check engine NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2647 of 4801

HEATING AND COOLING UNIT ASSEMBLYHA-41

< REMOVAL AND INSTALLATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

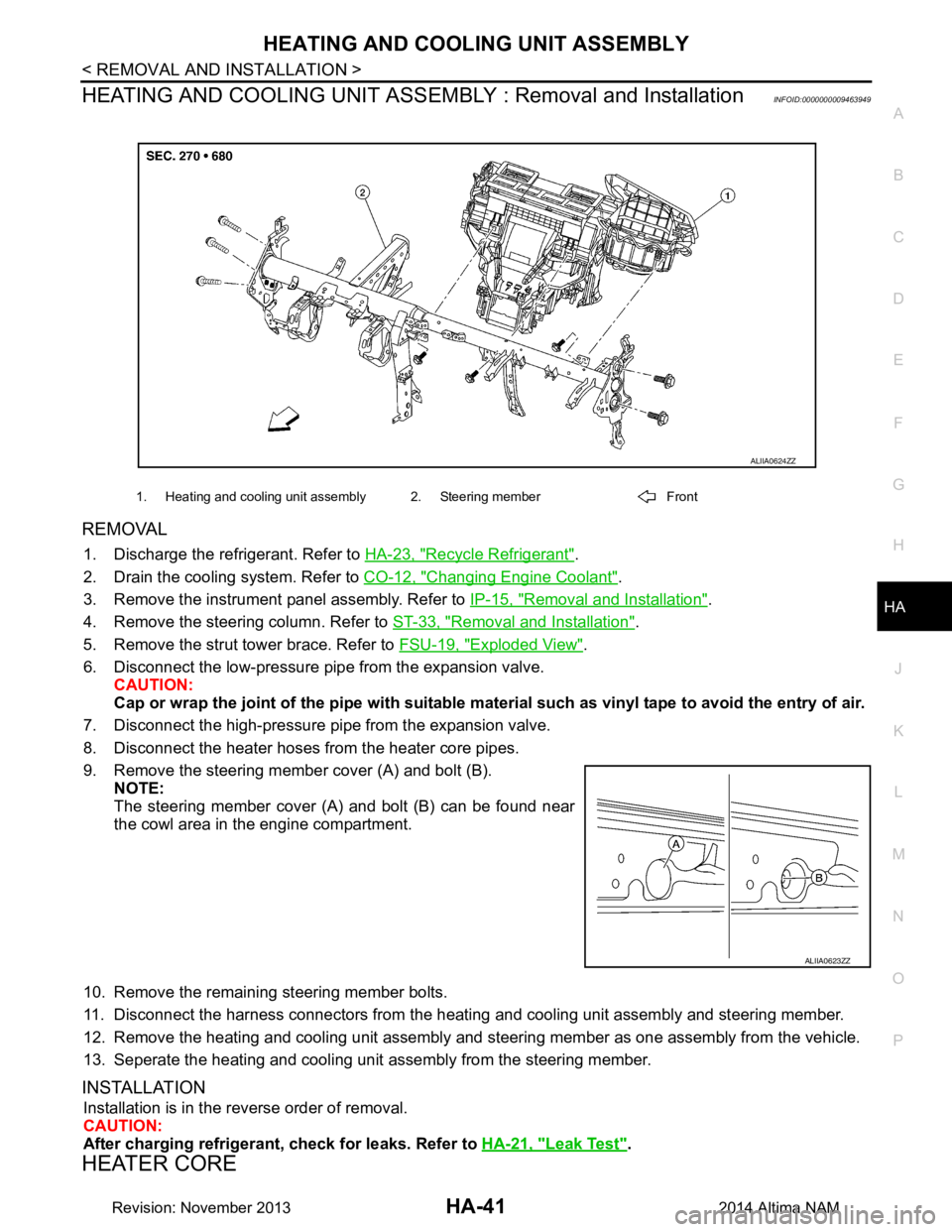

HEATING AND COOLING UNIT ASSEMB LY : Removal and InstallationINFOID:0000000009463949

REMOVAL

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

2. Drain the cooling system. Refer to CO-12, "Changing Engine Coolant"

.

3. Remove the instrument panel assembly. Refer to IP-15, "Removal and Installation"

.

4. Remove the steering column. Refer to ST-33, "Removal and Installation"

.

5. Remove the strut tower brace. Refer to FSU-19, "Exploded View"

.

6. Disconnect the low-pressure pipe from the expansion valve. CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

7. Disconnect the high-pressure pi pe from the expansion valve.

8. Disconnect the heater hoses from the heater core pipes.

9. Remove the steering member cover (A) and bolt (B). NOTE:

The steering member cover (A) and bolt (B) can be found near

the cowl area in the engine compartment.

