ECU NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 22 of 1767

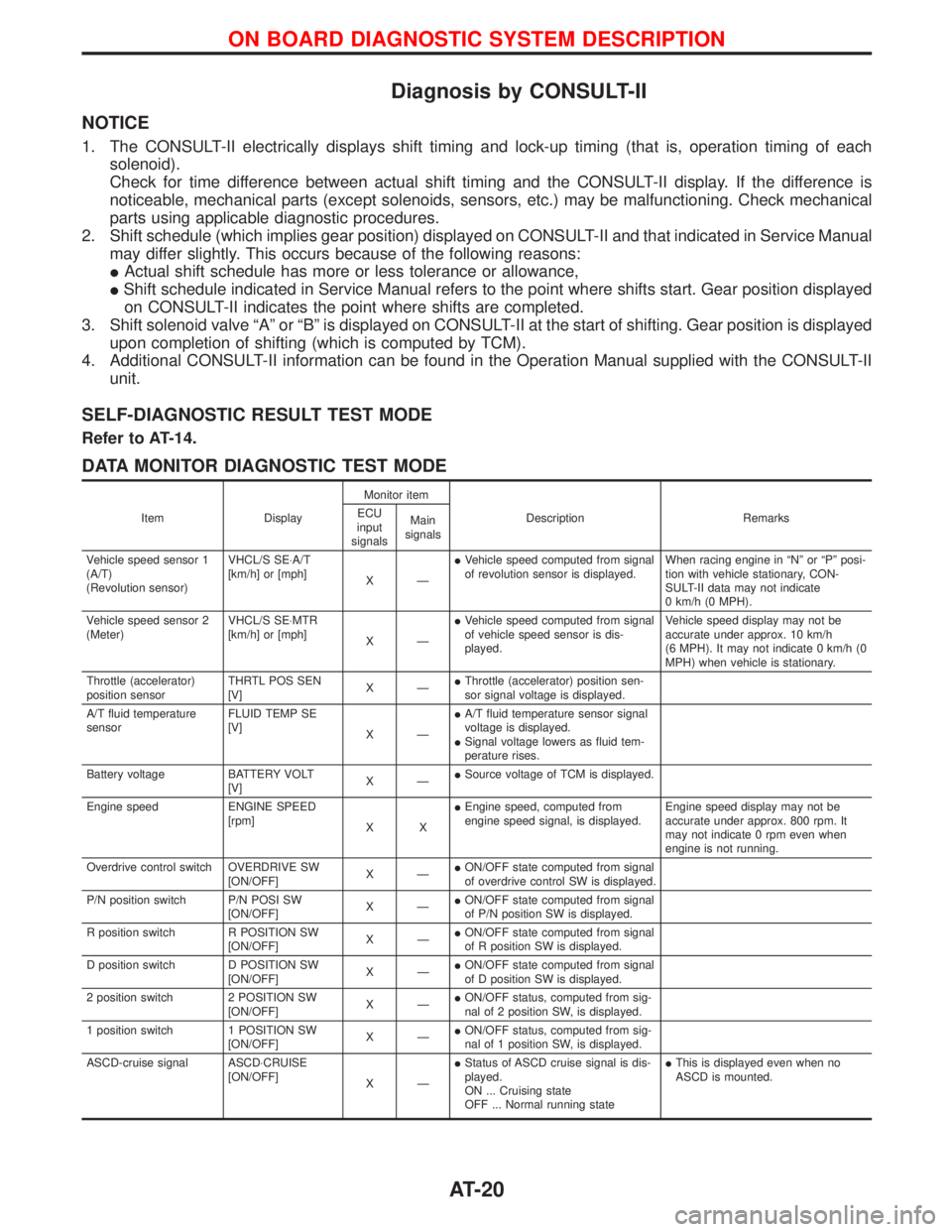

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed

upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor)VHCL/S SE×A/T

[km/h] or [mph]

XÐIVehicle speed computed from signal

of revolution sensor is displayed.When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SE×MTR

[km/h] or [mph]

XÐIVehicle speed computed from signal

of vehicle speed sensor is dis-

played.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensorTHRTL POS SEN

[V]XÐIThrottle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensorFLUID TEMP SE

[V]

XÐIA/T fluid temperature sensor signal

voltage is displayed.

ISignal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT

[V]XÐISource voltage of TCM is displayed.

Engine speed ENGINE SPEED

[rpm]

XXIEngine speed, computed from

engine speed signal, is displayed.Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF]XÐION/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW

[ON/OFF]XÐION/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE

[ON/OFF]

XÐIStatus of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running stateIThis is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

Page 23 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

ASCD-OD cut signal ASCD×OD CUT

[ON/OFF]

XÐIStatus of ASCD×OD release signal is

displayed.

ON ... OD released

OFF ... OD no NISSAN TERRANO 2002 Service Repair Manual Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

ASCD-OD cut signal ASCD×OD CUT

[ON/OFF]

XÐIStatus of ASCD×OD release signal is

displayed.

ON ... OD released

OFF ... OD no](/img/5/57393/w960_57393-22.png)

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

ASCD-OD cut signal ASCD×OD CUT

[ON/OFF]

XÐIStatus of ASCD×OD release signal is

displayed.

ON ... OD released

OFF ... OD not releasedIThis is displayed even when no

ASCD is mounted.

Kickdown switch KICKDOWN SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of kickdown SW, is displayed.IThis is displayed even when no

kickdown switch is equipped.

A/T mode switch POWER SHIFT SW

[ON/OFF]XÐION/OFF state computed from signal

of SPORT shift SW is displayed.

Closed throttle position

switchCLOSED THL/SW

[ON/OFF] X ÐION/OFF status, computed from sig-

nal of closed throttle (accelerator)

position SW, is displayed.

Wide open throttle posi-

tion switchW/O THRL/P-SW

[ON/OFF] X ÐION/OFF status, computed from sig-

nal of wide open throttle (accelera-

tor) position SW, is displayed.

A/T mode switch HOLD SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of SNOW shift SW, is displayed.

Gear position GEAR

ÐXIGear position data used for compu-

tation by TCM, is displayed.

Selector lever position SLCT LVR POSI

ÐXISelector lever position data, used

for computation by TCM, is dis-

played.IA specific value used for control is

displayed if fail-safe is activated due

to error.

Vehicle speed VEHICLE SPEED

[km/h] or [mph]ÐXIVehicle speed data, used for com-

putation by TCM, is displayed.

Throttle (accelerator)

positionTHROTTLE POSI

[/8] Ð XIThrottle (accelerator) position data,

used for computation by TCM, is

displayed.IA specific value used for control is

displayed if fail-safe is activated due

to error.

Line pressure duty LINE PRES DTY

[%] Ð XIControl value of line pressure sole-

noid valve, computed by TCM from

each input signal, is displayed.

Torque converter clutch

solenoid valve dutyTCC S/V DUTY

[%]

ÐXIControl value of torque converter

clutch solenoid valve, computed by

TCM from each input signal, is dis-

played.

Shift solenoid valve A SHIFT S/V A

[ON/OFF] Ð XIControl value of shift solenoid valve

A, computed by TCM from each

input signal, is displayed.Control value of solenoid is displayed

even if solenoid circuit is discon-

nected.

The ªOFFº signal is displayed if sole-

noid circuit is shorted. Shift solenoid valve B SHIFT S/V B

[ON/OFF] Ð XIControl value of shift solenoid valve

B, computed by TCM from each

input signal, is displayed.

Overrun clutch solenoid

valveOVERRUN/C S/V

[ON/OFF] Ð XIControl value of overrun clutch sole-

noid valve computed by TCM from

each input signal is displayed.

Self-diagnosis display

lamp

(SPORT indicator lamp)SELF-D DP LMP

[ON/OFF] Ð XIControl status of SPORT indicator

lamp is displayed.

X: Applicable

Ð: Not applicable

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Diagnosis by CONSULT-II (Cont'd)

AT-21

Page 53 of 1767

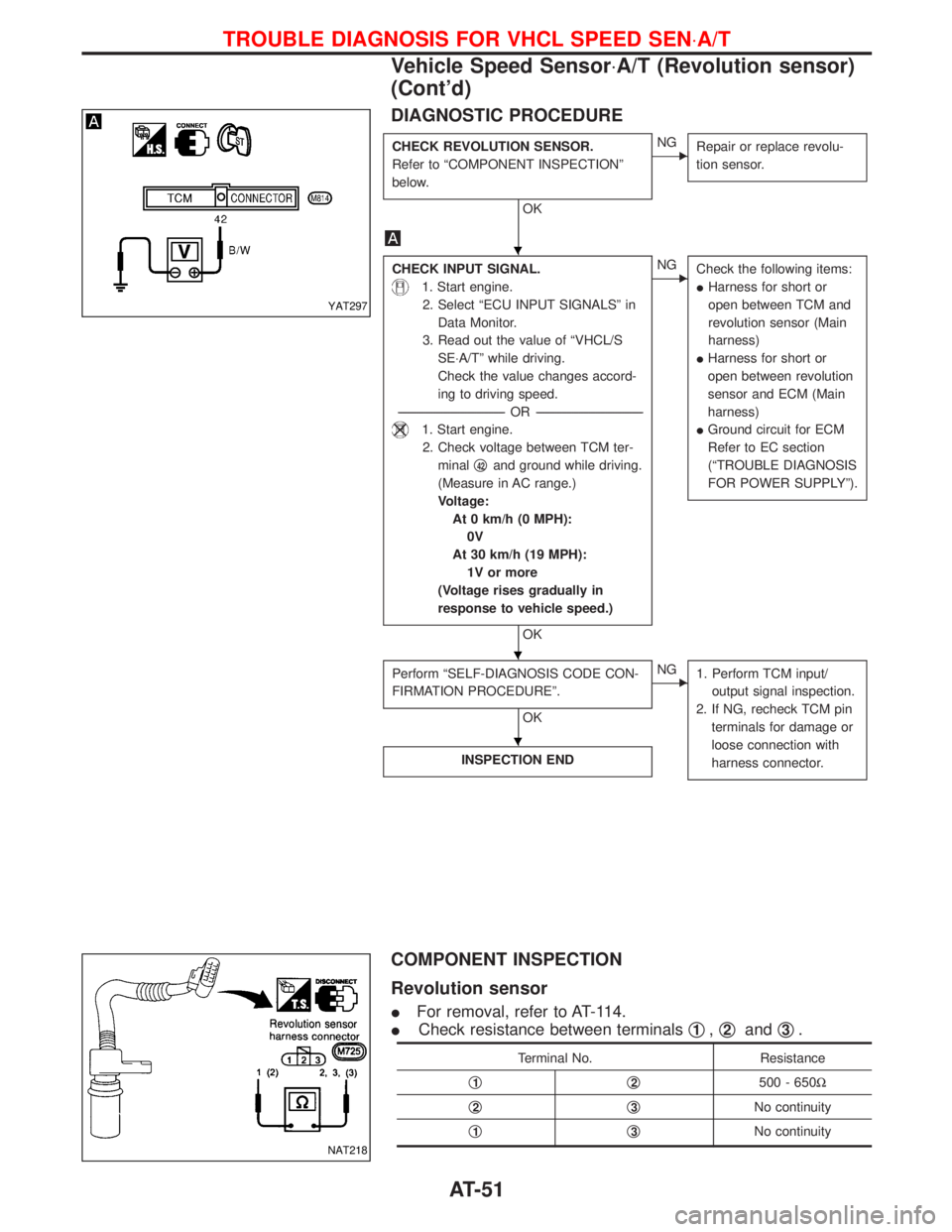

DIAGNOSTIC PROCEDURE

CHECK REVOLUTION SENSOR.

Refer to ªCOMPONENT INSPECTIONº

below.

OK

ENG

Repair or replace revolu-

tion sensor.

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªVHCL/S

SE×A/Tº while driving.

Check the value changes accord-

ing to driving speed.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter-

minalq

42and ground while driving.

(Measure in AC range.)

Voltage:

At 0 km/h (0 MPH):

0V

At 30 km/h (19 MPH):

1V or more

(Voltage rises gradually in

response to vehicle speed.)

OK

ENG

Check the following items:

IHarness for short or

open between TCM and

revolution sensor (Main

harness)

IHarness for short or

open between revolution

sensor and ECM (Main

harness)

IGround circuit for ECM

Refer to EC section

(ªTROUBLE DIAGNOSIS

FOR POWER SUPPLYº).

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Revolution sensor

IFor removal, refer to AT-114.

ICheck resistance between terminalsq

1,q2andq3.

Terminal No. Resistance

q

1q2500 - 650W

q

2q3No continuity

q

1q3No continuity

YAT297

NAT218

H

H

H

TROUBLE DIAGNOSIS FOR VHCL SPEED SEN×A/T

Vehicle Speed Sensor×A/T (Revolution sensor)

(Cont'd)

AT-51

Page 57 of 1767

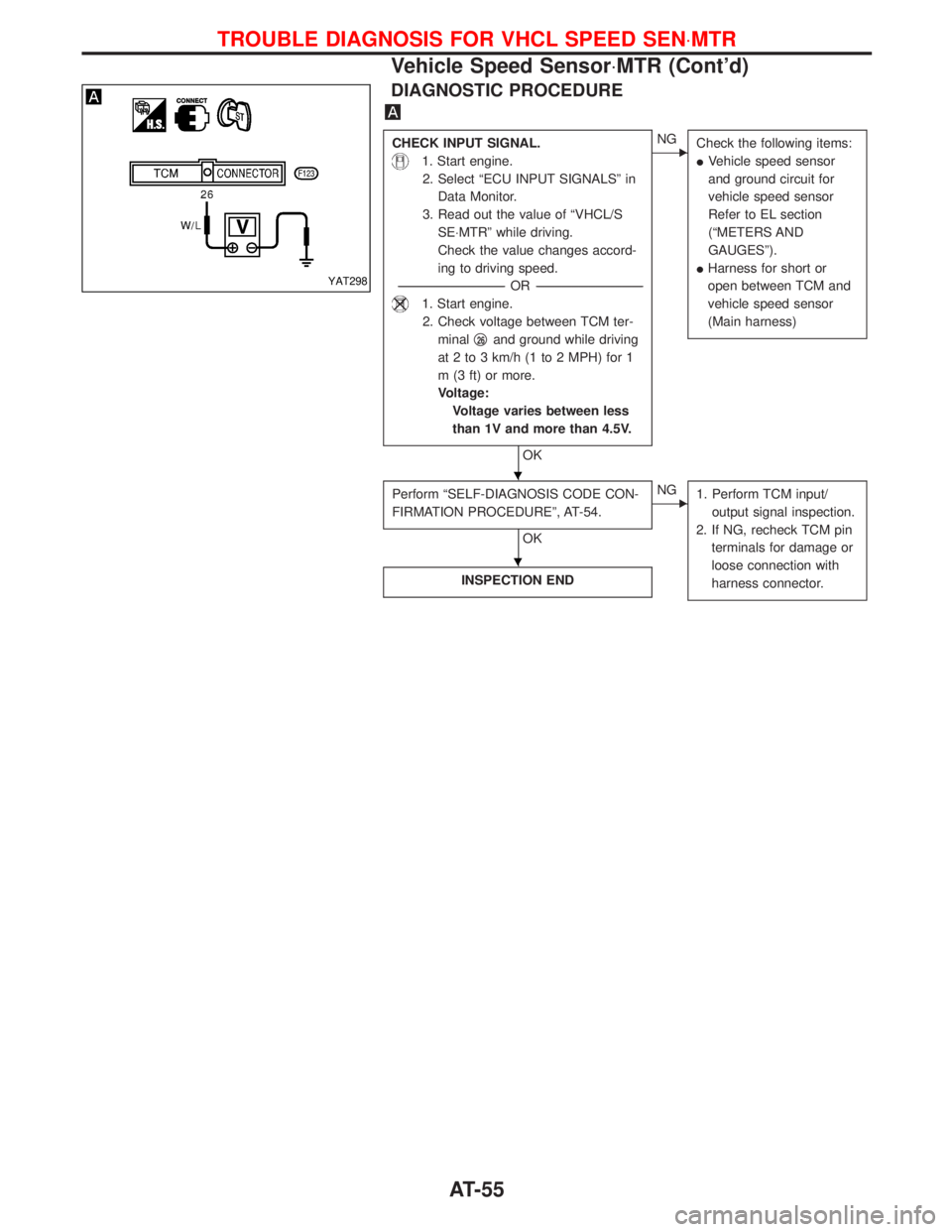

DIAGNOSTIC PROCEDURE

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªVHCL/S

SE×MTRº while driving.

Check the value changes accord-

ing to driving speed.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter-

minalq

26and ground while driving

at 2 to 3 km/h (1 to 2 MPH) for 1

m (3 ft) or more.

Voltage:

Voltage varies between less

than 1V and more than 4.5V.

OK

ENG

Check the following items:

IVehicle speed sensor

and ground circuit for

vehicle speed sensor

Refer to EL section

(ªMETERS AND

GAUGESº).

IHarness for short or

open between TCM and

vehicle speed sensor

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-54.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT298

H

H

TROUBLE DIAGNOSIS FOR VHCL SPEED SEN×MTR

Vehicle Speed Sensor×MTR (Cont'd)

AT-55

Page 63 of 1767

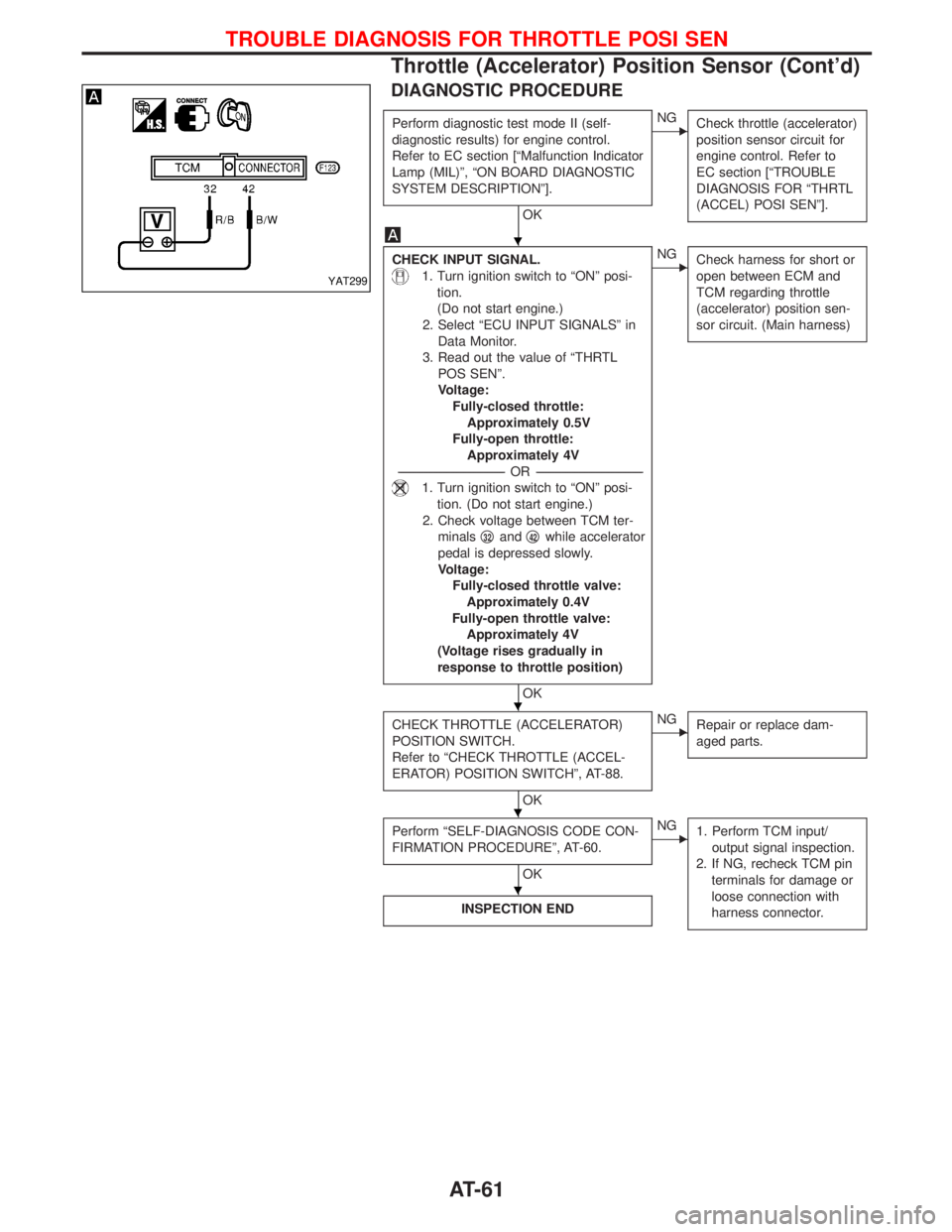

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indicator

Lamp (MIL)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

OK

ENG

Check throttle (accelerator)

position sensor circuit for

engine control. Refer to

EC section [ªTROUBLE

DIAGNOSIS FOR ªTHRTL

(ACCEL) POSI SENº].

CHECK INPUT SIGNAL.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªTHRTL

POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter-

minalsq

32andq42while accelerator

pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.4V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in

response to throttle position)

OK

ENG

Check harness for short or

open between ECM and

TCM regarding throttle

(accelerator) position sen-

sor circuit. (Main harness)

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH.

Refer to ªCHECK THROTTLE (ACCEL-

ERATOR) POSITION SWITCHº, AT-88.

OK

ENG

Repair or replace dam-

aged parts.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-60.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT299

H

H

H

H

TROUBLE DIAGNOSIS FOR THROTTLE POSI SEN

Throttle (Accelerator) Position Sensor (Cont'd)

AT-61

Page 80 of 1767

![NISSAN TERRANO 2002 Service Repair Manual qA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot NISSAN TERRANO 2002 Service Repair Manual qA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot](/img/5/57393/w960_57393-79.png)

qA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter-

minalq

47and ground while warm-

ing up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

OK

ENG

Check the following item:

IHarness for short or

open between TCM and

terminal cord assembly

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-76.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

A/T fluid temperature sensor

IFor removal, refer to AT-113.

ICheck resistance between terminalsq

6andq7while changing

temperature as shown at left.

Temperature ÉC (ÉF) Resistance

20 (68) Approximately 2.5 kW

80 (176) Approximately 0.3 kW

YAT318

YAT319

H

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont'd)

AT-78

Page 83 of 1767

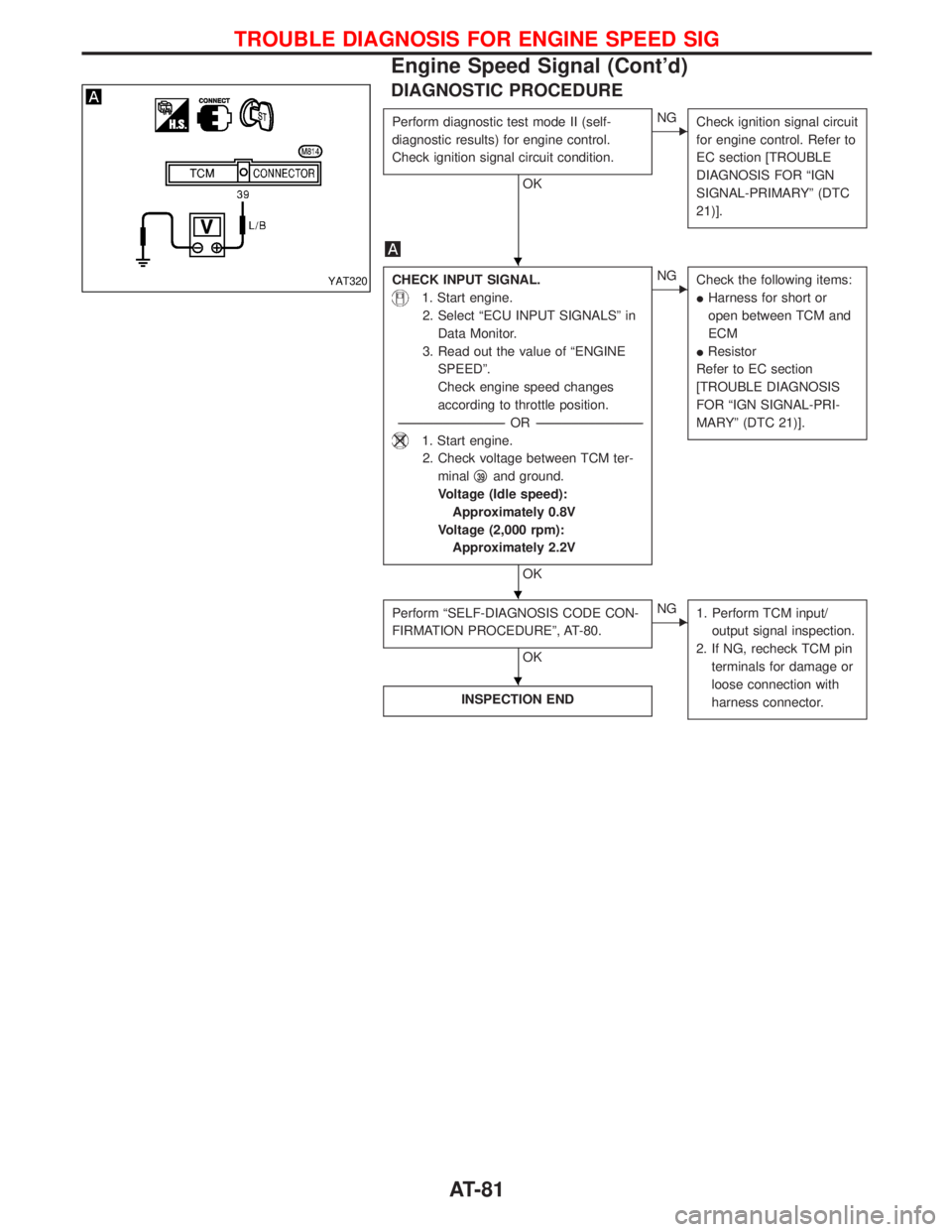

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Check ignition signal circuit condition.

OK

ENG

Check ignition signal circuit

for engine control. Refer to

EC section [TROUBLE

DIAGNOSIS FOR ªIGN

SIGNAL-PRIMARYº (DTC

21)].

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªENGINE

SPEEDº.

Check engine speed changes

according to throttle position.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter-

minalq

39and ground.

Voltage (Idle speed):

Approximately 0.8V

Voltage (2,000 rpm):

Approximately 2.2V

OK

ENG

Check the following items:

IHarness for short or

open between TCM and

ECM

IResistor

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-80.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT320

H

H

H

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

Engine Speed Signal (Cont'd)

AT-81

Page 91 of 1767

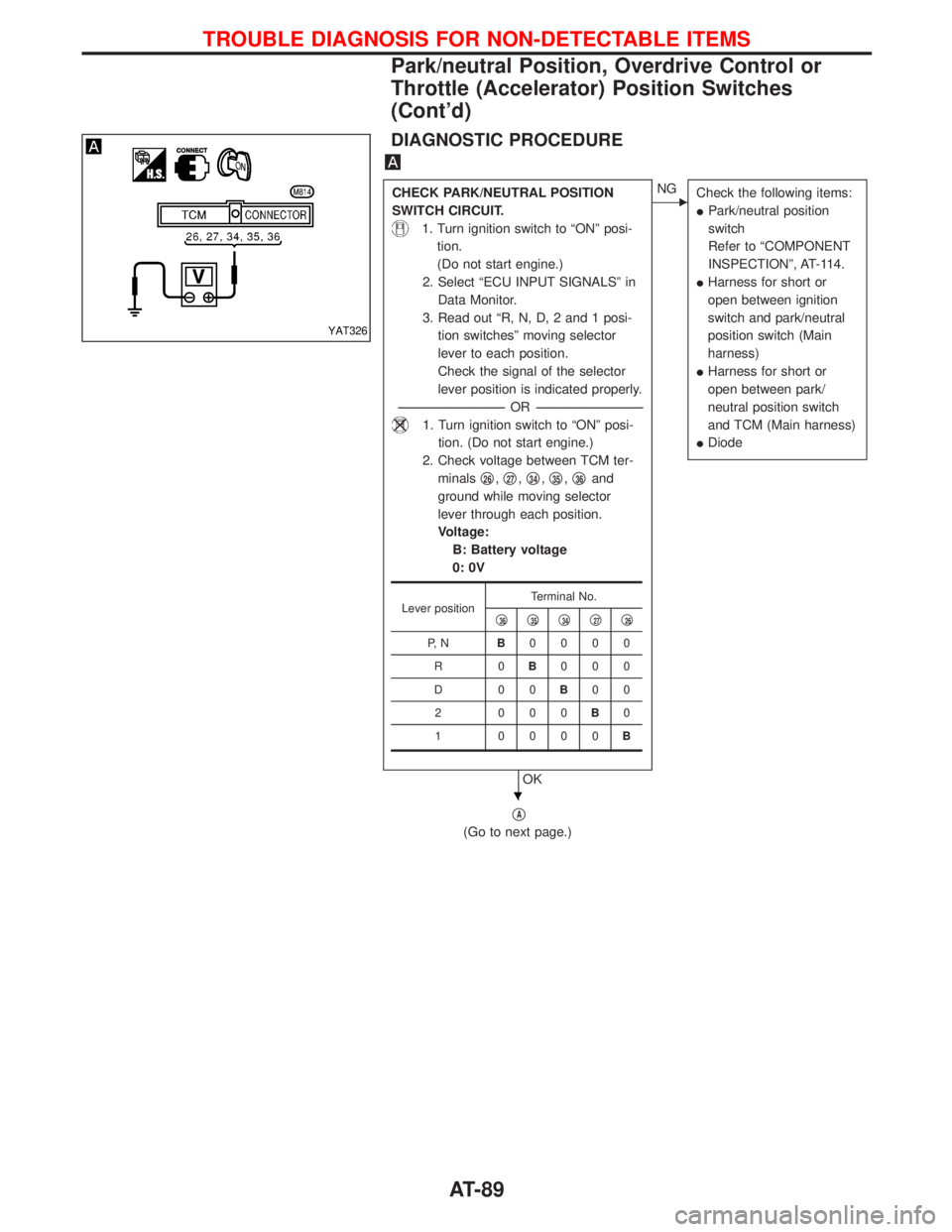

DIAGNOSTIC PROCEDURE

CHECK PARK/NEUTRAL POSITION

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªR, N, D, 2 and 1 posi-

tion switchesº moving selector

lever to each position.

Check the signal of the selector

lever position is indicated properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter-

minalsq

26,q27,q34,q35,q36and

ground while moving selector

lever through each position.

Voltage:

B: Battery voltage

0: 0V

OK

ENG

Check the following items:

IPark/neutral position

switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and park/neutral

position switch (Main

harness)

IHarness for short or

open between park/

neutral position switch

and TCM (Main harness)

IDiode

qA

(Go to next page.)

Lever positionTerminal No.

q36q35q34q27q26

P, NB0000

R0B000

D00B00

2 000B0

1 0000B

YAT326

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-89

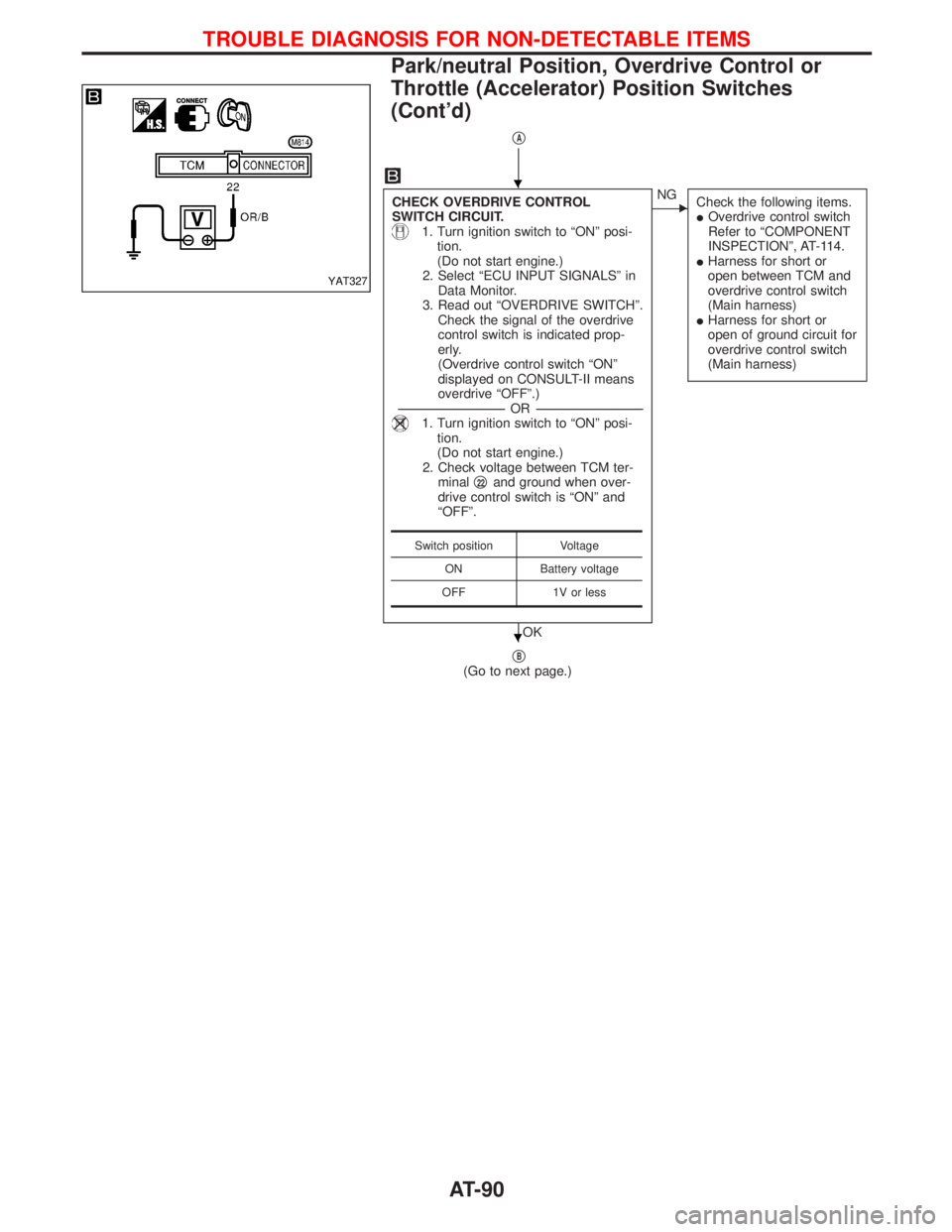

Page 92 of 1767

qA

CHECK OVERDRIVE CONTROL

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªOVERDRIVE SWITCHº.

Check the signal of the overdrive

control switch is indicated prop-

erly.

(Overdrive control switch ªONº

displayed on CONSULT-II means

overdrive ªOFFº.)

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalq

22and ground when over-

drive control switch is ªONº and

ªOFFº.

OK

ENG

Check the following items.

IOverdrive control switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between TCM and

overdrive control switch

(Main harness)

IHarness for short or

open of ground circuit for

overdrive control switch

(Main harness)

qB(Go to next page.)

Switch position Voltage

ON Battery voltage

OFF 1V or less

YAT327

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-90

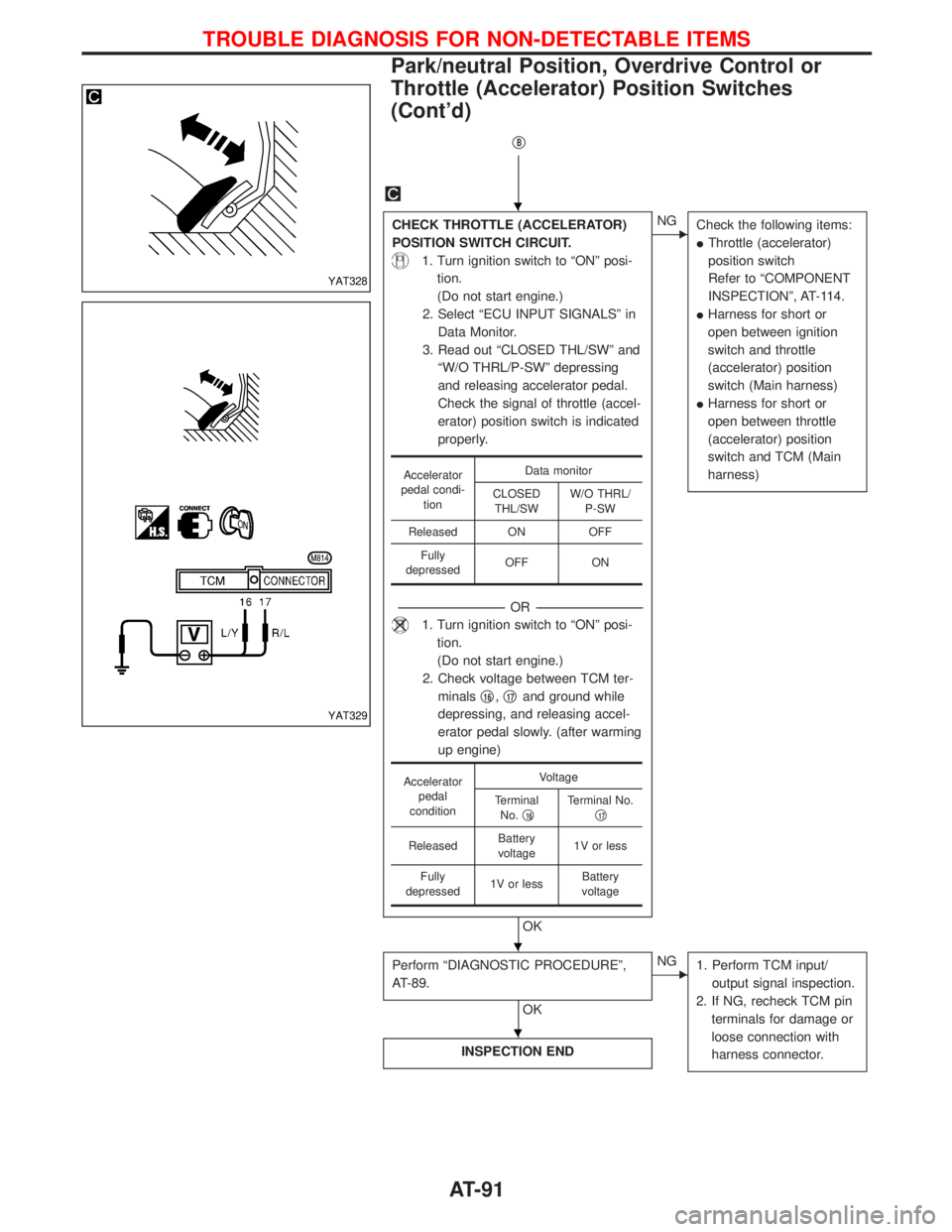

Page 93 of 1767

qB

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªCLOSED THL/SWº and

ªW/O THRL/P-SWº depressing

and releasing accelerator pedal.

Check the signal of throttle (accel-

erator) position switch is indicated

properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalsq

16,q17and ground while

depressing, and releasing accel-

erator pedal slowly. (after warming

up engine)

OK

ENG

Check the following items:

IThrottle (accelerator)

position switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and throttle

(accelerator) position

switch (Main harness)

IHarness for short or

open between throttle

(accelerator) position

switch and TCM (Main

harness)

Perform ªDIAGNOSTIC PROCEDUREº,

AT-89.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

Accelerator

pedal condi-

tionData monitor

CLOSED

THL/SWW/O THRL/

P-SW

Released ON OFF

Fully

depressedOFF ON

Accelerator

pedal

conditionVoltage

Terminal

No.q

16Terminal No.

q17

ReleasedBattery

voltage1V or less

Fully

depressed1V or lessBattery

voltage

YAT328

YAT329

H

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-91