tire pressure NISSAN TEANA 2014 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1561 of 4801

![NISSAN TEANA 2014 Owners Guide

COMPONENT PARTSEC-561

< SYSTEM DESCRIPTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The mass air flow sensor (1) is plac

ed in the stream of intake air. It

measures the intake flow rate by measuri NISSAN TEANA 2014 Owners Guide

COMPONENT PARTSEC-561

< SYSTEM DESCRIPTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The mass air flow sensor (1) is plac

ed in the stream of intake air. It

measures the intake flow rate by measuri](/img/5/57390/w960_57390-1560.png)

COMPONENT PARTSEC-561

< SYSTEM DESCRIPTION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The mass air flow sensor (1) is plac

ed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sens or controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor is built-into mass air flow sensor. The sensor detects intake air temperature

and transmits a signal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to the change in temperature. Electrical

resistance of the thermistor decreases in response to the temperature rise.

*: These data are reference values and are measured between ECM terminals.

Oil Pressure Warning LampINFOID:0000000009462506

Oil pressure warning lamp is located on the combination meter.

It indicates the low pressure of the engine oil and the malfunction of

the engine oil pressure system.

Combination meter turns the oil pressure warning lamp ON/OFF

according to the oil pressure warning lamp signal received from

ECM via CAN communication.

For details, refer to EC-583, "ENGINE PROTECTION CONTROL AT

LOW ENGINE OIL PRESSURE : System Description".

Power Valve Actuator 1 and 2INFOID:0000000009462507

The power valves are used to control the suction pa ssage of the variable induction air control system. They

are set in the fully closed or fully opened position by t he power valve actuators operated by the vacuum stored

in the vacuum tank. The vacuum to power valve actuat ors is controlled by the VIAS control solenoid valves.

PBIA9559J

Intake air temperature

[° C ( °F)] Voltag e* (V)

Resistance (k

Ω)

25 (77) 3.3 1.800 - 2.200

80 (176) 1.2 0.283 - 0.359

SEF012P

PBIA8559J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2082 of 4801

![NISSAN TEANA 2014 Owners Guide

EM-84

< UNIT REMOVAL AND INSTALLATION >[QR25DE]

ENGINE ASSEMBLY

Removal and Installation

INFOID:0000000009460508

WARNING:

• Place chocks at the front and back of the rear wheels.

• For engines n NISSAN TEANA 2014 Owners Guide

EM-84

< UNIT REMOVAL AND INSTALLATION >[QR25DE]

ENGINE ASSEMBLY

Removal and Installation

INFOID:0000000009460508

WARNING:

• Place chocks at the front and back of the rear wheels.

• For engines n](/img/5/57390/w960_57390-2081.png)

EM-84

< UNIT REMOVAL AND INSTALLATION >[QR25DE]

ENGINE ASSEMBLY

Removal and Installation

INFOID:0000000009460508

WARNING:

• Place chocks at the front and back of the rear wheels.

• For engines not equipped with slin gers, attach proper slingers and bolts as described in the Parts

Catalog.

CAUTION:

• Do not start working until the exh aust system and coolant are cool.

• If items or work required are not covered by the en gine main body section, follow the applicable pro-

cedures.

• Use the correct supporting points for lifting and jacking. Refer to GI-33, "Garage Jack and Safety

Stand".

• In removing the drive shaft, be careful not to damage the grease seals on the transaxle.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove engine cover using power tool. Refer to EM-28, "Removal and Installation".

2. Release fuel pressure. Refer to EC-182, "Work Procedure"

.

3. Disconnect the negative and positive battery terminal. Refer to PG-73, "Removal and Installation (Bat-

tery)".

4. Disconnect the fuel rail at the fuel hose quick connector (engine side). Refer to EM-41, "Removal and

Installation".

5. Drain the engine coolant. Refer to CO-12, "Changing Engine Coolant"

.

6. Remove the engine under cover. Refer to EXT-28, "Removal and Installation"

.

7. Remove hood assembly. Refer to DLK-170, "HOOD ASSEMBLY : Removal and Installation"

.

8. Remove core support cover.

9. Remove the front air duct and air cleaner case assembly. Refer to EM-29, "Removal and Installation"

.

10. Remove battery and battery tray. Refer to PG-74, "Removal and Installation (Battery Tray)"

.

11. Remove cowl top. Refer to EXT-24, "Removal and Installation"

.

12. Remove strut brace. Refer to FSU-19, "Exploded View"

.

13. Disconnect EVAP hose and vacuum hose from intake manifold.

14. Remove upper and lower radiator hoses (engine side).

15. Remove CVT cooler lines.

16. Disconnect engine room harness connecto r at the CVT and ECM connectors.

CAUTION:

Protect the harness connector with plastic bags or suitable covering to help prevent damage and

intrusion of foreign mate rials into the connectors.

17. Remove the brake booster vacuum hose.

18. Disconnect the heater hoses.

19. Remove the front wheels and tires using a power tool. Refer to WT-55, "Adjustment"

.

20. Remove the fender protector side covers (RH) and (LH). Refer to EXT-26, "FENDER PROTECTOR :

Removal and Installation".

21. Remove tie rod ends from the steering knuckles. Refer to ST-36, "Removal and Installation"

.

22. Remove the power steering gear bolts and support the power steering gear. Refer to ST-36, "Exploded

View".

23. Remove rear cover plate.

24. Remove the torque converter nuts.

25. Remove the rear engine mount torque rod.

26. Remove front exhaust tube and gaskets. Refer to EX-5, "Exploded View"

.

G. 90 N·m (9.2 kg-m, 66 ft-lb) H. 103 N·m (11 kg-m, 76 ft-lb) J. Follow installation procedure

Front

Revision: November 20132014 Altima NAM

Page 2219 of 4801

![NISSAN TEANA 2014 Owners Guide

ENGINE ASSEMBLYEM-221

< UNIT REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Do not damage the edge of the crankshaft

position sensor (POS) or the ring gear teeth.

REMOVAL

NISSAN TEANA 2014 Owners Guide

ENGINE ASSEMBLYEM-221

< UNIT REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Do not damage the edge of the crankshaft

position sensor (POS) or the ring gear teeth.

REMOVAL](/img/5/57390/w960_57390-2218.png)

ENGINE ASSEMBLYEM-221

< UNIT REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

• Do not damage the edge of the crankshaft

position sensor (POS) or the ring gear teeth.

REMOVAL

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Remove hood assembly. Refer to DLK-170, "HOOD ASSEMBLY : Removal and Installation"

.

2. Release fuel pressure. Refer to FL-5, "Inspection"

.

3. Drain engine coolant. Refer to CO-36, "Changing Engine Coolant"

.

4. Drain power steering fluid. Refer to ST-30, "Draining and Refilling"

.

5. Remove front wheels and tires (RH/LH). Refer to WT-55, "Adjustment"

.

6. Remove fender protector side covers (RH/LH). Refer to EXT-26, "FENDER PROTECTOR : Removal and

Installation".

7. Remove the engine under cover. Refer to EXT-17, "Removal and Installation"

.

8. Remove the engine room cover. Refer to EM-143, "Removal and Installation"

.

9. Remove air duct hose and resonator assembly and air cleaner case assembly with mass air flow sensor.

Refer to EM-144, "Removal and Installation"

.

10. Remove battery and battery tray. Refer to PG-74, "Removal and Installation (Battery Tray)"

.

11. Remove transmission control module. Refer to TM-183, "Removal and Installation"

.

12. Remove cowl top. Refer to EXT-24, "Removal and Installation"

.

13. Remove strut brace using power tools. Refer to FSU-19, "Exploded View"

.

14. Remove IPDM E/R. Refer to PCS-32, "Removal and Installation"

.

15. Remove the following parts: • EVAP vacuum hose

• Brake booster vacuum hose

• Heater hoses (engine side)

16. Disconnect transaxle shift control cables. Refer to TM-380, "Removal and Installation"

.

17. Remove upper and lower radiator hoses.

18. Disconnect CVT fluid cooler hoses.

19. Remove power steering reservoir, suction hose and high pressure hose.

20. Disconnect fuel hose quick connection at vehicle piping side. Refer to EM-163, "Removal and Installa-

tion".

21. Remove the front exhaust tube using power tools. Refer to EX-10, "Exploded View"

.

22. Discharge and recover the R134a refrigerant. Refer to HA-23, "Recycle Refrigerant"

.

23. Remove the A/C compressor using power tools. Refer to HA-30, "COMPRESSOR : Removal and Installa-

tion".

24. Install engine slingers into front of LH cylinder head and rear of RH cylinder head.

• (A): RH cylinder head

ALBIA0262GB

Revision: November 20132014 Altima NAM

Page 2388 of 4801

EXL-122

< PERIODIC MAINTENANCE >

HEADLAMP

PERIODIC MAINTENANCE

HEADLAMP

Aiming AdjustmentINFOID:0000000009463617

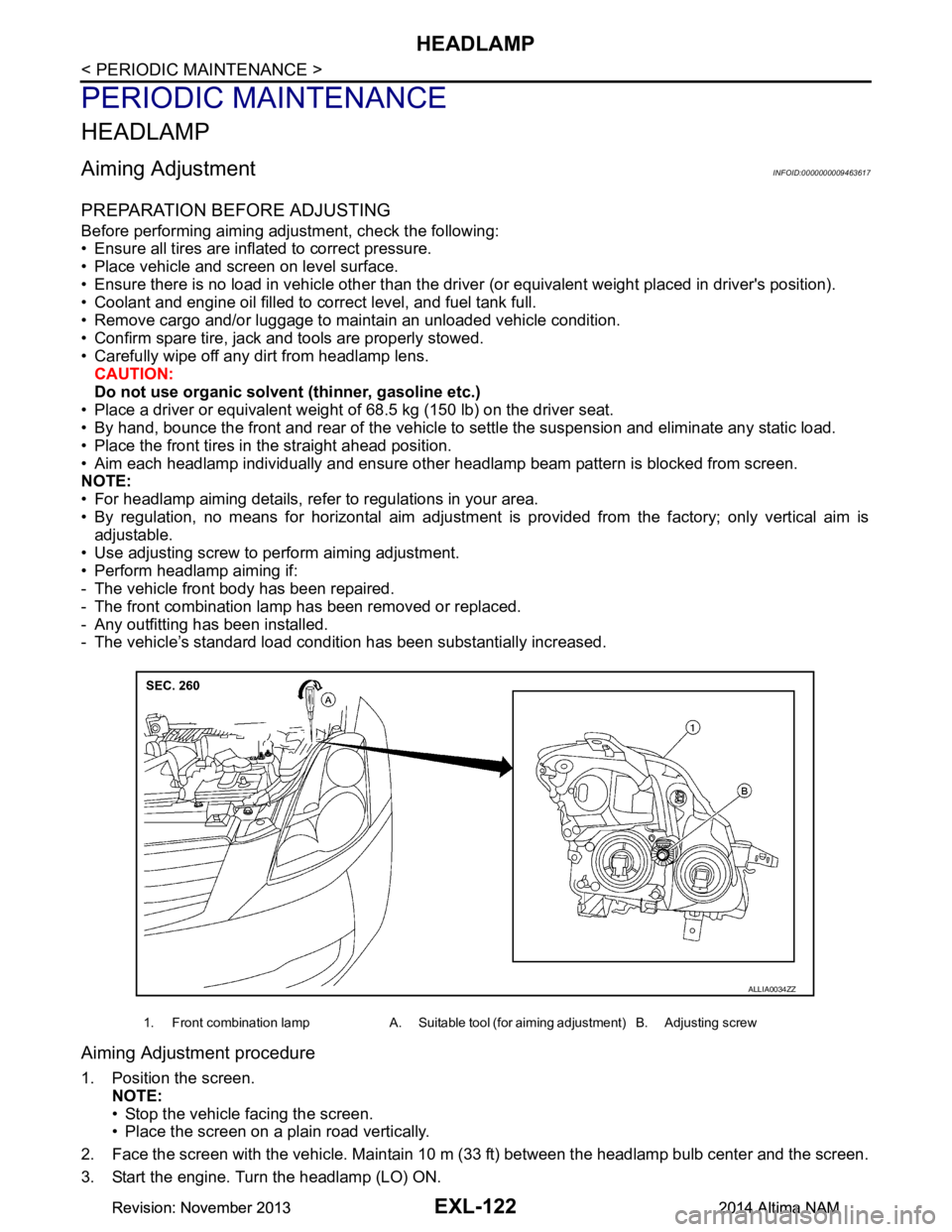

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

Aiming Adjustment procedure

1. Position the screen.

NOTE:

• Stop the vehicle facing the screen.

• Place the screen on a plain road vertically.

2. Face the screen with the vehicle. Maintain 10 m (33 ft) between the headlamp bulb center and the screen.

3. Start the engine. Turn the headlamp (LO) ON.

1. Front combination lamp A. Suitable tool (for aiming adjustment) B. Adjusting screw

ALLIA0034ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2390 of 4801

EXL-124

< PERIODIC MAINTENANCE >

FRONT FOG LAMP

FRONT FOG LAMP

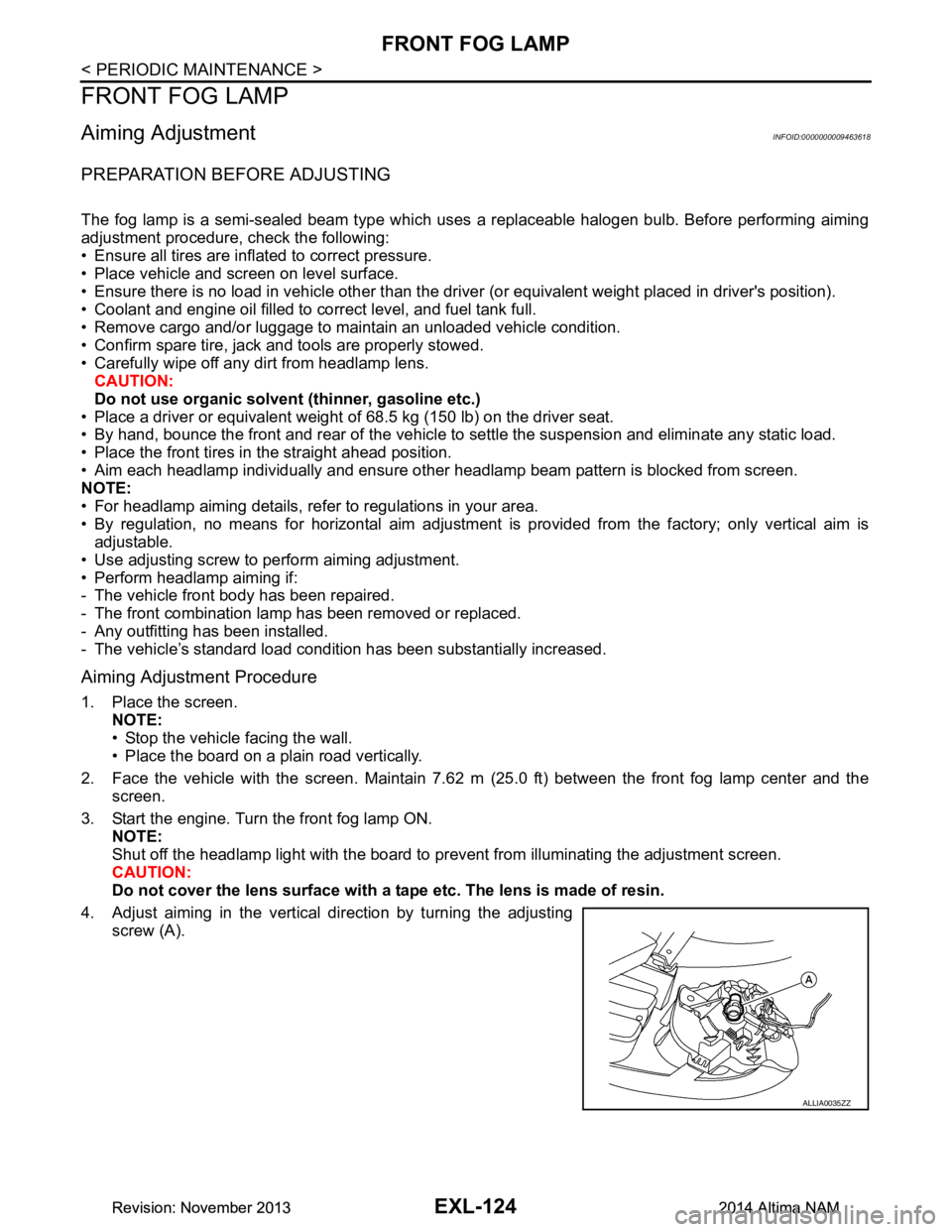

Aiming AdjustmentINFOID:0000000009463618

PREPARATION BEFORE ADJUSTING

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment procedure, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

Aiming Adjustment Procedure

1. Place the screen. NOTE:

• Stop the vehicle facing the wall.

• Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 7.62 m (25.0 ft) between the front fog lamp center and the

screen.

3. Start the engine. Turn the front fog lamp ON. NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

CAUTION:

Do not cover the lens surface with a tape etc. The lens is made of resin.

4. Adjust aiming in the vertical direction by turning the adjusting screw (A).

ALLIA0035ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2508 of 4801

FRONT SUSPENSION ASSEMBLYFSU-7

< PERIODIC MAINTENANCE >

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

PERIODIC MAINTENANCE

FRONT SUSPENSION ASSEMBLY

Inspection and AdjustmentINFOID:0000000009460626

INSPECTION

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between upper link and steering knuckle.

3. Measure axial end play by prying it up and down.Refer to FSU-26, "Ball Joint"

.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

SHOCK ABSORBER

Check for oil leakage, damage and repl ace if malfunction is detected.

WHEEL ALIGNMENT

Description

Measure wheel alignment under unladen conditions.

NOTE:

"Unladen conditions" means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

General Information and Recommendations

• A four-wheel thrust alignment should be performed.

- This type of alignment is re commended for any NISSAN vehicle.

- The four-wheel "thrust" process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN vehicle.

- The rack should be checked to ensure that it is level.

• Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

Preliminary Check

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-60, "Road Wheel"

.

3. Wheel bearing axial end play. Refer to FAX-27, "Wheel Bearing"

.

4. Transverse link ball joint axial end play. Refer to FSU-11, "Removal and Installation"

.

5. Shock absorber operation.

6. Each mounting part of axle and suspension for looseness and deformation.

7. Each of suspension member, shock absorber, upper link and transverse link for cracks, deformation and other damage.

8. Vehicle height (posture).

Alignment Process

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

• When displaying the alignment settings, m any alignment machines use "indicators" Do not use these indi-

cators. : (Green/red, plus or minus, Go/No Go).

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

Revision: November 20132014 Altima NAM

Page 2544 of 4801

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

P

R

S

T

U

V

OL Open loop

OSS Output shaft speed

ABBREVIATION DESCRIPTION P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position PSP Power steering pressurePTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION RAM Random access memoryRAS Rear active steer RH Right-hand

ROM Read only memory RPM Engine speed RR Rear

ABBREVIATION DESCRIPTION SAE Society of Automotive Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications SRT System readiness testSST Special Service Tools

ABBREVIATION DESCRIPTION TC Turbocharger

TCM Transmission control module TCS Traction control system

TCU Telematics communication unit TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

ABBREVIATION DESCRIPTION USS Uphill start support

ABBREVIATION DESCRIPTION VCM Vehicle control moduleVDC Vehicle dynamics control system

ABBREVIATION DESCRIPTION

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2983 of 4801

![NISSAN TEANA 2014 Owners Guide

LAN-34

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Paddle shift down signal*2

RT

Paddle shift up signal

*2RT

Manual mode signal

*2RT

Market information signal T R R

Not manual mode signal

*2RT

Overdrive cont NISSAN TEANA 2014 Owners Guide

LAN-34

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Paddle shift down signal*2

RT

Paddle shift up signal

*2RT

Manual mode signal

*2RT

Market information signal T R R

Not manual mode signal

*2RT

Overdrive cont](/img/5/57390/w960_57390-2982.png)

LAN-34

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Paddle shift down signal*2

RT

Paddle shift up signal

*2RT

Manual mode signal

*2RT

Market information signal T R R

Not manual mode signal

*2RT

Overdrive control switch signal

*1RT

Parking brake switch signal T R R R

Seat belt buckle switch signal T R

Vehicle speed signal RRRR T R R R

RRRRRR TR

Steering angle sensor signal R T R R

Buzzer output signal RT

RT

Meter display signal R T

A/C switch signal R T

*3T*4

Ambient sensor signal*3RT

Blower fan motor switch signal R T

*3T*4

ABS operation signal R T

ABS warning lamp signal R T

Brake warning lamp signal R T

SLIP indicator lamp signal R T

TCS operation signal R T

VDC OFF indicator lamp signal R T

VDC operation signal R T

Yaw rate signal RT

Day time running light request signal R R R T

Door switch signal R R R R T

Front fog light request signal R R R R T

Front wiper request signal R R T

High beam request signal R R R R T

Horn reminder signal R T

Ignition switch ON signal R T

Key warning signal R T

Low beam request signal R R R R T

Meter TPMS display signal R T

Position light request signal R R R R T

Rear window defogger switch signal R R T

Sleep wake up signal R R T

Starter control relay signal R T

Theft warning horn request signal R T

Tire pressure data signal R R T Signal name

ECM

EPS

IPDM-E TCM

M&A

STRG AV

AV M

HVAC ABS

BCM

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3183 of 4801

![NISSAN TEANA 2014 Owners Guide

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

in NISSAN TEANA 2014 Owners Guide

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

in](/img/5/57390/w960_57390-3182.png)

OIL COOLERLU-33

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

LU

NP

O

When removing components such as hoses, tubes/lines, etc.

, cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine under cover. Refer to EXT-17, "Removal and Installation".

2. Remove the RH wheel and tire. Refer to WT-53, "Inspection"

.

3. Remove the front fender protector side cover RH. Refer to EXT-26, "FENDER PROTECTOR : Exploded

View".

4. Drain engine coolant. Refer to CO-36, "Changing Engine Coolant"

.

CAUTION:

Do not spill coolant on the drive belt.

5. Disconnect water hoses from oil cooler.

6. Remove the oil filter. Refer to LU-27, "Removal and Installation"

.

7. Remove oil cooler.

8. Remove core support cover. Refer to DLK-179, "Removal and Installation"

.

9. Remove front air duct. Refer to EM-84, "Removal and Installation"

.

10. Remove reservoir tank. Refer to CO-40, "Exploded View"

.

INSPECTION AFTER REMOVAL

1. Check oil cooler for cracks.

2. Check oil cooler for clogging by blowing through coolant inlet. If necessary, replace oil cooler.

Oil Pressure Relief Valve

Inspect oil pressure relief valve for movement, cracks and breaks by pushing the ball. If replacement is neces-

sary, remove valve by prying it out with a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Do not reuse copper gasket.

• When installing the oil cooler, align the oil cooler slot with the stopper of the oil pan.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to LU-9, "Inspection"

and CO-11, "System Inspection".

2. Start the engine, and check that there is no leakage of engine oil or engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and the engine coolant level again. Refer to LU-9, "Inspection"

and CO-11,

"System Inspection".

Revision: November 20132014 Altima NAM

Page 3189 of 4801

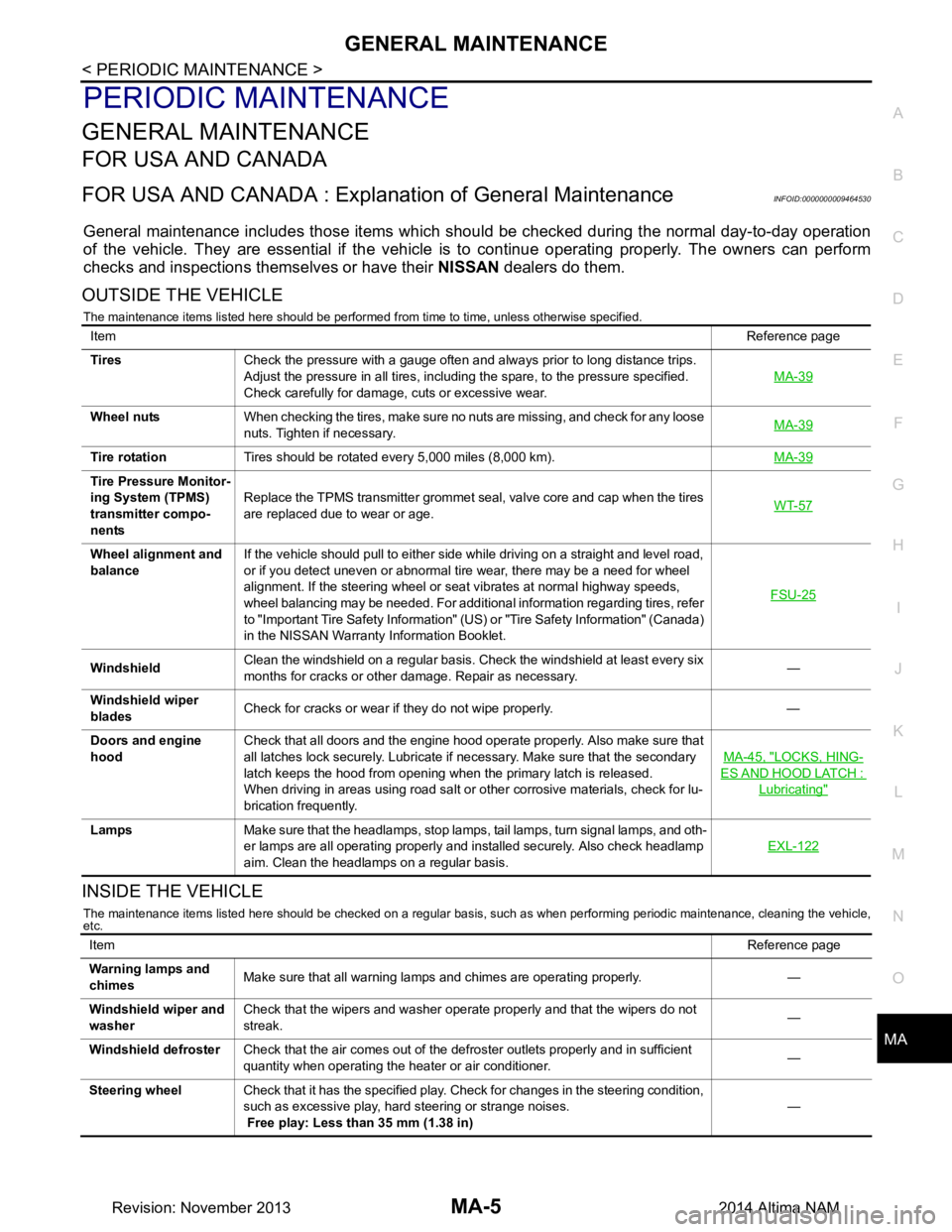

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

FOR USA AND CANADA

FOR USA AND CANADA : Explana

tion of General MaintenanceINFOID:0000000009464530

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. MA-39

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. MA-39

Tire rotation

Tires should be rotated every 5,000 miles (8,000 km). MA-39

Tire Pressure Monitor-

ing System (TPMS)

transmitter compo-

nents Replace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age. WT-57

Wheel alignment and

balance If the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to "Important Tire Safety Information" (US) or "Tire Safety Information" (Canada)

in the NISSAN Warranty Information Booklet. FSU-25

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate properly. Also make sure that

all latches lock securely. Lubricate if necessary. Make sure that the secondary

latch keeps the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lu-

brication frequently. MA-45, "LOCKS, HING-

ES AND HOOD LATCH :

Lubricating"

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. EXL-122

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. —

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: November 20132014 Altima NAM