system NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 702 of 1767

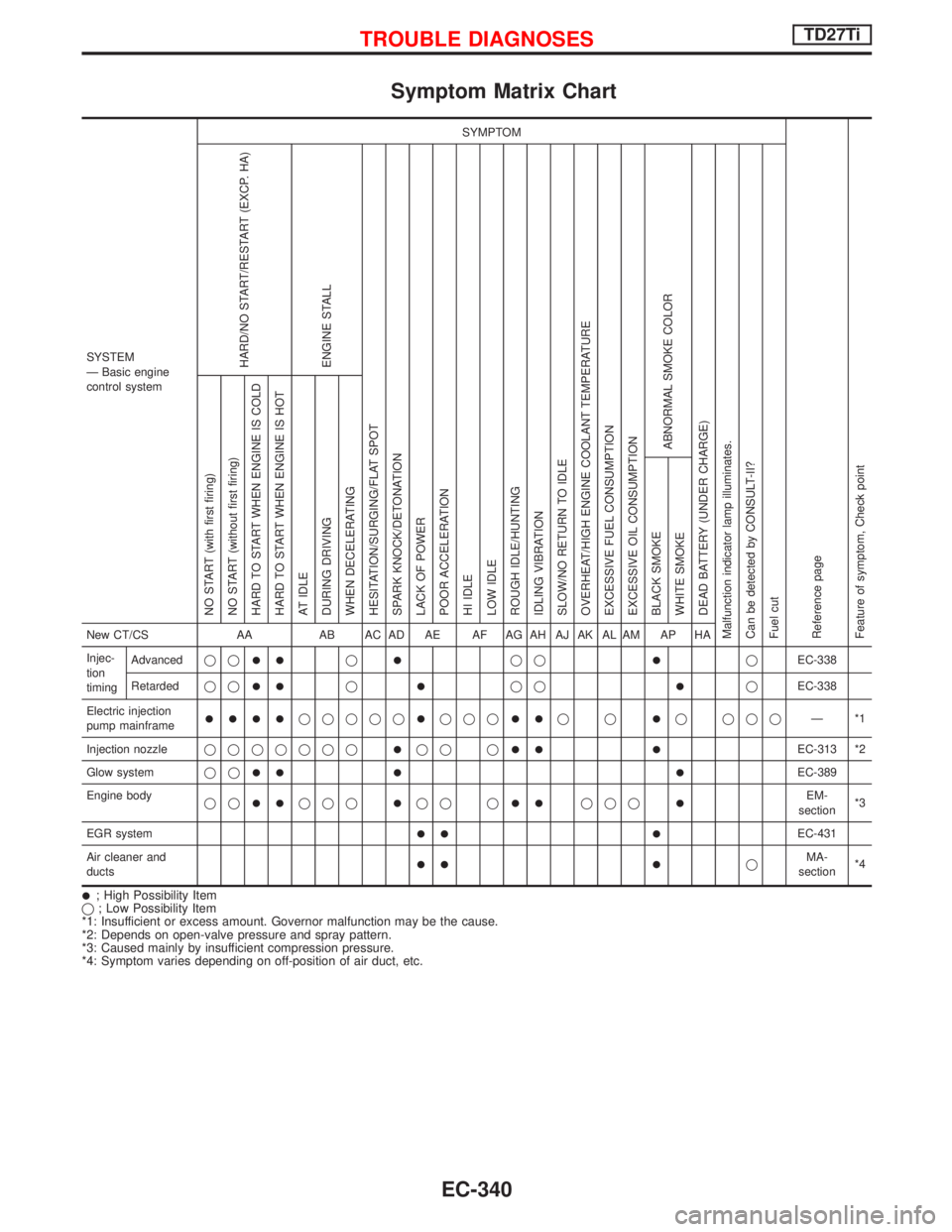

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cutNO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timingAdvancedqq

IIqIqqIqEC-338

Retardedqq

IIqIqqIqEC-338

Electric injection

pump mainframe

IIIIqqqqqIqqqIIqqIq qqqÐ*1

Injection nozzleqqqqqqq

Iqq qII IEC-313 *2

Glow systemqq

II I IEC-389

Engine body

qq

IIqqqIqq qIIqqqIEM-

section*3

EGR system

II IEC-431

Air cleaner and

ducts

II IqMA-

section*4

I; High Possibility Item

q; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSESTD27Ti

EC-340

Page 703 of 1767

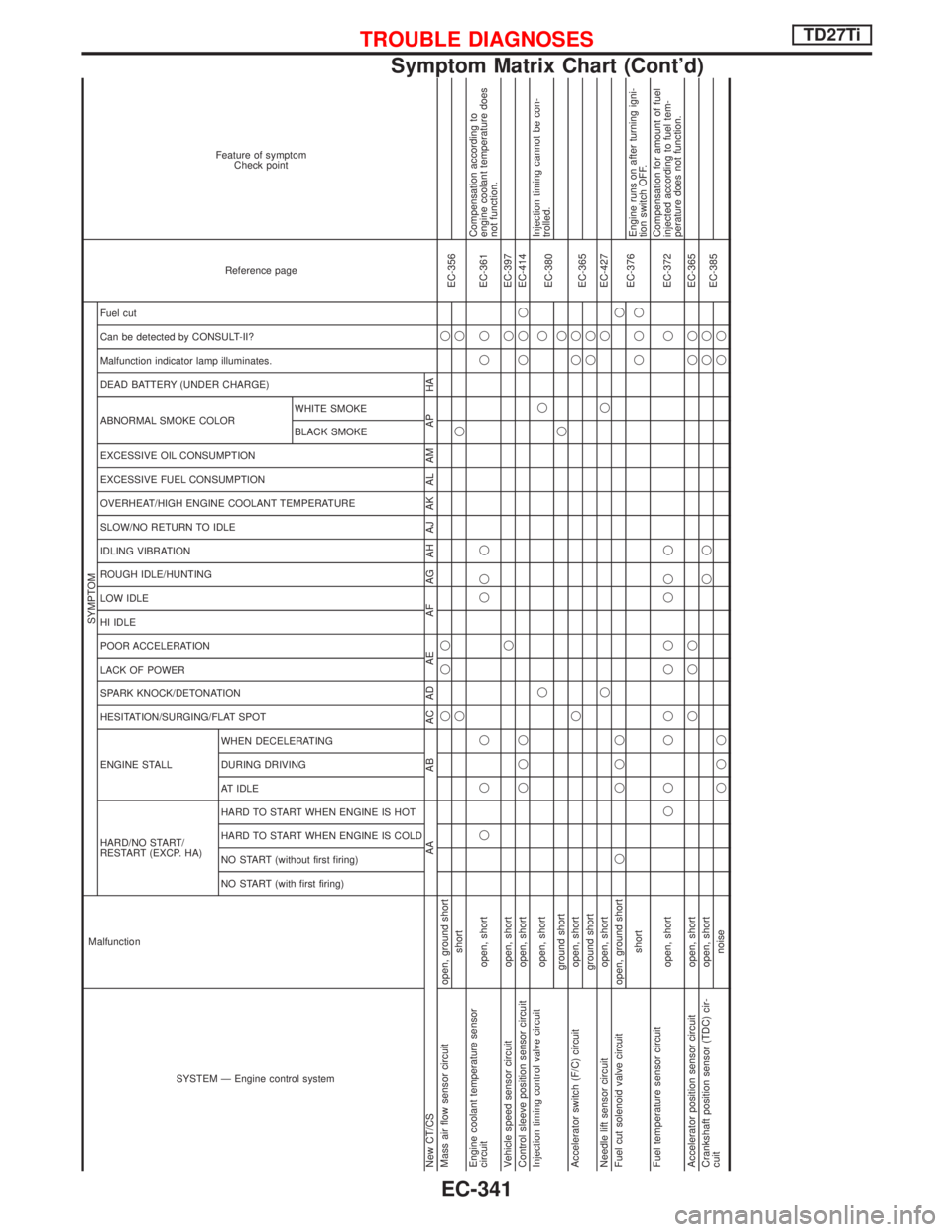

SYSTEM Ð Engine control system Malfunction

SYMPTOM

Reference page Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut

NO START (with first firing) NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

New CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Mass air flow sensor circuit open, ground shortqqq q

EC-356

shortqqq

Engine coolant temperature sensor

circuit open, shortqqq qqq qqEC-361Compensation according to

engine coolant temperature does

not function.

Vehicle speed sensor circuit open, shortqqEC-397

Control sleeve position sensor circuit open, shortqqqqqqEC-414

Injection timing control valve circuit

open, shortqqq

EC-380Injection timing cannot be con-

trolled.

ground shortqq

Accelerator switch (F/C) circuit open, shortqqq

EC-365

ground shortqq

Needle lift sensor circuit open, shortqqqEC-427

Fuel cut solenoid valve circuit open, ground shortq qqqq

EC-376

shortqqqEngine runs on after turning igni-

tion switch OFF.

Fuel temperature sensor circuit

open, shortqq qq qq qq q qEC-372Compensation for amount of fuel

injected according to fuel tem-

perature does not function.

Accelerator position sensor circuit open, shortqqq qqEC-365

Crankshaft position sensor (TDC) cir-

cuitopen, shortqq qq

EC-385

noiseqqqqq

TROUBLE DIAGNOSESTD27Ti

Symptom Matrix Chart (Cont'd)

EC-341

Page 704 of 1767

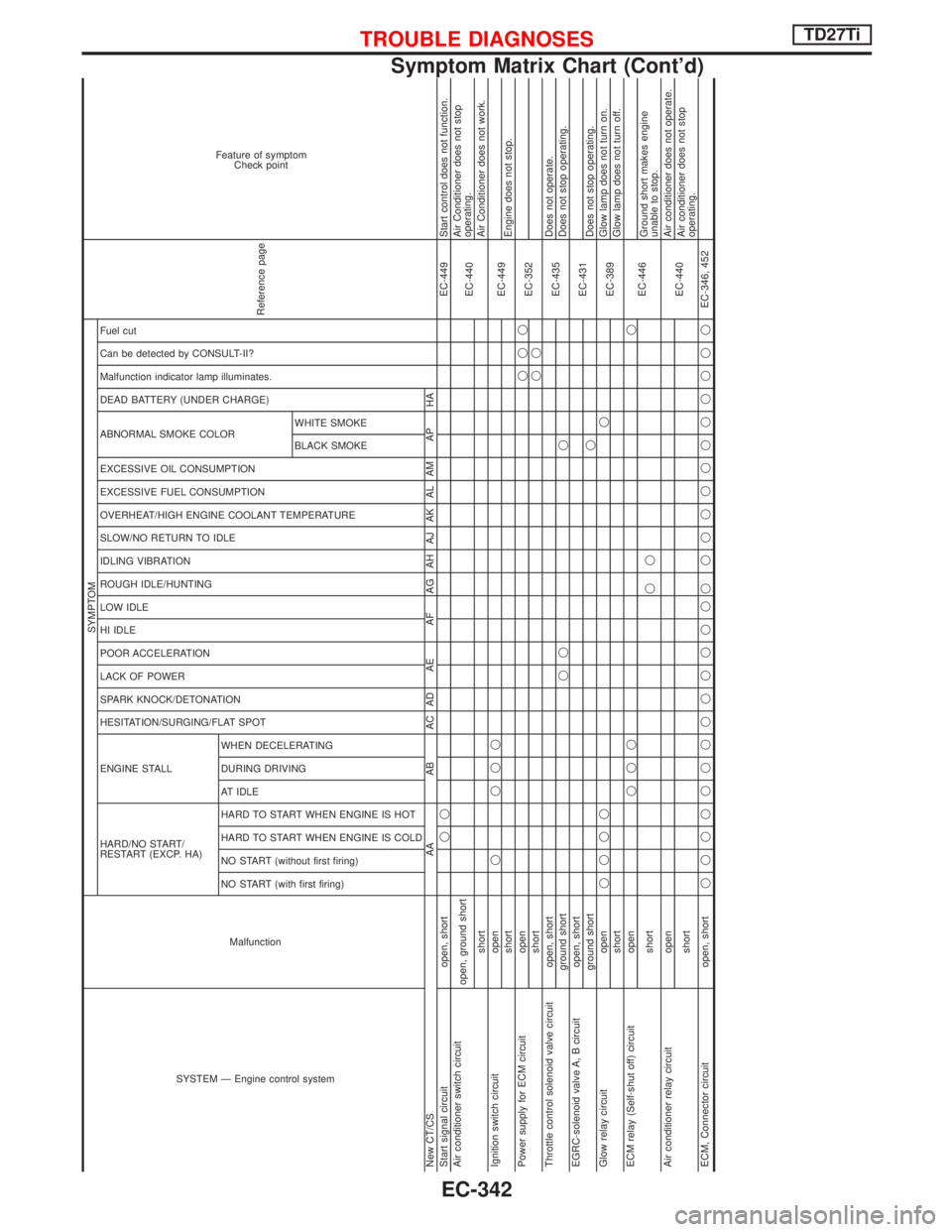

SYSTEM Ð Engine control systemMalfunction

SYMPTOM

Reference page

Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut

NO START (with first firing) NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

New CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Start signal circuit open, shortqqEC-449 Start control does not function.

Air conditioner switch circuit

open, ground short

EC-440Air Conditioner does not stop

operating.

shortAir Conditioner does not work.

Ignition switch circuit openq qqq

EC-449

shortEngine does not stop.

Power supply for ECM circuit openqqq

EC-352

shortqq

Throttle control solenoid valve circuit open, short

EC-435Does not operate.

ground shortqq qDoes not stop operating.

EGRC-solenoid valve A, B circuit open, short

EC-431

ground shortqDoes not stop operating.

Glow relay circuit openqqqqq

EC-389Glow lamp does not turn on.

shortGlow lamp does not turn off.

ECM relay (Self-shut off) circuit openqqqq

EC-446

shortqqGround short makes engine

unable to stop.

Air conditioner relay circuit open

EC-440Air conditioner does not operate.

shortAir conditioner does not stop

operating.

ECM, Connector circuit open, shortqqqqqqqqqqqqqq qqqqqqqqqqqEC-346, 452

TROUBLE DIAGNOSESTD27Ti

Symptom Matrix Chart (Cont'd)

EC-342

Page 710 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up](/img/5/57393/w960_57393-709.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpmBATTERY VOLTAGE

(11 - 14V)

213 G/YThrottle control solenoid

valve[Engine is running]

IWarm-up condition

ILow loadApproximately 0V

Except above condition Battery voltage (12 - 14V)

214 LG Glow relay Refer to ªGlow Control Systemº, EC-389.

215 L Malfunction indicator (MI)[Ignition switch ªONº]Approximately 1.0V

[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

218 G/R Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

219 LG/R Cooling fan relay[Engine is running]

ICooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

ICooling fan is operatingApproximately 0.1V

221 G/W Glow lamp[Ignition switch ªONº]

IGlow lamp is ªONºApproximately 1V

[Ignition switch ªONº]

IGlow lamp is ªOFFºBATTERY VOLTAGE

(11 - 14V)

223 R/LMass air flow sensor

power supply[Ignition switch ªONº]Approximately 5V

224 L/W Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.5 - 2.0V

320 WControl sleeve position

sensor[Engine is running]

IIdle speedApproximately 2.6V

NEF477

321 RControl sleeve position

sensor power supply[Engine is running]

IIdle speedApproximately 2.6V

NEF476

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-348

Page 742 of 1767

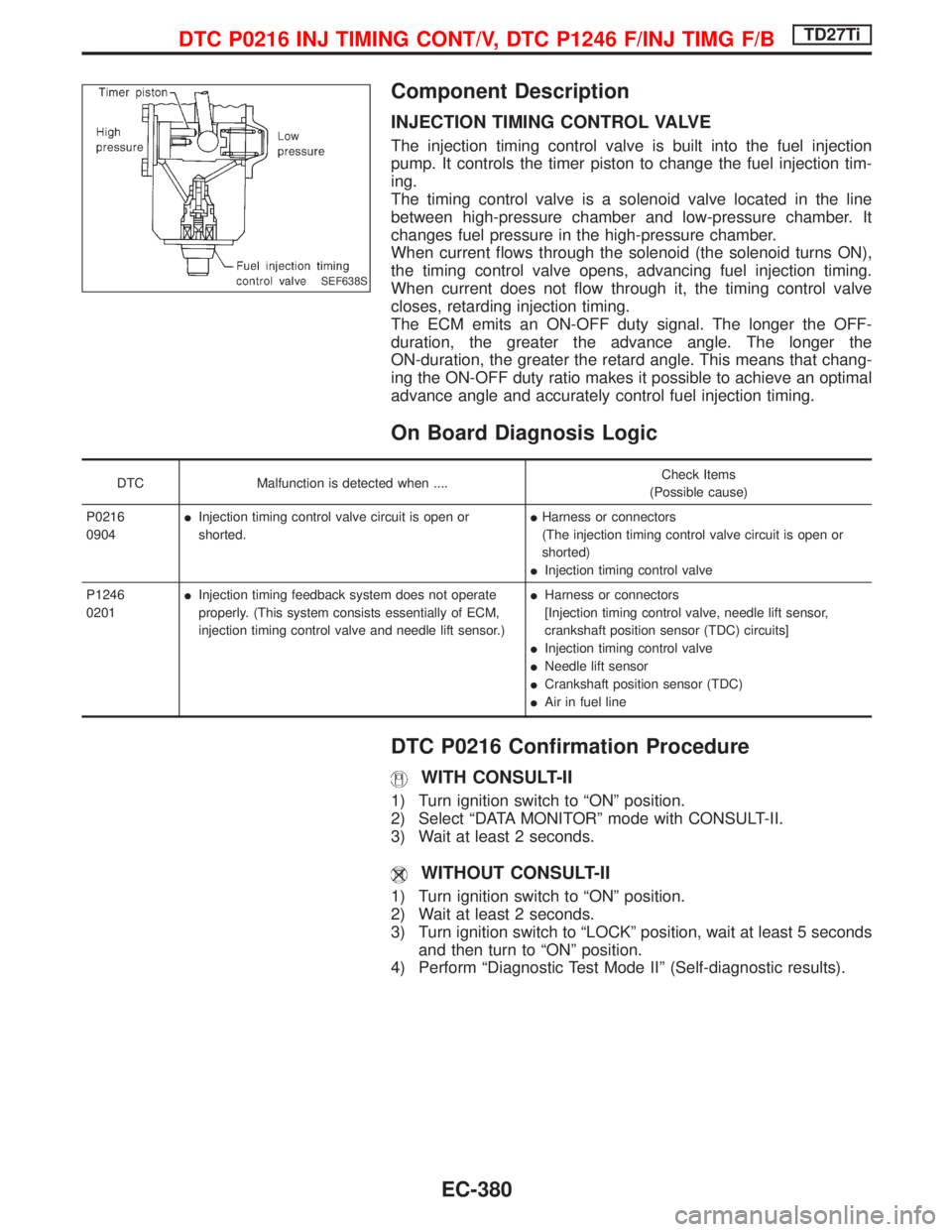

Component Description

INJECTION TIMING CONTROL VALVE

The injection timing control valve is built into the fuel injection

pump. It controls the timer piston to change the fuel injection tim-

ing.

The timing control valve is a solenoid valve located in the line

between high-pressure chamber and low-pressure chamber. It

changes fuel pressure in the high-pressure chamber.

When current flows through the solenoid (the solenoid turns ON),

the timing control valve opens, advancing fuel injection timing.

When current does not flow through it, the timing control valve

closes, retarding injection timing.

The ECM emits an ON-OFF duty signal. The longer the OFF-

duration, the greater the advance angle. The longer the

ON-duration, the greater the retard angle. This means that chang-

ing the ON-OFF duty ratio makes it possible to achieve an optimal

advance angle and accurately control fuel injection timing.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible cause)

P0216

0904IInjection timing control valve circuit is open or

shorted.IHarness or connectors

(The injection timing control valve circuit is open or

shorted)

IInjection timing control valve

P1246

0201IInjection timing feedback system does not operate

properly. (This system consists essentially of ECM,

injection timing control valve and needle lift sensor.)IHarness or connectors

[Injection timing control valve, needle lift sensor,

crankshaft position sensor (TDC) circuits]

IInjection timing control valve

INeedle lift sensor

ICrankshaft position sensor (TDC)

IAir in fuel line

DTC P0216 Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch to ªONº position.

2) Wait at least 2 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF638S

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/INJ TIMG F/BTD27Ti

EC-380

Page 751 of 1767

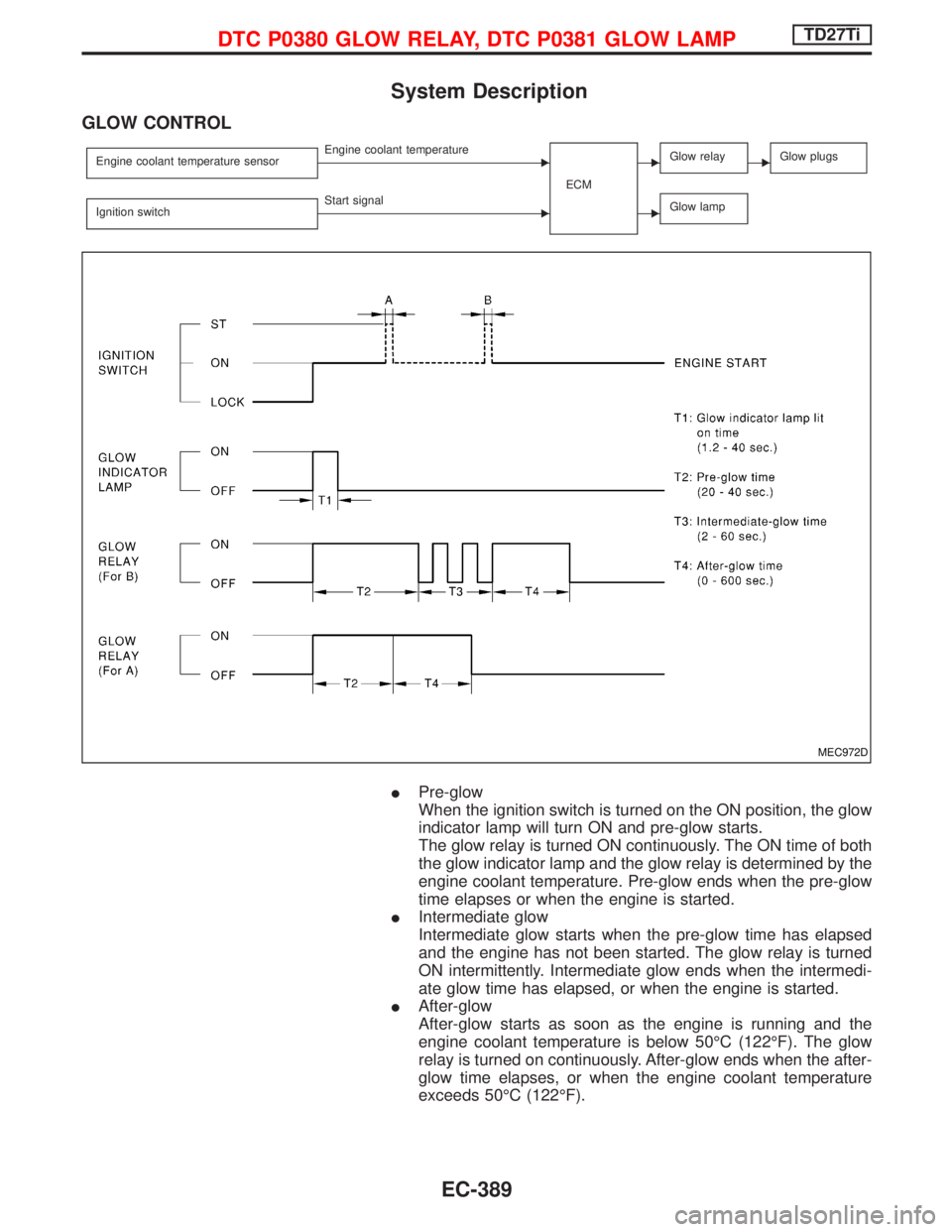

System Description

GLOW CONTROL

Engine coolant temperature sensorEEngine coolant temperature

ECMEGlow relayEGlow plugs

Ignition switchEStart signalEGlow lamp

IPre-glow

When the ignition switch is turned on the ON position, the glow

indicator lamp will turn ON and pre-glow starts.

The glow relay is turned ON continuously. The ON time of both

the glow indicator lamp and the glow relay is determined by the

engine coolant temperature. Pre-glow ends when the pre-glow

time elapses or when the engine is started.

IIntermediate glow

Intermediate glow starts when the pre-glow time has elapsed

and the engine has not been started. The glow relay is turned

ON intermittently. Intermediate glow ends when the intermedi-

ate glow time has elapsed, or when the engine is started.

IAfter-glow

After-glow starts as soon as the engine is running and the

engine coolant temperature is below 50ÉC (122ÉF). The glow

relay is turned on continuously. After-glow ends when the after-

glow time elapses, or when the engine coolant temperature

exceeds 50ÉC (122ÉF).

MEC972D

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-389

Page 755 of 1767

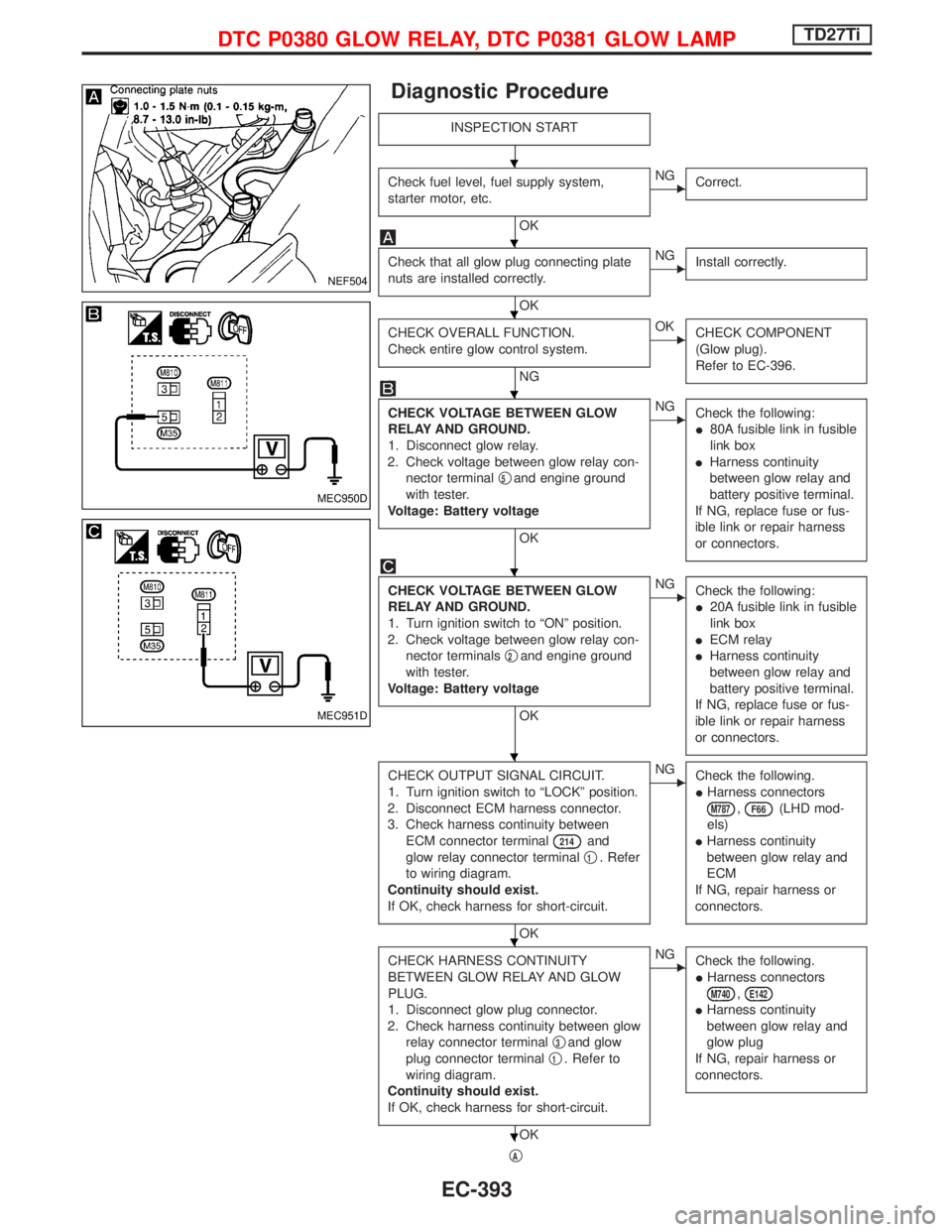

Diagnostic Procedure

INSPECTION START

Check fuel level, fuel supply system,

starter motor, etc.

OK

ENG

Correct.

Check that all glow plug connecting plate

nuts are installed correctly.

OK

ENG

Install correctly.

CHECK OVERALL FUNCTION.

Check entire glow control system.

NG

EOK

CHECK COMPONENT

(Glow plug).

Refer to EC-396.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Disconnect glow relay.

2. Check voltage between glow relay con-

nector terminalq

5and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I80A fusible link in fusible

link box

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Turn ignition switch to ªONº position.

2. Check voltage between glow relay con-

nector terminalsq

2and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I20A fusible link in fusible

link box

IECM relay

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM connector terminal

214and

glow relay connector terminalq

1. Refer

to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

IHarness continuity

between glow relay and

ECM

If NG, repair harness or

connectors.

CHECK HARNESS CONTINUITY

BETWEEN GLOW RELAY AND GLOW

PLUG.

1. Disconnect glow plug connector.

2. Check harness continuity between glow

relay connector terminalq

3and glow

plug connector terminalq

1. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M740,E142

IHarness continuity

between glow relay and

glow plug

If NG, repair harness or

connectors.

qA

NEF504

MEC950D

MEC951D

H

H

H

H

H

H

H

H

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-393

Page 757 of 1767

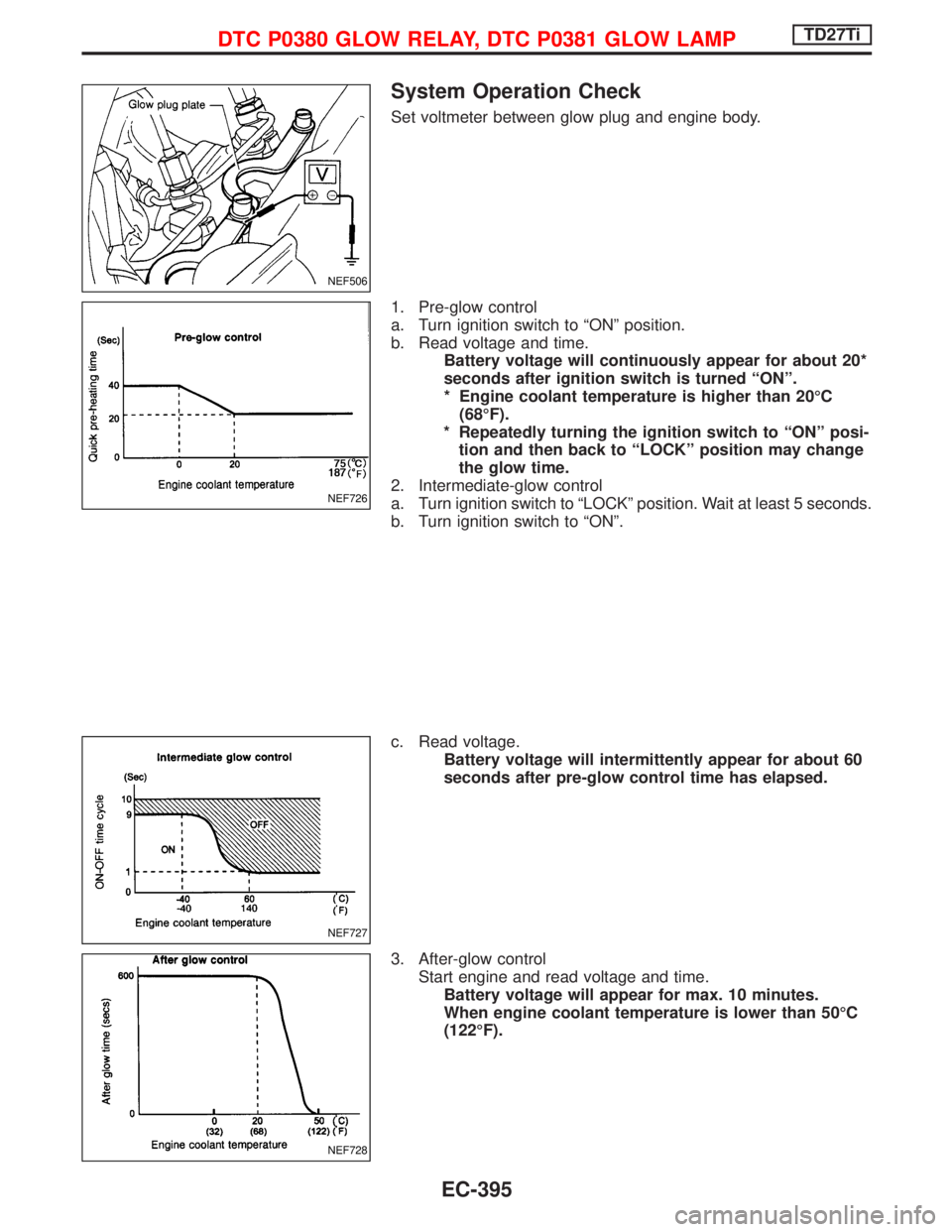

System Operation Check

Set voltmeter between glow plug and engine body.

1. Pre-glow control

a. Turn ignition switch to ªONº position.

b. Read voltage and time.

Battery voltage will continuously appear for about 20*

seconds after ignition switch is turned ªONº.

* Engine coolant temperature is higher than 20ÉC

(68ÉF).

* Repeatedly turning the ignition switch to ªONº posi-

tion and then back to ªLOCKº position may change

the glow time.

2. Intermediate-glow control

a. Turn ignition switch to ªLOCKº position. Wait at least 5 seconds.

b. Turn ignition switch to ªONº.

c. Read voltage.

Battery voltage will intermittently appear for about 60

seconds after pre-glow control time has elapsed.

3. After-glow control

Start engine and read voltage and time.

Battery voltage will appear for max. 10 minutes.

When engine coolant temperature is lower than 50ÉC

(122ÉF).

NEF506

NEF726

NEF727

NEF728

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-395

Page 766 of 1767

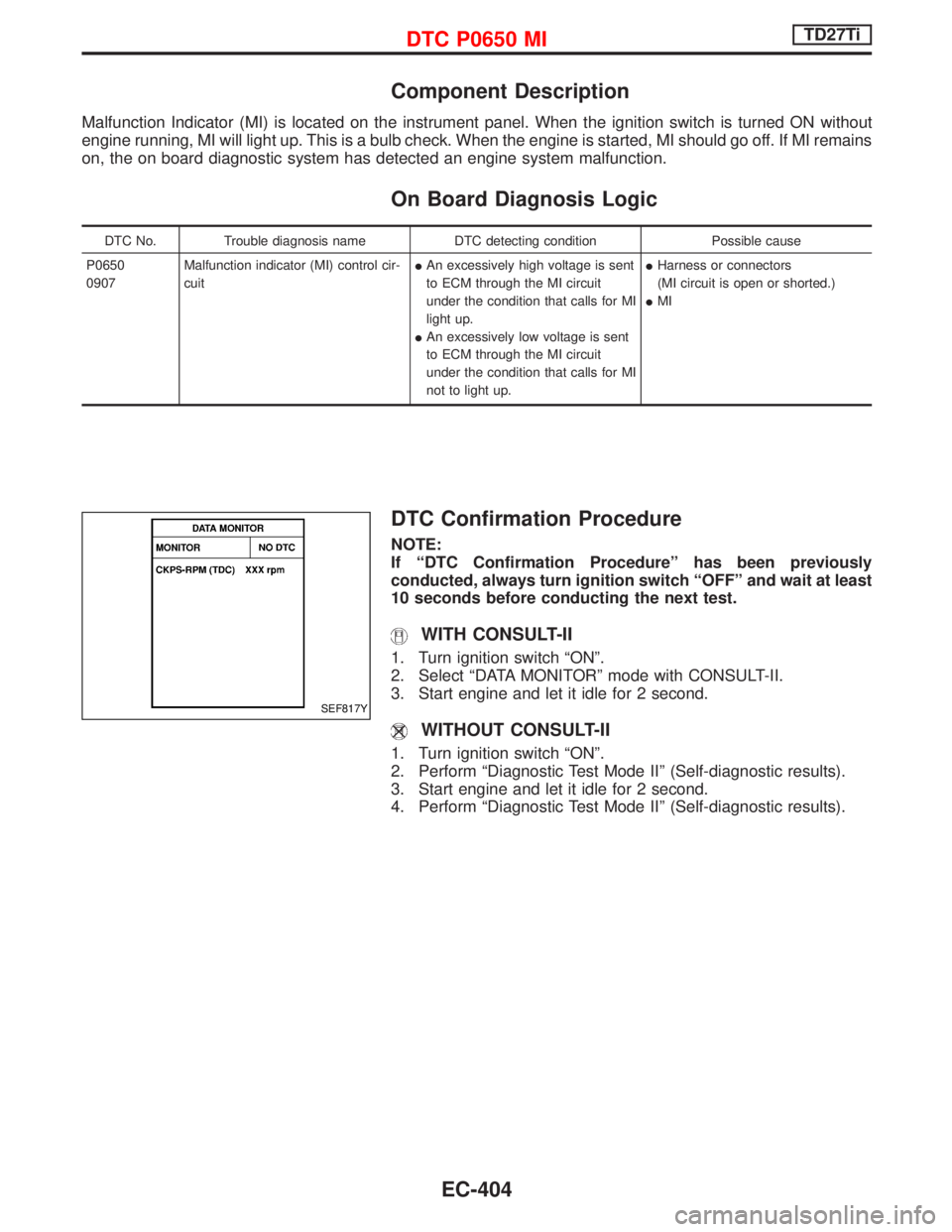

Component Description

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI remains

on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis Logic

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0650

0907Malfunction indicator (MI) control cir-

cuitIAn excessively high voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

light up.

IAn excessively low voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

not to light up.IHarness or connectors

(MI circuit is open or shorted.)

IMI

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Start engine and let it idle for 2 second.

WITHOUT CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

3. Start engine and let it idle for 2 second.

4. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF817Y

DTC P0650 MITD27Ti

EC-404

Page 771 of 1767

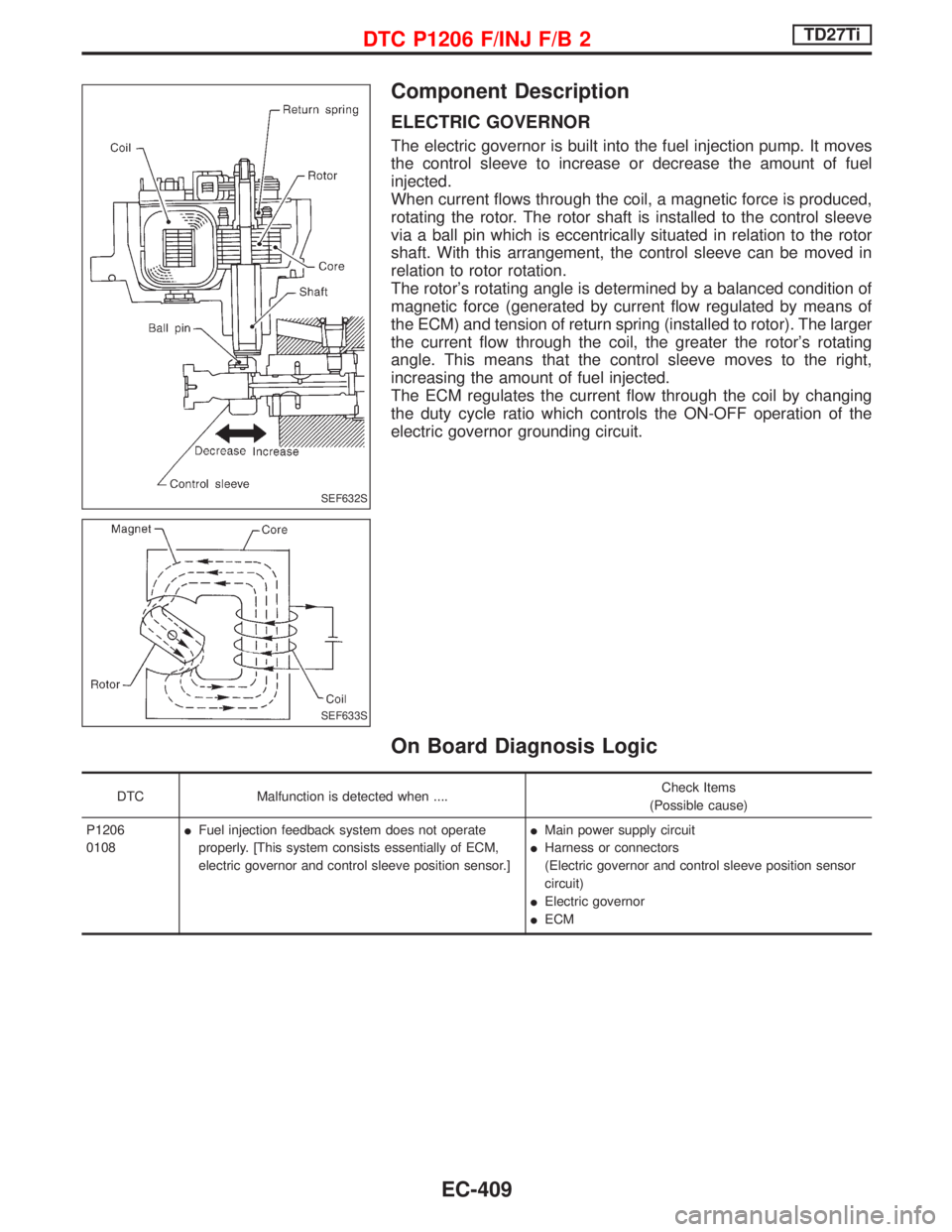

Component Description

ELECTRIC GOVERNOR

The electric governor is built into the fuel injection pump. It moves

the control sleeve to increase or decrease the amount of fuel

injected.

When current flows through the coil, a magnetic force is produced,

rotating the rotor. The rotor shaft is installed to the control sleeve

via a ball pin which is eccentrically situated in relation to the rotor

shaft. With this arrangement, the control sleeve can be moved in

relation to rotor rotation.

The rotor's rotating angle is determined by a balanced condition of

magnetic force (generated by current flow regulated by means of

the ECM) and tension of return spring (installed to rotor). The larger

the current flow through the coil, the greater the rotor's rotating

angle. This means that the control sleeve moves to the right,

increasing the amount of fuel injected.

The ECM regulates the current flow through the coil by changing

the duty cycle ratio which controls the ON-OFF operation of the

electric governor grounding circuit.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible cause)

P1206

0108IFuel injection feedback system does not operate

properly. [This system consists essentially of ECM,

electric governor and control sleeve position sensor.]IMain power supply circuit

IHarness or connectors

(Electric governor and control sleeve position sensor

circuit)

IElectric governor

IECM

SEF632S

SEF633S

DTC P1206 F/INJ F/B 2TD27Ti

EC-409