10. Remove the remaining steering member bolts.

11. Disconnect the harness connectors from the heati ng and cooling unit assembly and steering member.

12. Remove the heating and cooling unit assembly and steering member as one assembly from the vehicle.

13. Seperate the heating and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test"

.

HEATER CORE

1. Heating and cooling unit assembly 2. Steering member Front

ALIIA0624ZZ

ALIIA0623ZZ

Revision: November 20132014 Altima NAM

Page 2654 of 4801

![NISSAN TEANA 2014 Service Manual

PRECAUTIONSHAC-5

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PR NISSAN TEANA 2014 Service Manual

PRECAUTIONSHAC-5

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PR](/img/5/57390/w960_57390-2653.png)

PRECAUTIONSHAC-5

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951773

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for WorkINFOID:0000000009463086

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Working with HFC-134a (R-134a)INFOID:0000000009463087

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-25, "Inspection"

. To determine the purity

of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharg-

ing equipment and Refrigerant Identifier.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2697 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck th NISSAN TEANA 2014 Service Manual

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck th](/img/5/57390/w960_57390-2696.png)

HAC-48

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463110

DESCRIPTION

The purpose of the operational check is to che

ck that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

2. Operate the temperature control switch (drive r side) and raise the temperature setting to 32°C (90 °F).

3. Press the OFF switch.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

6. Press the AUTO switch.

7. Check that the temperature setting, before turning the ignition switch OFF, is stored.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check power and ground circuits for A/C auto amp. Refer to HAC-78, "A/C AUTO AMP. : Diagno-

sis Procedure".

2.CHECK BLOWER MOTOR SPEED

1. Operate the fan control dial. Check that the fan speed changes.

2. Check the operation for all fan speeds.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check blower motor system. Refer to HAC-84, "Diagnosis Procedure"

.

3.CHECK DISCHARGE AIR (MODE SWITCH AND DEF SWITCH)

1. Press the MODE switch and the DEF switch.

2. Check that the air outlets change according to each i ndicated air outlet by placing a hand in front of the

outlets. Refer to HAC-13, "System Description"

.

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRE ( ) when the D/F ( ) or DEF ( ) is selected.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Check mode door system. Refer to HAC-80, "MODE DOOR MOTOR : Diagnosis Procedure"

.

4.CHECK INTAKE AIR

1. Press the REC ( ) switch. Indicator is turned ON.

2. Press the FRE ( ) switch. Indicator is turned ON.

3. Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual inspection) and the FRE ( ) switch is

pressed when the D/F ( ) or DEF ( ) is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Check intake door system. Refer to HAC-81, "INTAKE DOOR MOTOR : Diagnosis Procedure"

.

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. The A/C switch indicator is turned ON.

Confirm that the A/C compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

Conditions : Engine running at normal operating temperature

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2698 of 4801

![NISSAN TEANA 2014 Service Manual

OPERATION INSPECTIONHAC-49

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> GO TO 6.

NO >> Check magnet clutch system. Refer to HAC-87, "Diagnosis Procedu NISSAN TEANA 2014 Service Manual

OPERATION INSPECTIONHAC-49

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> GO TO 6.

NO >> Check magnet clutch system. Refer to HAC-87, "Diagnosis Procedu](/img/5/57390/w960_57390-2697.png)

OPERATION INSPECTIONHAC-49

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> GO TO 6.

NO >> Check magnet clutch system. Refer to HAC-87, "Diagnosis Procedure"

.

6.CHECK TEMPERATURE DECREASE

1. Operate the A/C compressor.

2. Operate the temperature control switch (drive r side) and lower the temperature setting to 18°C (60 °F).

3. Check that the cool air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Check for insufficient cooling. Refer to HAC-96, "Diagnosis Procedure"

.

7.CHECK TEMPERATURE INCREASE

1. Operate the temperature control switch (drive r side) and raise the temperature setting to 32°C (90 °F) after

warming up the engine.

2. Check that the warm air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Check for insufficient heating. Refer to HAC-98, "Diagnosis Procedure"

.

8.CHECK DUAL MODE FUNCTION

1. Press the DUAL mode switch, and then check that “DUAL” is shown on the display.

2. Operate the temperature control switch (driver si de). Check that the discharge air temperature (driver

side) changes.

3. Operate the temperature control switch (passenger side). Check that the discharge air temperature (pas-

senger side) changes.

4. Press the DUAL mode switch, and then check that the temperature setting (driver/passenger) is unified to

the driver side temperature setting.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Refer to HAC-94, "Diagnosis Chart By Symptom"

and perform the appropriate diagnosis.

9.CHECK AUTO MODE

1. Press the AUTO switch, and then check t hat “AUTO” is shown on the display.

2. Operate the temperature control switch (driver side) . Check that the fan speed, outlet air or intake air

changes. The discharge air temperature or fan speed varies depending on the ambient temperature, in-

vehicle temperature, and temperature setting.

Is the inspection result normal?

YES >> Inspection End

NO >> Refer to HAC-94, "Diagnosis Chart By Symptom"

and perform the appropriate diagnosis.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2747 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-98

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

DescriptionINFOID:0000000009463169

Symptom

• Insufficient heating

• No warm air comes out. (Air NISSAN TEANA 2014 Service Manual

HAC-98

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

DescriptionINFOID:0000000009463169

Symptom

• Insufficient heating

• No warm air comes out. (Air](/img/5/57390/w960_57390-2746.png)

HAC-98

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

DescriptionINFOID:0000000009463169

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis ProcedureINFOID:0000000009463170

NOTE:

Perform self-diagnosis with CONSULT before performing symptom diagnosis. If DTC is detected, perform the

corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check leakage. Refer to CO-11, "System Inspection"

(QR25DE) or CO-

35, "System Inspection" (VQ35DE).

2. Check reservoir tank cap. Refer to CO-11, "System Inspection"

(QR25DE) or CO-35, "System Inspection"

(VQ35DE).

3. Check water flow sounds of the engine coolant. Refer to CO-11, "System Inspection"

(QR25DE) or CO-

35, "System Inspection" (VQ35DE).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill engine coolant and repair or repl ace parts depending on the inspection results.

2.CHECK HEATER HOSE

Check installation of heater hose visually or by touching.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK HEATER CORE

1. Check temperature of inlet hose and outlet hose of front heater core.

2. Check that inlet side of heater core is hot and the outle t side is slightly lower than/almost equal to the inlet

side.

CAUTION:

Always perform the temperature in spection in a short period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace heater core. Refer to HA-42, "HEATER CORE : Removal and Installation"

.

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of front air conditioning system for air leakage.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts depending on the inspection results.

5.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (FRONT)

1. Check setting value of temperature setting trimmer (front). Refer to HAC-50, "Temperature Setting Trim-

mer".

2. Check that temperature setting trimmer (front) is set to “ − direction”.

NOTE:

The control temperature can be set by t he temperature setting trimmer (front).

3. Set difference between the set temperature and control temperature to “0”.

Are the symptoms solved?

YES >> Inspection End.

NO >> Replace A/C auto amp. Refer to HAC-102, "Removal and Installation"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2749 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-100

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

COMPRESSOR DOES NOT OPERATE

1. Start engine.

2. Check “AC COMP REQ” in “DATA MONITO R” mode of “IPDM E/R” using CONSULT.

Is the i NISSAN TEANA 2014 Service Manual

HAC-100

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

COMPRESSOR DOES NOT OPERATE

1. Start engine.

2. Check “AC COMP REQ” in “DATA MONITO R” mode of “IPDM E/R” using CONSULT.

Is the i](/img/5/57390/w960_57390-2748.png)

HAC-100

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

COMPRESSOR DOES NOT OPERATE

1. Start engine.

2. Check “AC COMP REQ” in “DATA MONITO R” mode of “IPDM E/R” using CONSULT.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check CAN communication system. Refer to LAN-18, "Trouble Diagnosis Flow Chart"

.

Monitor item Condition Status

AC COMP REQ A/C switch ON On

OFF Off

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2759 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-110

< PRECAUTION >[MANUAL AIR CONDITIONER]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951776

NISSAN TEANA 2014 Service Manual

HAC-110

< PRECAUTION >[MANUAL AIR CONDITIONER]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951776](/img/5/57390/w960_57390-2758.png)

HAC-110

< PRECAUTION >[MANUAL AIR CONDITIONER]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951776

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000009463187

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Working with HFC-134a (R-134a)INFOID:0000000009463188

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-25, "Inspection"

. To determine the purity

of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharg-

ing equipment and Refrigerant Identifier.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2789 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-140

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463210

DESCRIPTION

The purpose of the operational check is to che

ck that NISSAN TEANA 2014 Service Manual

HAC-140

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463210

DESCRIPTION

The purpose of the operational check is to che

ck that](/img/5/57390/w960_57390-2788.png)

HAC-140

< BASIC INSPECTION >[MANUAL AIR CONDITIONER]

OPERATION INSPECTION

OPERATION INSPECTION

Work ProcedureINFOID:0000000009463210

DESCRIPTION

The purpose of the operational check is to che

ck that the individual system operates normally.

OPERATION INSPECTION

1.CHECK BLOWER

1. Rotate the blower control dial clockwise one detent. Blower should operate on low speed.

2. Rotate the blower control dial one detent at a time, and continue checking blower speed until all speeds

are checked.

3. Leave blower on maximum speed.

Is the test result normal?

YES >> GO TO 2.

NO >> Refer to HAC-148, "Diagnosis Procedure"

.

2.CHECK A/C SWITCH LED

1. Press A/C switch.

2. A/C switch indicator should turn ON.

Is the test result normal?

YES >> GO TO 3.

NO >> Refer to HAC-152, "Diagnosis Procedure"

.

3.CHECK A/C SWITCH

Confirm that the compressor clutch engages (sound or visual inspection).

Is the test result normal?

YES >> GO TO 4.

NO >> Refer to HAC-151, "Diagnosis Procedure"

.

4.CHECK FRONT AIR CONTROL MODE LEDS

1. Press D/F ( ), FOOT ( ), B/L , and VENT , MAX A/C, and DEF ( ).

2. Each button indicator should illuminate.

Is the test result normal?

YES >> GO TO 5.

NO >> Refer to HAC-152, "Diagnosis Procedure"

.

5.CHECK DISCHARGE AIR

1. Press D/F ( ), FOOT ( ), B/L , and VENT and DEF ( ).

2. Confirm that discharge air comes out accordi ng to the air distribution table. Refer to HAC-119, "Door Con-

trol".

Is the test result normal?

YES >> GO TO 6.

NO >> Refer to HAC-154, "Symptom Table"

.

6.CHECK REC LED

1. Press DEF ( ) and make sure LED is off.

2. Make sure VENT ( ) or B/L ( ) is selected.

3. Press REC ( ) switch one time. REC indicator should illuminate. Check condition : Engine running

at normal operating temperature.

Check condition : Blower cont rol dial in OFF position.

Check condition : REC o ff (LED extinguished).

Check condition : VENT select ed (LED illuminated).

Check condition : DEF off (LED extinguished).

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2805 of 4801

![NISSAN TEANA 2014 Service Manual

HAC-156

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

YES >> GO TO 9

NO >> Check contaminated refrigerant. Refer to HA-9, "HFC-134a (R-134a) Service Tool and Equip-

ment".

9. C NISSAN TEANA 2014 Service Manual

HAC-156

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

YES >> GO TO 9

NO >> Check contaminated refrigerant. Refer to HA-9, "HFC-134a (R-134a) Service Tool and Equip-

ment".

9. C](/img/5/57390/w960_57390-2804.png)

HAC-156

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

INSUFFICIENT COOLING

YES >> GO TO 9

NO >> Check contaminated refrigerant. Refer to HA-9, "HFC-134a (R-134a) Service Tool and Equip-

ment".

9. CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected. Refer to HA-28, "Inspection"

.

Is the inspection result normal?

YES >> Perform diagnostic work flow. Refer to HA-15, "Workflow".

NO >> GO TO 10

10. CHECK FOR EVAPORATOR FREEZE UP

Start engine and run A/C. Check for evaporator freeze up.

Does evaporator freeze up?

YES >> Perform diagnostic work flow. Refer HA-15, "Workflow".

NO >> GO TO 11

11 . CHECK AIR DUCTS

Check ducts for air leaks.

Is the inspection result normal?

YES >> System OK.

NO >> Repair air leaks.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2806 of 4801

![NISSAN TEANA 2014 Service Manual

INSUFFICIENT HEATINGHAC-157

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000009463224

SYMPTOM: Insufficie NISSAN TEANA 2014 Service Manual

INSUFFICIENT HEATINGHAC-157

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000009463224

SYMPTOM: Insufficie](/img/5/57390/w960_57390-2805.png)

INSUFFICIENT HEATINGHAC-157

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONER]

C

D E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000009463224

SYMPTOM: Insufficient heating

INSPECTION FLOW

1. CONFIRM SYMPTOM BY PERFORMING OP ERATION CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat.

2. Check for hot air at discharge air outlets.

Can a symptom be duplicated?

YES >> GO TO 3

NO >> GO TO 2

2. CHECK FOR ANY SYMPTOMS

Perform a complete operational check and check for any symptoms. Refer to HAC-140, "Work Procedure"

.

Does another symptom exist?

YES >> Refer to HAC-154, "Symptom Table".

NO >> System OK.

3. CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4

4. CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-11, "System Inspection"

(QR25DE) or CO-35, "System

Inspection" (VQ35DE).

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-11, "System Inspection"

(QR25DE) or CO-35, "System Inspection"

(VQ35DE).

4. Check for air in cooling system.

>> GO TO 5

5. CHECK AIR MIX DOOR MOTOR OPERATION

Check and verify air mix door mechanism for smooth operation.

Does air mix door operate correctly?

YES >> GO TO 6

NO >> Check the air mix door motor circuit. Refer to HAC-144, "Diagnosis Procedure"

.

6. CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7

NO >> Repair all disconnected or leaking air ducts.

7. CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses. The inlet hose should be hot and the outlet hose should be

warm.

Is the inspection result normal?

YES >> GO TO 8

NO >> Both hoses warm: GO TO 9

8. CHECK ENGINE COOLANT SYSTEM

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM