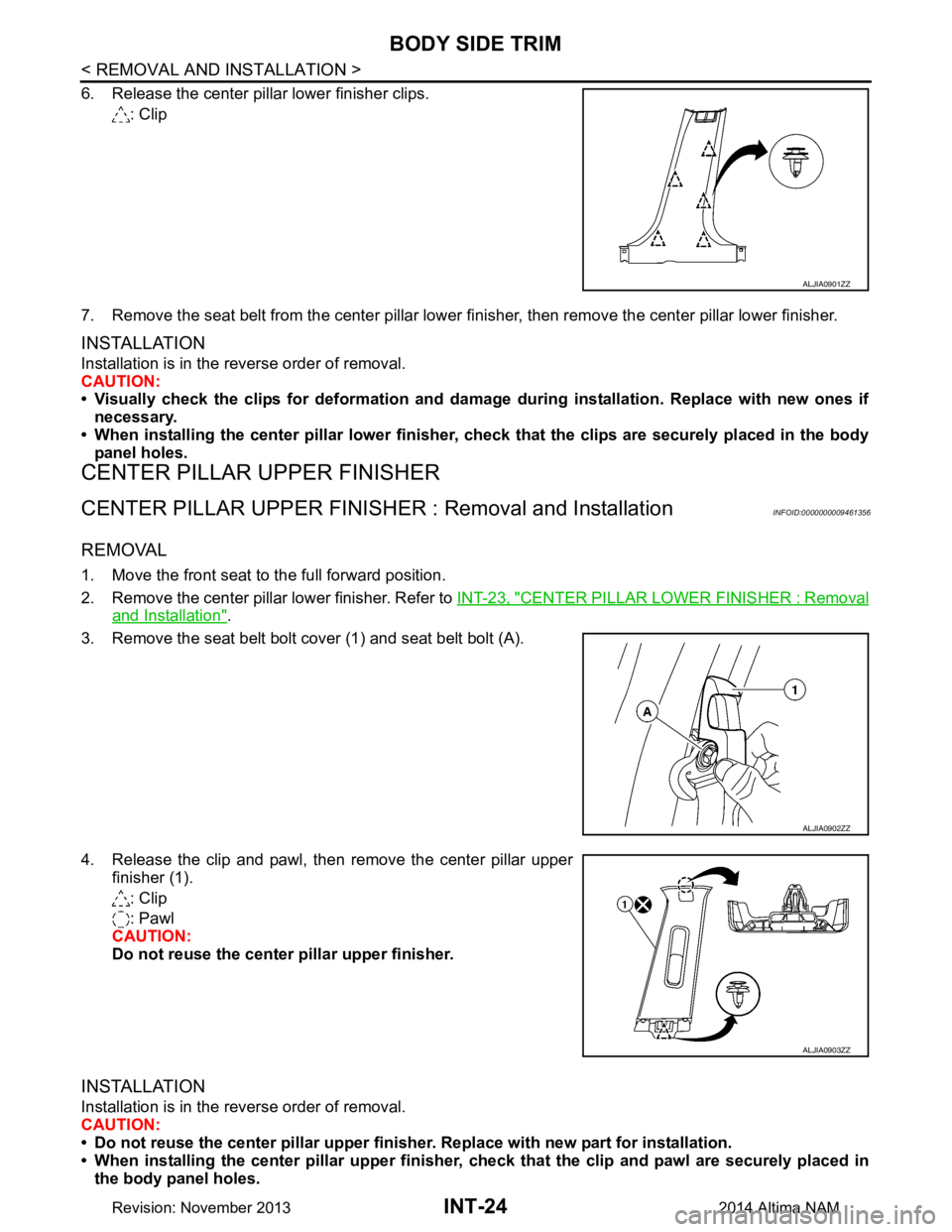

1. Move the front seat to the full forward position.

2. Remove the front kicking plate inner. Refer to INT-21, "FRONT KICKING PLATE : Removal and Installa-

tion - Inner".

3. Remove the rear kicking plate inner. Refer to INT-22, "REAR KICKING PLATE : Removal and Installation

- Inner".

4. Partially remove the front body side welt. Refer to INT-23, "BODY SIDE WELT : Removal and Installation

- Front Body Side Welt".

