check engine light NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 397 of 1767

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-291.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

Page 466 of 1767

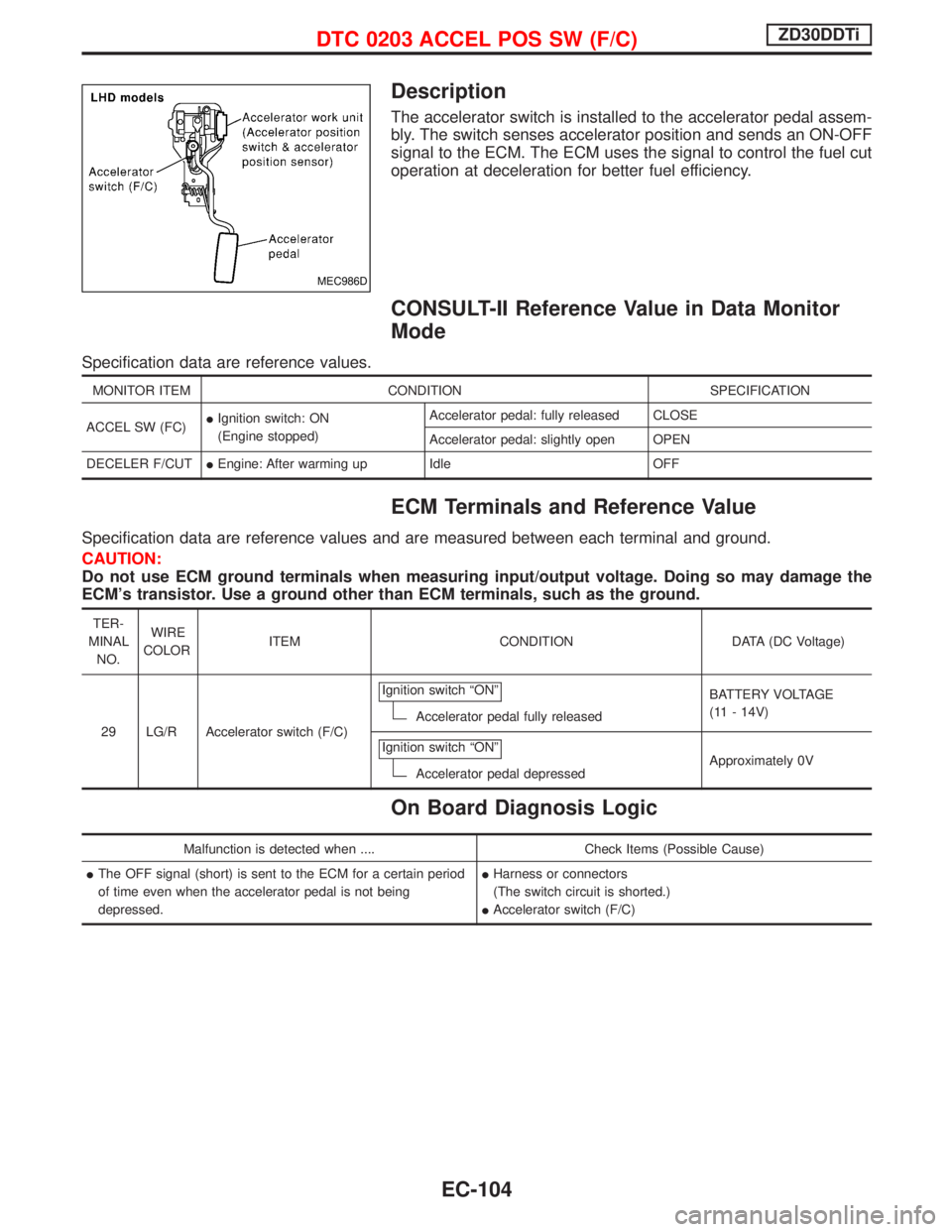

Description

The accelerator switch is installed to the accelerator pedal assem-

bly. The switch senses accelerator position and sends an ON-OFF

signal to the ECM. The ECM uses the signal to control the fuel cut

operation at deceleration for better fuel efficiency.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SW (FC)IIgnition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

DECELER F/CUTIEngine: After warming up Idle OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 LG/R Accelerator switch (F/C)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible Cause)

IThe OFF signal (short) is sent to the ECM for a certain period

of time even when the accelerator pedal is not being

depressed.IHarness or connectors

(The switch circuit is shorted.)

IAccelerator switch (F/C)

MEC986D

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-104

Page 684 of 1767

How to Erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-323.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

Malfunction Indicator (MI)

1. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is a bulb check.

IIf the malfunction indicator does not light up, refer to EL sec-

tion (ªWARNING LAMPS/WIRING DIAGRAMº) or see MI &

DATA LINK CONNECTORS.

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or flashes irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

Diagnostic

Test ModeKEY and ENG.

StatusFunction Explanation of Function

Mode IIgnition switch in

ON position

Engine stoppedBULB CHECKThis function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (See EC-452.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM detects a

malfunction, the MI will light up to inform the driver that a mal-

function has been detected.

Mode IIIgnition switch in

ON position

Engine stopped

SELF-DIAGNOSTIC

RESULTSThis function allows DTCs to be read.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Diagnostic Trouble Code (DTC) (Cont'd)

EC-322

Page 766 of 1767

Component Description

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI remains

on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis Logic

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0650

0907Malfunction indicator (MI) control cir-

cuitIAn excessively high voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

light up.

IAn excessively low voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

not to light up.IHarness or connectors

(MI circuit is open or shorted.)

IMI

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Start engine and let it idle for 2 second.

WITHOUT CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

3. Start engine and let it idle for 2 second.

4. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF817Y

DTC P0650 MITD27Ti

EC-404

Page 1011 of 1767

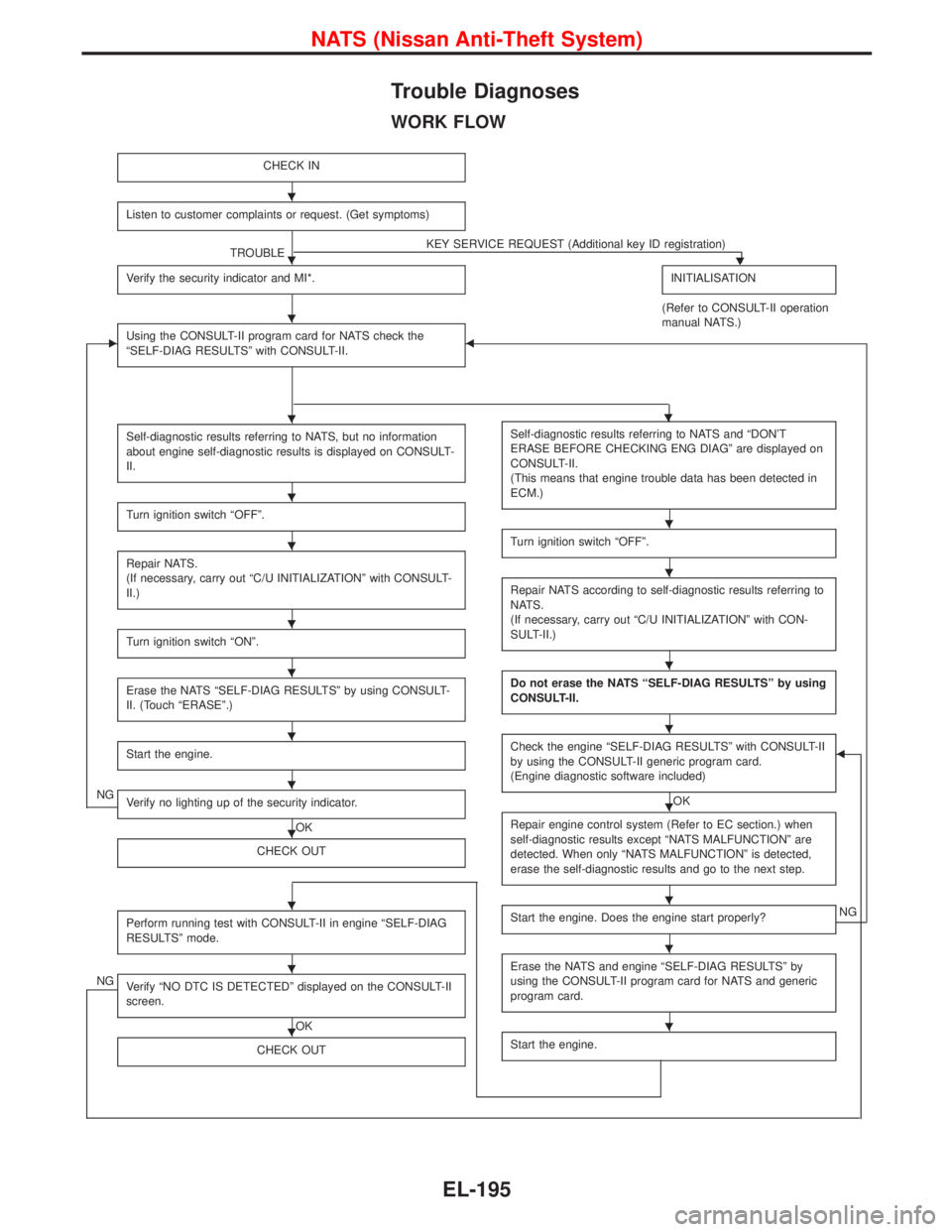

Trouble Diagnoses

WORK FLOW

CHECK IN

Listen to customer complaints or request. (Get symptoms)

TROUBLEKEY SERVICE REQUEST (Additional key ID registration)H

Verify the security indicator and MI*.INITIALISATION

(Refer to CONSULT-II operation

manual NATS.)

EUsing the CONSULT-II program card for NATS check the

ªSELF-DIAG RESULTSº with CONSULT-II.F

Self-diagnostic results referring to NATS, but no information

about engine self-diagnostic results is displayed on CONSULT-

II.

Turn ignition switch ªOFFº.

Repair NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CONSULT-

II.)

Turn ignition switch ªONº.

Erase the NATS ªSELF-DIAG RESULTSº by using CONSULT-

II. (Touch ªERASEº.)

Start the engine.

NGVerify no lighting up of the security indicator.

OK

CHECK OUT

Perform running test with CONSULT-II in engine ªSELF-DIAG

RESULTSº mode.

NGVerify ªNO DTC IS DETECTEDº displayed on the CONSULT-II

screen.

OK

CHECK OUT

Self-diagnostic results referring to NATS and ªDON'T

ERASE BEFORE CHECKING ENG DIAGº are displayed on

CONSULT-II.

(This means that engine trouble data has been detected in

ECM.)

Turn ignition switch ªOFFº.

Repair NATS according to self-diagnostic results referring to

NATS.

(If necessary, carry out ªC/U INITIALIZATIONº with CON-

SULT-II.)

Do not erase the NATS ªSELF-DIAG RESULTSº by using

CONSULT-II.

Check the engine ªSELF-DIAG RESULTSº with CONSULT-II

by using the CONSULT-II generic program card.

(Engine diagnostic software included)

OK

F

Repair engine control system (Refer to EC section.) when

self-diagnostic results except ªNATS MALFUNCTIONº are

detected. When only ªNATS MALFUNCTIONº is detected,

erase the self-diagnostic results and go to the next step.

Start the engine. Does the engine start properly?NG

Erase the NATS and engine ªSELF-DIAG RESULTSº by

using the CONSULT-II program card for NATS and generic

program card.

Start the engine.

H

H

H

HH

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

NATS (Nissan Anti-Theft System)

EL-195

Page 1012 of 1767

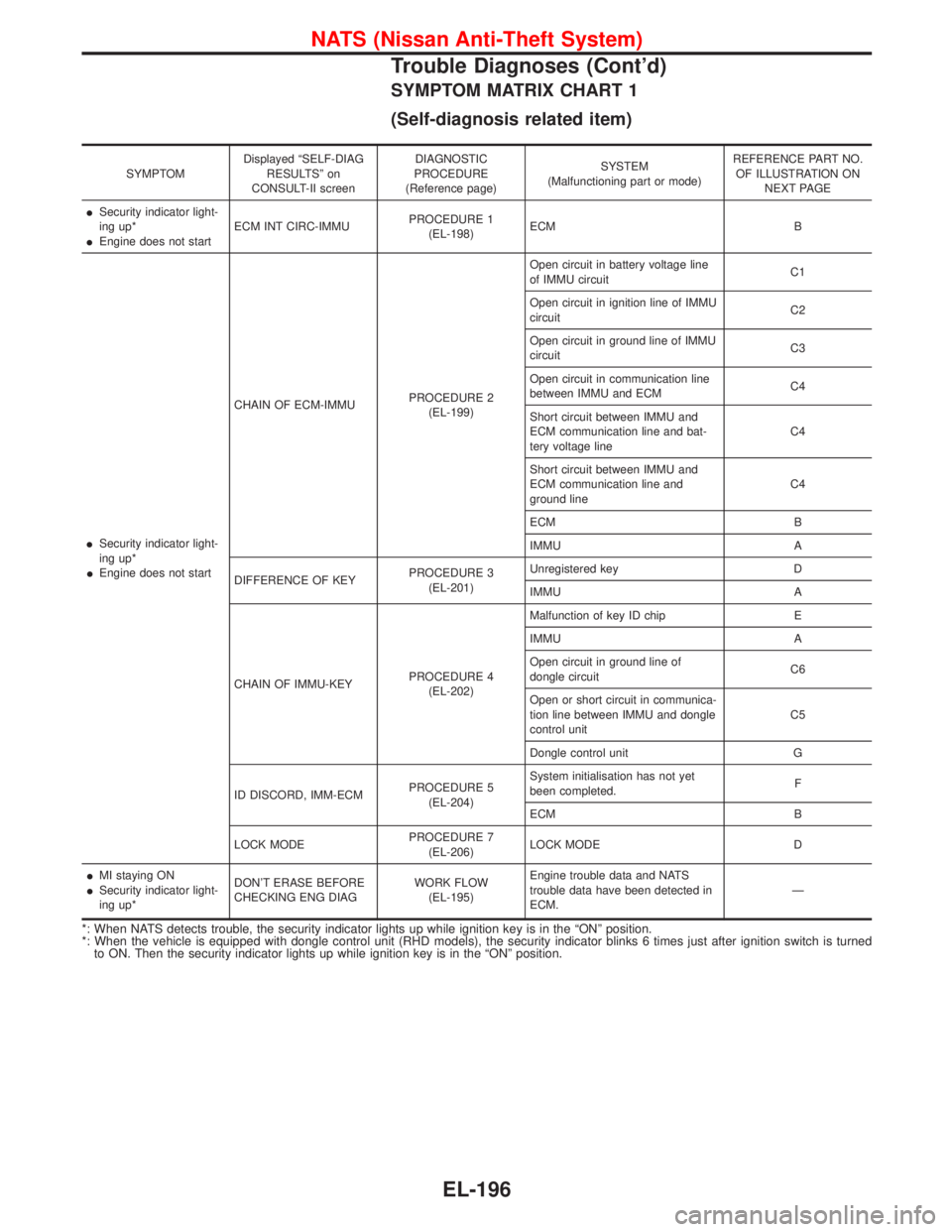

SYMPTOM MATRIX CHART 1

(Self-diagnosis related item)

SYMPTOMDisplayed ªSELF-DIAG

RESULTSº on

CONSULT-II screenDIAGNOSTIC

PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)REFERENCE PART NO.

OF ILLUSTRATION ON

NEXT PAGE

ISecurity indicator light-

ing up*

IEngine does not startECM INT CIRC-IMMUPROCEDURE 1

(EL-198)ECM B

ISecurity indicator light-

ing up*

IEngine does not startCHAIN OF ECM-IMMUPROCEDURE 2

(EL-199)Open circuit in battery voltage line

of IMMU circuitC1

Open circuit in ignition line of IMMU

circuitC2

Open circuit in ground line of IMMU

circuitC3

Open circuit in communication line

between IMMU and ECMC4

Short circuit between IMMU and

ECM communication line and bat-

tery voltage lineC4

Short circuit between IMMU and

ECM communication line and

ground lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(EL-201)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(EL-202)Malfunction of key ID chip E

IMMU A

Open circuit in ground line of

dongle circuitC6

Open or short circuit in communica-

tion line between IMMU and dongle

control unitC5

Dongle control unit G

ID DISCORD, IMM-ECMPROCEDURE 5

(EL-204)System initialisation has not yet

been completed.F

ECM B

LOCK MODEPROCEDURE 7

(EL-206)LOCK MODE D

IMI staying ON

ISecurity indicator light-

ing up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(EL-195)Engine trouble data and NATS

trouble data have been detected in

ECM.Ð

*: When NATS detects trouble, the security indicator lights up while ignition key is in the ªONº position.

*: When the vehicle is equipped with dongle control unit (RHD models), the security indicator blinks 6 times just after ignition switch is turned

to ON. Then the security indicator lights up while ignition key is in the ªONº position.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-196

Page 1021 of 1767

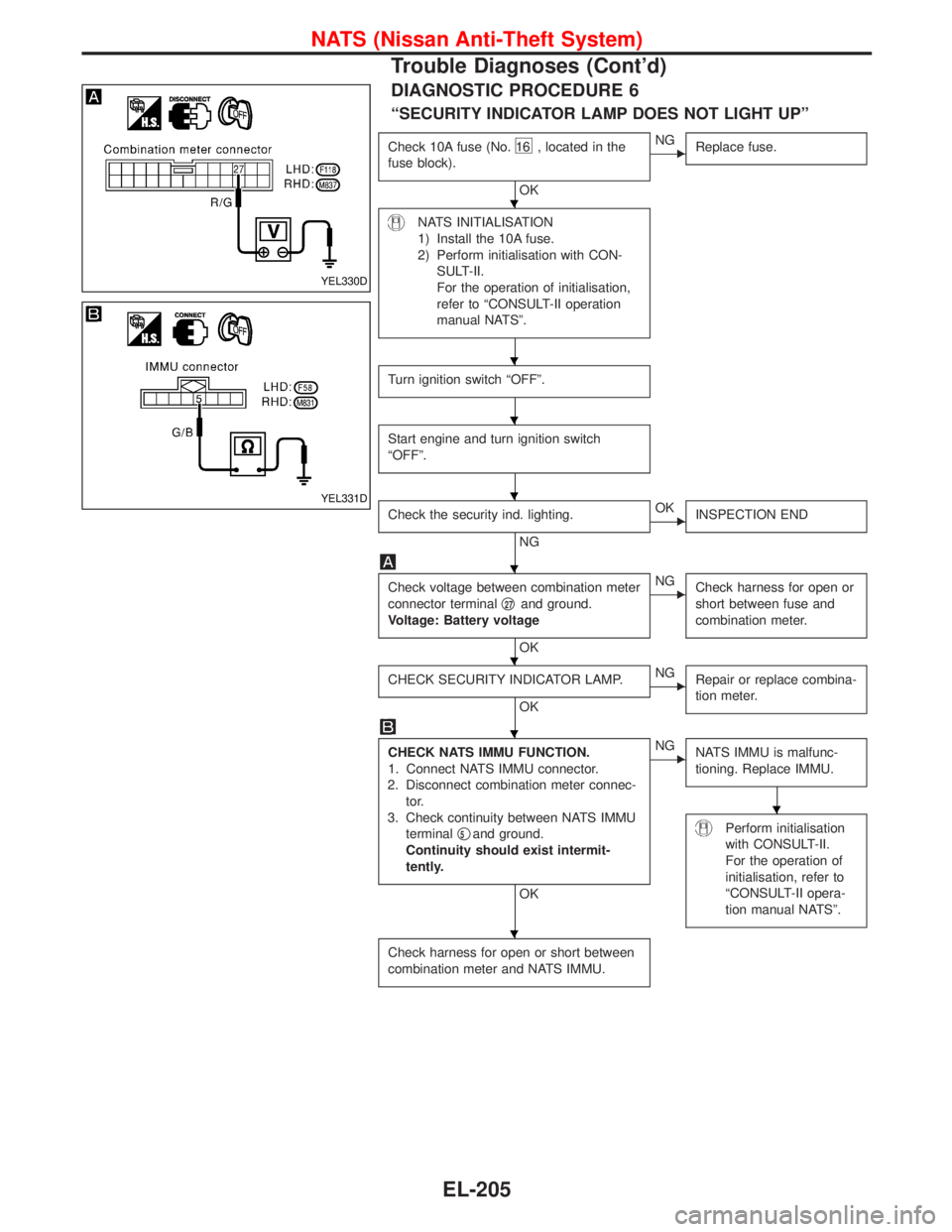

DIAGNOSTIC PROCEDURE 6

ªSECURITY INDICATOR LAMP DOES NOT LIGHT UPº

Check 10A fuse (No.16 , located in the

fuse block).

OK

ENG

Replace fuse.

NATS INITIALISATION

1) Install the 10A fuse.

2) Perform initialisation with CON-

SULT-II.

For the operation of initialisation,

refer to ªCONSULT-II operation

manual NATSº.

Turn ignition switch ªOFFº.

Start engine and turn ignition switch

ªOFFº.

Check the security ind. lighting.

NG

EOK

INSPECTION END

Check voltage between combination meter

connector terminalq

27and ground.

Voltage: Battery voltage

OK

ENG

Check harness for open or

short between fuse and

combination meter.

CHECK SECURITY INDICATOR LAMP.

OK

ENG

Repair or replace combina-

tion meter.

CHECK NATS IMMU FUNCTION.

1. Connect NATS IMMU connector.

2. Disconnect combination meter connec-

tor.

3. Check continuity between NATS IMMU

terminalq

5and ground.

Continuity should exist intermit-

tently.

OK

ENG

NATS IMMU is malfunc-

tioning. Replace IMMU.

Perform initialisation

with CONSULT-II.

For the operation of

initialisation, refer to

ªCONSULT-II opera-

tion manual NATSº.

Check harness for open or short between

combination meter and NATS IMMU.

YEL330D

YEL331D

H

H

H

H

H

H

H

H

H

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-205

Page 1300 of 1767

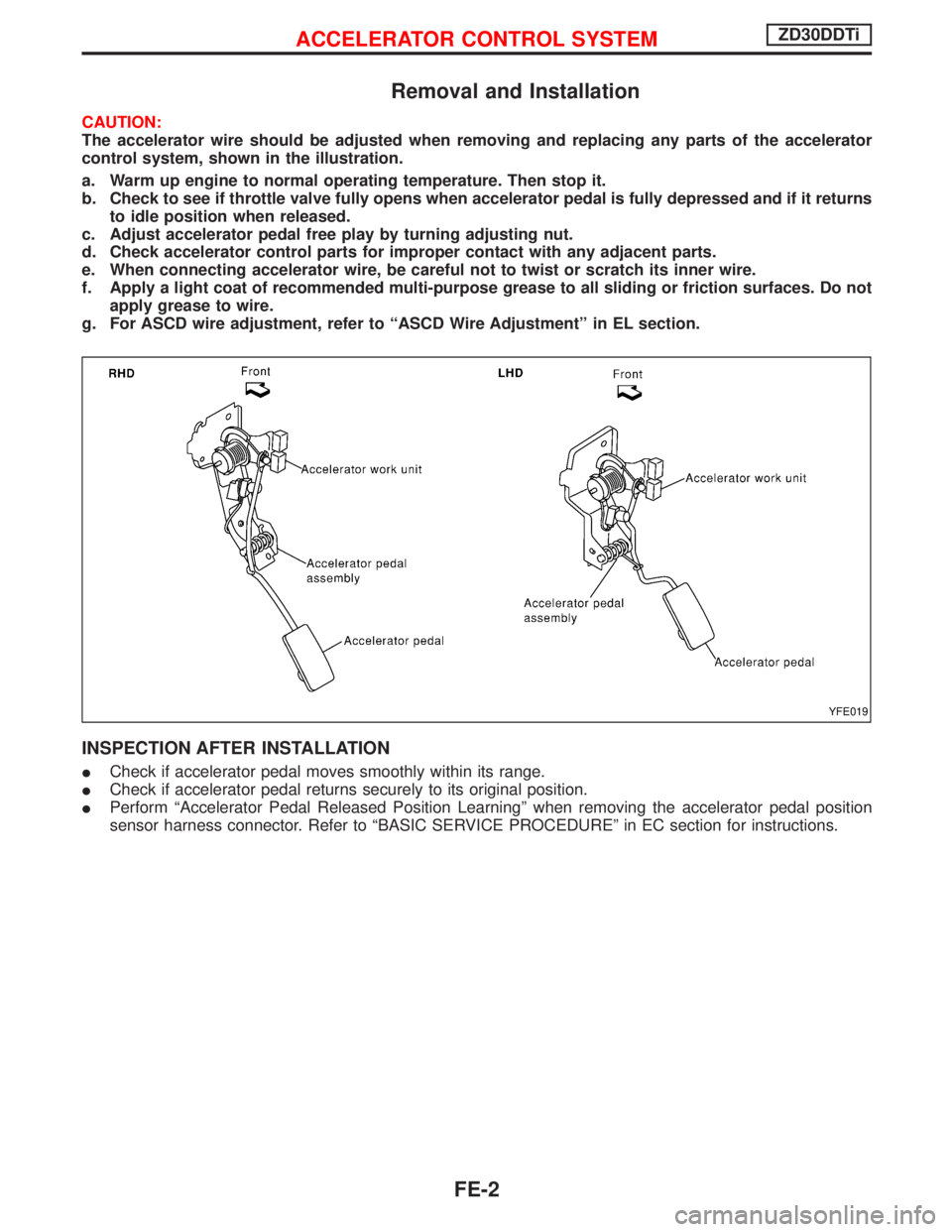

Removal and Installation

CAUTION:

The accelerator wire should be adjusted when removing and replacing any parts of the accelerator

control system, shown in the illustration.

a. Warm up engine to normal operating temperature. Then stop it.

b. Check to see if throttle valve fully opens when accelerator pedal is fully depressed and if it returns

to idle position when released.

c. Adjust accelerator pedal free play by turning adjusting nut.

d. Check accelerator control parts for improper contact with any adjacent parts.

e. When connecting accelerator wire, be careful not to twist or scratch its inner wire.

f. Apply a light coat of recommended multi-purpose grease to all sliding or friction surfaces. Do not

apply grease to wire.

g. For ASCD wire adjustment, refer to ªASCD Wire Adjustmentº in EL section.

INSPECTION AFTER INSTALLATION

ICheck if accelerator pedal moves smoothly within its range.

ICheck if accelerator pedal returns securely to its original position.

IPerform ªAccelerator Pedal Released Position Learningº when removing the accelerator pedal position

sensor harness connector. Refer to ªBASIC SERVICE PROCEDUREº in EC section for instructions.

YFE019

ACCELERATOR CONTROL SYSTEMZD30DDTi

FE-2

Page 1338 of 1767

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

IHeat sensitive

IFreezing

IWater intrusion

IElectrical load

ICold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

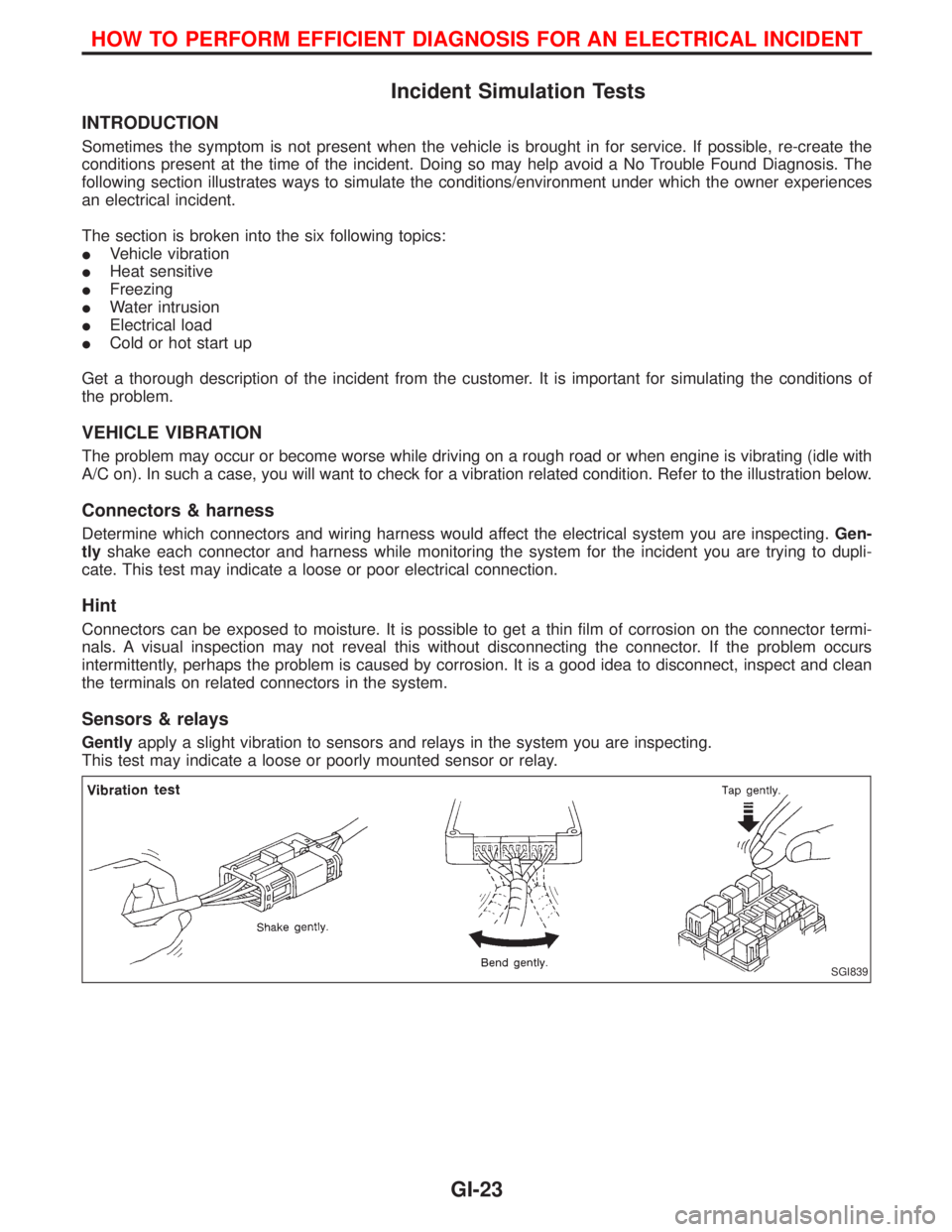

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

Page 1351 of 1767

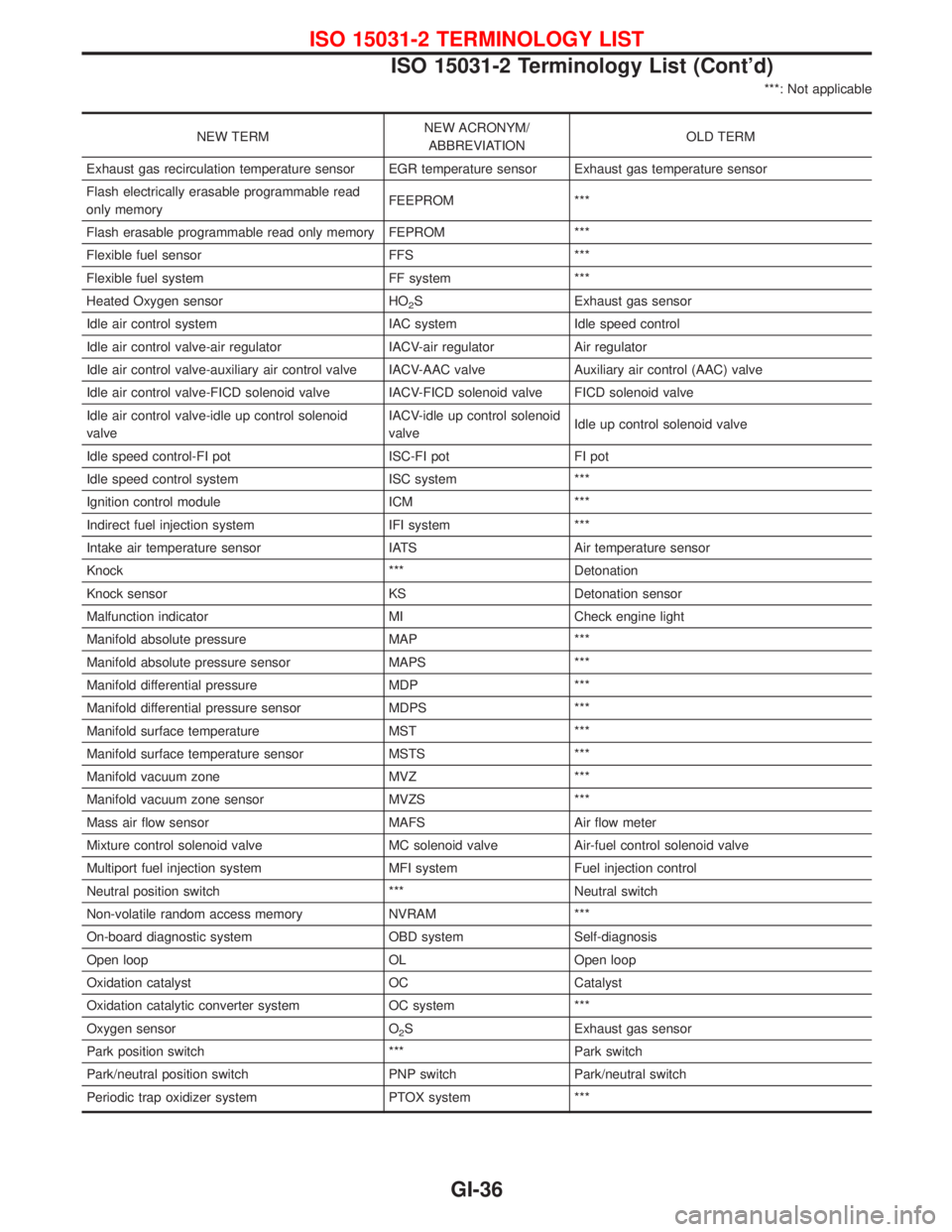

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATIONOLD TERM

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO

2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Neutral position switch *** Neutral switch

Non-volatile random access memory NVRAM ***

On-board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O

2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-36