DISPLAY UNIT NISSAN TEANA 2014 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 244 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-98

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1197 VACUUM SENSOR

C1197 VACUUM SENSOR

DTC LogicINFOID:0000000009463811

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

NISSAN TEANA 2014 Workshop Manual

BRC-98

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1197 VACUUM SENSOR

C1197 VACUUM SENSOR

DTC LogicINFOID:0000000009463811

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT](/img/5/57390/w960_57390-243.png)

BRC-98

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1197 VACUUM SENSOR

C1197 VACUUM SENSOR

DTC LogicINFOID:0000000009463811

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

1. Turn the ignition switch ON.

2. Perform self-diagnostic result.

Is DTC C1197 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-98, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463812

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

1.CHECK BRAKE BOOSTER

1. Turn the ignition switch OFF.

2. Check brake booster. Refer to BR-10, "Inspection"

.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace brake booster. Refer to BR-28, "Removal and Installation - QR25DE"

or BR-29,

"Removal and Installation - VQ35DE".

2.CHECK VACUUM PIPING

Check vacuum piping. Refer to BR-28, "Exploded View"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace vacuum piping. Refer to BR-32, "Removal and Installation"

.

3.CHECK VACUUM SENSOR CIRCUIT

1. Disconnect vacuum sensor harness connector.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check continuity between vacuum sensor harness connector and ABS ac tuator and electric unit (control

unit) harness connector.

4. Check continuity between vacuum sensor harness connector and ground.

DTC Display Item Malfunction detected condition Possible causes

C1197 VACUUM SENSOR When a malfunction is detected in vacuum sensor. • Harness or connector

• Vacuum sensor (brake booster)

• Vacuum piping

• ABS actuator and electric unit (control unit)

Vacuum sensor ABS actuator and el ectric unit (control unit)

Continuity

Connector Terminal Connector Terminal

E27 1

E54 12

Ye s

224

35

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 246 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-100

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1198 VACUUM SENSOR

C1198 VACUUM SENSOR

DTC LogicINFOID:0000000009463813

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

NISSAN TEANA 2014 Workshop Manual

BRC-100

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1198 VACUUM SENSOR

C1198 VACUUM SENSOR

DTC LogicINFOID:0000000009463813

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT](/img/5/57390/w960_57390-245.png)

BRC-100

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1198 VACUUM SENSOR

C1198 VACUUM SENSOR

DTC LogicINFOID:0000000009463813

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

1. Turn the ignition switch ON.

2. Perform self-diagnostic result.

Is DTC C1198 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-100, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463814

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

1.CHECK VACUUM SENSOR CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect vacuum sensor harness connector.

3. Disconnect ABS actuator and electric unit (control unit) harness connector.

4. Check continuity between vacuum sensor harness connector and ABS ac tuator and electric unit (control

unit) harness connector.

5. Check continuity between vacuum sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning components.

2.CHECK TERMINAL

DTC Display Item Malfunction detected condition Possible causes

C1198 VACUUM SEN CIR • When an open circuit is detected in vacuum sensor

circuit.

• When a short circuit is detected in vacuum sensor circuit.

• When a malfunction is detected in vacuum sensor

noise. • Harness or connector

• Vacuum sensor (brake booster)

• ABS actuator and electric unit (control unit)

Vacuum sensor ABS actuator and electric unit (control unit) Continuity

Connector Terminal Connector Terminal

E27 1

E54 12

Ye s

224

35

Vacuum sensor —Continuity

Connector Terminal

E27 1

Ground No

2

3

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 248 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-102

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1199 BRAKE BOOSTER

C1199 BRAKE BOOSTER

DTC LogicINFOID:0000000009463815

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

NISSAN TEANA 2014 Workshop Manual

BRC-102

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1199 BRAKE BOOSTER

C1199 BRAKE BOOSTER

DTC LogicINFOID:0000000009463815

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT](/img/5/57390/w960_57390-247.png)

BRC-102

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1199 BRAKE BOOSTER

C1199 BRAKE BOOSTER

DTC LogicINFOID:0000000009463815

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

1. Turn the ignition switch ON.

2. Perform self-diagnostic result.

Is DTC C1199 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-102, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463816

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

1.CHECK BRAKE BOOSTER

1. Turn the ignition switch OFF.

2. Check brake booster. Refer to BR-10, "Inspection"

.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace brake booster. Refer to BR-28, "Removal and Installation - QR25DE"

or BR-29,

"Removal and Installation - VQ35DE".

2.CHECK VACUUM PIPING

Check vacuum piping. Refer to BR-28, "Exploded View"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace vacuum piping. Refer to BR-32, "Removal and Installation"

.

3.CHECK VACUUM SENSOR CIRCUIT

1. Disconnect vacuum sensor harness connector.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check continuity between vacuum sensor harness connector and ABS ac tuator and electric unit (control

unit) harness connector.

4. Check continuity between vacuum sensor harness connector and ground.

DTC Display Item Malfunction detected condition Possible causes

C1199 BRAKE BOOSTER When brake booster vacuum is approx. 0 kPa (0 mm-

Hg) during engine running. • Harness or connector

• Vacuum sensor (brake booster)

• Vacuum piping

• ABS actuator and electric unit (control unit)

Vacuum sensor ABS actuator and el ectric unit (control unit)

Continuity

Connector Terminal Connector Terminal

E27 1

E54 12

Ye s

224

35

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 250 of 4801

![NISSAN TEANA 2014 Workshop Manual

BRC-104

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C119A VACUUM SENSOR

C119A VACUUM SENSOR

DTC LogicINFOID:0000000009463817

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

NISSAN TEANA 2014 Workshop Manual

BRC-104

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C119A VACUUM SENSOR

C119A VACUUM SENSOR

DTC LogicINFOID:0000000009463817

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT](/img/5/57390/w960_57390-249.png)

BRC-104

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C119A VACUUM SENSOR

C119A VACUUM SENSOR

DTC LogicINFOID:0000000009463817

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

1. Turn the ignition switch ON.

2. Perform self-diagnostic result.

Is DTC C119A detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-104, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463818

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

1.CHECK VACUUM SENSOR POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect vacuum sensor harness connector.

3. Check voltage between vacuum sensor harness connector and ground.

4. Turn the ignition switch ON. CAUTION:

Never start engine.

5. Check voltage between vacuum sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK VACUUM SENSOR POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check continuity between vacuum sensor harness connector and ABS ac tuator and electric unit (control

unit) harness connector.

DTC Display Item Malfunction detected condition Possible causes

C119A VACUUM SEN VOLT When a malfunction is detected in supply power volt-

age of vacuum sensor. • Harness or connector

• Vacuum sensor (brake booster)

• ABS actuator and electric unit (control unit)

Vacuum sensor —Voltag e

(Approx.)

Connector Terminal

E27 3 Ground 0 V

Vacuum sensor —Vo l ta g e

(Approx.)

Connector Terminal

E27 3 Ground 4.75 V – 5.25 V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 253 of 4801

![NISSAN TEANA 2014 Workshop Manual

U1002 SYSTEM COMM (CAN)BRC-107

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

U1002 SYSTEM COMM (CAN)

DTC LogicINFOID:0000000009463821

DTC DETECTION LOGIC

DTC CONFIRMATI NISSAN TEANA 2014 Workshop Manual

U1002 SYSTEM COMM (CAN)BRC-107

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

U1002 SYSTEM COMM (CAN)

DTC LogicINFOID:0000000009463821

DTC DETECTION LOGIC

DTC CONFIRMATI](/img/5/57390/w960_57390-252.png)

U1002 SYSTEM COMM (CAN)BRC-107

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

U1002 SYSTEM COMM (CAN)

DTC LogicINFOID:0000000009463821

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch ON.

2. Perform self diagnosis for “ABS”.

Is DTC

“U1002” detected?

YES >> Proceed to BRC-107, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463822

CAUTION:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

1.CHECK CAN DIAGNOSIS SUPPORT MONITOR

1. Select “ABS” and “CAN Diagnosis Support Monitor” in order with CONSULT.

2. Check malfunction history between each control unit c onnected to ABS actuator and electric unit (control

unit).

Check the result of

“PA S T”?

All items are “OK”>>Refer to GI-43, "Intermittent Incident".

“TRANSMIT DIAG” is other than “OK”>>GO TO 2.

A control unit other than ABS actuator and electric unit (control unit) is anything other than “OK”>>GO TO 3.

2.CHECK TRANSMITTING SIDE UNIT

Check the ABS actuator and electric unit (control unit) harness connector terminals 14 and 26 for damage or

loose connection.

Is the inspection result normal?

YES >> Erase self-diagnosis results. Then perform self-diagnosis for “ABS” with CONSULT.

NO >> Recheck terminals for damage or loose connection.

3.CHECK APPLICABLE CONTROL UNIT

Check damage or loose connection of each CAN communication line harness connector terminals.

Is the inspection result normal?

YES >> Erase self-diagnosis results. Then perform self-diagnosis for applicable control unit with CON-

SULT.

NO >> Recheck terminals for damage or loose connection.

DTC Display item Malfunction detected condition Possible cause

U1002 SYSTEM COMM(CAN) When ABS actuator and electric

unit (control unit) is not

transmitting or receiving CAN communication signal for 2

seconds or less. • CAN communication line

• ABS actuator and electric unit

(control unit)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 435 of 4801

DAS-2

U1000 CAN COMM CIRCUIT ............................48

Description ........................................................... ...48

DTC Logic ...............................................................48

Diagnosis Procedure ..............................................48

U1010 CONTROL UNIT (CAN) .........................49

Description ........................................................... ...49

DTC Logic ...............................................................49

Diagnosis Procedure ..............................................49

U111A REAR CAMERA IMAGE SIGNAL CIR-

CUIT ................................................................ ...

50

DTC Logic ............................................................ ...50

Diagnosis Procedure ..............................................50

U1232 STEERING ANGLE SENSOR ................52

DTC Logic ............................................................ ...52

Diagnosis Procedure ..............................................52

U1305 CAMERA IMAGE CALIB .......................53

DTC Logic ............................................................ ...53

Diagnosis Procedure ..............................................53

U1308 CAMERA CONFIG .................................54

DTC Logic ............................................................ ...54

Diagnosis Procedure ..............................................54

U1309 PUMP UNIT CURRENT .........................55

DTC Logic ............................................................ ...55

Diagnosis Procedure ..............................................55

U130B REAR CAMERA COMM ERROR ..........58

DTC Logic ............................................................ ...58

Diagnosis Procedure ..............................................58

U1310 PUMP UNIT CIRCUIT ............................59

DTC Logic ............................................................ ...59

Diagnosis Procedure ..............................................59

POWER SUPPLY AND GROUND CIRCUIT .....62

Diagnosis Procedure ........................................... ...62

WARNING SYSTEMS SWITCH CIRCUIT .........63

Component Function Check ................................ ...63

Diagnosis Procedure ..............................................63

Component Inspection ............................................64

WARNING SYSTEMS ON INDICATOR CIR-

CUIT ................................................................ ...

65

Component Function Check ................................ ...65

Diagnosis Procedure ..............................................65

Component Inspection ............................................66

WARNING BUZZER CIRCUIT ...........................67

Component Function Check ................................ ...67

Diagnosis Procedure ..............................................67

REMOVAL AND INSTALLATION ...............68

ITS CONTROL UNIT ....................................... ...68

Removal and Installation ..................................... ...68

REAR VIEW CAMERA ......................................69

Exploded View ..................................................... ...69

Removal and Installation .........................................69

REAR VIEW CAMERA WASHER CONTROL

UNIT ................................................................ ...

70

Exploded View ..................................................... ...70

Removal and Installation .........................................70

REAR VIEW CAMERA AIR PUMP MOTOR .. ...71

Exploded View ..................................................... ...71

Removal and Installation .........................................71

LDW

PRECAUTION ........ ....................................

72

PRECAUTIONS .............................................. ...72

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

72

Precaution for Work ................................................72

Precautions For Harness Repair .............................72

Precaution for LDW System Service .................... ...73

PREPARATION ..........................................74

PREPARATION .............................................. ...74

Special Service Tool ............................................ ...74

SYSTEM DESCRIPTION ...........................75

COMPONENT PARTS .................................... ...75

Component Parts Location .................................. ...75

Component Description ..........................................76

SYSTEM ............................................................77

System Description .............................................. ...77

Fail-safe (ITS Control Unit) .....................................79

Fail-safe (Rear View Camera) ................................79

OPERATION ......................................................80

Switch Name and Function .................................. ...80

Menu Displayed by Pressing Each Switch ..............80

HANDLING PRECAUTION ............................ ...82

Precautions for Lane Departure Warning ............ ...82

DIAGNOSIS SYSTEM (ITS CONTROL UNIT) ...83

CONSULT Function (AVM) .................................. ...83

ECU DIAGNOSIS INFORMATION .............86

ITS CONTROL UNIT .........................................86

Reference Value .................................................. ...86

Fail-safe ..................................................................88

DTC Inspection Priority Chart .............................. ...88

DTC Index ............................................................ ...89

WIRING DIAGRAM ....................................91

DRIVER ASSISTANCE SYSTEMS ................ ...91

Wiring Diagram .................................................... ...91

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 437 of 4801

DAS-4

LDW SYSTEM SETTINGS CANNOT BE

TURNED ON/OFF IN VEHICLE INFORMA-

TION DISPLAY ............................................... .

140

Description ........................................................... ..140

Diagnosis Procedure .............................................140

NORMAL OPERATING CONDITION ..............141

Description ........................................................... ..141

REMOVAL AND INSTALLATION ..............142

WARNING SYSTEMS SWITCH ..................... .142

Removal and Installation ..................................... ..142

REAR VIEW CAMERA ....................................143

Exploded View ..................................................... ..143

Removal and Installation .......................................143

REAR VIEW CAMERA WASHER CONTROL

UNIT ................................................................ .

144

Exploded View ..................................................... ..144

Removal and Installation .......................................144

REAR VIEW CAMERA AIR PUMP MOTOR ...145

Exploded View ..................................................... ..145

Removal and Installation .......................................145

BSW

PRECAUTION .............. ..............................

146

PRECAUTIONS .............................................. .146

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

146

Precaution for Work ...............................................146

Precautions For Harness Repair ...........................146

Precaution for BSW System Service .....................147

PREPARATION ..........................................148

PREPARATION .............................................. .148

Special Service Tool ............................................ ..148

SYSTEM DESCRIPTION ...........................149

COMPONENT PARTS .................................... .149

Component Parts Location .................................. ..149

Component Description .........................................150

SYSTEM .......................................................... .152

System Description .............................................. ..152

Fail-safe (ITS Control Unit) ....................................154

OPERATION ................................................... .155

Switch Name and Function .................................. ..155

System Display and Warning ................................155

HANDLING PRECAUTION ..............................157

Precautions for Blind Spot Warning ..................... ..157

DIAGNOSIS SYSTEM (ITS CONTROL UNIT) .158

CONSULT Function (AVM) ................................. ..158

ECU DIAGNOSIS INFORMATION ............161

ITS CONTROL UNIT ........................................161

Reference Value .................................................. .161

Fail-safe ................................................................163

DTC Inspection Priority Chart .............................. .163

DTC Index ............................................................ .164

WIRING DIAGRAM ...................................166

DRIVER ASSISTANCE SYSTEMS ................ ..166

Wiring Diagram .................................................... .166

BASIC INSPECTION .................................175

DIAGNOSIS AND REPAIR WORK FLOW ..... ..175

Work Flow ............................................................ .175

Diagnostic Work Sheet .........................................176

PRE-INSPECTION FOR DIAGNOSIS ..............178

Inspection Procedure ........................................... .178

ACTION TEST ..................................................179

Description ........................................................... .179

Inspection Procedure ............................................179

ADDITIONAL SERVICE WHEN REPLACING

REAR VIEW CAMERA ................................... ..

181

Description ........................................................... .181

Work Procedure ....................................................181

REAR VIEW CAMERA CALIBRATION ...........182

Description ........................................................... .182

Work Procedure (Preparation) ..............................182

Work Procedure (Target Se tting) ..........................183

Work Procedure (Rear View Camera Calibration) .184

DTC/CIRCUIT DIAGNOSIS .......................186

C1A03 VEHICLE SPEED SENSOR .................186

DTC Logic ............................................................ .186

Diagnosis Procedure .............................................186

C1A04 ABS/TCS/VDC SYSTEM ......................187

DTC Logic ............................................................ .187

Diagnosis Procedure .............................................187

C1A39 STEERING ANGLE SENSOR ..............188

DTC Logic ............................................................ .188

Diagnosis Procedure .............................................188

U0122 VDC P-RUN DIAG .................................189

DTC Logic ............................................................ .189

Diagnosis Procedure .............................................189

U0416 VDC CHECKSUM DIAG .......................190

DTC Logic ............................................................ .190

Diagnosis Procedure .............................................190

U0428 STEERING ANGLE SENSOR ..............191

DTC Logic ............................................................ .191

Diagnosis Procedure .............................................191

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 438 of 4801

DAS-5

C

D E

F

G H

I

J

K L

M B

DAS

N

P

A

U1000 CAN COMM CI

RCUIT ...........................192

Description .......................................................... ..192

DTC Logic .............................................................192

Diagnosis Procedure .............................................192

U1010 CONTROL UNIT (CAN) ........................193

Description .......................................................... ..193

DTC Logic .............................................................193

Diagnosis Procedure .............................................193

U111A REAR CAMERA IMAGE SIGNAL CIR-

CUIT ................................................................ ..

194

DTC Logic ........................................................... ..194

Diagnosis Procedure .............................................194

U1232 STEERING ANGLE SENSOR ..............196

DTC Logic ........................................................... ..196

Diagnosis Procedure .............................................196

U1305 CAMERA IMAGE CALIB ......................197

DTC Logic ........................................................... ..197

Diagnosis Procedure .............................................197

U1308 CAMERA CONFIG ................................198

DTC Logic ........................................................... ..198

Diagnosis Procedure .............................................198

U1309 PUMP UNIT CURRENT ........................199

DTC Logic ........................................................... ..199

Diagnosis Procedure .............................................199

U130B REAR CAMERA COMM ERROR ........202

DTC Logic ........................................................... ..202

Diagnosis Procedure .............................................202

U1310 PUMP UNIT CIRCUIT ...........................203

DTC Logic ........................................................... ..203

Diagnosis Procedure .............................................203

POWER SUPPLY AND GROUND CIRCUIT ....206

Diagnosis Procedure ........................................... ..206

WARNING SYSTEMS SWITCH CIRCUIT .......207

Component Function Check ................................ ..207

Diagnosis Procedure .............................................207

Component Inspection ..........................................208

WARNING SYSTEMS ON INDICATOR CIR-

CUIT ................................................................ ..

209

Component Function Check ................................ ..209

Diagnosis Procedure .............................................209

Component Inspection ..........................................210

WARNING BUZZER CIRCUIT .........................211

Component Function Check ................................ ..211

Diagnosis Procedure .............................................211

SYMPTOM DIAGNOSIS ............................212

BSW SYSTEM SYMPTOMS .......................... ..212

Symptom Table ................................................... ..212

SWITCH DOES NOT TURN ON / SWITCH

DOES NOT TURN OFF ...................................

213

Description ........................................................... ..213

Diagnosis Procedure .............................................213

BSW SYSTEM SETTINGS CANNOT BE

TURNED ON/OFF IN VEHICLE INFORMA-

TION DISPLAY ................................................

215

Description ........................................................... ..215

Diagnosis Procedure .............................................215

NORMAL OPERATING CONDITION .............216

Description .............................................................216

REMOVAL AND INSTALLATION .............217

WARNING SYSTEMS SWITCH ......................217

Removal and Installation ..................................... ..217

BSW INDICATOR ...........................................218

Exploded View .......................................................218

Removal and Installation .......................................218

REAR VIEW CAMERA ....................................219

Exploded View .......................................................219

Removal and Installation .......................................219

REAR VIEW CAMERA WASHER CONTROL

UNIT ................................................................

220

Exploded View ..................................................... ..220

Removal and Installation .......................................220

REAR VIEW CAMERA AIR PUMP MOTOR ...221

Exploded View .......................................................221

Removal and Installation .......................................221

MOD

PRECAUTION ...... ......................................

222

PRECAUTIONS ...............................................222

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

222

Precaution for Work ...............................................222

Precautions For Harness Repair ...........................222

PREPARATION .........................................224

PREPARATION ...............................................224

Special Service Tool ............................................ ..224

SYSTEM DESCRIPTION ...........................225

COMPONENT PARTS ....................................225

Component Parts Location .................................. ..225

Component Description .........................................226

SYSTEM ..........................................................228

System Description .............................................. ..228

OPERATION ...................................................231

System Display and Warning ................................231

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 440 of 4801

DAS-7

C

D E

F

G H

I

J

K L

M B

DAS

N

P

A

Diagnosis Procedure ...........................................

..

285

SYMPTOM DIAGNOSIS ............................286

MOD SYSTEM SYMPTOMS .......................... ..286

Symptom Table ................................................... ..286

MOD SYSTEM DOES NOT ACTIVATE ...........287

Description .......................................................... ..287

Diagnosis Procedure .............................................287

MOD SYSTEM SETTINGS CANNOT BE

TURNED ON/OFF IN VEHICLE INFORMA-

TION DISPLAY ............................................... ..

289

Description .......................................................... ..289

Diagnosis Procedure ........................................... ..289

NORMAL OPERATING CONDITION .............290

Description .............................................................290

REMOVAL AND INSTALLATION .............291

REAR VIEW CAMERA WASHER CONTROL

UNIT ................................................................

291

Exploded View ..................................................... ..291

Removal and Installation .......................................291

REAR VIEW CAMERA AIR PUMP MOTOR ...292

Exploded View .......................................................292

Removal and Installation .......................................292

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 443 of 4801

![NISSAN TEANA 2014 Workshop Manual

DAS-10

< SYSTEM DESCRIPTION >[ITS CONTROL UNIT]

COMPONENT PARTS

Component Description

INFOID:0000000009464649

1. Combination meter 2. Vehicle information display 3. BCM (view with combination meter r NISSAN TEANA 2014 Workshop Manual

DAS-10

< SYSTEM DESCRIPTION >[ITS CONTROL UNIT]

COMPONENT PARTS

Component Description

INFOID:0000000009464649

1. Combination meter 2. Vehicle information display 3. BCM (view with combination meter r](/img/5/57390/w960_57390-442.png)

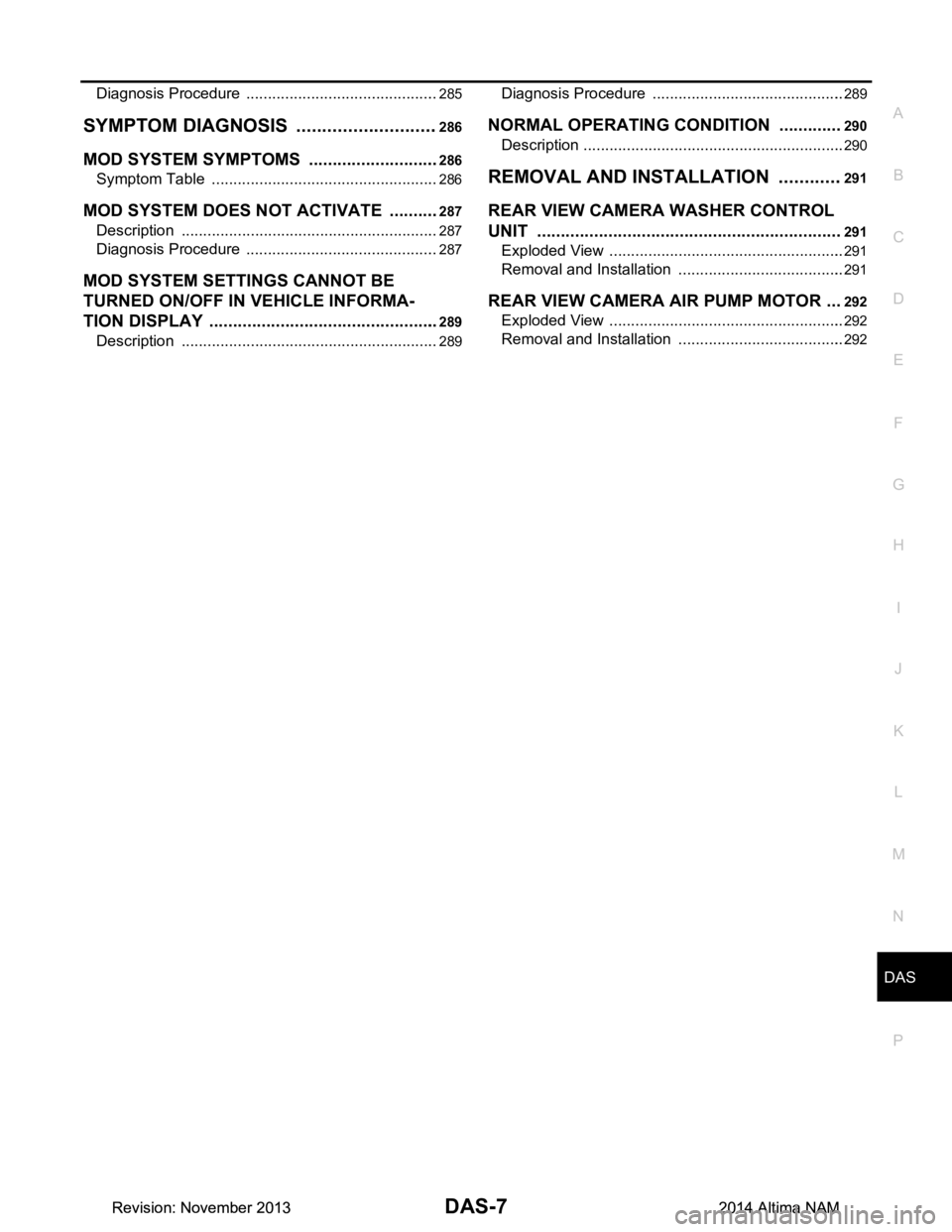

DAS-10

< SYSTEM DESCRIPTION >[ITS CONTROL UNIT]

COMPONENT PARTS

Component Description

INFOID:0000000009464649

1. Combination meter 2. Vehicle information display 3. BCM (view with combination meter re- moved)

4. Blind spot warning indicator RH 5. Blind spot warning indicator LH 6. TCM

7. ECM 8. Warning systems switch 9. Warning systems ON indicator

10. Rear view camera washer control unit 11. Rear view camera air pump motor 12. Rear view camera

13. AV control unit (center display) (with navi- gation system and bose audio system)

Audio unit (center display) (with display

audio system and bose audio system) 14. ITS control unit

(view with center console removed) 15. Steering angle sensor

(view with steeri ng wheel removed)

16. Washer fluid level switch (view with front fascia removed)

Component Description

ITS control unit • Controls each system, based on signals received from the rear view camera and CAN communica-

tion signals received from each control unit

• Transmits signals necessary for control between CAN communication

Blind Spot Warning indicator

LH/ RH Receives Blind Spot Warning indicator operation signal from rear view camera and turns OFF, turns

ON or blinks

Warning systems switch Inputs the switch signal to ITS control unit

Warning systems ON indicator

(On the warning systems

switch) Indicates BSW/LDW system status

Rear view camera • Detects the lane marker by the built-in camera

• Transmits detected lane condition signal to ITS control unit

ABS actuator and electric unit

(control unit) • Transmits vehicle speed signal to ITS control unit via CAN communication

• Transmits yaw rate signal/side G sensor signal to ITS control unit via CAN communication

Buzzer (combination meter) Receives buzzer signal from ITS control unit and sounds buzzer.

Combination meter • Turns the Lane Departure Warning/Blind Spot Warning indicator ON/OFF according to the signals

from the ITS control unit via CAN communication

• Receives Lane Departure Warning/Blind Spot Warning ON indicator signal via CAN communication.

Steering angle sensor Transmits steering angle sensor signal to ITS control unit via CAN communication

BCM • Transmits turn signal indicator to ITS control unit via CAN communication

• Transmits dimmer signal to ITS control unit via CAN communication

ECM Transmits engine speed signal to ITS control unit via CAN communication

TCM Transmits the output shaft speed signal, input speed signal, current gear position signal and shift po-

sition signal to ITS control unit via CAN communication

AV c o n t r o l u n i t

(with navigation system and

bose audio system) Receives the various systems and camera signals via CAN communication and routes them to the

center display

Audio unit

(with display audio system

and bose audio system) Receives the various systems and camera signals and routes them to the center display

Center display Displays the various system screen signals according to the priority level received via CAN commu-

nication

Rear view camera washer

control unit Controls the air pump to drive air to the rear camera lens according to the signals received from the

ITS control unit

Rear view camera air pump

motor Drives air to the rear camera lens according to the signals received from the pump control unit

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM