sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2516 of 4801

FRONT STABILIZERFSU-15

< REMOVAL AND INSTALLATION >

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

6. Position the steering gear aside. Refer to ST-36, "Exploded View".

• Disconnect the steering gear from steering column.

• Remove the steering gear support bracket on the right side.

• Remove the steering gear bolts.

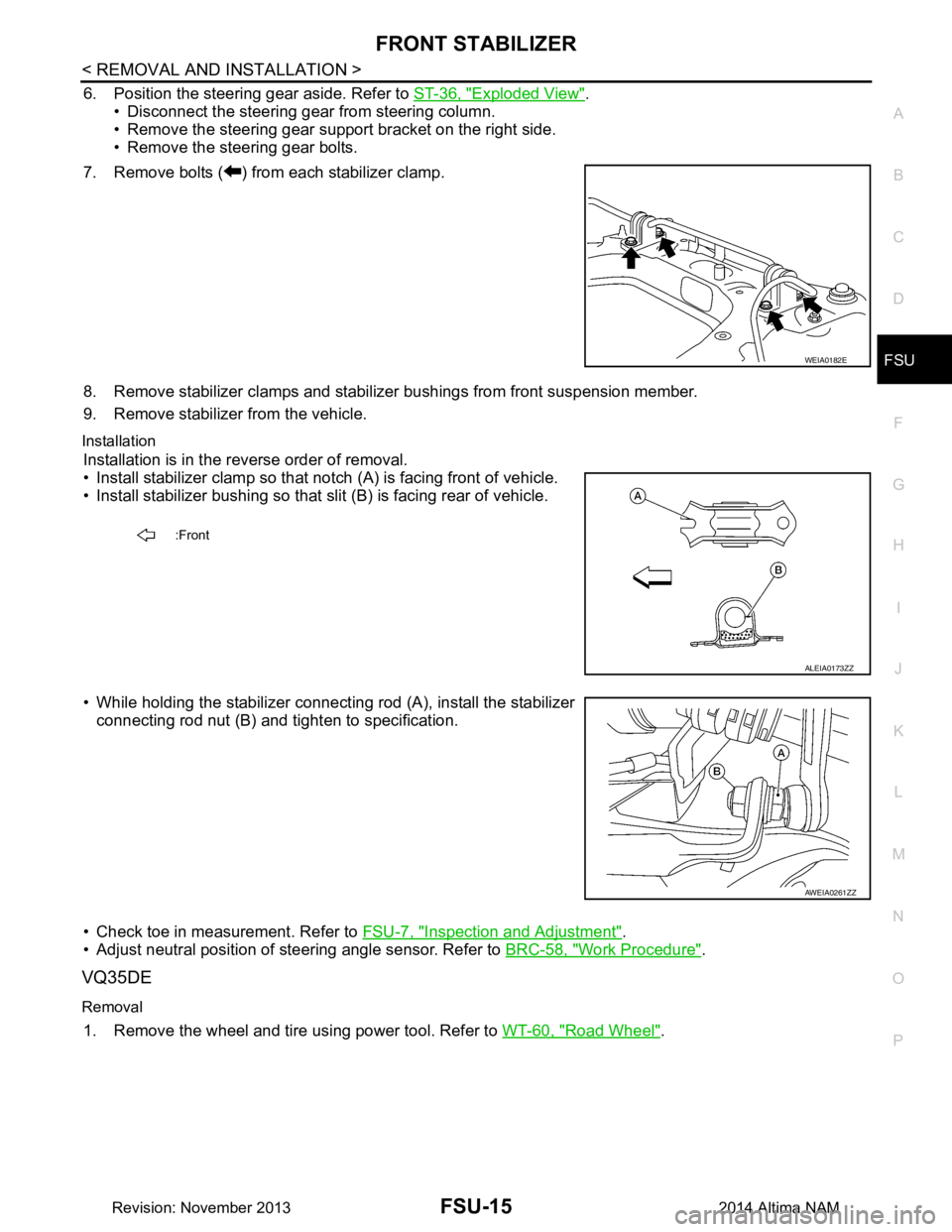

7. Remove bolts ( ) from each stabilizer clamp.

8. Remove stabilizer clamps and stabilizer bushings from front suspension member.

9. Remove stabilizer from the vehicle.

Installation

Installation is in the reverse order of removal.

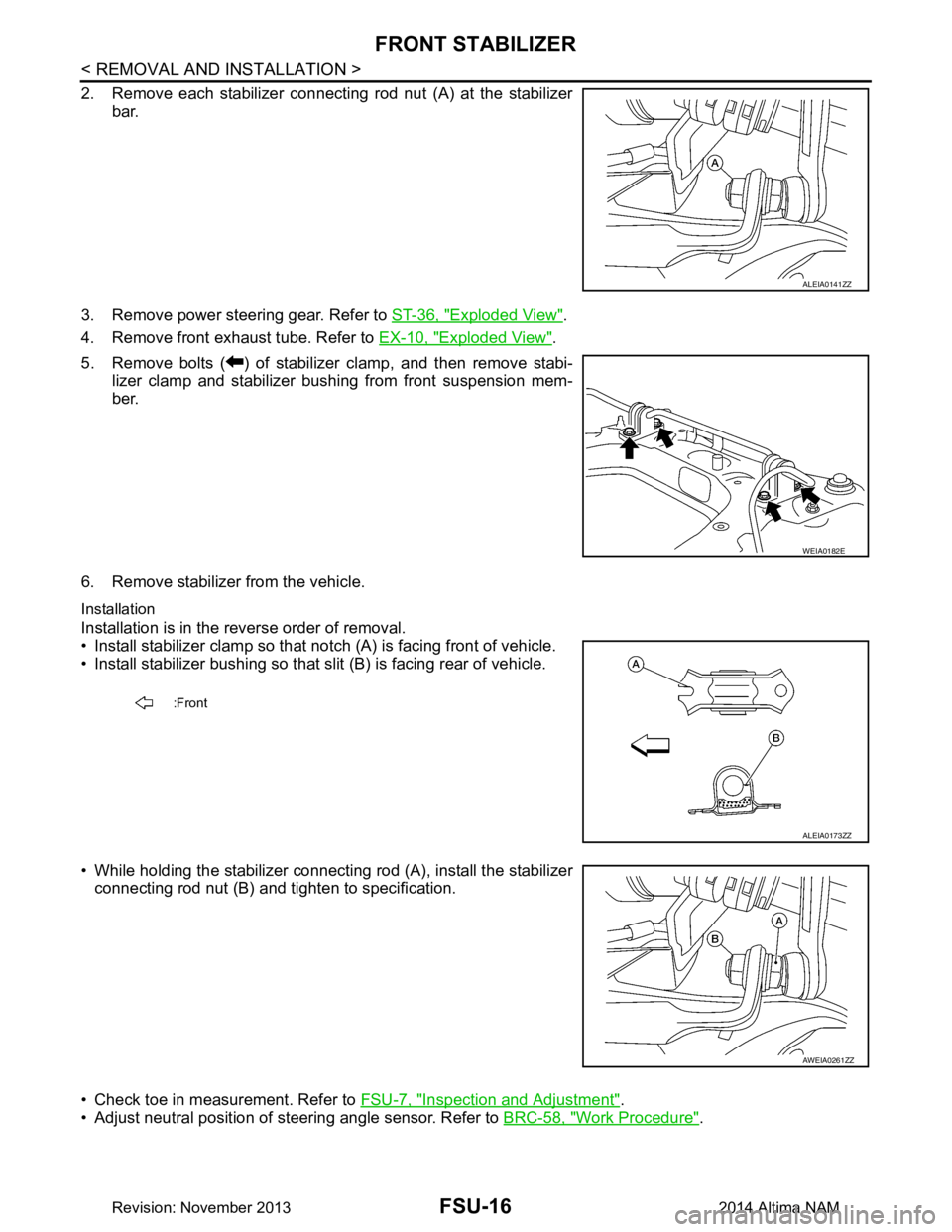

• Install stabilizer clamp so that notch (A) is facing front of vehicle.

• Install stabilizer bushing so that slit (B) is facing rear of vehicle.

• While holding the stabilizer connecting rod (A), install the stabilizer connecting rod nut (B) and ti ghten to specification.

• Check toe in measurement. Refer to FSU-7, "Inspection and Adjustment"

.

• Adjust neutral position of steering angle sensor. Refer to BRC-58, "Work Procedure"

.

VQ35DE

Removal

1. Remove the wheel and tire using power tool. Refer to WT-60, "Road Wheel".

WEIA0182E

:Front

ALEIA0173ZZ

AWEIA0261ZZ

Revision: November 20132014 Altima NAM

Page 2517 of 4801

FSU-16

< REMOVAL AND INSTALLATION >

FRONT STABILIZER

2. Remove each stabilizer connecting rod nut (A) at the stabilizerbar.

3. Remove power steering gear. Refer to ST-36, "Exploded View"

.

4. Remove front exhaust tube. Refer to EX-10, "Exploded View"

.

5. Remove bolts ( ) of stabilizer clamp, and then remove stabi- lizer clamp and stabilizer bushing from front suspension mem-

ber.

6. Remove stabilizer from the vehicle.

Installation

Installation is in the reverse order of removal.

• Install stabilizer clamp so that not ch (A) is facing front of vehicle.

• Install stabilizer bushing so that slit (B) is facing rear of vehicle.

• While holding the stabilizer connecting rod (A), install the stabilizer connecting rod nut (B) and tighten to specification.

• Check toe in measurement. Refer to FSU-7, "Inspection and Adjustment"

.

• Adjust neutral position of steering angle sensor. Refer to BRC-58, "Work Procedure"

.

ALEIA0141ZZ

WEIA0182E

:Front

ALEIA0173ZZ

AWEIA0261ZZ

Revision: November 20132014 Altima NAM

Page 2519 of 4801

FSU-18

< REMOVAL AND INSTALLATION >

STEERING KNUCKLE

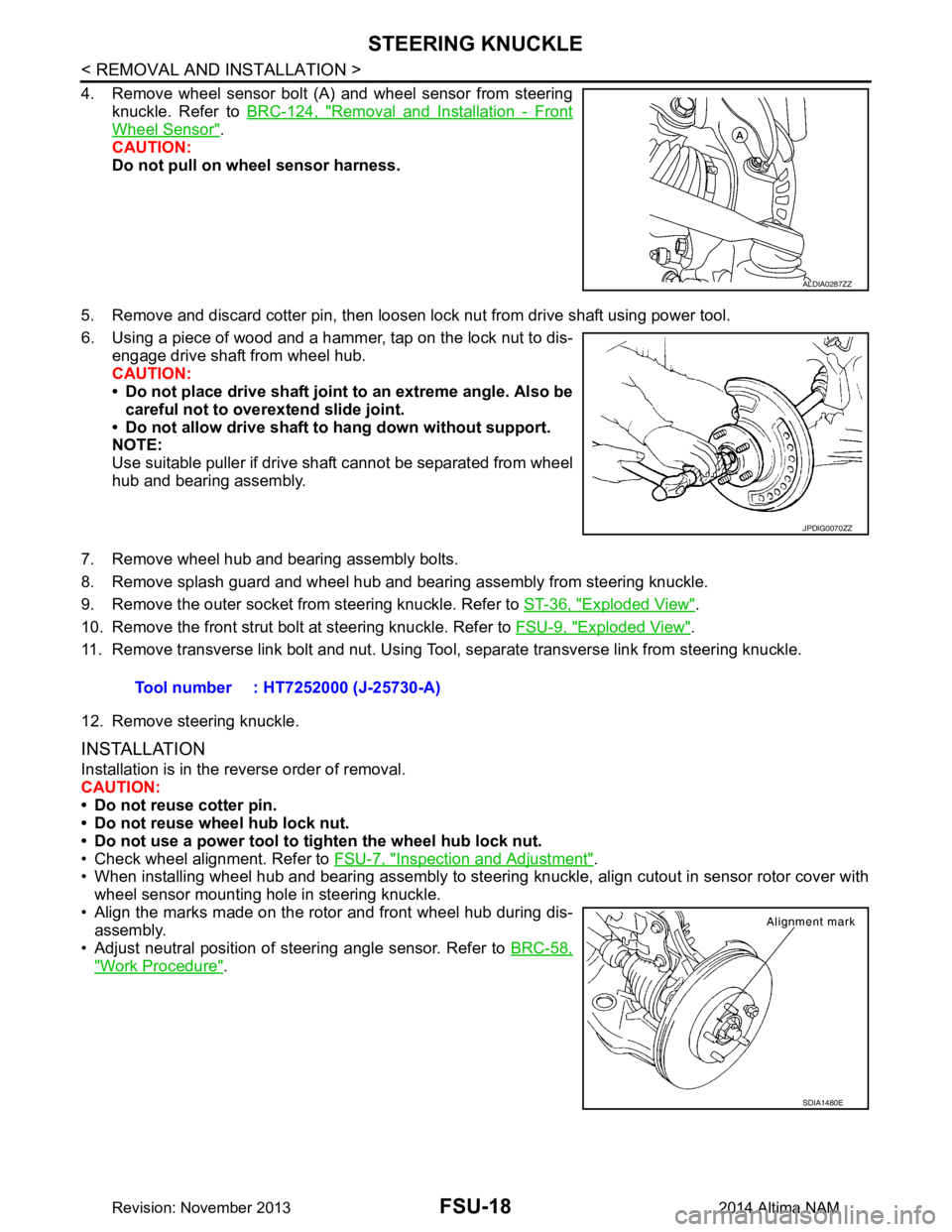

4. Remove wheel sensor bolt (A) and wheel sensor from steeringknuckle. Refer to BRC-124, "Removal and Installation - Front

Wheel Sensor".

CAUTION:

Do not pull on wheel sensor harness.

5. Remove and discard cotter pin, then loosen lock nut from drive shaft using power tool.

6. Using a piece of wood and a hammer, tap on the lock nut to dis- engage drive shaft from wheel hub.

CAUTION:

• Do not place drive shaft joint to an extreme angle. Also be

careful not to over extend slide joint.

• Do not allow drive shaft to hang down without support.

NOTE:

Use suitable puller if drive shaft cannot be separated from wheel

hub and bearing assembly.

7. Remove wheel hub and bearing assembly bolts.

8. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

9. Remove the outer socket from steering knuckle. Refer to ST-36, "Exploded View"

.

10. Remove the front strut bolt at steering knuckle. Refer to FSU-9, "Exploded View"

.

11. Remove transverse link bolt and nut. Using Tool, separate transverse link from steering knuckle.

12. Remove steering knuckle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse cotter pin.

• Do not reuse wheel hub lock nut.

• Do not use a power tool to tighten the wheel hub lock nut.

• Check wheel alignment. Refer to FSU-7, "Inspection and Adjustment"

.

• When installing wheel hub and bearing assembly to steering knuckle, align cutout in sensor rotor cover with

wheel sensor mounting hole in steering knuckle.

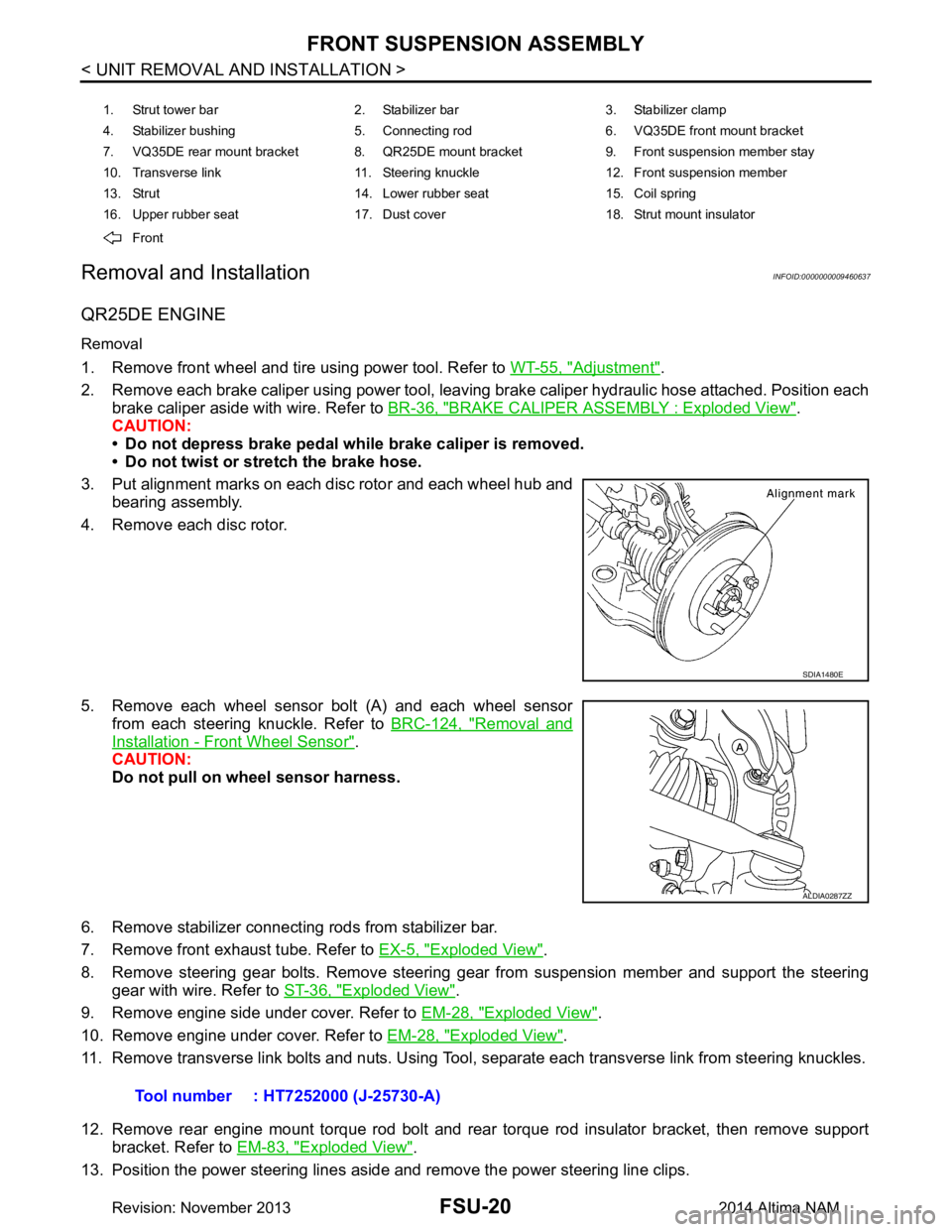

• Align the marks made on the rotor and front wheel hub during dis- assembly.

• Adjust neutral position of steering angle sensor. Refer to BRC-58,

"Work Procedure".

ALDIA0287ZZ

JPDIG0070ZZ

Tool number : HT7252000 (J-25730-A)

SDIA1480E

Revision: November 20132014 Altima NAM

Page 2521 of 4801

FSU-20

< UNIT REMOVAL AND INSTALLATION >

FRONT SUSPENSION ASSEMBLY

Removal and Installation

INFOID:0000000009460637

QR25DE ENGINE

Removal

1. Remove front wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove each brake caliper using power tool, leaving brake caliper hydraulic hose attached. Position each brake caliper aside with wire. Refer to BR-36, "BRAKE CALIPER ASSEMBLY : Exploded View"

.

CAUTION:

• Do not depress brake pedal while brake caliper is removed.

• Do not twist or stretch the brake hose.

3. Put alignment marks on each disc rotor and each wheel hub and bearing assembly.

4. Remove each disc rotor.

5. Remove each wheel sensor bolt (A) and each wheel sensor from each steering knuckle. Refer to BRC-124, "Removal and

Installation - Front Wheel Sensor".

CAUTION:

Do not pull on wheel sensor harness.

6. Remove stabilizer connecting rods from stabilizer bar.

7. Remove front exhaust tube. Refer to EX-5, "Exploded View"

.

8. Remove steering gear bolts. Remove steering gear from suspension member and support the steering gear with wire. Refer to ST-36, "Exploded View"

.

9. Remove engine side under cover. Refer to EM-28, "Exploded View"

.

10. Remove engine under cover. Refer to EM-28, "Exploded View"

.

11. Remove transverse link bolts and nuts. Using Tool, separate each transverse link from steering knuckles.

12. Remove rear engine mount torque rod bolt and rear torque rod insulator bracket, then remove support bracket. Refer to EM-83, "Exploded View"

.

13. Position the power steering lines aside and remove the power steering line clips.

1. Strut tower bar 2. Stabilizer bar 3. Stabilizer clamp

4. Stabilizer bushing 5. Connecting rod 6. VQ35DE front mount bracket

7. VQ35DE rear mount bracket 8. QR25DE mount bracket 9. Front suspension member stay

10. Transverse link 11. Steering knuckle 12. Front suspension member

13. Strut 14. Lower rubber seat 15. Coil spring

16. Upper rubber seat 17. Dust cover 18. Strut mount insulator

Front

SDIA1480E

ALDIA0287ZZ

Tool number : HT7252000 (J-25730-A)

Revision: November 20132014 Altima NAM

Page 2522 of 4801

FRONT SUSPENSION ASSEMBLYFSU-21

< UNIT REMOVAL AND INSTALLATION >

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

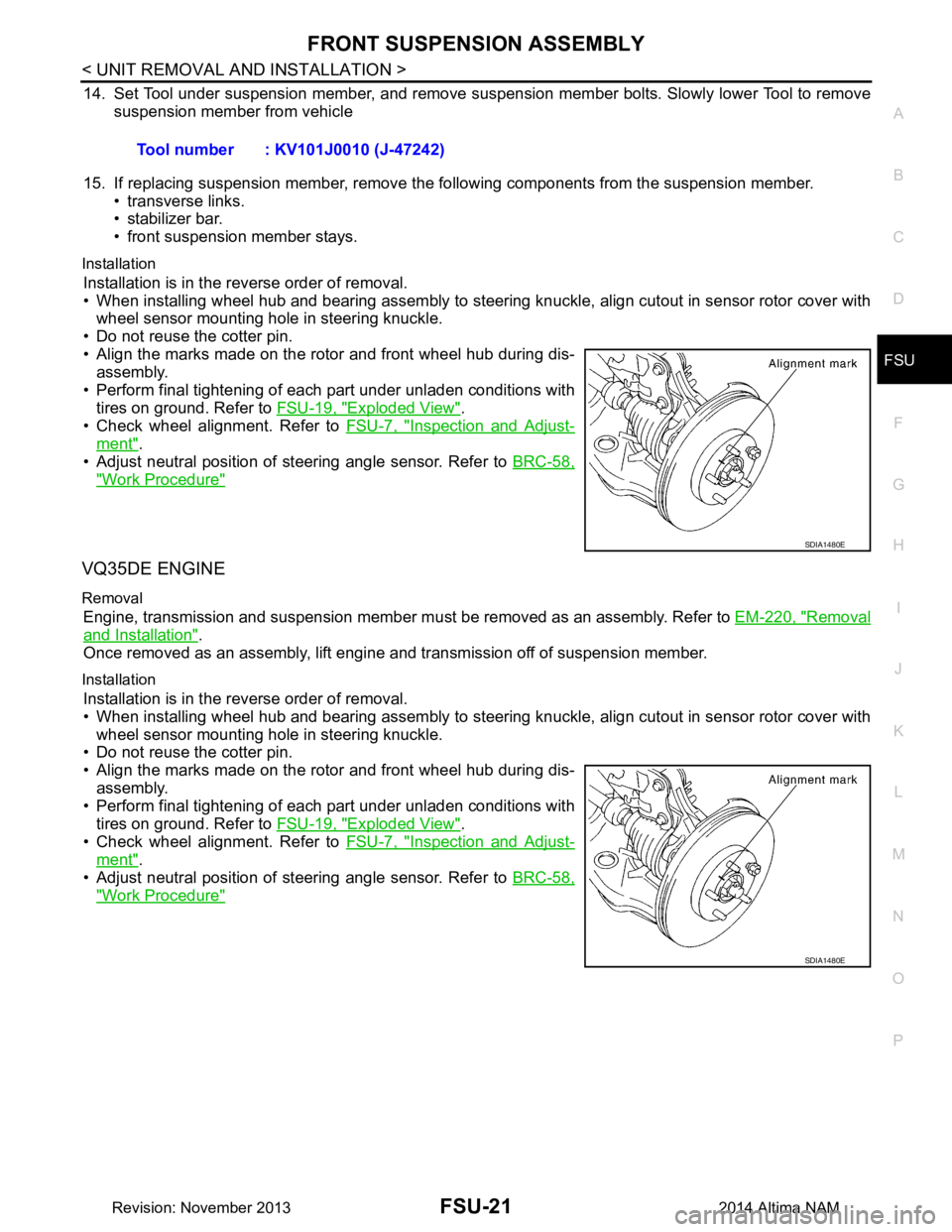

14. Set Tool under suspension member, and remove suspension member bolts. Slowly lower Tool to remove suspension member from vehicle

15. If replacing suspension member, remove the following components from the suspension member. • transverse links.

• stabilizer bar.

• front suspension member stays.

Installation

Installation is in the reverse order of removal.

• When installing wheel hub and bearing assembly to steering knuckle, align cutout in sensor rotor cover with wheel sensor mounting hole in steering knuckle.

• Do not reuse the cotter pin.

• Align the marks made on the rotor and front wheel hub during dis- assembly.

• Perform final tightening of each part under unladen conditions with tires on ground. Refer to FSU-19, "Exploded View"

.

• Check wheel alignment. Refer to FSU-7, "Inspection and Adjust-

ment".

• Adjust neutral position of steering angle sensor. Refer to BRC-58,

"Work Procedure"

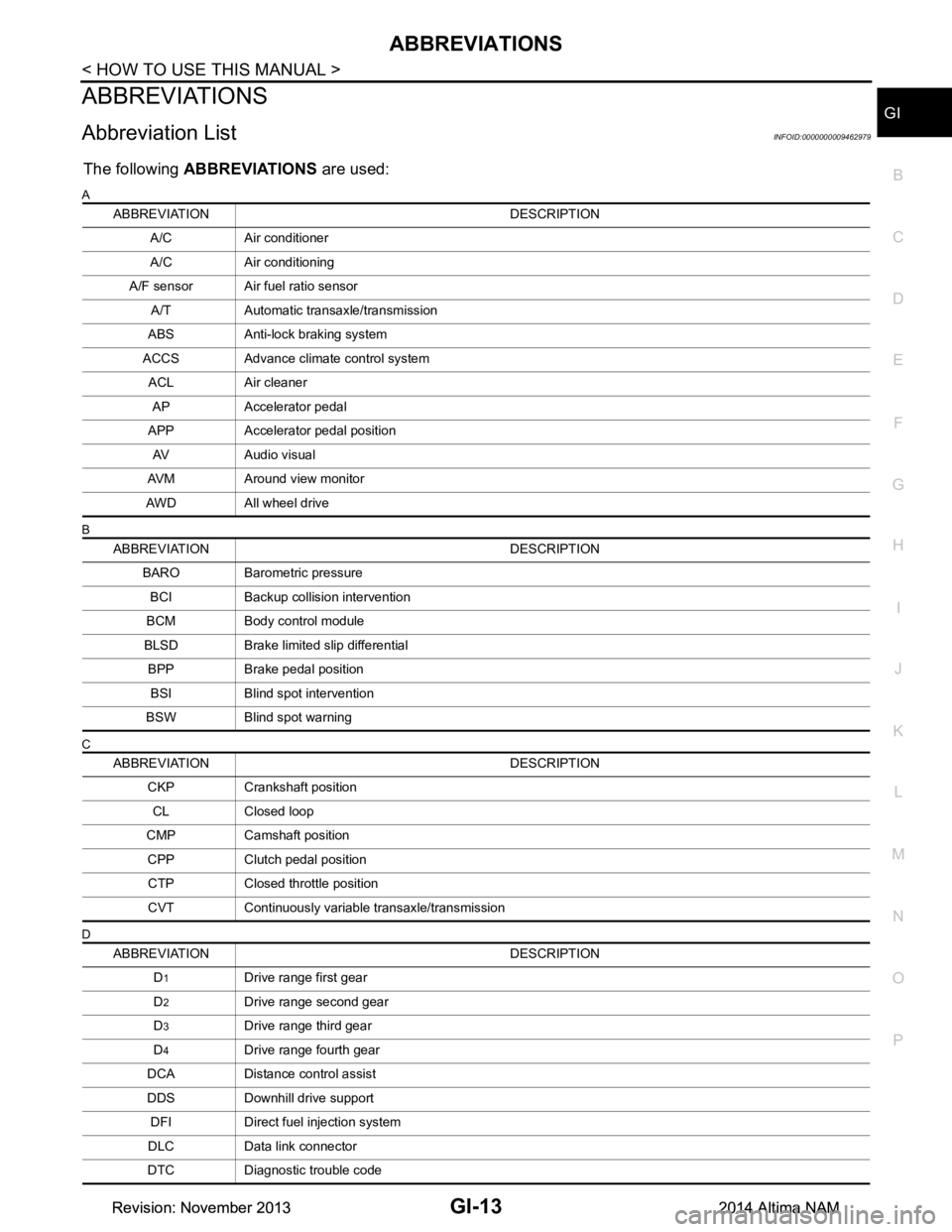

VQ35DE ENGINE

Removal

Engine, transmission and suspension member must be removed as an assembly. Refer to EM-220, "Removal

and Installation".

Once removed as an assembly, lift engine and transmission off of suspension member.

Installation

Installation is in the reverse order of removal.

• When installing wheel hub and bearing assembly to steering knuckle, align cutout in sensor rotor cover with

wheel sensor mounting hole in steering knuckle.

• Do not reuse the cotter pin.

• Align the marks made on the rotor and front wheel hub during dis-

assembly.

• Perform final tightening of each part under unladen conditions with tires on ground. Refer to FSU-19, "Exploded View"

.

• Check wheel alignment. Refer to FSU-7, "Inspection and Adjust-

ment".

• Adjust neutral position of steering angle sensor. Refer to BRC-58,

"Work Procedure"

Tool number : KV101J0010 (J-47242)

SDIA1480E

SDIA1480E

Revision: November 20132014 Altima NAM

Page 2541 of 4801

ABBREVIATIONSGI-13

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PABBREVIATIONS

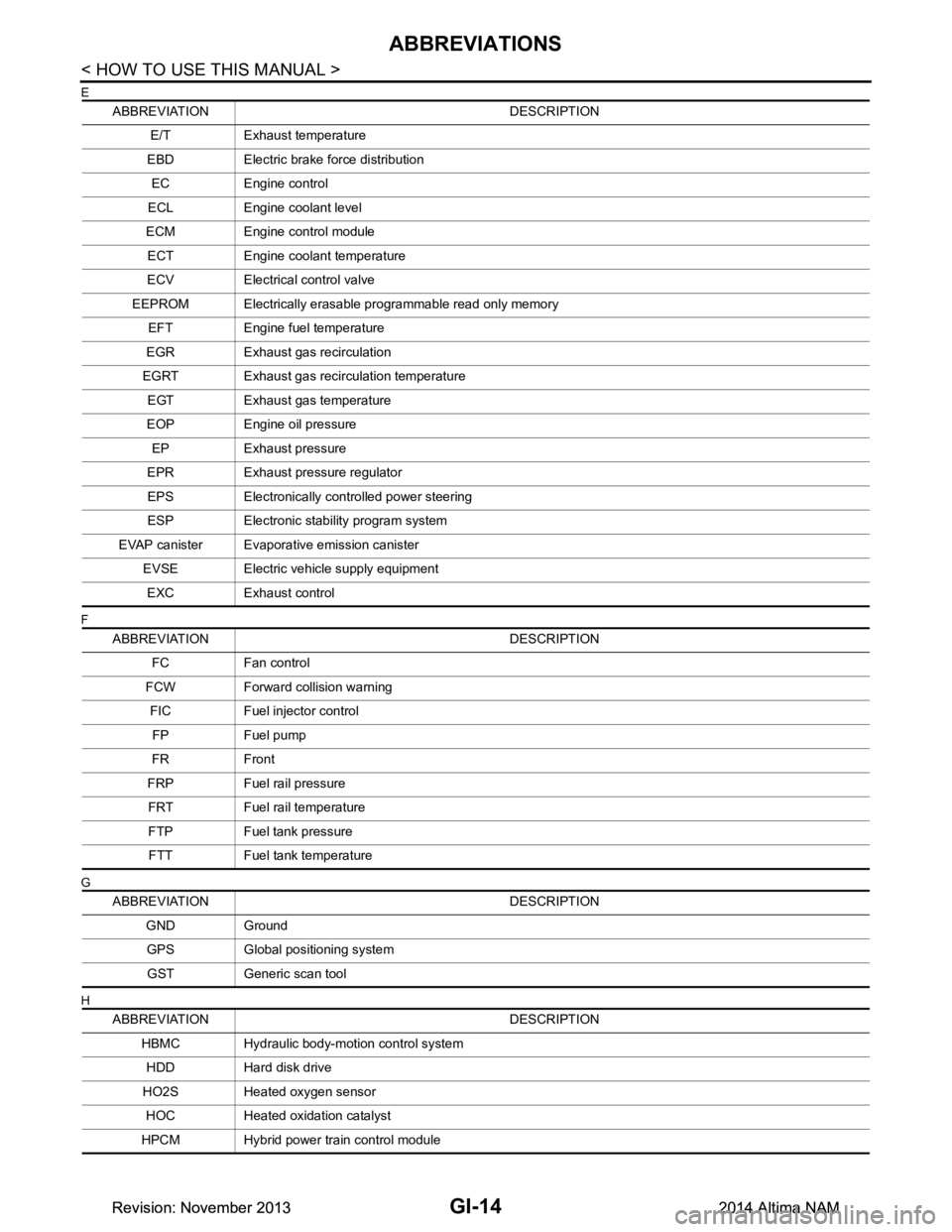

Abbreviation ListINFOID:0000000009462979

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position AV Audio visual

AVM Around view monitor

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCI Backup collision intervention

BCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist

DDS Downhill drive support DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2542 of 4801

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

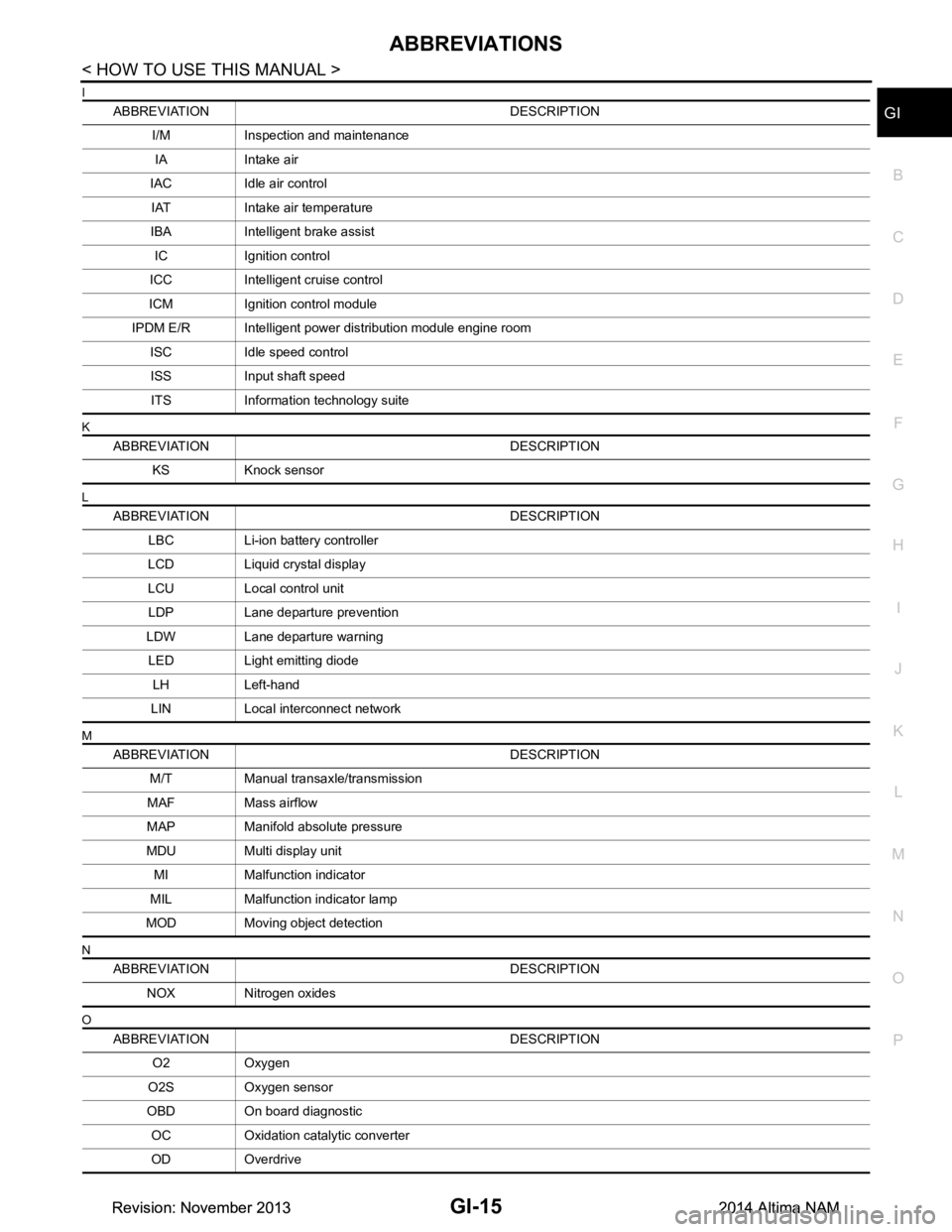

E

F

G

H

ABBREVIATION DESCRIPTION E/T Exhaust temperature

EBD Electric brake force distribution EC Engine control

ECL Engine coolant level

ECM Engine control module ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable pr ogrammable read only memory

EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure EP Exhaust pressure

EPR Exhaust pressure regulator EPS Electronically cont rolled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipmentEXC Exhaust control

ABBREVIATION DESCRIPTION FC Fan control

FCW Forward collision warning FIC Fuel injector controlFP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperatureFTP Fuel tank pressure FTT Fuel tank temperature

ABBREVIATION DESCRIPTION GND GroundGPS Global positioning systemGST Generic scan tool

ABBREVIATION DESCRIPTION HBMC Hydraulic body-motion control systemHDD Hard disk drive

HO2S Heated oxygen sensor HOC Heated oxidation catalyst

HPCM Hybrid power train control module

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2543 of 4801

ABBREVIATIONSGI-15

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

I

K

L

M

N

O

ABBREVIATION DESCRIPTION I/M Inspection and maintenanceIA Intake air

IAC Idle air control IAT Intake air temperature

IBA Intelligent brake assist IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed controlISS Input shaft speed ITS Information technology suite

ABBREVIATION DESCRIPTION KS Knock sensor

ABBREVIATION DESCRIPTION LBC Li-ion battery controller

LCD Liquid crystal display

LCU Local control unit LDP Lane departure prevention

LDW Lane departure warning LED Light emitting diode LH Left-hand

LIN Local interconnect network

ABBREVIATION DESCRIPTION M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure

MDU Multi display unit MI Malfunction indicator

MIL Malfunction indicator lamp

MOD Moving object detection

ABBREVIATION DESCRIPTION NOX Nitrogen oxides

ABBREVIATION DESCRIPTION O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic OC Oxidation catalytic converter

OD Overdrive

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2545 of 4801

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

W

1

2

3

4

5

6

VIN Vehicle identification number

VSS Vehicle speed sensor

ABBREVIATION DESCRIPTION WOT Wide open throttle

ABBREVIATION DESCRIPTION 1

11st range first gear

1

21st range second gear

1GR First gear

ABBREVIATION DESCRIPTION 2

12nd range first gear

2

22nd range second gear

2GR Second gear

2WD 2-wheel drive

ABBREVIATION DESCRIPTION 3GR Third gear

ABBREVIATION DESCRIPTION 4GR Fourth gear

4WAS Four wheel active steer 4WD Four wheel drive

ABBREVIATION DESCRIPTION 5GR Fifth gear

ABBREVIATION DESCRIPTION 6GR Sixth gear

ABBREVIATION DESCRIPTION

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2554 of 4801

GI-26

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

DescriptionINFOID:0000000009462991

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009462992

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least 3 minutes before performing any service.

Precautions For Xeno n Headlamp ServiceINFOID:0000000009462993

WARNING:

Comply with the following warnings to prevent any serious accident.

• Disconnect the battery cable (n egative terminal) or the power

supply fuse before in stalling, removing, or touching the

xenon headlamp (bulb included) . The xenon headlamp con-

tains high-voltage generated parts.

• Never work with wet hands.

• Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon headlamp ON in other

conditions. Connect the power supply to the vehicle-side con-

nector.

(Turning it ON outside the la mp case may cause fire or visual

impairments.)

• Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

WKIA0460E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM