engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 395 of 1767

DTC and MI Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

IOutput of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

HOW TO ERASE DTC

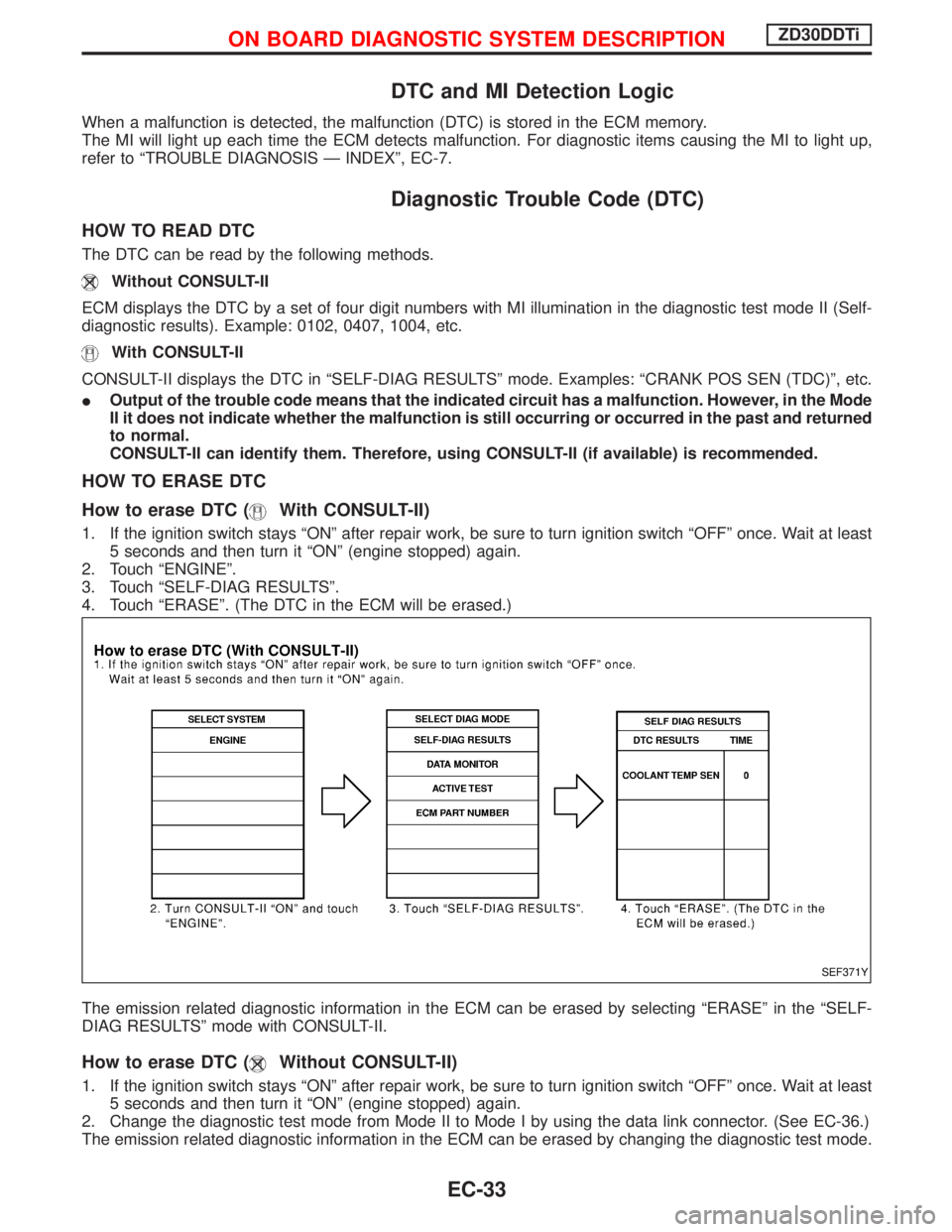

How to erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-36.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

SEF371Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-33

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

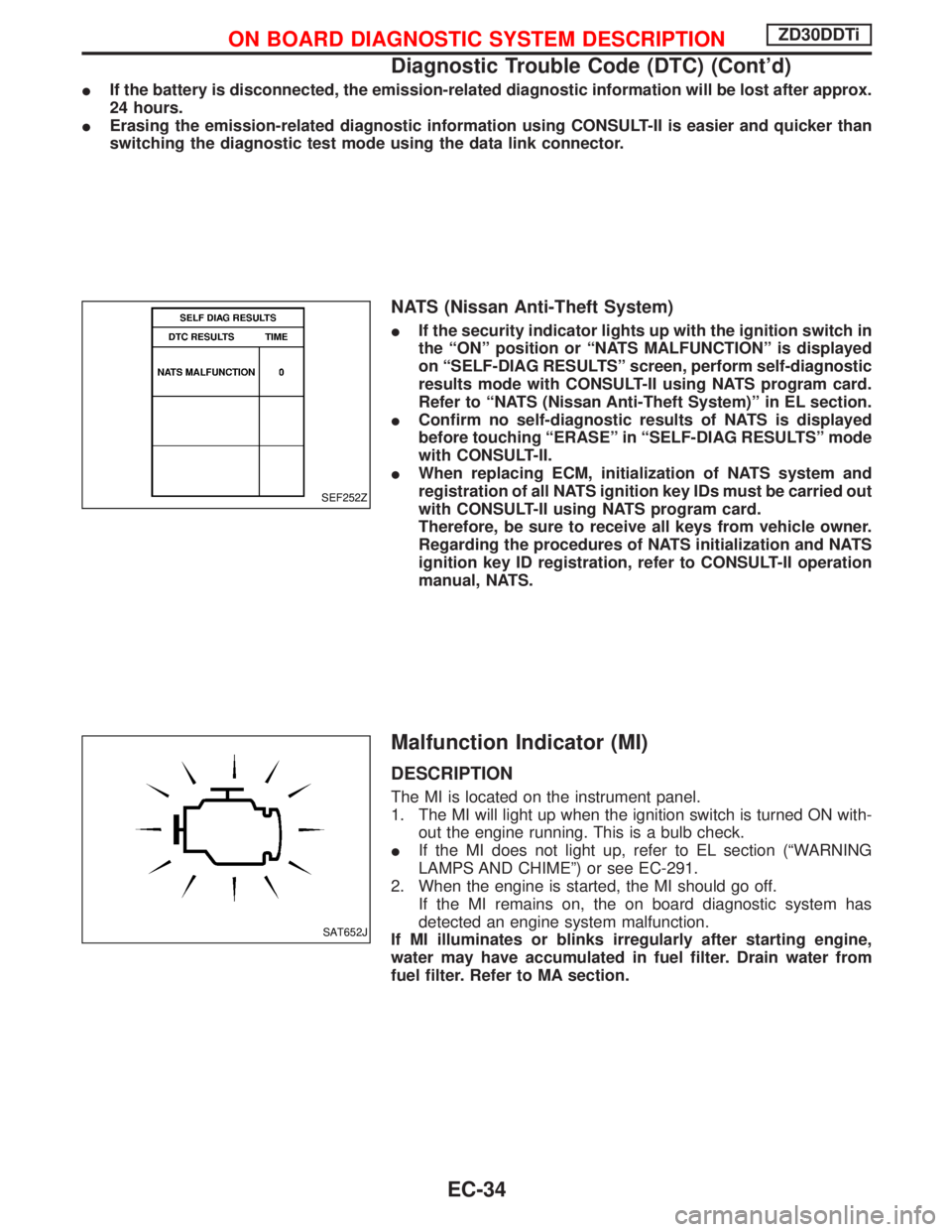

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

Page 397 of 1767

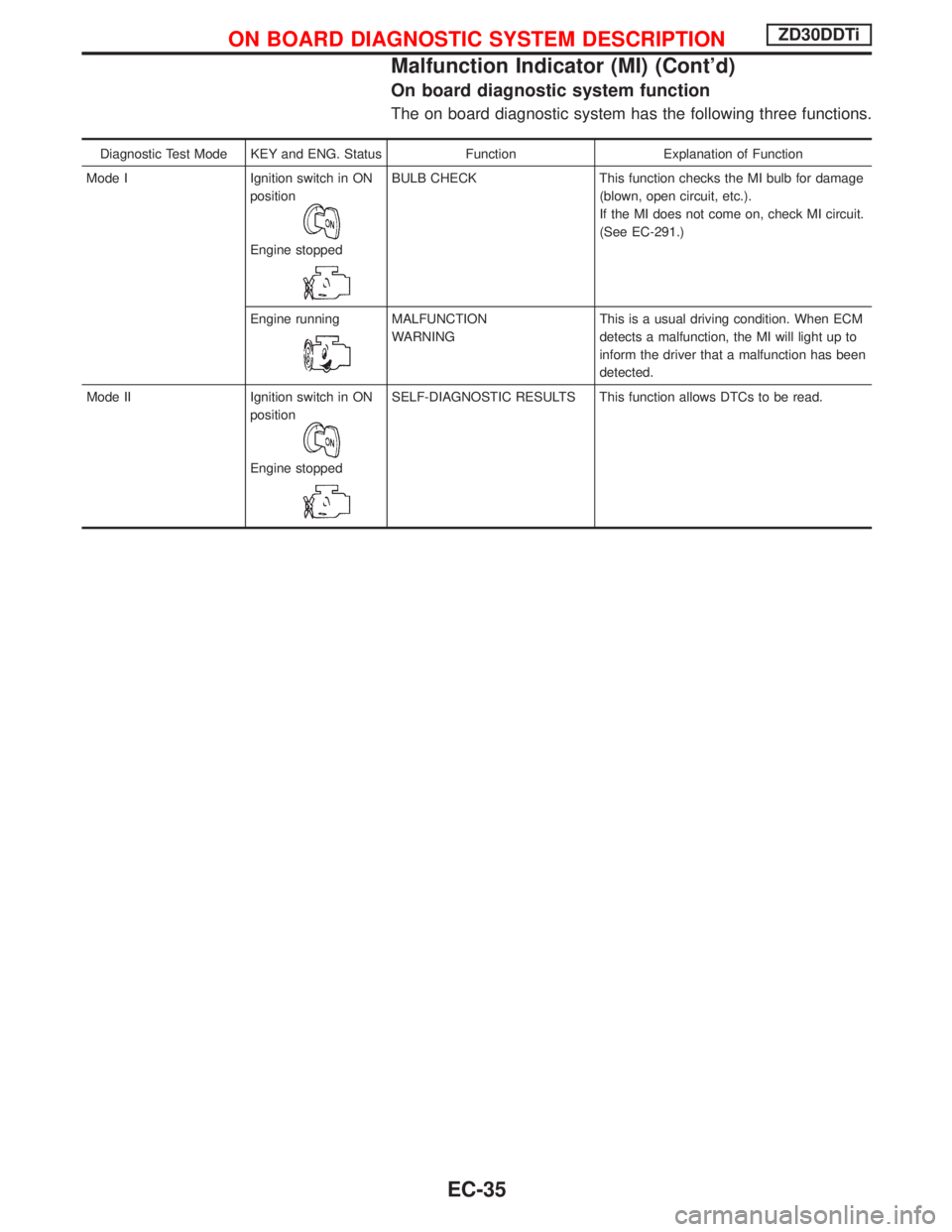

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-291.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

Page 401 of 1767

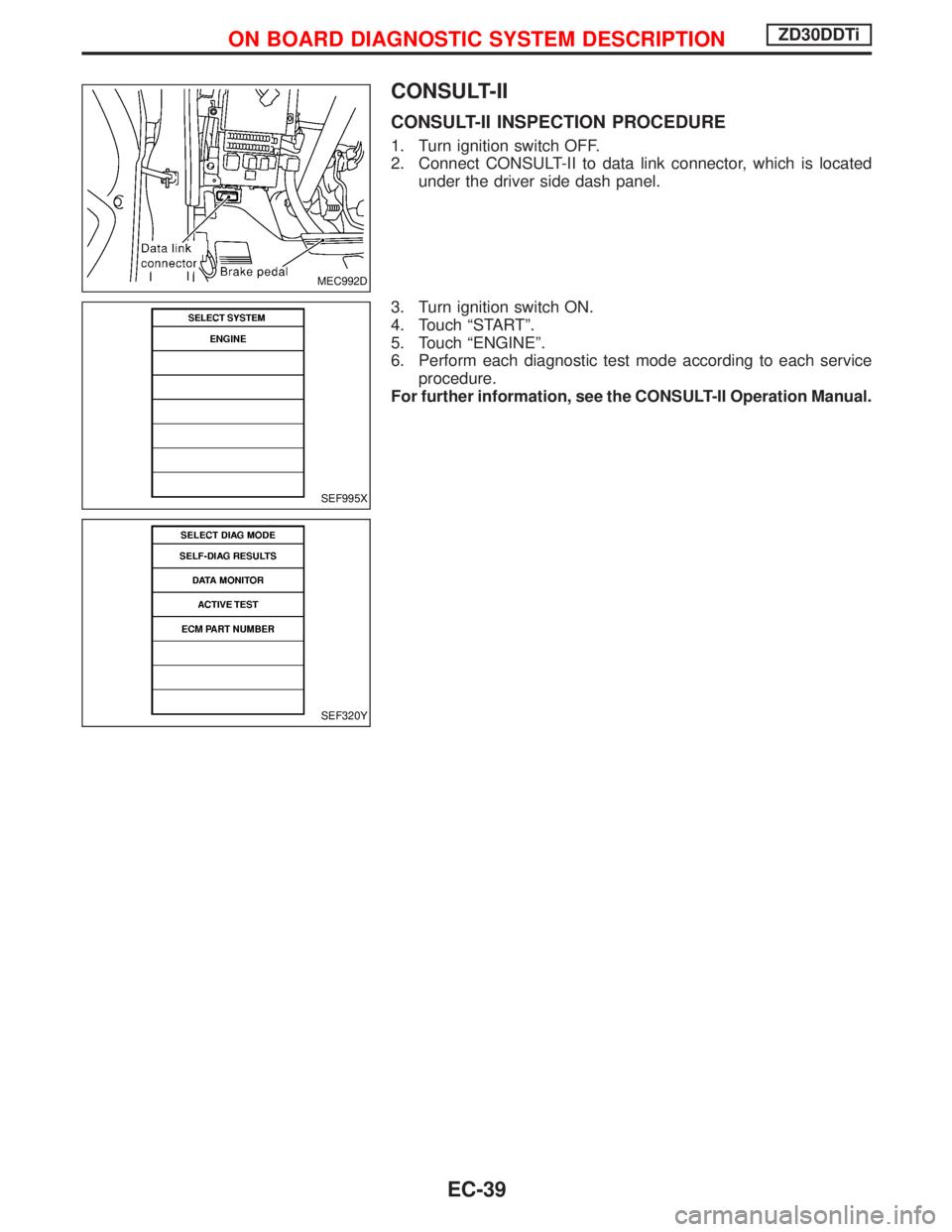

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector, which is located

under the driver side dash panel.

3. Turn ignition switch ON.

4. Touch ªSTARTº.

5. Touch ªENGINEº.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

MEC992D

SEF995X

SEF320Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-39

Page 402 of 1767

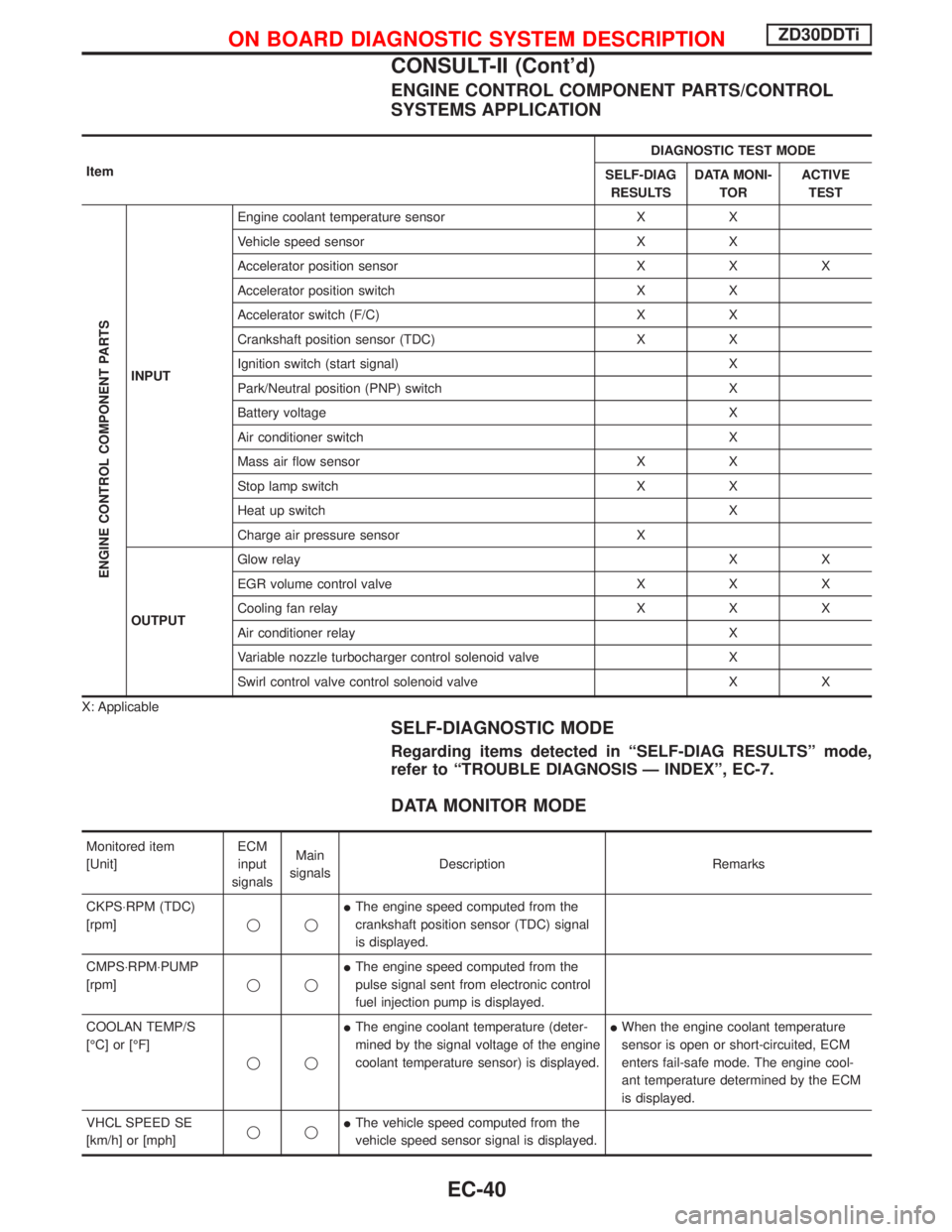

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG

RESULTSDATA MONI-

TORACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUTEngine coolant temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X X

Accelerator position switch X X

Accelerator switch (F/C) X X

Crankshaft position sensor (TDC) X X

Ignition switch (start signal) X

Park/Neutral position (PNP) switch X

Battery voltage X

Air conditioner switch X

Mass air flow sensor X X

Stop lamp switch X X

Heat up switch X

Charge air pressure sensor X

OUTPUTGlow relayXX

EGR volume control valve X X X

Cooling fan relay X X X

Air conditioner relay X

Variable nozzle turbocharger control solenoid valve X

Swirl control valve control solenoid valve X X

X: Applicable

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPS×RPM (TDC)

[rpm]qqIThe engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPS×RPM×PUMP

[rpm]qqIThe engine speed computed from the

pulse signal sent from electronic control

fuel injection pump is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

qqIThe engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the

vehicle speed sensor signal is displayed.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-40

Page 403 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL TEMP SEN

[ÉC] or [ÉF]qqIThe fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS NISSAN TERRANO 2002 Service Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL TEMP SEN

[ÉC] or [ÉF]qqIThe fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS](/img/5/57393/w960_57393-402.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL TEMP SEN

[ÉC] or [ÉF]qqIThe fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ACCEL POS SEN [V]

qqIThe accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE]qqIIndicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

accelerator position switch signal.

SPILL/V [ÉCA]

qIThe control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V]

qqIThe power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

starter signal.IAfter starting the engine, [OFF] is dis-

played regardless of the starter signal.

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

BRAKE SW [ON/OFF]

qqIIndicates [ON/OFF] condition from the

stop lamp switch signal.

IGN SW

[ON/OFF]qqIIndicates [ON/OFF] condition from igni-

tion switch signal.

WARM UP SW

[ON/OFF]qIIndicates [ON/OFF] condition from the

heat up switch signal.

MAS AIR/FL SE [V]

qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

DECELER F/CUT

[ON/OFF]qIThe [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

INJ TIMG C/V [%]

qIThe duty ratio of fuel injection timing

control valve (sent from electronic control

fuel injection pump) is displayed.

AIR COND RLY

[ON/OFF]qIIndicates the control condition of the air

conditioner relay (determined by ECM

according to the input signals).

GLOW RLY [ON/OFF]

qIThe glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[ON/OFF]

qIIndicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

ION ... Operates.

OFF ... Stopped.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-41

Page 405 of 1767

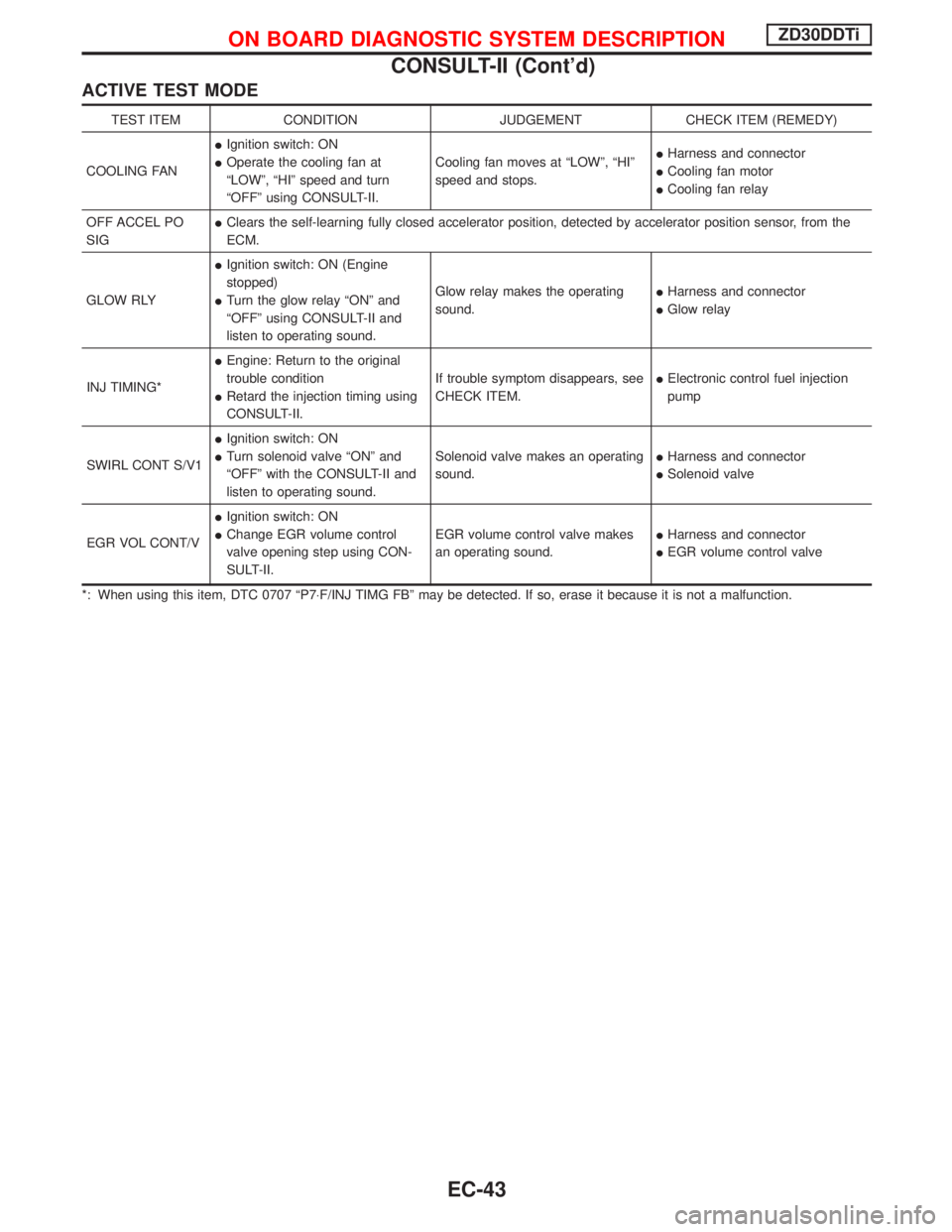

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

COOLING FANIIgnition switch: ON

IOperate the cooling fan at

ªLOWº, ªHIº speed and turn

ªOFFº using CONSULT-II.Cooling fan moves at ªLOWº, ªHIº

speed and stops.IHarness and connector

ICooling fan motor

ICooling fan relay

OFF ACCEL PO

SIGIClears the self-learning fully closed accelerator position, detected by accelerator position sensor, from the

ECM.

GLOW RLYIIgnition switch: ON (Engine

stopped)

ITurn the glow relay ªONº and

ªOFFº using CONSULT-II and

listen to operating sound.Glow relay makes the operating

sound.IHarness and connector

IGlow relay

INJ TIMING*IEngine: Return to the original

trouble condition

IRetard the injection timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IElectronic control fuel injection

pump

SWIRL CONT S/V1IIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

EGR VOL CONT/VIIgnition switch: ON

IChange EGR volume control

valve opening step using CON-

SULT-II.EGR volume control valve makes

an operating sound.IHarness and connector

IEGR volume control valve

*: When using this item, DTC 0707 ªP7×F/INJ TIMG FBº may be detected. If so, erase it because it is not a malfunction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

CONSULT-II (Cont'd)

EC-43

Page 408 of 1767

Introduction

The engine has an ECM to control major systems such as fuel

injection control, fuel injection timing control, glow control system,

etc. The ECM accepts input signals from sensors and instantly

drives electronic control fuel injection pump. It is essential that both

input and output signals are proper and stable. At the same time,

it is important that there are no problems such as vacuum leaks,

or other problems with the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº, EC-48.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

DIAGNOSTIC WORKSHEET

There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

SEF858S

SEF233G

SEF234G

SEF907L

TROUBLE DIAGNOSIS Ð INTRODUCTIONZD30DDTi

EC-46

Page 410 of 1767

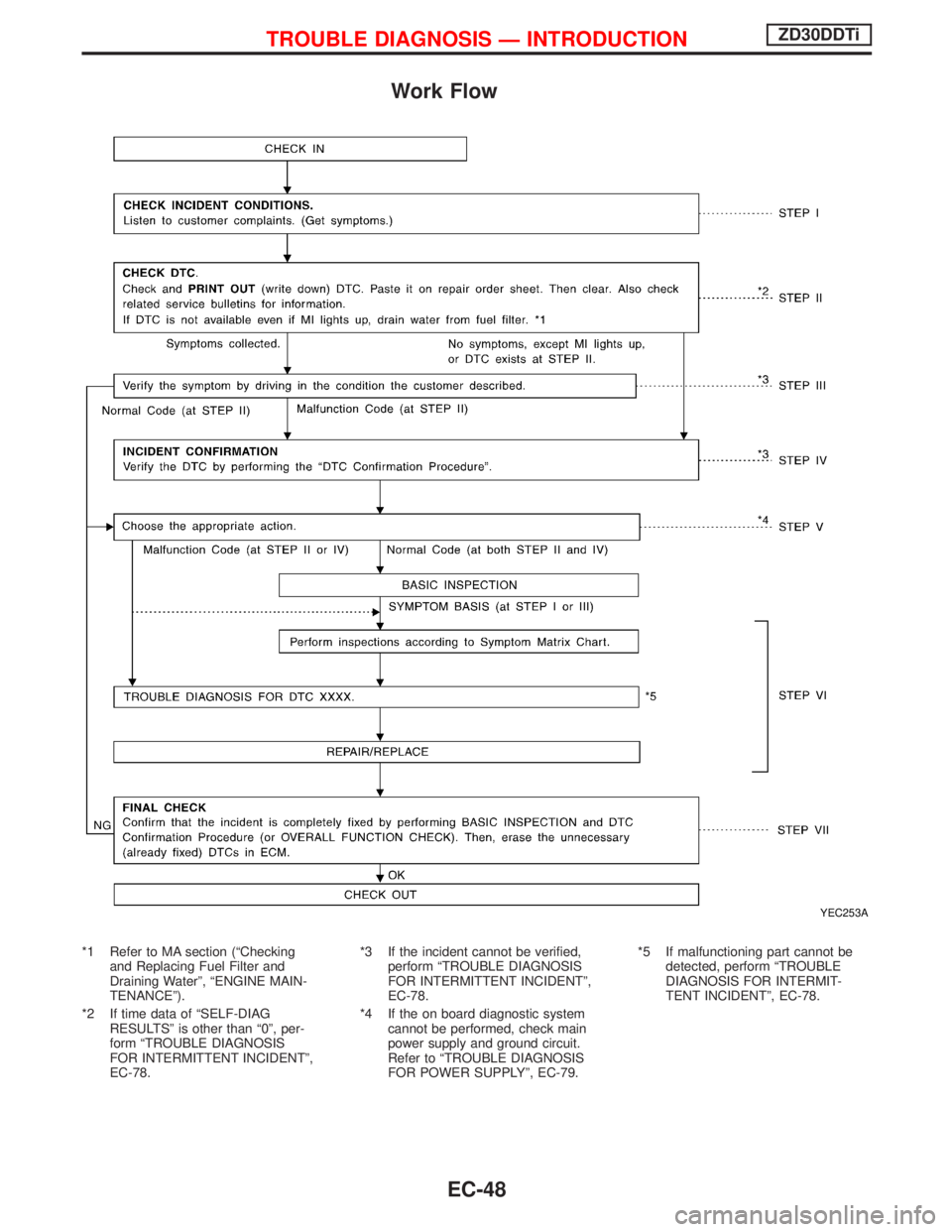

Work Flow

*1 Refer to MA section (ªChecking

and Replacing Fuel Filter and

Draining Waterº, ªENGINE MAIN-

TENANCEº).

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º, per-

form ªTROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENTº,

EC-78.*3 If the incident cannot be verified,

perform ªTROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENTº,

EC-78.

*4 If the on board diagnostic system

cannot be performed, check main

power supply and ground circuit.

Refer to ªTROUBLE DIAGNOSIS

FOR POWER SUPPLYº, EC-79.*5 If malfunctioning part cannot be

detected, perform ªTROUBLE

DIAGNOSIS FOR INTERMIT-

TENT INCIDENTº, EC-78.

YEC253A

TROUBLE DIAGNOSIS Ð INTRODUCTIONZD30DDTi

EC-48

Page 411 of 1767

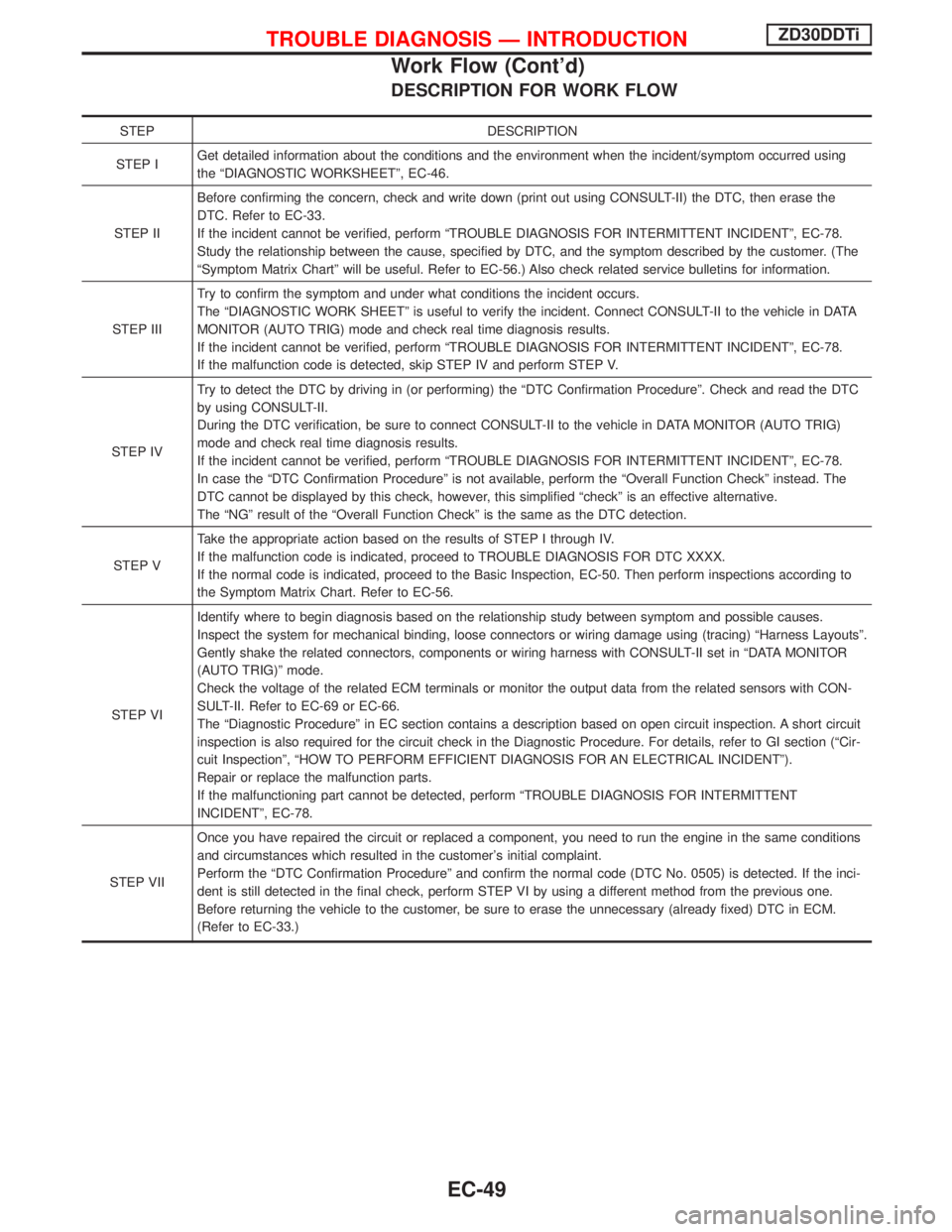

DESCRIPTION FOR WORK FLOW

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the ªDIAGNOSTIC WORKSHEETº, EC-46.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the DTC, then erase the

DTC. Refer to EC-33.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

Study the relationship between the cause, specified by DTC, and the symptom described by the customer. (The

ªSymptom Matrix Chartº will be useful. Refer to EC-56.) Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº is useful to verify the incident. Connect CONSULT-II to the vehicle in DATA

MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the DTC by driving in (or performing) the ªDTC Confirmation Procedureº. Check and read the DTC

by using CONSULT-II.

During the DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG)

mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

In case the ªDTC Confirmation Procedureº is not available, perform the ªOverall Function Checkº instead. The

DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOverall Function Checkº is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC XXXX.

If the normal code is indicated, proceed to the Basic Inspection, EC-50. Then perform inspections according to

the Symptom Matrix Chart. Refer to EC-56.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-69 or EC-66.

The ªDiagnostic Procedureº in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI section (ªCir-

cuit Inspectionº, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº).

Repair or replace the malfunction parts.

If the malfunctioning part cannot be detected, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENTº, EC-78.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC Confirmation Procedureº and confirm the normal code (DTC No. 0505) is detected. If the inci-

dent is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) DTC in ECM.

(Refer to EC-33.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONZD30DDTi

Work Flow (Cont'd)

EC-49