5. Partially remove the rear body side welt. Refer to INT-23, "BODY SIDE WELT : Removal and Installation -

Rear Body Side Welt".

ALJIA0890ZZ

Revision: November 20132014 Altima NAM

Page 2915 of 4801

INT-24

< REMOVAL AND INSTALLATION >

BODY SIDE TRIM

6. Release the center pillar lower finisher clips.: Clip

7. Remove the seat belt from the center pillar lower fi nisher, then remove the center pillar lower finisher.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the clips for deformation and dama ge during installation. Replace with new ones if

necessary.

• When installing the center pillar lower finisher, check that the clips are securely placed in the body

panel holes.

CENTER PILLAR UPPER FINISHER

CENTER PILLAR UPPER FINISHER : Removal and InstallationINFOID:0000000009461356

REMOVAL

1. Move the front seat to the full forward position.

2. Remove the center pillar lower finisher. Refer to INT-23, "CENTER PILLAR LOWER FINISHER : Removal

and Installation".

3. Remove the seat belt bolt cover (1) and seat belt bolt (A).

4. Release the clip and pawl, then remove the center pillar upper finisher (1).

: Clip

: Pawl

CAUTION:

Do not reuse the center pillar upper finisher.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse the center pillar upper finisher. Replace with new part for installation.

• When installing the center pillar upper finisher, check that the clip and pawl are securely placed in

the body panel holes.

ALJIA0901ZZ

ALJIA0902ZZ

ALJIA0903ZZ

Revision: November 20132014 Altima NAM

Page 2916 of 4801

BODY SIDE TRIMINT-25

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

K L

M A

B

INT

N

O P

REAR PILLAR FINISHER

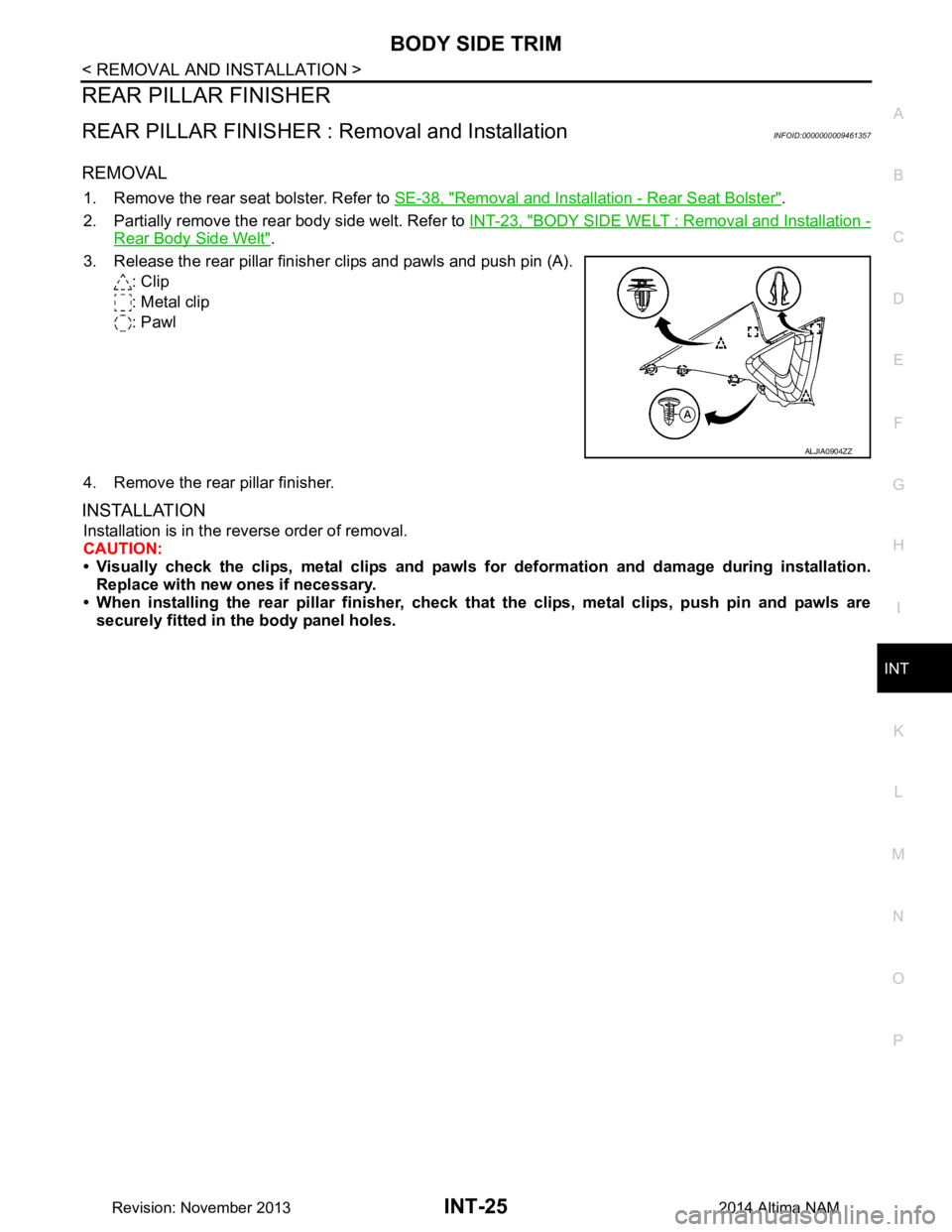

REAR PILLAR FINISHER : Removal and InstallationINFOID:0000000009461357

REMOVAL

1. Remove the rear seat bolster. Refer to SE-38, "Removal and Installation - Rear Seat Bolster".

2. Partially remove the rear body side welt. Refer to INT-23, "BODY SIDE WELT : Removal and Installation -

Rear Body Side Welt".

3. Release the rear pillar finisher clips and pawls and push pin (A). : Clip

: Metal clip

: Pawl

4. Remove the rear pillar finisher.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the clips, metal clips and pawls for deformation and damage during installation.

Replace with new ones if necessary.

• When installing the rear pillar finisher, check that the clips, metal clips, push pin and pawls are

securely fitted in the body panel holes.

ALJIA0904ZZ

Revision: November 20132014 Altima NAM

Page 2928 of 4801

IP-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951558

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000009461371

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAM

Page 2935 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

K L

M A

B

IP

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to IP-9, "Generic Squeak and Rattle Troubleshooting"

.

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-50397) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered seperately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000009889929

Refer to Table of Contents for specific component removal and installation information.

Revision: November 20132014 Altima NAM

Page 2937 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-11

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

K L

M A

B

IP

N

O P

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: November 20132014 Altima NAM

Page 2956 of 4801

![NISSAN TEANA 2014 Service Manual

LAN

HOW TO USE THIS SECTIONLAN-7

< HOW TO USE THIS MANUAL > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461390

• “ NISSAN TEANA 2014 Service Manual

LAN

HOW TO USE THIS SECTIONLAN-7

< HOW TO USE THIS MANUAL > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461390

• “](/img/5/57390/w960_57390-2955.png)

LAN

HOW TO USE THIS SECTIONLAN-7

< HOW TO USE THIS MANUAL > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461390

• “CAN FUNDAMENTAL” of LAN Section describes t

he basic knowledge of the CAN communication system

and the method of trouble diagnosis.

• For information peculiar to a vehicle and inspection procedure, refer to “CAN”.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2972 of 4801

![NISSAN TEANA 2014 Service Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461404

• “CAN” of L NISSAN TEANA 2014 Service Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461404

• “CAN” of L](/img/5/57390/w960_57390-2971.png)

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D E

F

G H

I

J

K L

B

A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

InformationINFOID:0000000009461404

• “CAN” of LAN Section describes information

peculiar to a vehicle and inspection procedures.

• For trouble diagnosis procedure, refer to LAN-18, "Trouble Diagnosis Flow Chart"

of “CAN FUNDAMEN-

TA L ” .

Abbreviation ListINFOID:0000000009461405

Unit name abbreviations in CONSULT CAN diagnosis and in this section are as per the following list.

Abbreviation Unit name

A-BAG Air bag diagnosis sensor unitABS ABS actuator and electric unit (control unit)

AV AV control unit

AV M I T S c o n t r o l u n i t

BCM BCM DLC Data link connector

ECM ECM EPS Power steering control module

HVAC A/C auto amp.

IPDM-E IPDM E/R M&A Combination meter

STRG Steering angle sensor TCM TCM

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM