sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2557 of 4801

PRECAUTIONSGI-29

< PRECAUTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

To prevent ECM from storing the diagnostic trou ble codes, do not carelessly disconnect the harness

connectors which are related to the engine cont rol system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and TM sections.

Three Way CatalystINFOID:0000000009462996

If a large amount of unburned fuel flows into the catalyst , the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec- essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Fuel (Regular Unleaded Ga soline Recommended) QR25DEINFOID:0000000009462997

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91). E-85 fuel (85% fuel ethanol, 15% unl eaded gasoline) may only be used in vehicles specif-

ically designed for E-85 fuel (i.e. Flexible Fuel Vehicle - FFV models).

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Fuel (Regular Unleaded Gasoline Recommended) VQ35DEINFOID:0000000009462998

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91). E-85 fuel (85% fuel ethanol, 15% unl eaded gasoline) may only be used in vehicles specif-

ically designed for E-85 fuel (i.e. Flexible Fuel Vehicle - FFV models).

CAUTION:

Do not use leaded gasoli ne. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unlead ed gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fu el other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Multiport Fuel Injection System or Engine Control SystemINFOID:0000000009462999

• Before connecting or disconnecti ng any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injec-

tors, be sure to release fuel pressure.

• Be careful not to jar components such as ECM and mass air flow sensor.

HosesINFOID:0000000009463000

HOSE REMOVAL AND INSTALLATION

SGI787

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2572 of 4801

GI-44

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer . It is important for simulating the conditions of the

problem.

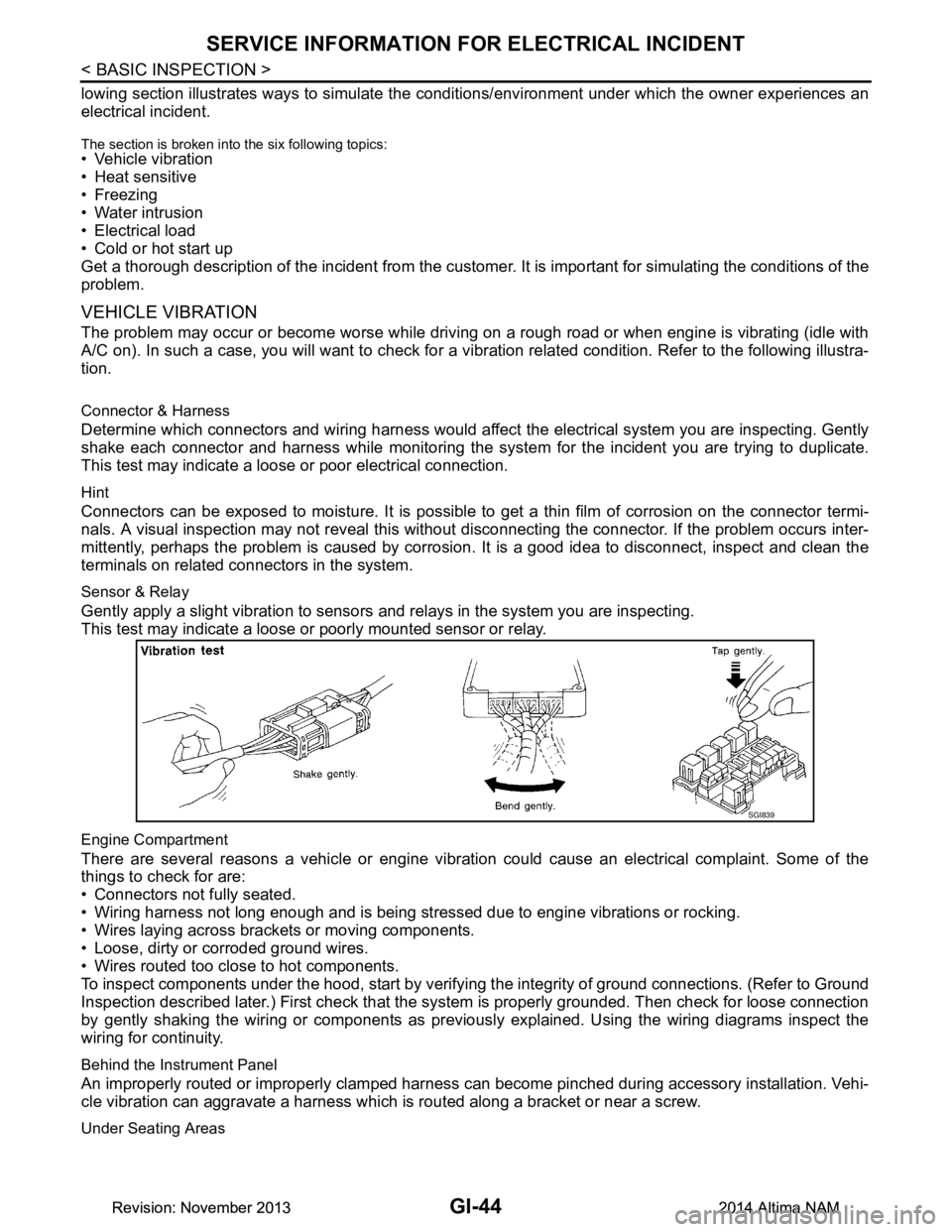

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

SGI839

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2582 of 4801

GW-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951564

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

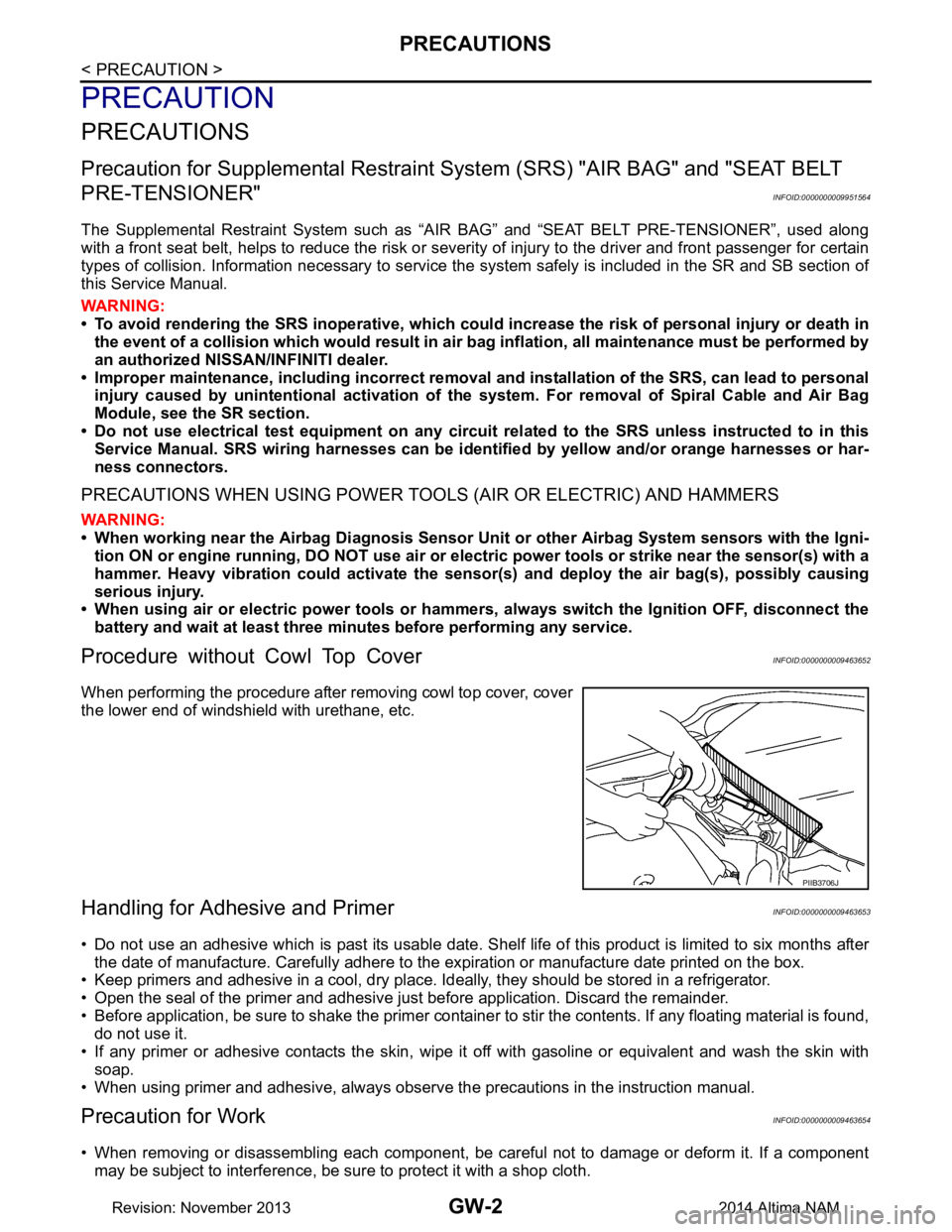

Procedure without Cowl Top CoverINFOID:0000000009463652

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Handling for Adhe sive and PrimerINFOID:0000000009463653

• Do not use an adhesive which is past its usable date. Shel f life of this product is limited to six months after

the date of manufacture. Carefully adhere to the ex piration or manufacture date printed on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Open the seal of the primer and adhesive just before application. Discard the remainder.

• Before application, be sure to shake the primer container to stir the contents. If any floating material is found,

do not use it.

• If any primer or adhesive contacts the skin, wipe it off with gasoline or equivalent and wash the skin with

soap.

• When using primer and adhesive, always observe the precautions in the instruction manual.

Precaution for WorkINFOID:0000000009463654

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

PIIB3706J

Revision: November 20132014 Altima NAM

Page 2608 of 4801

HA-2

LOW-PRESSURE PIPE ............................................35

LOW-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

35

HIGH-PRESSURE PIPE ......................................... ...36

HIGH-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ...

36

CONDENSER ....................................................38

Exploded View ..................................................... ...38

CONDENSER ......................................................... ...38

CONDENSER : Removal and Installation ..............38

LIQUID TANK ......................................................... ...38

LIQUID TANK : Removal and Installation ...............38

REFRIGERANT PRESSURE SENSOR ....................39

REFRIGERANT PRESSURE SENSOR : Remov-

al and Installation ................................................. ...

39

HEATING AND COOLING UNIT ASSEMBLY ...40

Exploded View ..................................................... ...40

HEATING AND COOLING UNIT ASSEMBLY ....... ...40

HEATING AND COOLING UNIT ASSEMBLY :

Removal and Installation .........................................

41

HEATER CORE ...................................................... ...41

HEATER CORE : Removal and Installation ............42

EVAPORATOR ....................................................... ...42

EVAPORATOR : Removal and Installation .............42

EXPANSION VALVE .............................................. ...42

EXPANSION VALVE : Removal and Installation

for Expansion Valve ............................................. ...

42

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

43

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

43

Service Data and Specification (SDS) ....................43

Revision: November 20132014 Altima NAM

Page 2609 of 4801

PRECAUTIONSHA-3

< PRECAUTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951784

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for WorkINFOID:0000000009463909

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precaution for Workin g with HFC-134a (R-134a)INFOID:0000000009463910

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-21, "Leak Test"

. To determine the purity

of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharg-

ing equipment and Refrigerant Identifier.

Revision: November 20132014 Altima NAM

Page 2610 of 4801

HA-4

< PRECAUTION >

PRECAUTIONS

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used , compressor failure is likely to occur.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant co mponents to a vehicle, do not remove the caps (unseal) until just

before connecting the components . Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usin g certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtain ed from refrigerant and oil manufac-

turers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Contaminated RefrigerantINFOID:0000000009463911

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the locati on of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not recover contamin ated refrigerant into your existing service equipment. If your facility does

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

Precaution for Leak Detection DyeINFOID:0000000009463912

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and HC-12 (R- 12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in R-12 A/C systems or HC-12 (R-12) leak detection dye in HFC-134a (R-

134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

Precaution for Refrigerant ConnectionINFOID:0000000009463913

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

Revision: November 20132014 Altima NAM

Page 2619 of 4801

REFRIGERATION SYSTEMHA-13

< SYSTEM DESCRIPTION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

SYSTEM DESCRIPTION

REFRIGERATION SYSTEM

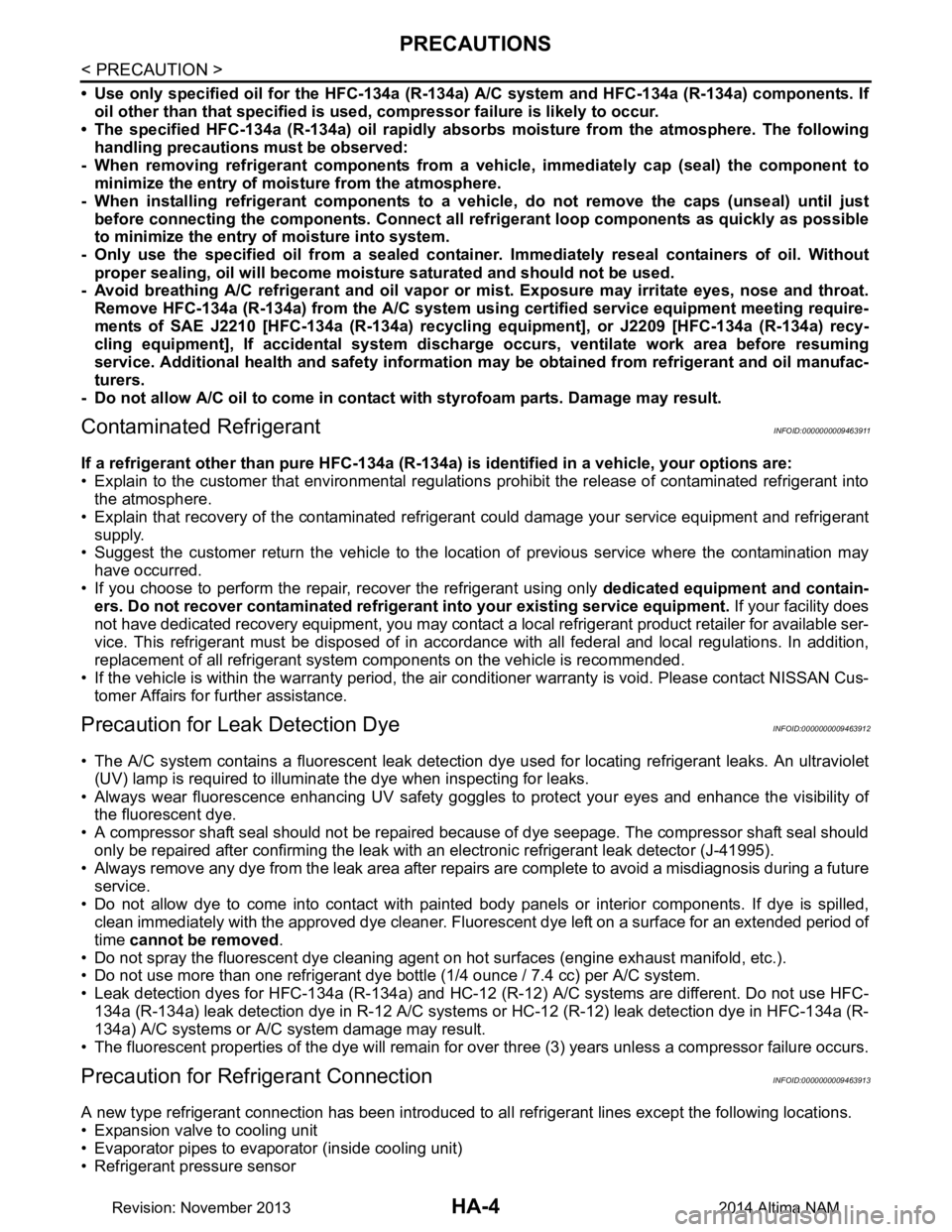

Refrigerant CycleINFOID:0000000009463918

Refrigerant flow

Refrigerant Flow

The refrigerant from the compressor flows though the c ondenser with liquid tank, evaporator, and return to the

compressor. The refrigerant evaporation in the evaporator is controlled by an expansion valve.

Freeze Protection

To prevent evaporator from freezing up, the evaporator air temperature is monitored and the voltage signal to

the A/C auto amp. makes the A/C relay go OFF and stop the compressor.

Refrigerant System ProtectionINFOID:0000000009463919

Refrigerant pressure sensor

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rise s above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

The ECM then ceases to supply power to the A/C relay which disengages and stops the compressor when

pressure on the high pressure side (as detected by refr igerant pressure sensor) is over approximately 2,746

kPa (28 kg/cm

2, 398 psi), or below approximately 120 kPa (1.22 kg/cm2, 17.4 psi).

Pressure Relief Valve

1. Electric compressor 2. Pressure relief valve 3. Liquid tank

4. Refrigerant pressure sensor 5. Condenser 6. Expansion valve

7. Evaporator 8. Blower motor A. High-pressure gas

B. High-pressure liquid C. Low-pressure liquid D. Low-pressure gas

E. Suction port F. Discharge port G Outside air

AWIIA0054ZZ

Revision: November 20132014 Altima NAM

Page 2625 of 4801

REFRIGERATION SYSTEM SYMPTOMSHA-19

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

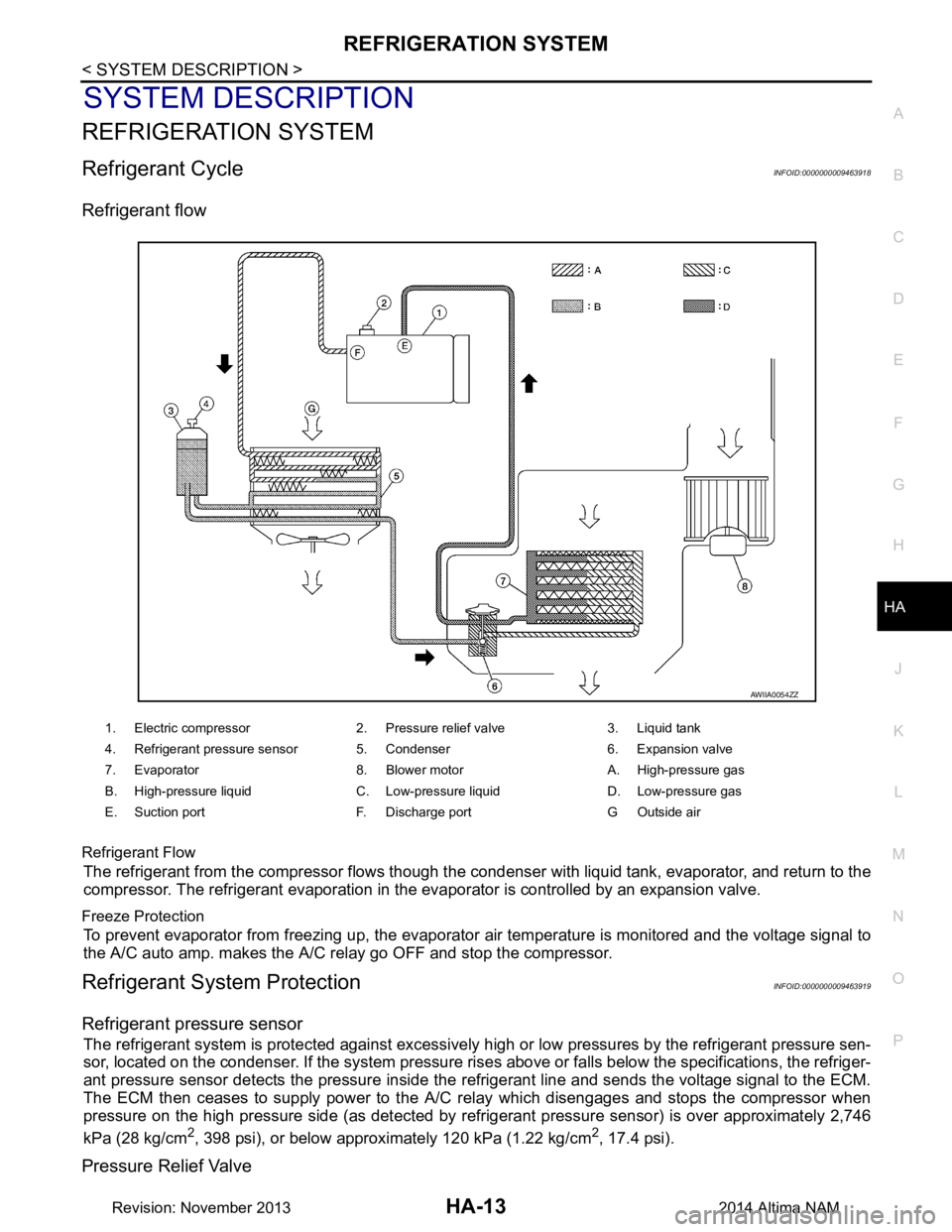

Both high and low pressure sides

are too low. • The area around evapora-

tor outlet does not become

cold.

• The area around evapora- tor inlet becomes frosted. Clogged expansion valve.

• Breakage of temperature sensor.

• Clogging by foreign material. Eliminate foreign material from

expansion valve or replace it.

• There is a temperature dif- ference between the areas

around outlet and inlet

pipes of liquid tank.

• Liquid tank becomes frost- ed. Malfunction in inner liquid tank

(clogged strainer). Replace liquid tank.

Evaporator becomes frosted. Clogged or crushed low-pres-

sure pipe. Repair or replace malfunction-

ing parts.

Malfunction in intake air tem-

perature sensor. Check intake sensor system.

Refer to HAC-64, "Component

Inspection".

There is a small temperature

difference between the high

and low pressure pipes for re-

frigerant cycle. • Shortage of refrigerant.

• Leakage of refrigerant. • Check for leakage.

• Collect all refrigerant, evacu-

ate refrigerant cycle again,

and then refill it with the spec-

ified amount of refrigerant.

Low-pressure side sometimes be-

comes negative. • Sometimes the area

around evaporator outlet

does not become cold.

• Sometimes the area

around evaporator inlet is

frosted. • Icing caused by the mixing of

water in cooler cycle.

• Deteriorated dryer in liquid

tank. • Collect all refrigerant.

• Evacuate refrigerant cycle completely, and then refill it

with the specified amount of

refrigerant. At this time, al-

ways replace liquid tank.

Hunting in high-pressure side. There is no temperature dif-

ference between high- and

low-pressure sides. Malfunctioning variable valve

in compressor. • Replace compressor.

• Check ECV system.

Gauge indication Refrigerant cycle Probable cause Corrective action

AC353A

AC354A

Revision: November 20132014 Altima NAM

Page 2644 of 4801

HA-38

< REMOVAL AND INSTALLATION >

CONDENSER

CONDENSER

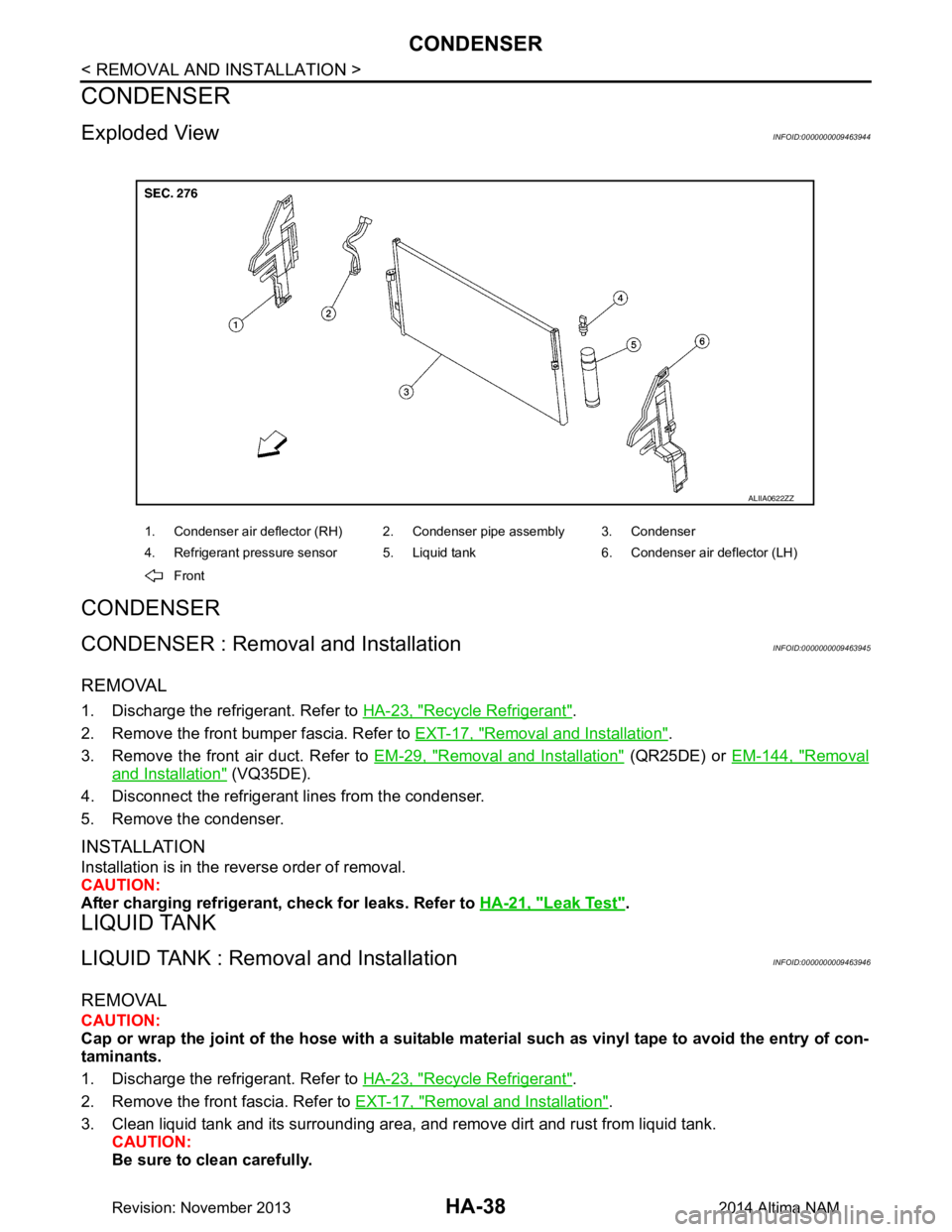

Exploded ViewINFOID:0000000009463944

CONDENSER

CONDENSER : Removal and InstallationINFOID:0000000009463945

REMOVAL

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

2. Remove the front bumper fascia. Refer to EXT-17, "Removal and Installation"

.

3. Remove the front air duct. Refer to EM-29, "Removal and Installation"

(QR25DE) or EM-144, "Removal

and Installation" (VQ35DE).

4. Disconnect the refrigerant lines from the condenser.

5. Remove the condenser.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test"

.

LIQUID TANK

LIQUID TANK : Removal and InstallationINFOID:0000000009463946

REMOVAL

CAUTION:

Cap or wrap the joint of the hose with a suitable ma terial such as vinyl tape to avoid the entry of con-

taminants.

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant"

.

2. Remove the front fascia. Refer to EXT-17, "Removal and Installation"

.

3. Clean liquid tank and its surrounding area, and remove dirt and rust from liquid tank. CAUTION:

Be sure to clean carefully.

1. Condenser air deflector (RH) 2. Condenser pipe assembly 3. Condenser

4. Refrigerant pressure sensor 5. Liquid tank 6. Condenser air deflector (LH)

Front

ALIIA0622ZZ

Revision: November 20132014 Altima NAM

Page 2645 of 4801

CONDENSERHA-39

< REMOVAL AND INSTALLATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

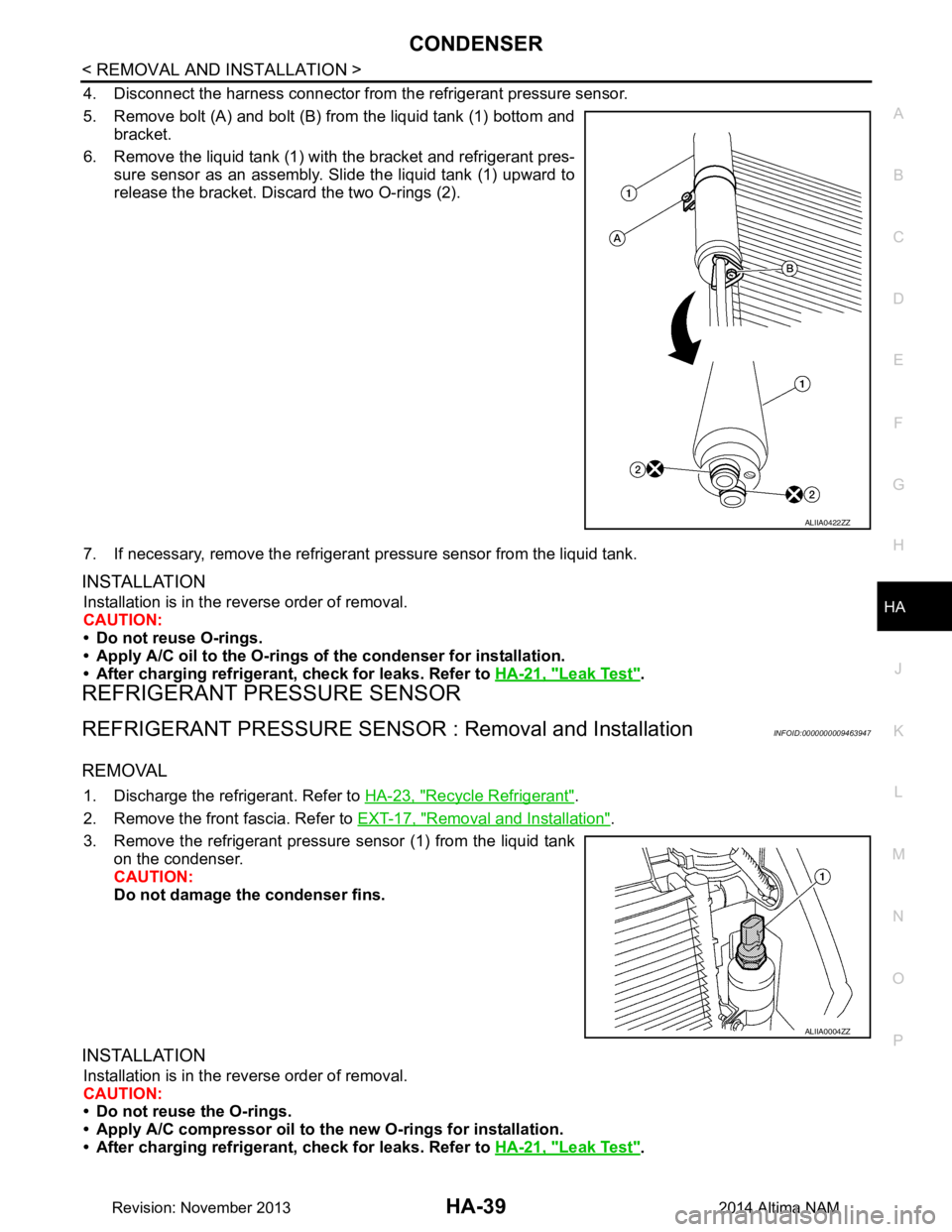

4. Disconnect the harness connector from the refrigerant pressure sensor.

5. Remove bolt (A) and bolt (B) from the liquid tank (1) bottom and bracket.

6. Remove the liquid tank (1) with the bracket and refrigerant pres-

sure sensor as an assembly. Slide the liquid tank (1) upward to

release the bracket. Discard the two O-rings (2).

7. If necessary, remove the refrigerant pressure sensor from the liquid tank.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply A/C oil to the O-rings of the condenser for installation.

• After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test"

.

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR : Removal and InstallationINFOID:0000000009463947

REMOVAL

1. Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

2. Remove the front fascia. Refer to EXT-17, "Removal and Installation"

.

3. Remove the refrigerant pressure sensor (1) from the liquid tank on the condenser.

CAUTION:

Do not damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse the O-rings.

• Apply A/C compressor oil to th e new O-rings for installation.

• After charging refrigerant, check for leaks. Refer to HA-21, "Leak Test"

.

ALIIA0422ZZ

ALIIA0004ZZ

Revision: November 20132014 Altima NAM