heating NISSAN TEANA 2014 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1804 of 4801

![NISSAN TEANA 2014 Owners Guide

EC-804

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0196 EOT SENSOR

4. Check resistance between engine oi

l temperature sensor termi-

nals by heating with hot wate r as shown in the figure.

Is the inspection r NISSAN TEANA 2014 Owners Guide

EC-804

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0196 EOT SENSOR

4. Check resistance between engine oi

l temperature sensor termi-

nals by heating with hot wate r as shown in the figure.

Is the inspection r](/img/5/57390/w960_57390-1803.png)

EC-804

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0196 EOT SENSOR

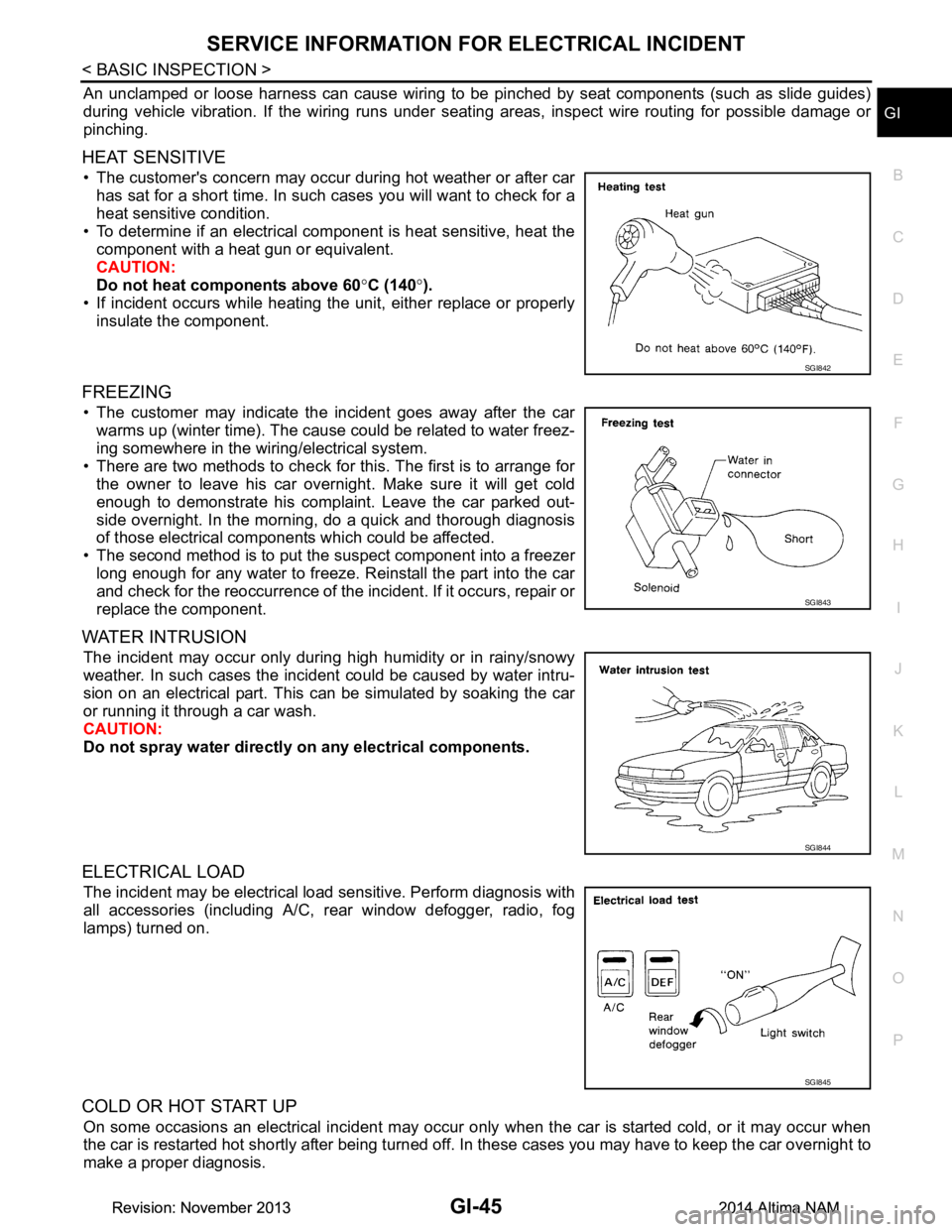

4. Check resistance between engine oi

l temperature sensor termi-

nals by heating with hot wate r as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine oil temperature sensor. Refer to EC-

548, "ENGINE CONTROL SYSTEM : Component Parts Location".

Terminals Condition Resistance (k Ω)

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

JMBIA0080ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1806 of 4801

![NISSAN TEANA 2014 Owners Guide

EC-806

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0197, P0198 EOT SENSOR

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connector NISSAN TEANA 2014 Owners Guide

EC-806

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0197, P0198 EOT SENSOR

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connector](/img/5/57390/w960_57390-1805.png)

EC-806

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0197, P0198 EOT SENSOR

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK ENGINE OIL TEMPERATURE SENSOR

Check engine oil temperature sensor. Refer to EC-806, "Component Inspection"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace engine oil temperature sensor. Refer to EC-548, "ENGINE CONTROL SYSTEM : Com-

ponent Parts Location".

Component InspectionINFOID:0000000009462662

1.CHECK ENGINE OIL TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine oil temperature sensor harness connector.

3. Remove engine oil temperature sensor. Refer to EC-548, "ENGINE CONTROL SYSTEM : Component

Parts Location".

4. Check resistance between engine oi l temperature sensor termi-

nals by heating with hot wate r as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace engine oil temperature sensor. Refer to EC-

548, "ENGINE CONTROL SYSTEM : Component Parts Location".

Terminals Condition Resistance (k Ω)

1 and 2 Temperature [ °C ( °F)] 20 (68) 2.37 - 2.63

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

JMBIA0080ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1809 of 4801

![NISSAN TEANA 2014 Owners Guide

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-809

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303,

P0304, P0305, P0306 MISFIRE

DTC LogicIN NISSAN TEANA 2014 Owners Guide

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-809

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303,

P0304, P0305, P0306 MISFIRE

DTC LogicIN](/img/5/57390/w960_57390-1808.png)

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-809

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303,

P0304, P0305, P0306 MISFIRE

DTC LogicINFOID:0000000009462666

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

illuminate when the misfire is detected on a second tr ip. During this condition, the ECM monitors the CKP

sensor signal every 1,000 engine revolutions.

A misfire malfunction can be detected in any one cylinder or in multiple cylinders.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Restart engine and let it idle for approximately 15 minutes.

6. Check 1st trip DTC.

Is 1st trip DTC detected?

Sensor Input signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300 Multiple cylinder misfires detected Multiple cylinders misfire. • Improper spark plug • Insufficient compression

• Incorrect fuel pressure

• The fuel injector circuit is open or shorted

• Fuel injector

• Intake air leakage

• The ignition signal circuit is open or shorted

• Lack of fuel

• Signal plate

• A/F sensor 1

• Incorrect PCV hose connection

P0301 No. 1 cylinder misfire detected No. 1 cylinder misfires.

P0302 No. 2 cylinder misfire detected No. 2 cylinder misfires.

P0303 No. 3 cylinder misfire detected No. 3 cylinder misfires.

P0304 No. 4 cylinder misfire detected No. 4 cylinder misfires.

P0305 No. 5 cylinder misfire detected No. 5 cylinder misfires.

P0306 No. 6 cylinder misfire detected No. 6 cylinder misfires.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1873 of 4801

![NISSAN TEANA 2014 Owners Guide

P050A, P050E COLD START CONTROLEC-873

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P050A, P050E COLD START CONTROL

DescriptionINFOID:0000000009462723

ECM controls ignition timi NISSAN TEANA 2014 Owners Guide

P050A, P050E COLD START CONTROLEC-873

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P050A, P050E COLD START CONTROL

DescriptionINFOID:0000000009462723

ECM controls ignition timi](/img/5/57390/w960_57390-1872.png)

P050A, P050E COLD START CONTROLEC-873

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

P050A, P050E COLD START CONTROL

DescriptionINFOID:0000000009462723

ECM controls ignition timing and engine idle speed when engine is started with pre-warming up condition.

This control promotes the activation of three way ca talyst by heating the catalyst and reduces emissions.

DTC LogicINFOID:0000000009462724

DTC DETECTION LOGIC

NOTE:

If DTC P050A, P050E is displayed with other DTC, first perform the trouble diagnosis for other DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT.

4. Check the indication of “COOLAN TEMP/S”.

With GST

Follow the procedure “With CONSULT” above.

Is the value of

“COOLAN TEMP/S” between 4°C (39°F) and 36°C (97°F)?

YES >> GO TO 3.

NO-1 [If it is below 4 °C (39 °F)]>>Warm up the engine until the value of “COOLAN TEMP/S” reaches 4 °C

(39 °F) or more. Retry from step 1.

NO-2 [If it is above 36 °C (97 °F)]>>Cool engine down to less than 36 °C (97 °F). Retry from step 1.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

With CONSULT

1. Set the select lever in N range.

2. Start the engine and warm up in idle with the value of “COOLAN TEMP/S” between 4°C (39 °F) and 40 °C

(104 °F) for more than 15 seconds.

3. Check 1st trip DTC.

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES >> Proceed to EC-874, "Diagnosis Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P050A Cold start idle air control system

performance ECM does not control engine idle speed properly

when engine is started with pre-warming up con-

dition. • Lack of intake air volume

• Fuel injection system

•ECM

P050E Cold start engine exhaust temper-

ature too low The temperature of the catalyst inlet does not

rise to the proper temperature when the engine

is started with pre-warming up condition.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1894 of 4801

![NISSAN TEANA 2014 Owners Guide

EC-894

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1217 ENGINE OVER TEMPERATURE

>> Repair or replace malfunctioning part.

4.CHECK RADIATOR CAP

Check radiator cap. Refer to CO-35, "System Inspection"

.

Is the NISSAN TEANA 2014 Owners Guide

EC-894

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1217 ENGINE OVER TEMPERATURE

>> Repair or replace malfunctioning part.

4.CHECK RADIATOR CAP

Check radiator cap. Refer to CO-35, "System Inspection"

.

Is the](/img/5/57390/w960_57390-1893.png)

EC-894

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1217 ENGINE OVER TEMPERATURE

>> Repair or replace malfunctioning part.

4.CHECK RADIATOR CAP

Check radiator cap. Refer to CO-35, "System Inspection"

.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace radiator cap. Refer to CO-40, "Exploded View"

.

5.CHECK THERMOSTAT

Check thermostat. Refer to CO-49, "Removal and Installation"

.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace thermostat. Refer to CO-49, "Removal and Installation"

.

6.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-741, "Component Inspection"

.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace engine coolant temperature sensor. Refer to CO-51, "Exploded View"

.

7.OVERHEATING CAUSE ANALYSIS

If the cause cannot be isolated, check the CO-33, "Troubleshooting Chart"

.

>> INSPECTION END

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2573 of 4801

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-45

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

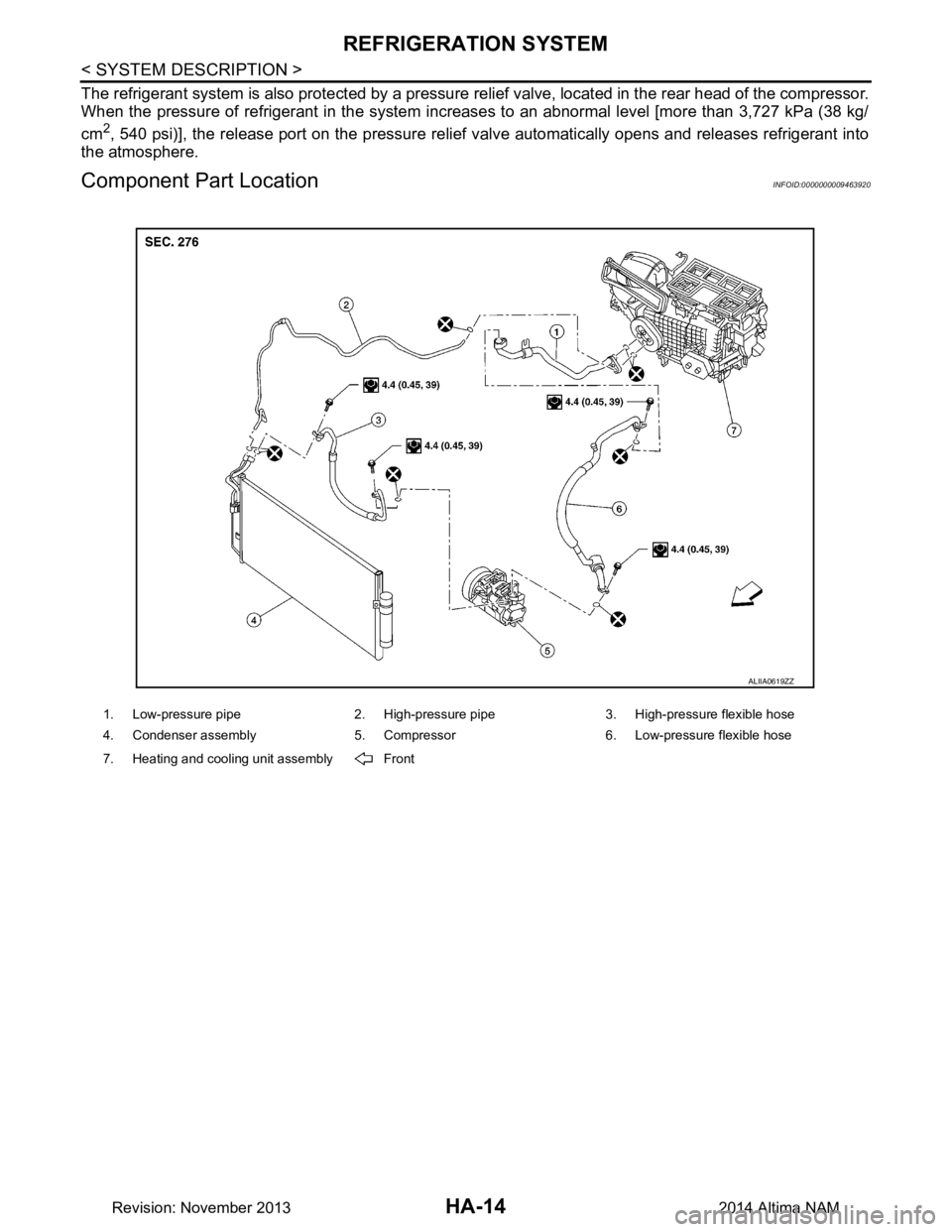

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

• The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

• To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60 °C (140 °).

• If incident occurs while heating t he unit, either replace or properly

insulate the component.

FREEZING

• The customer may indicate the incident goes away after the car warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

• There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnosis

of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This c an be simulated by soaking the car

or running it through a car wash.

CAUTION:

Do not spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

SGI842

SGI843

SGI844

SGI845

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2608 of 4801

HA-2

LOW-PRESSURE PIPE ............................................35

LOW-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

35

HIGH-PRESSURE PIPE ......................................... ...36

HIGH-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

36

CONDENSER ....................................................38

Exploded View ..................................................... ...38

CONDENSER ......................................................... ...38

CONDENSER : Removal and Installation ..............38

LIQUID TANK ......................................................... ...38

LIQUID TANK : Removal and Installation ...............38

REFRIGERANT PRESSURE SENSOR ....................39

REFRIGERANT PRESSURE SENSOR : Remov-

al and Installation ................................................. ...

39

HEATING AND COOLING UNIT ASSEMBLY ...40

Exploded View ..................................................... ...40

HEATING AND COOLING UNIT ASSEMBLY ....... ...40

HEATING AND COOLING UNIT ASSEMBLY :

Removal and Installation .........................................

41

HEATER CORE ...................................................... ...41

HEATER CORE : Removal and Installation ............42

EVAPORATOR ....................................................... ...42

EVAPORATOR : Removal and Installation .............42

EXPANSION VALVE .............................................. ...42

EXPANSION VALVE : Removal and Installation

for Expansion Valve ............................................. ...

42

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

43

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

43

Service Data and Specification (SDS) ....................43

Revision: November 20132014 Altima NAM

Page 2611 of 4801

PRECAUTIONSHA-5

< PRECAUTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

• The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi- nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacti ng surface of the mating part to improve sealing charac-

teristics.

• The reaction force of the O-ring will not occur in the dire ction that causes the joint to pull out, thereby facili-

tating piping connections.

O-RING AND REFRIGERANT CONNECTION

CAUTION:

SHA815E

1. Low-pressure pipe 2. High-pressure pipe 3. High-pressure flexible hose

4. Condenser assembly 5. Compressor 6. Low-pressure flexible hose

7. Heating and cooling unit assembly Front

ALIIA0619ZZ

Revision: November 20132014 Altima NAM

Page 2620 of 4801

HA-14

< SYSTEM DESCRIPTION >

REFRIGERATION SYSTEM

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38 kg/

cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

Component Part LocationINFOID:0000000009463920

1. Low-pressure pipe 2. High-pressure pipe 3. High-pressure flexible hose

4. Condenser assembly 5. Compressor 6. Low-pressure flexible hose

7. Heating and cooling unit assembly Front

ALIIA0619ZZ

Revision: November 20132014 Altima NAM

Page 2623 of 4801

HEATER AND AIR CONDITIONING SYSTEM SYMPTOMS

HA-17

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

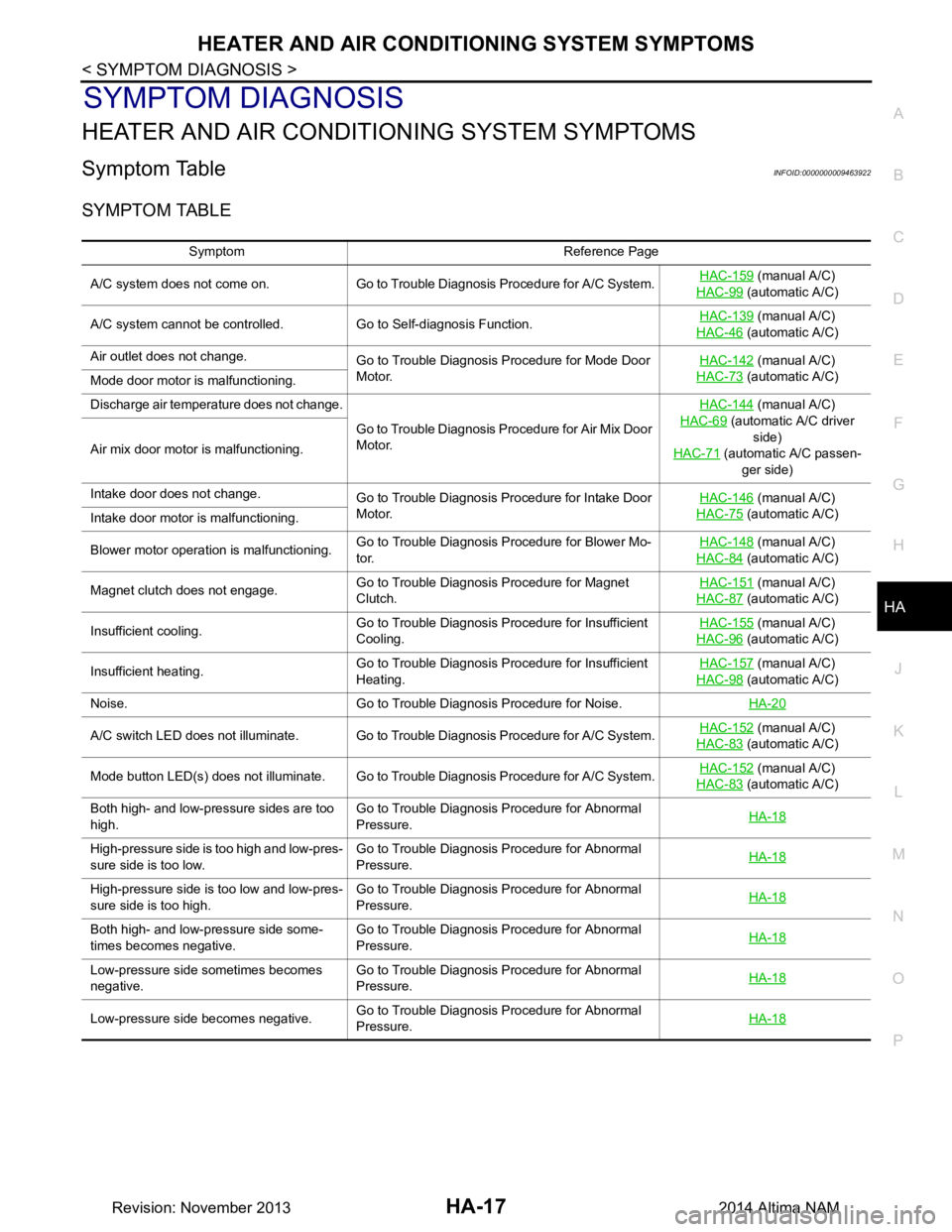

SYMPTOM DIAGNOSIS

HEATER AND AIR CONDITIONING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000009463922

SYMPTOM TABLE

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System. HAC-159

(manual A/C)

HAC-99

(automatic A/C)

A/C system cannot be controlled. Go to Self-diagnosis Function. HAC-139

(manual A/C)

HAC-46

(automatic A/C)

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door

Motor. HAC-142

(manual A/C)

HAC-73

(automatic A/C)

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door

Motor. HAC-144

(manual A/C)

HAC-69

(automatic A/C driver side)

HAC-71

(automatic A/C passen-

ger side)

Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door

Motor. HAC-146

(manual A/C)

HAC-75

(automatic A/C)

Intake door motor is malfunctioning.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Mo-

tor. HAC-148

(manual A/C)

HAC-84

(automatic A/C)

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet

Clutch. HAC-151

(manual A/C)

HAC-87

(automatic A/C)

Insufficient cooling. Go to Trouble Diagnosis Procedure for Insufficient

Cooling. HAC-155

(manual A/C)

HAC-96

(automatic A/C)

Insufficient heating. Go to Trouble Diagnosis Procedure for Insufficient

Heating. HAC-157

(manual A/C)

HAC-98

(automatic A/C)

Noise. Go to Trouble Diagnosis Procedure for Noise. HA-20

A/C switch LED does not illuminate. Go to Trouble Diagnosis Procedure for A/C System.HAC-152 (manual A/C)

HAC-83

(automatic A/C)

Mode button LED(s) does not illuminate. Go to Trouble Diagnosis Procedure for A/C System. HAC-152

(manual A/C)

HAC-83

(automatic A/C)

Both high- and low-pressure sides are too

high. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

High-pressure side is too high and low-pres-

sure side is too low. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

High-pressure side is too low and low-pres-

sure side is too high. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Both high- and low-pressure side some-

times becomes negative. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Low-pressure side sometimes becomes

negative. Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Low-pressure side becomes negative.

Go to Trouble Diagnosis Procedure for Abnormal

Pressure. HA-18

Revision: November 20132014 Altima NAM