battery NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2360 of 4801

EXL-94

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

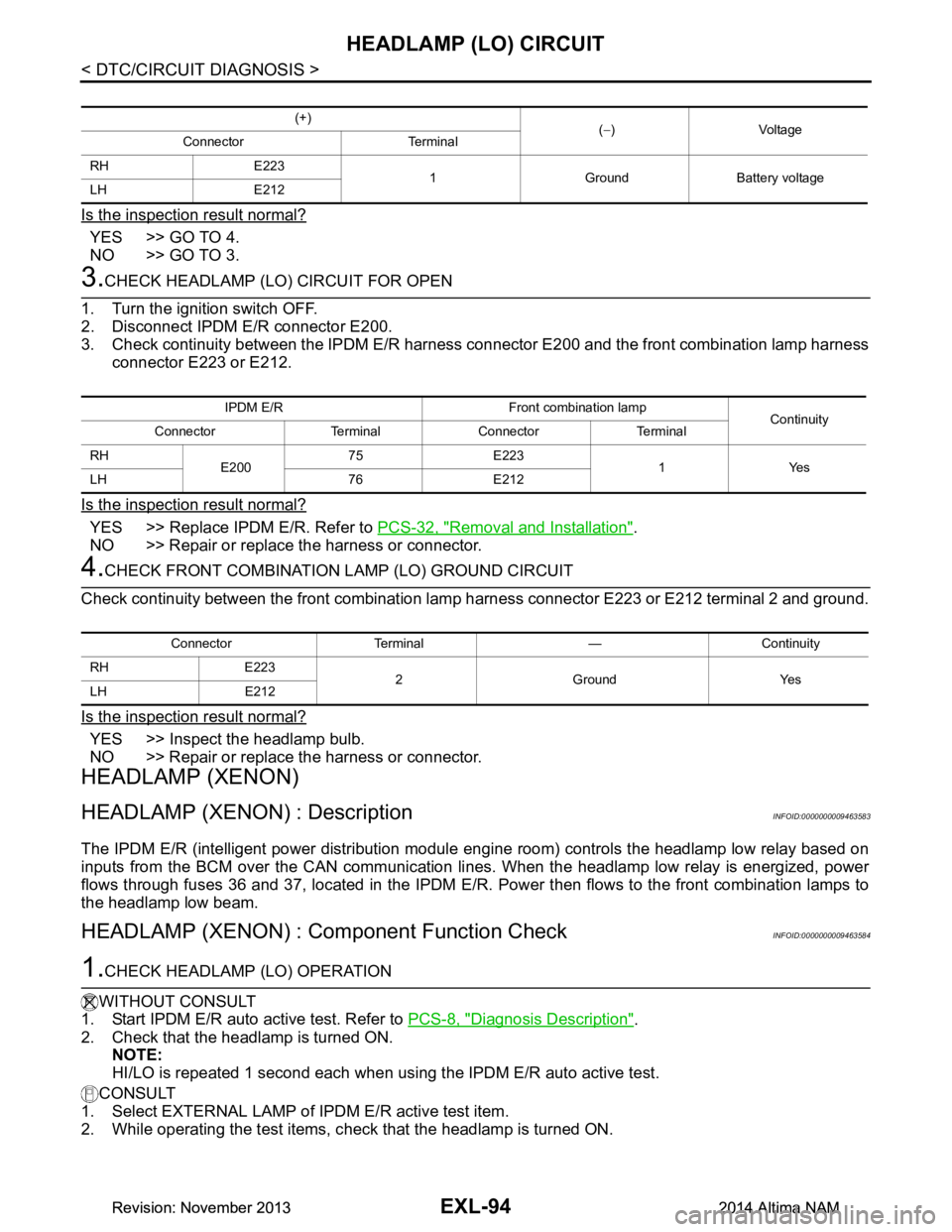

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness c onnector E200 and the front combination lamp harness

connector E223 or E212.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace the harness or connector.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination la mp harness connector E223 or E212 terminal 2 and ground.

Is the inspection result normal?

YES >> Inspect the headlamp bulb.

NO >> Repair or replace the harness or connector.

HEADLAMP (XENON)

HEADLAMP (XENON) : DescriptionINFOID:0000000009463583

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM over the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 36 and 37, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

HEADLAMP (XENON) : Component Function CheckINFOID:0000000009463584

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the headlamp is turned ON. NOTE:

HI/LO is repeated 1 second each when usi ng the IPDM E/R auto active test.

CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, c heck that the headlamp is turned ON.

(+)

(− )Voltage

Connector Terminal

RH E223 1 Ground Battery voltage

LH E212

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

RH E20075 E223

1Yes

LH 76 E212

Connector Terminal — Continuity

RH E223 2GroundYes

LH E212

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2361 of 4801

HEADLAMP (LO) CIRCUITEXL-95

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

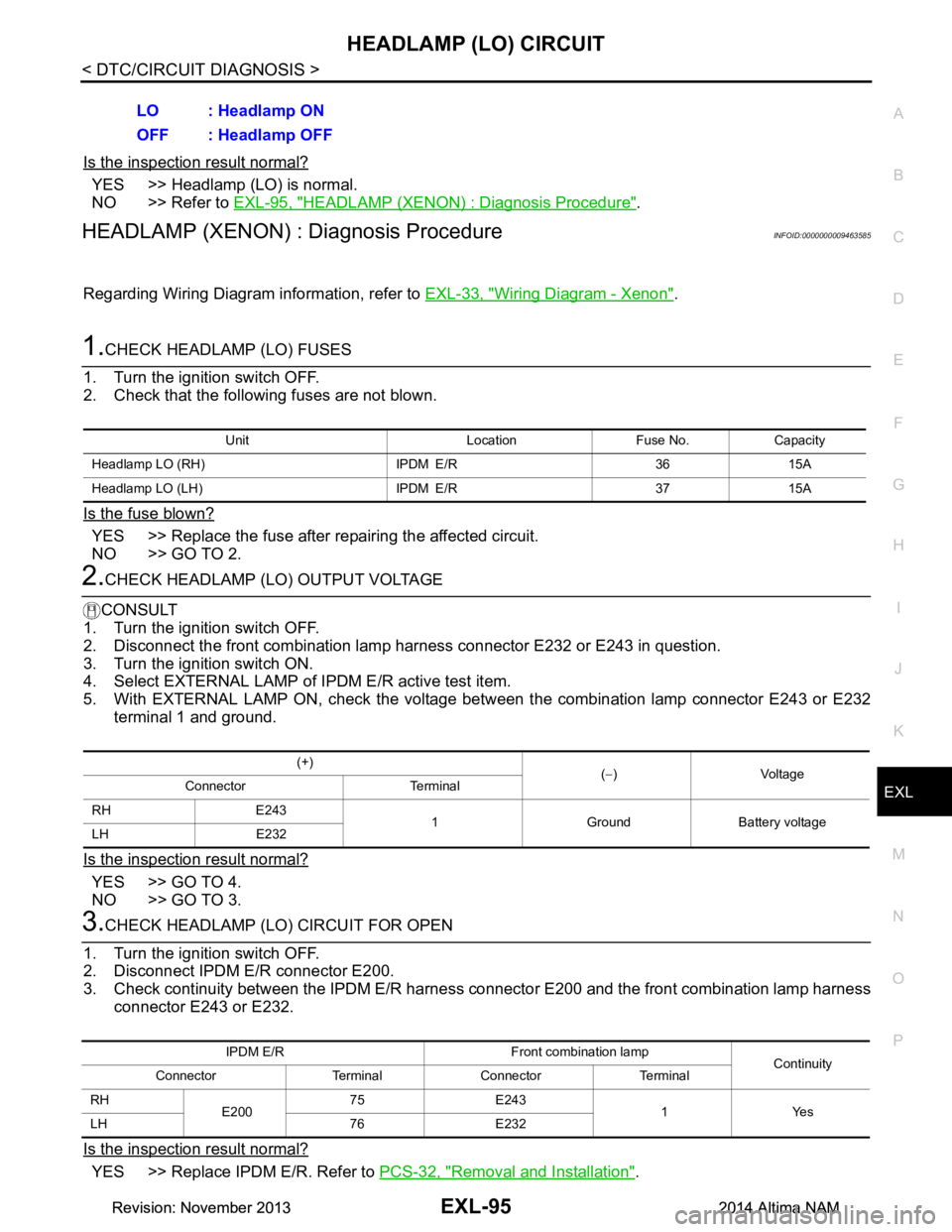

Is the inspection result normal?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-95, "HEADLAMP (XEN ON) : Diagnosis Procedure"

.

HEADLAMP (XENON) : Diagnosis ProcedureINFOID:0000000009463585

Regarding Wiring Diagram information, refer to EXL-33, "Wiring Diagram - Xenon".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

CONSULT

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp harness connector E232 or E243 in question.

3. Turn the ignition switch ON.

4. Select EXTERNAL LAMP of IP DM E/R active test item.

5. With EXTERNAL LAMP ON, check the voltage betw een the combination lamp connector E243 or E232

terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E200.

3. Check continuity between the IPDM E/R harness c onnector E200 and the front combination lamp harness

connector E243 or E232.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

LO : Headlamp ON

OFF : Headlamp OFF

Unit Location Fuse No. Capacity

Headlamp LO (RH) IPDM E/R 36 15A

Headlamp LO (L H) IPDM E/R 37 15A

(+)

(− )Voltage

Connector Terminal

RH E243 1 Ground Battery voltage

LH E232

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

RH E20075 E243

1Yes

LH 76 E232

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2364 of 4801

EXL-98

< DTC/CIRCUIT DIAGNOSIS >

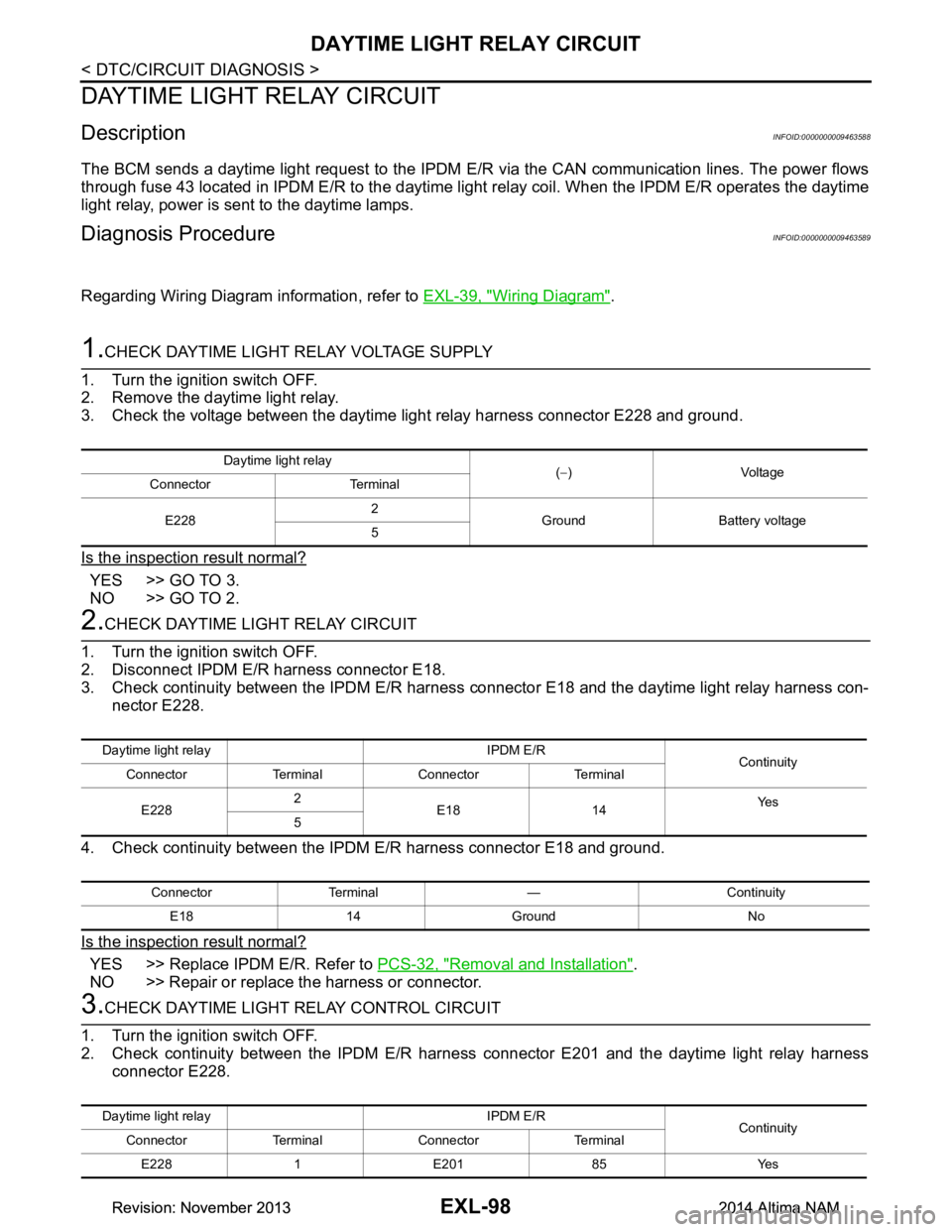

DAYTIME LIGHT RELAY CIRCUIT

DAYTIME LIGHT RELAY CIRCUIT

DescriptionINFOID:0000000009463588

The BCM sends a daytime light request to the IPDM E/R via the CAN communication lines. The power flows

through fuse 43 located in IPDM E/R to the daytime li ght relay coil. When the IPDM E/R operates the daytime

light relay, power is sent to the daytime lamps.

Diagnosis ProcedureINFOID:0000000009463589

Regarding Wiring Diagram information, refer to EXL-39, "Wiring Diagram".

1.CHECK DAYTIME LIGHT RELAY VOLTAGE SUPPLY

1. Turn the ignition switch OFF.

2. Remove the daytime light relay.

3. Check the voltage between the daytime light relay harness connector E228 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DAYTIME LIGHT RELAY CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R harness connector E18.

3. Check continuity between the IPDM E/R harness c onnector E18 and the daytime light relay harness con-

nector E228.

4. Check continuity between the IP DM E/R harness connector E18 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace the harness or connector.

3.CHECK DAYTIME LIGHT RELAY CONTROL CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between the IPDM E/R harness connector E201 and the daytime light relay harness

connector E228.

Daytime light relay (− )Voltage

Connector Terminal

E228 2

Ground Battery voltage

5

Daytime light relay IPDM E/R Continuity

Connector Terminal Connector Terminal

E228 2

E18 14 Ye s

5

Connector Terminal — Continuity

E18 14 Ground No

Daytime light relay IPDM E/R Continuity

Connector Terminal Connector Terminal

E228 1 E201 85 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2367 of 4801

FRONT FOG LAMP CIRCUITEXL-101

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

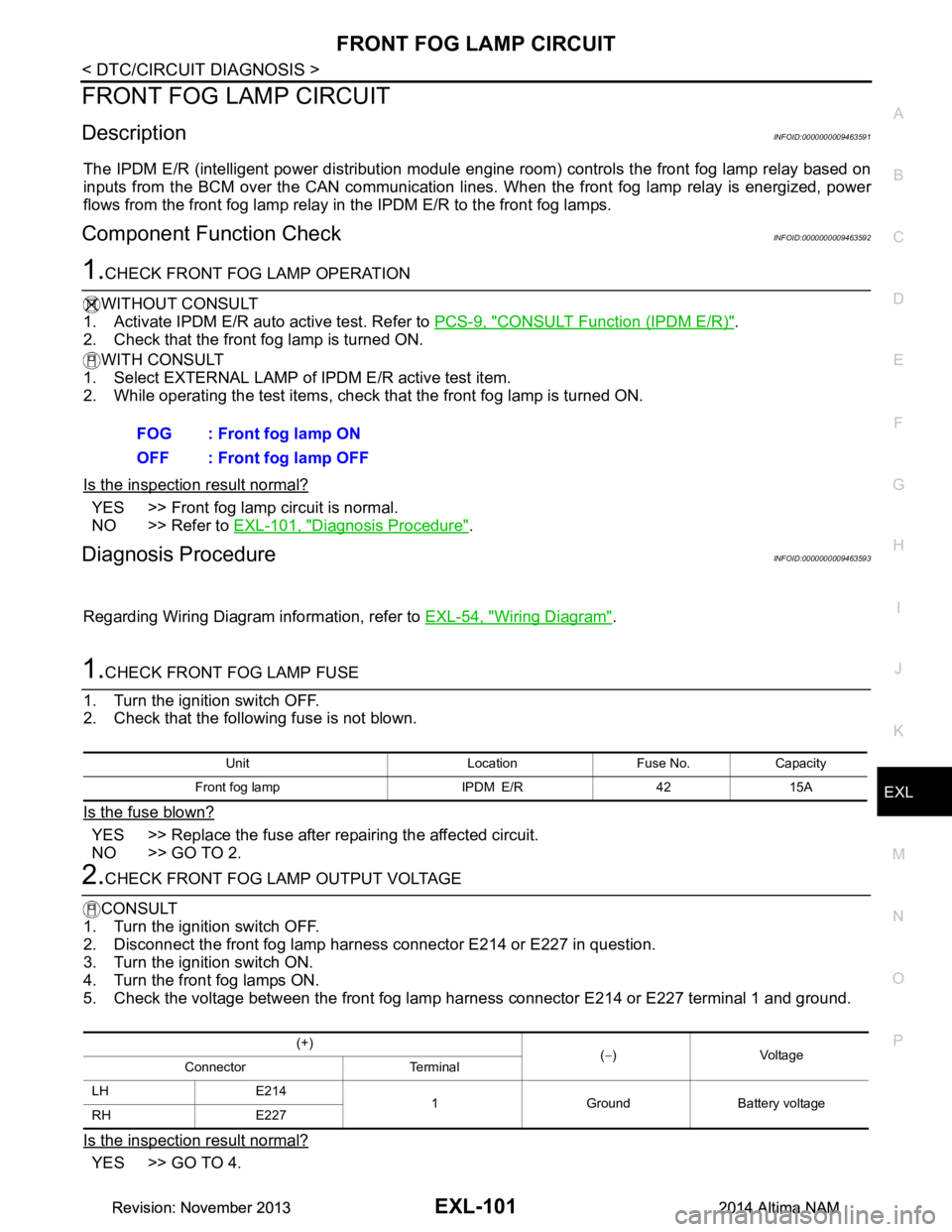

FRONT FOG LAMP CIRCUIT

DescriptionINFOID:0000000009463591

The IPDM E/R (intelligent power di stribution module engine room) controls the front fog lamp relay based on

inputs from the BCM over the CAN communication lines . When the front fog lamp relay is energized, power

flows from the front fog lamp relay in the IPDM E/R to the front fog lamps.

Component Function CheckINFOID:0000000009463592

1.CHECK FRONT FOG LAMP OPERATION

WITHOUT CONSULT

1. Activate IPDM E/R auto active test. Refer to PCS-9, "CONSULT Function (IPDM E/R)"

.

2. Check that the front fog lamp is turned ON.

WITH CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check that the front fog lamp is turned ON.

Is the inspection result normal?

YES >> Front fog lamp circuit is normal.

NO >> Refer to EXL-101, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463593

Regarding Wiring Diagram information, refer to EXL-54, "Wiring Diagram".

1.CHECK FRONT FOG LAMP FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK FRONT FOG LAMP OUTPUT VOLTAGE

CONSULT

1. Turn the ignition switch OFF.

2. Disconnect the front fog lamp harness connector E214 or E227 in question.

3. Turn the ignition switch ON.

4. Turn the front fog lamps ON.

5. Check the voltage between the front fog lamp harness connector E214 or E227 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 4. FOG : Front fog lamp ON

OFF : Front fog lamp OFF

Unit Location Fuse No. Capacity

Front fog lamp IPDM E/R 42 15A

(+) (− )Voltage

Connector Terminal

LH E214 1 Ground Battery voltage

RH E227

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2369 of 4801

PARKING LAMP CIRCUITEXL-103

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

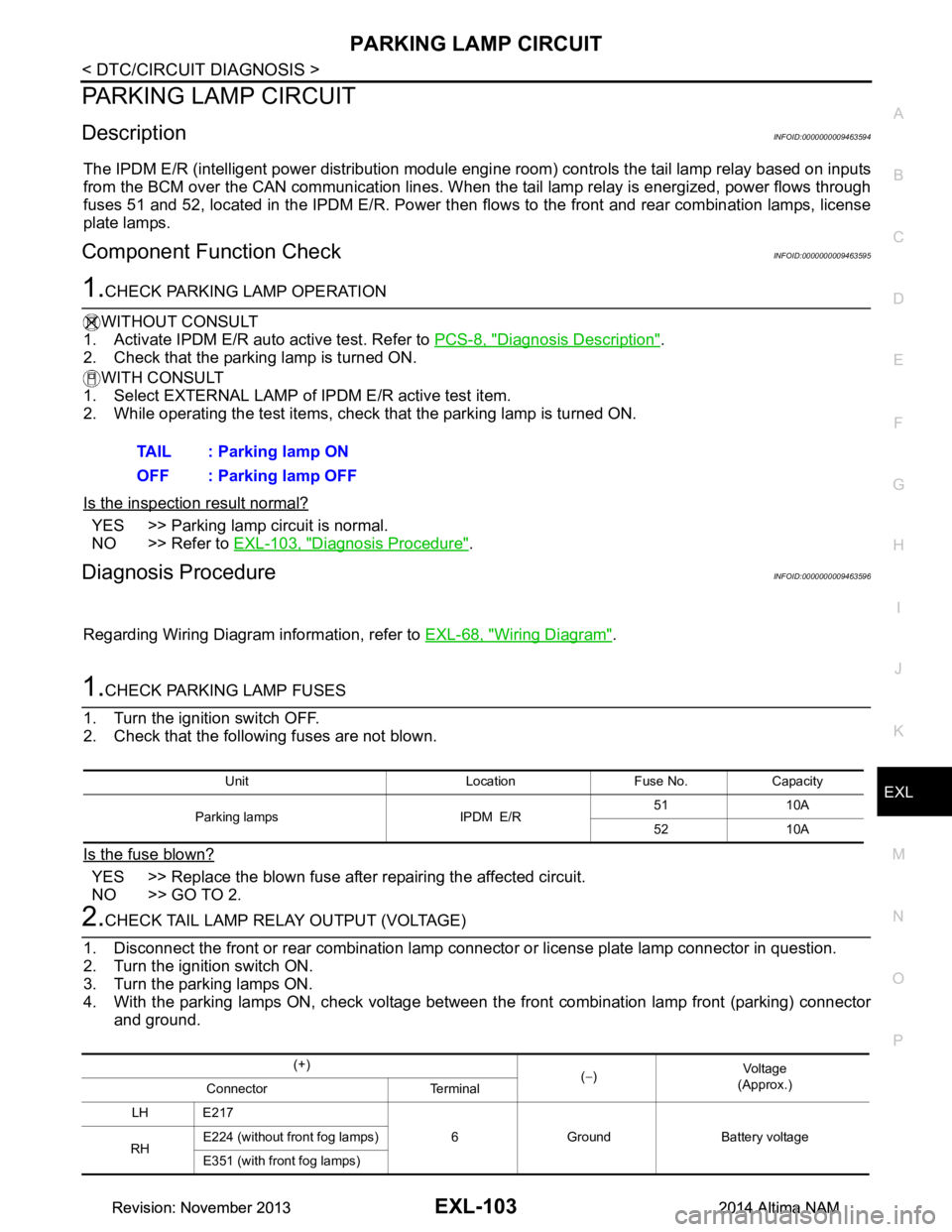

PARKING LAMP CIRCUIT

DescriptionINFOID:0000000009463594

The IPDM E/R (intelligent power distribution module engi ne room) controls the tail lamp relay based on inputs

from the BCM over the CAN communication lines. When t he tail lamp relay is energized, power flows through

fuses 51 and 52, located in the IPDM E/R. Power then fl ows to the front and rear combination lamps, license

plate lamps.

Component Function CheckINFOID:0000000009463595

1.CHECK PARKING LAMP OPERATION

WITHOUT CONSULT

1. Activate IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the parking lamp is turned ON.

WITH CONSULT

1. Select EXTERNAL LAMP of IP DM E/R active test item.

2. While operating the test items, check that the parking lamp is turned ON.

Is the inspection result normal?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-103, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009463596

Regarding Wiring Diagram information, refer to EXL-68, "Wiring Diagram".

1.CHECK PARKING LAMP FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK TAIL LAMP RELAY OUTPUT (VOLTAGE)

1. Disconnect the front or rear combination lamp connector or license plate lamp connector in question.

2. Turn the ignition switch ON.

3. Turn the parking lamps ON.

4. With the parking lamps ON, check voltage between t he front combination lamp front (parking) connector

and ground. TAIL : Parking lamp ON

OFF : Parking lamp OFF

Unit Location Fuse No. Capacity

Parking lamps IPDM E/R 51 10A

52 10A

(+) (− ) Vo l ta g e

(Approx.)

Connector Terminal

LH E217 6 Ground Battery voltage

RH E224 (without front fog lamps)

E351 (with front fog lamps)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2370 of 4801

EXL-104

< DTC/CIRCUIT DIAGNOSIS >

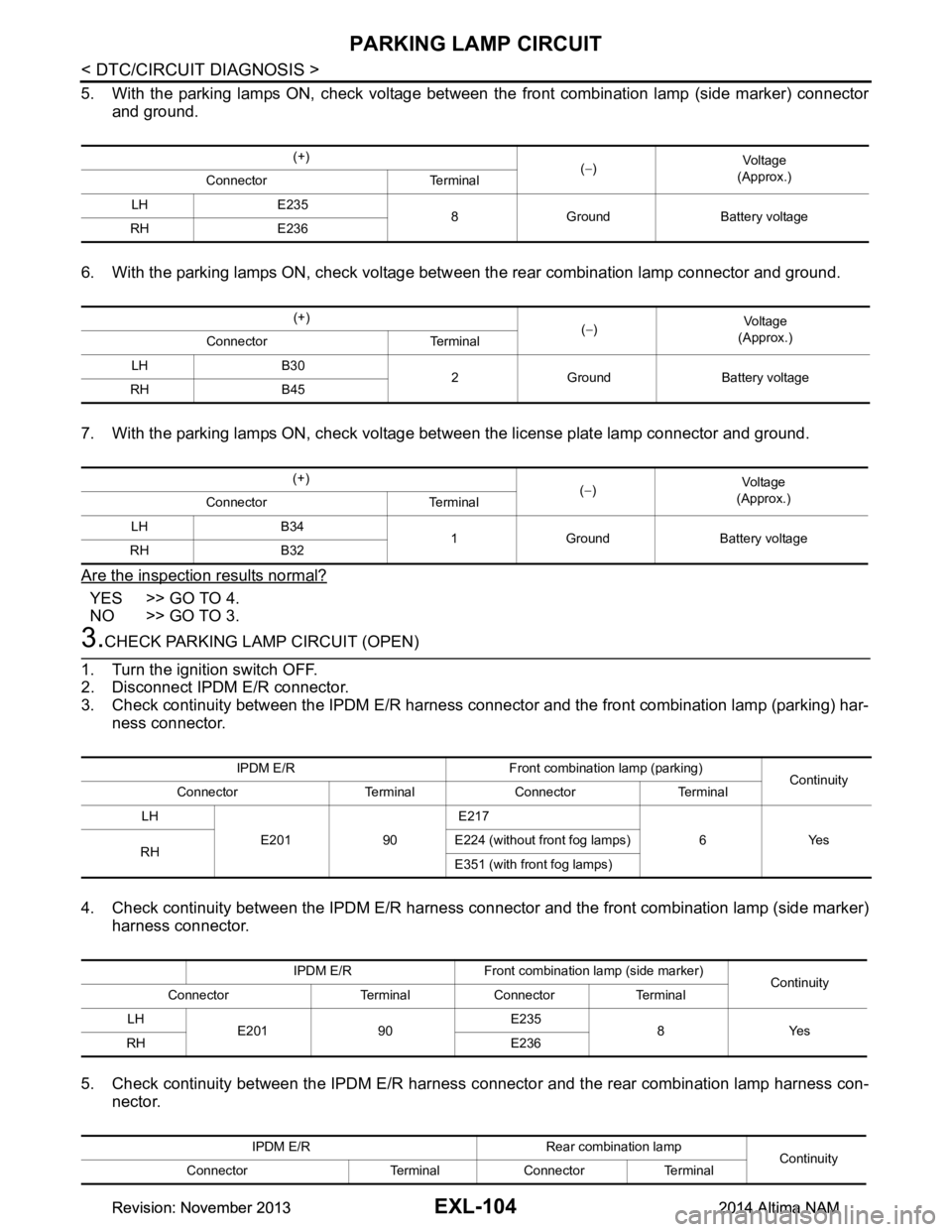

PARKING LAMP CIRCUIT

5. With the parking lamps ON, check voltage between the front combination lamp (side marker) connector

and ground.

6. With the parking lamps ON, check voltage betw een the rear combination lamp connector and ground.

7. With the parking lamps ON, check voltage between the license plate lamp connector and ground.

Are the inspection results normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK PARKING LAMP CIRCUIT (OPEN)

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and the front combination lamp (parking) har-

ness connector.

4. Check continuity between the IPDM E/R harness connec tor and the front combination lamp (side marker)

harness connector.

5. Check continuity between the IPDM E/R harness c onnector and the rear combination lamp harness con-

nector.

(+) (− ) Vol tag e

(Approx.)

Connector Terminal

LH E235 8 Ground Battery voltage

RH E236

(+) (− ) Vo l ta g e

(Approx.)

Connector Terminal

LH B30 2 Ground Battery voltage

RH B45

(+) (− ) Vo l ta g e

(Approx.)

Connector Terminal

LH B34 1 Ground Battery voltage

RH B32

IPDM E/R Front combination lamp (parking) Continuity

Connector Terminal Connector Terminal

LH E201 90 E217

6Yes

RH E224 (without front fog lamps)

E351 (with front fog lamps)

IPDM E/R Front combination lamp (side marker) Continuity

Connector Terminal Connector Terminal

LH E201 90 E235

8Yes

RH E236

IPDM E/R Rear combination lamp Continuity

Connector Terminal Connector Terminal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2380 of 4801

EXL-114

< SYMPTOM DIAGNOSIS >

EXTERIOR LIGHTING SYSTEM SYMPTOMS

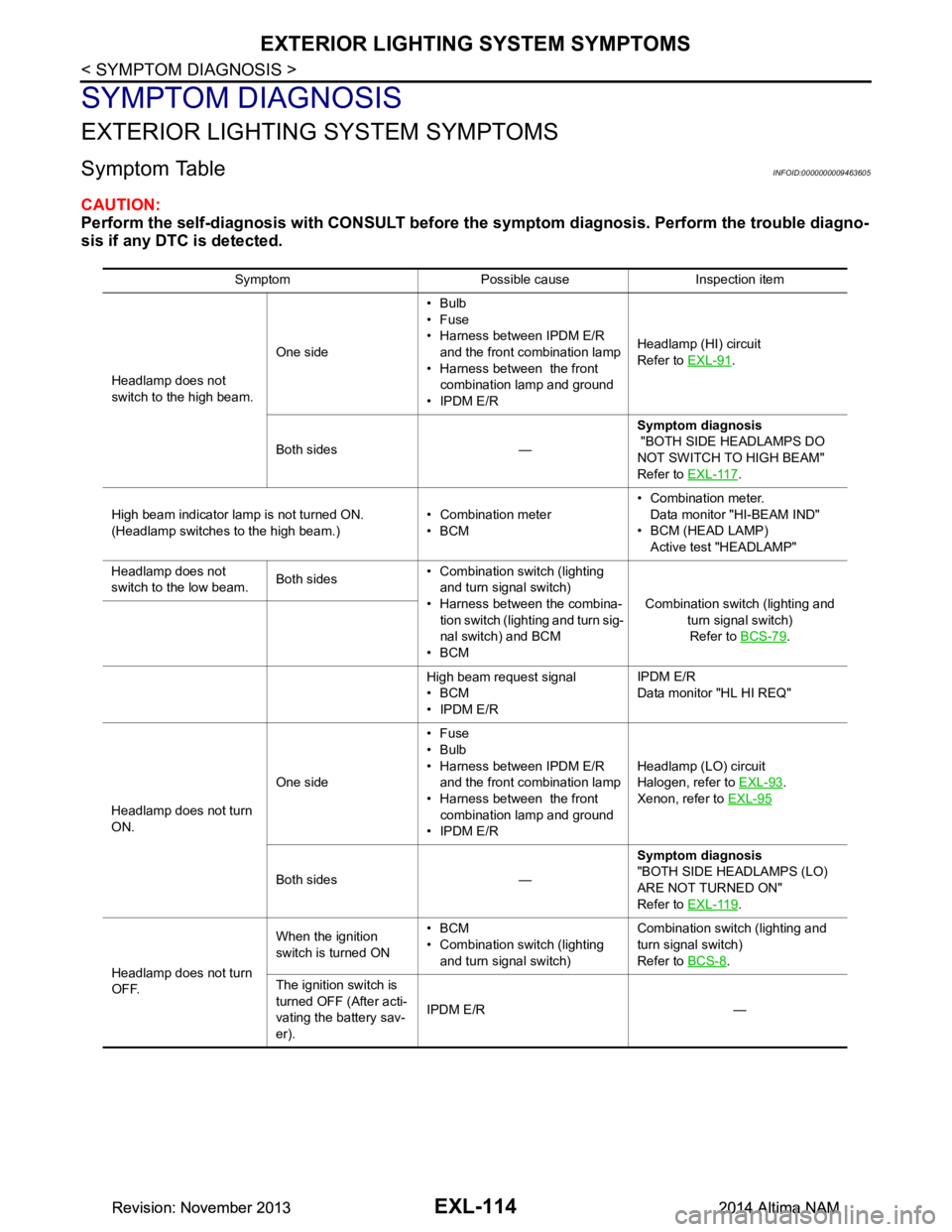

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000009463605

CAUTION:

Perform the self-diagnosis with CONSULT before th e symptom diagnosis. Perform the trouble diagno-

sis if any DTC is detected.

Symptom Possible cause Inspection item

Headlamp does not

switch to the high beam. One side•Bulb

•Fuse

• Harness between IPDM E/R and the front combination lamp

• Harness between the front combination lamp and ground

• IPDM E/R Headlamp (HI) circuit

Refer to EXL-91

.

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS DO

NOT SWITCH TO HIGH BEAM"

Refer to EXL-117

.

High beam indicator lamp is not turned ON.

(Headlamp switches to the high beam.) • Combination meter

•BCM • Combination meter.

Data monitor "HI-BEAM IND"

• BCM (HEAD LAMP) Active test "HEADLAMP"

Headlamp does not

switch to the low beam. Both sides• Combination switch (lighting

and turn signal switch)

• Harness between the combina- tion switch (lighting and turn sig-

nal switch) and BCM

•BCM Combination switch (lighting and

turn signal switch)Refer to BCS-79

.

High beam request signal

•BCM

• IPDM E/R IPDM E/R

Data monitor "HL HI REQ"

Headlamp does not turn

ON. One side•Fuse

•Bulb

• Harness between IPDM E/R and the front combination lamp

• Harness between the front combination lamp and ground

• IPDM E/R Headlamp (L

O) circuit

Halogen, refer to EXL-93

.

Xenon, refer to EXL-95

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS (LO)

ARE NOT TURNED ON"

Refer to EXL-119

.

Headlamp does not turn

OFF. When the ignition

switch is turned ON •BCM

• Combination switch (lighting and turn signal switch) Combination switch (lighting and

turn signal switch)

Refer to BCS-8

.

The ignition switch is

turned OFF (After acti-

vating the battery sav-

er). IPDM E/R —

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2392 of 4801

EXL-126

< REMOVAL AND INSTALLATION >

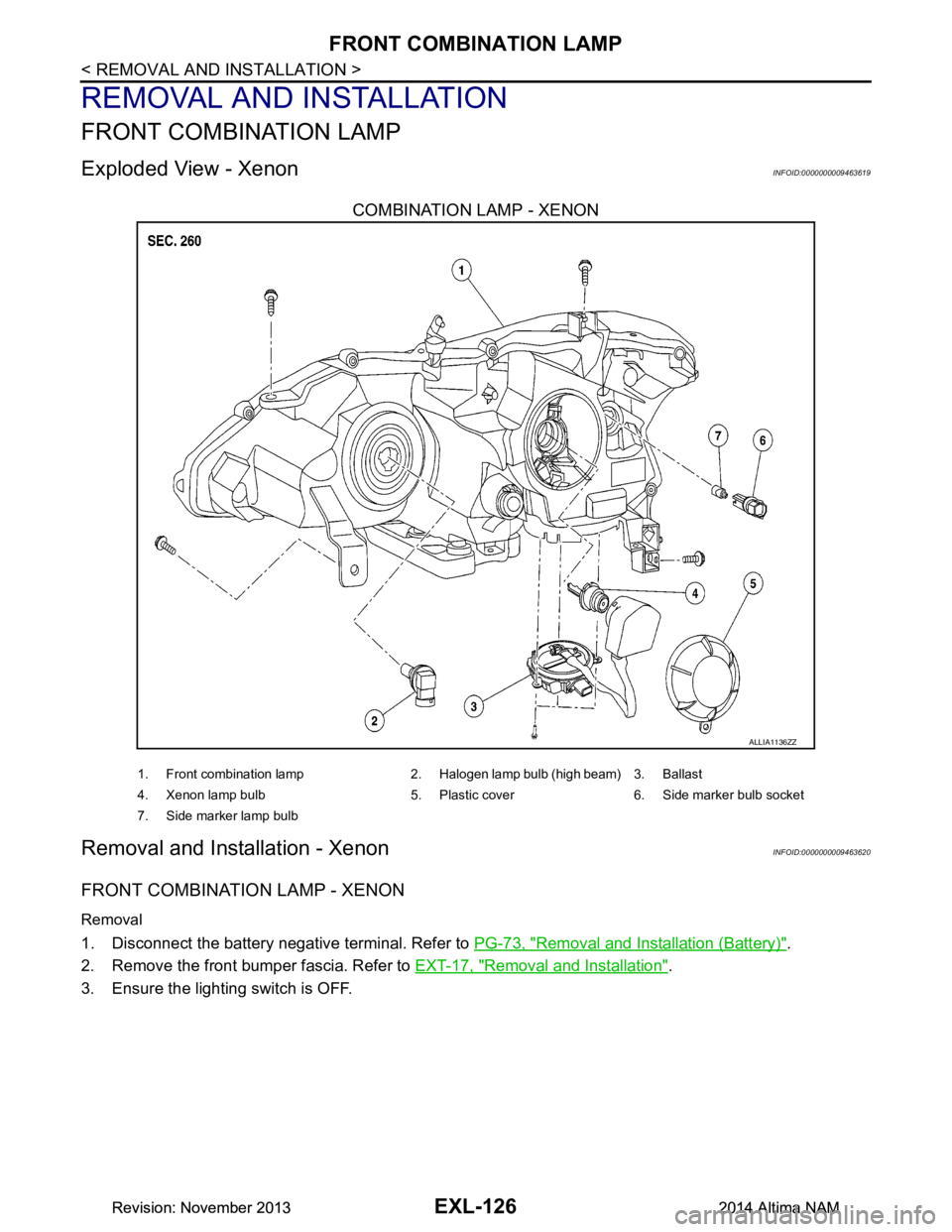

FRONT COMBINATION LAMP

REMOVAL AND INSTALLATION

FRONT COMBINATION LAMP

Exploded View - XenonINFOID:0000000009463619

COMBINATION LAMP - XENON

Removal and Installation - XenonINFOID:0000000009463620

FRONT COMBINATION LAMP - XENON

Removal

1. Disconnect the battery negative terminal. Refer to PG-73, "Removal and Installation (Battery)".

2. Remove the front bumper fascia. Refer to EXT-17, "Removal and Installation"

.

3. Ensure the lighting switch is OFF.

ALLIA1136ZZ

1. Front combination lamp 2. Halogen lamp bulb (high beam) 3. Ballast

4. Xenon lamp bulb 5. Plastic cover 6. Side marker bulb socket

7. Side marker lamp bulb

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2393 of 4801

FRONT COMBINATION LAMPEXL-127

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

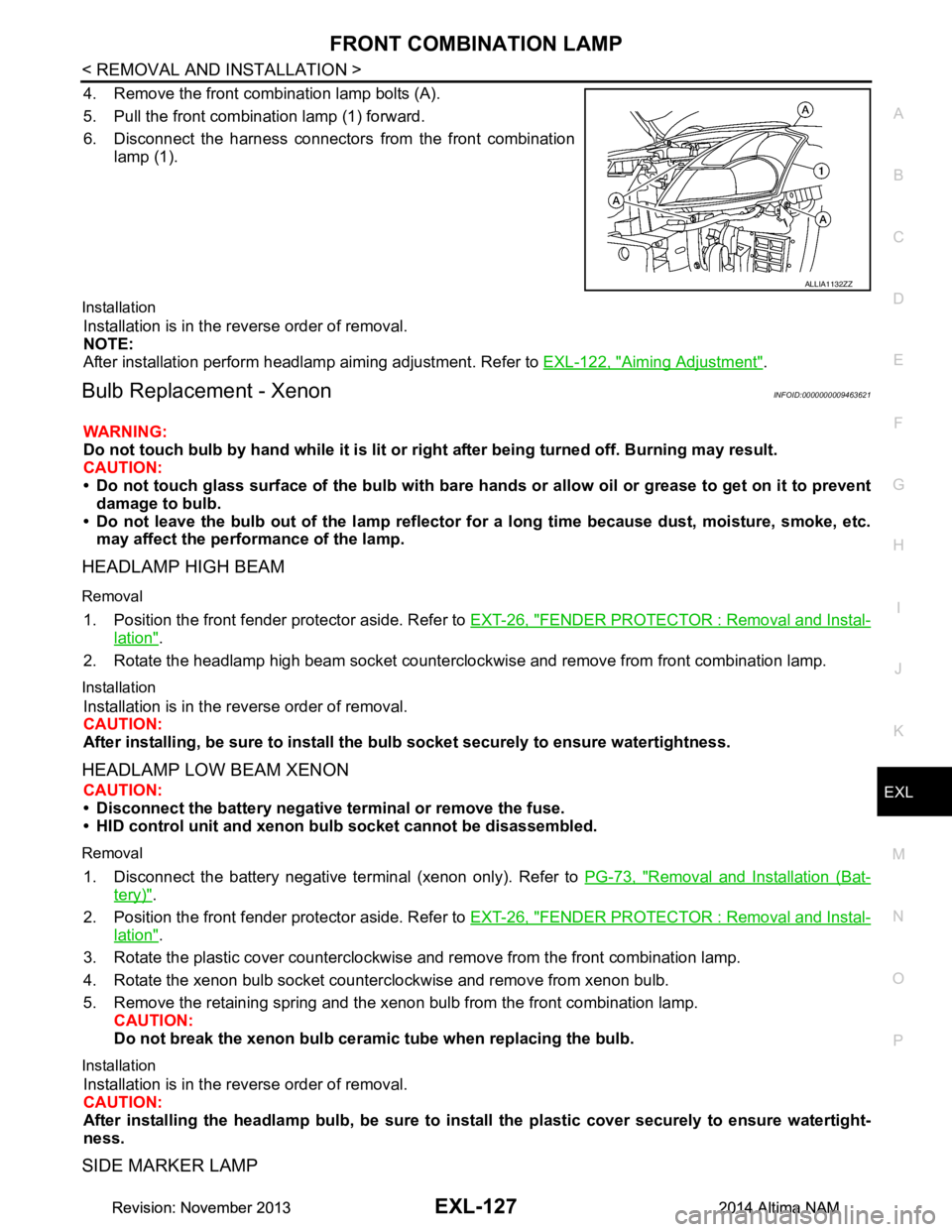

4. Remove the front combination lamp bolts (A).

5. Pull the front combination lamp (1) forward.

6. Disconnect the harness connectors from the front combination

lamp (1).

Installation

Installation is in the reverse order of removal.

NOTE:

After installation perform headlamp aiming adjustment. Refer to EXL-122, "Aiming Adjustment"

.

Bulb Replacement - XenonINFOID:0000000009463621

WARNING:

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

CAUTION:

• Do not touch glass surface of the bulb with bare hand s or allow oil or grease to get on it to prevent

damage to bulb.

• Do not leave the bulb out of the lamp reflector fo r a long time because dust, moisture, smoke, etc.

may affect the performance of the lamp.

HEADLAMP HIGH BEAM

Removal

1. Position the front fender pr otector aside. Refer to EXT-26, "FENDER PROTECTOR : Removal and Instal-

lation".

2. Rotate the headlamp high beam socket countercloc kwise and remove from front combination lamp.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing, be sure to install the bulb socket securely to ensure watertightness.

HEADLAMP LOW BEAM XENON

CAUTION:

• Disconnect the battery negative terminal or remove the fuse.

• HID control unit and xenon bu lb socket cannot be disassembled.

Removal

1. Disconnect the battery negative te rminal (xenon only). Refer to PG-73, "Removal and Installation (Bat-

tery)".

2. Position the front fender pr otector aside. Refer to EXT-26, "FENDER PROTECTOR : Removal and Instal-

lation".

3. Rotate the plastic cover counterclockwise and remove from the front combination lamp.

4. Rotate the xenon bulb socket counterclockwise and remove from xenon bulb.

5. Remove the retaining spring and the xenon bulb from the front combination lamp. CAUTION:

Do not break the xenon bulb ceramic tube when replacing the bulb.

Installation

Installation is in the reverse order of removal.

CAUTION:

After installing the headlamp bulb, be sure to inst all the plastic cover securely to ensure watertight-

ness.

SIDE MARKER LAMP

ALLIA1132ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2405 of 4801

COMBINATION SWITCHEXL-139

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

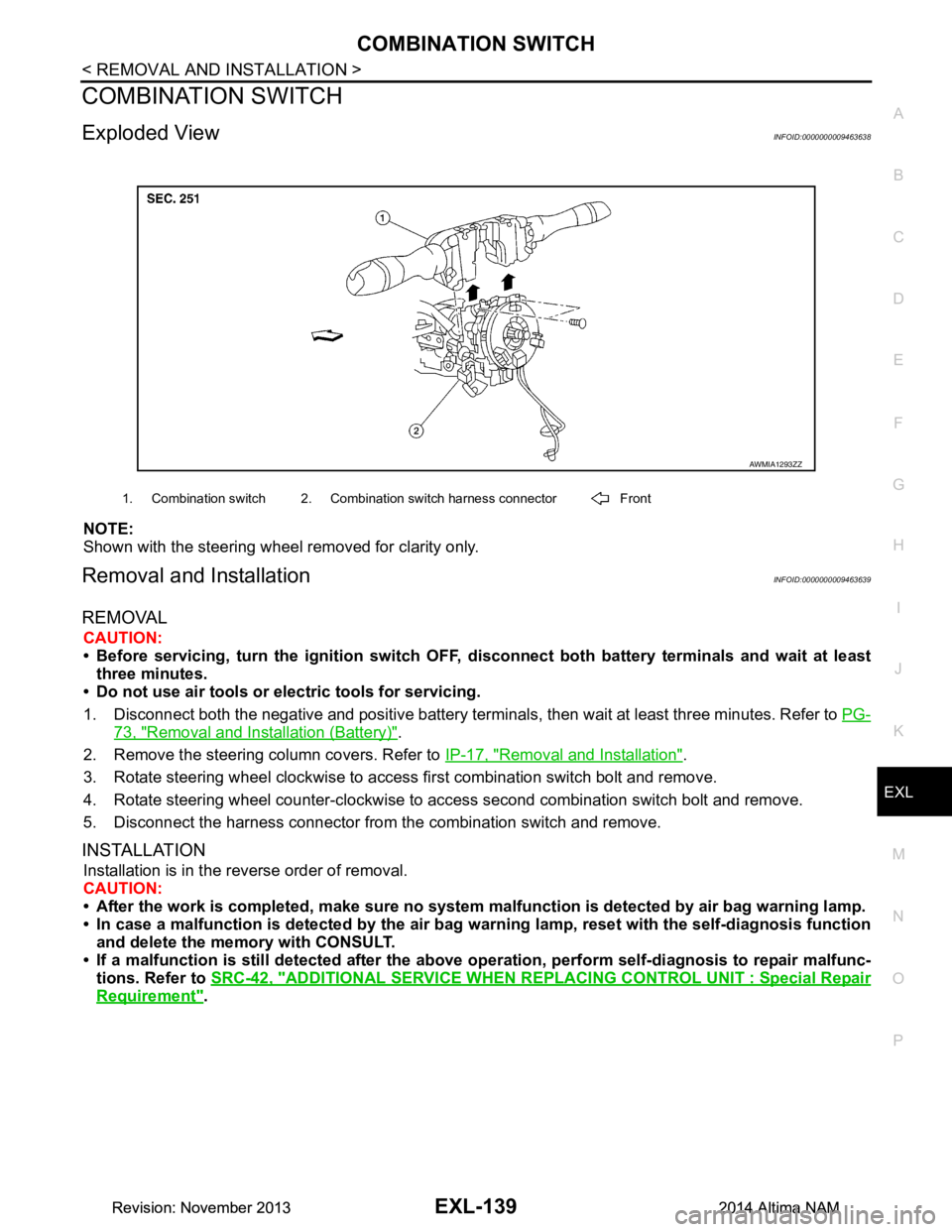

COMBINATION SWITCH

Exploded ViewINFOID:0000000009463638

NOTE:

Shown with the steering wheel removed for clarity only.

Removal and InstallationINFOID:0000000009463639

REMOVAL

CAUTION:

• Before servicing, turn the ignition switch OFF, disconnect both battery terminals and wait at least

three minutes.

• Do not use air tools or electric tools for servicing.

1. Disconnect both the negative and positive battery terminal s, then wait at least three minutes. Refer to PG-

73, "Removal and Installation (Battery)".

2. Remove the steering column covers. Refer to IP-17, "Removal and Installation"

.

3. Rotate steering wheel clockwise to access first combination switch bolt and remove.

4. Rotate steering wheel counter-clockwise to access second combination switch bolt and remove.

5. Disconnect the harness connector from the combination switch and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

• In case a malfunction is detected by the air bag wa rning lamp, reset with the self-diagnosis function

and delete the memory with CONSULT.

• If a malfunction is still detected after the above operation, perform self-diagnosis to repair malfunc-

tions. Refer to SRC-42, "ADDITIONAL SERVICE WHEN RE PLACING CONTROL UNIT : Special Repair

Requirement".

AWMIA1293ZZ

1. Combination switch 2. Combination switch harness connector Front

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM