jump cable NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1430 of 4801

![NISSAN TEANA 2014 Service Manual

EC-430

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1550 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage betw NISSAN TEANA 2014 Service Manual

EC-430

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1550 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage betw](/img/5/57390/w960_57390-1429.png)

EC-430

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1550 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and

ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

JPBIA3286ZZ

ECM

Vo l ta g e

(Approx.)

Connector +-

Te r m i n a l

F13

*1

F90*263 62 2.5 V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1433 of 4801

![NISSAN TEANA 2014 Service Manual

P1551, P1552 BATTERY CURRENT SENSOR

EC-433

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignit NISSAN TEANA 2014 Service Manual

P1551, P1552 BATTERY CURRENT SENSOR

EC-433

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignit](/img/5/57390/w960_57390-1432.png)

P1551, P1552 BATTERY CURRENT SENSOR

EC-433

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and

ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

JPBIA3286ZZ

ECM

Vo l ta g e

(Approx.)

Connector +-

Te r m i n a l

F13

*1

F90*263 62 2.5 V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1436 of 4801

![NISSAN TEANA 2014 Service Manual

EC-436

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1553 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage betw NISSAN TEANA 2014 Service Manual

EC-436

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1553 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage betw](/img/5/57390/w960_57390-1435.png)

EC-436

< DTC/CIRCUIT DIAGNOSIS >[QR25DE]

P1553 BATTERY CURRENT SENSOR

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and

ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

JPBIA3286ZZ

ECM

Vo l ta g e

(Approx.)

Connector +-

Te r m i n a l

F13

*1

F90*263 62 2.5 V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1439 of 4801

![NISSAN TEANA 2014 Service Manual

P1554 BATTERY CURRENT SENSOREC-439

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

*1: Except for California

*2: For California

2. Also check harness for short to ground and to p NISSAN TEANA 2014 Service Manual

P1554 BATTERY CURRENT SENSOREC-439

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

*1: Except for California

*2: For California

2. Also check harness for short to ground and to p](/img/5/57390/w960_57390-1438.png)

P1554 BATTERY CURRENT SENSOREC-439

< DTC/CIRCUIT DIAGNOSIS > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

*1: Except for California

*2: For California

2. Also check harness for short to ground and to power.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace error-detected parts

5.CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to EC-439, "Component Inspection"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace battery negative cable assembly.

Component InspectionINFOID:0000000009462371

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

*1: Except for California

*2: For California

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

JPBIA3286ZZ

ECM

Vo l ta g e

(Approx.)

Connector +-

Te r m i n a l

F13

*1

F90*263 62 2.5 V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1898 of 4801

![NISSAN TEANA 2014 Service Manual

EC-898

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1550 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair ope NISSAN TEANA 2014 Service Manual

EC-898

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1550 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair ope](/img/5/57390/w960_57390-1897.png)

EC-898

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1550 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BATTERY CURRENT SENSOR

Check battery current sensor. Refer to EC-898, "Component Inspection"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace battery negative cable assembly.

Component InspectionINFOID:0000000009462758

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector terminals under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

Battery current sensor ECM Continuity

Connector Terminal Connector Terminal

F5 4 F79 66 Existed

ECM Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

F79 66 68 Approx. 2.5

JPBIA3287ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1900 of 4801

![NISSAN TEANA 2014 Service Manual

EC-900

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1551, P1552 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Rep NISSAN TEANA 2014 Service Manual

EC-900

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1551, P1552 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Rep](/img/5/57390/w960_57390-1899.png)

EC-900

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1551, P1552 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BATTERY CURRENT SENSOR

Check battery current sensor. Refer to EC-904, "Component Inspection"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace battery negative cable assembly.

Component InspectionINFOID:0000000009462761

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector terminals

under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

Battery current sensor ECM Continuity

Connector Terminal Connector Terminal

F5 3 F79 68 Existed

Battery current sensor ECM Continuity

Connector Terminal Connector Terminal

F5 4 F79 66 Existed

ECM Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

F79 66 68 Approx. 2.5

JPBIA3287ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1902 of 4801

![NISSAN TEANA 2014 Service Manual

EC-902

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1553 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair ope NISSAN TEANA 2014 Service Manual

EC-902

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1553 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair ope](/img/5/57390/w960_57390-1901.png)

EC-902

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P1553 BATTERY CURRENT SENSOR

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BATTERY CURRENT SENSOR

Check battery current sensor. Refer to EC-904, "Component Inspection"

.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-43, "Intermittent Incident".

NO >> Replace battery negative cable assembly.

Component InspectionINFOID:0000000009462764

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector terminals under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

Battery current sensor ECM Continuity

Connector Terminal Connector Terminal

F5 4 F79 66 Existed

ECM Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

F79 66 68 Approx. 2.5

JPBIA3287ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1905 of 4801

![NISSAN TEANA 2014 Service Manual

P1554 BATTERY CURRENT SENSOREC-905

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal NISSAN TEANA 2014 Service Manual

P1554 BATTERY CURRENT SENSOREC-905

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal](/img/5/57390/w960_57390-1904.png)

P1554 BATTERY CURRENT SENSOREC-905

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector terminals under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

ECM

Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

F79 66 68 Approx. 2.5

JPBIA3287ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2575 of 4801

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-47

< BASIC INSPECTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

no voltage; open is between fuse block and SW1 (point A).

• Close SW1 and probe at relay. voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

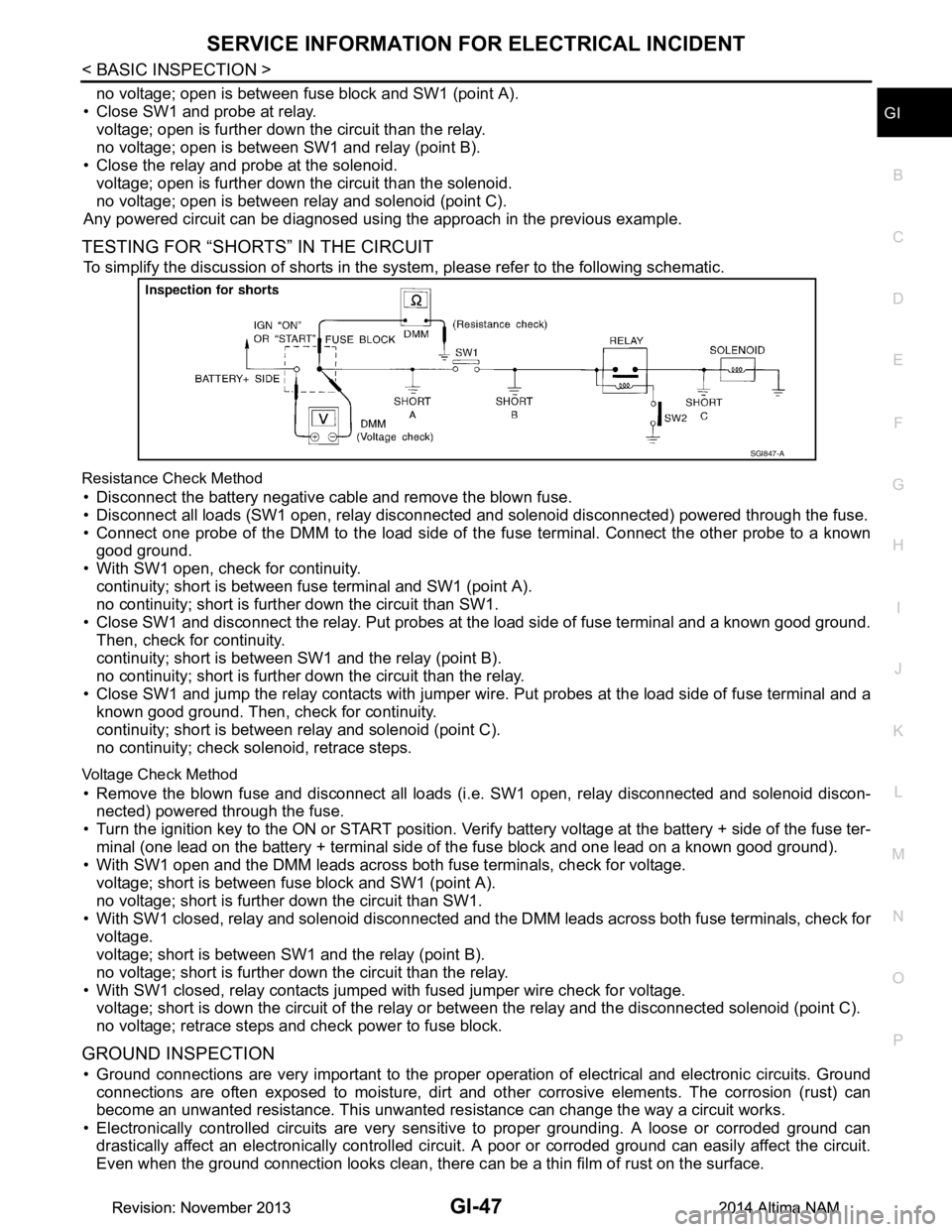

TESTING FOR “SHORTS” IN THE CIRCUIT

To simplify the discussion of shorts in the system, please refer to the following schematic.

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and t he DMM leads across both fuse terminals, check for

voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and ot her corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted re sistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

SGI847-A

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3436 of 4801

PG-4

< BASIC INSPECTION >

BATTERY

BASIC INSPECTION

BATTERY

How to Handle BatteryINFOID:0000000009460432

CAUTION:

• If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

• Never add distilled water through the hole used to check specific gravity.

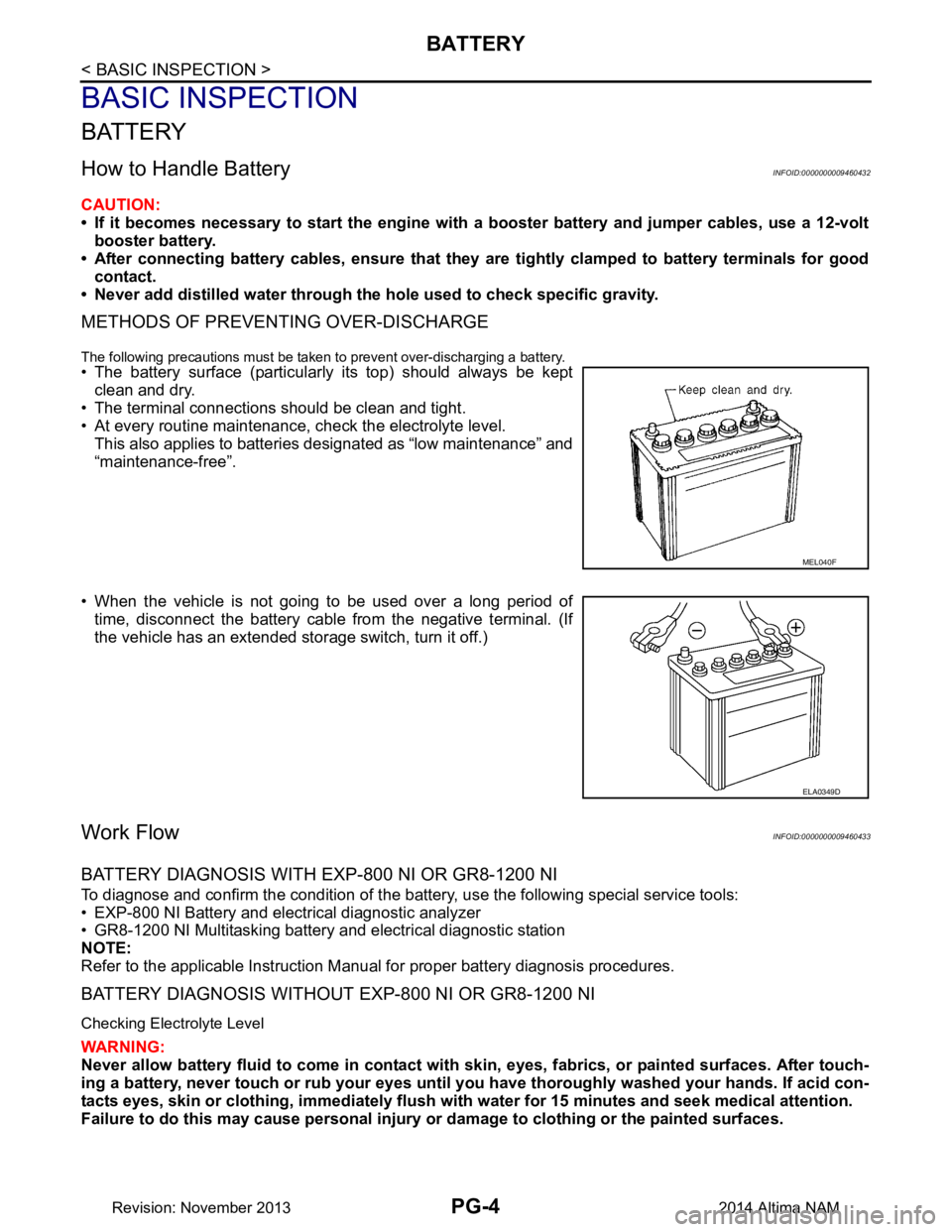

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

• The battery surface (particularly its top) should always be kept

clean and dry.

• The terminal connections should be clean and tight.

• At every routine maintenance, check the electrolyte level. This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

• When the vehicle is not going to be used over a long period of time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

Work FlowINFOID:0000000009460433

BATTERY DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To diagnose and confirm the condition of the batte ry, use the following special service tools:

• EXP-800 NI Battery and electrical diagnostic analyzer

• GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE:

Refer to the applicable Instruction Manual for proper battery diagnosis procedures.

BATTERY DIAGNOSIS WITHOUT EXP-800 NI OR GR8-1200 NI

Checking Electrolyte Level

WARNING:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush wit h water for 15 minutes and seek medical attention.

Failure to do this may cause personal injury or damage to clothing or the painted surfaces.

MEL040F

ELA0349D

Revision: November 20132014 Altima NAM