low beam NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 845 of 1767

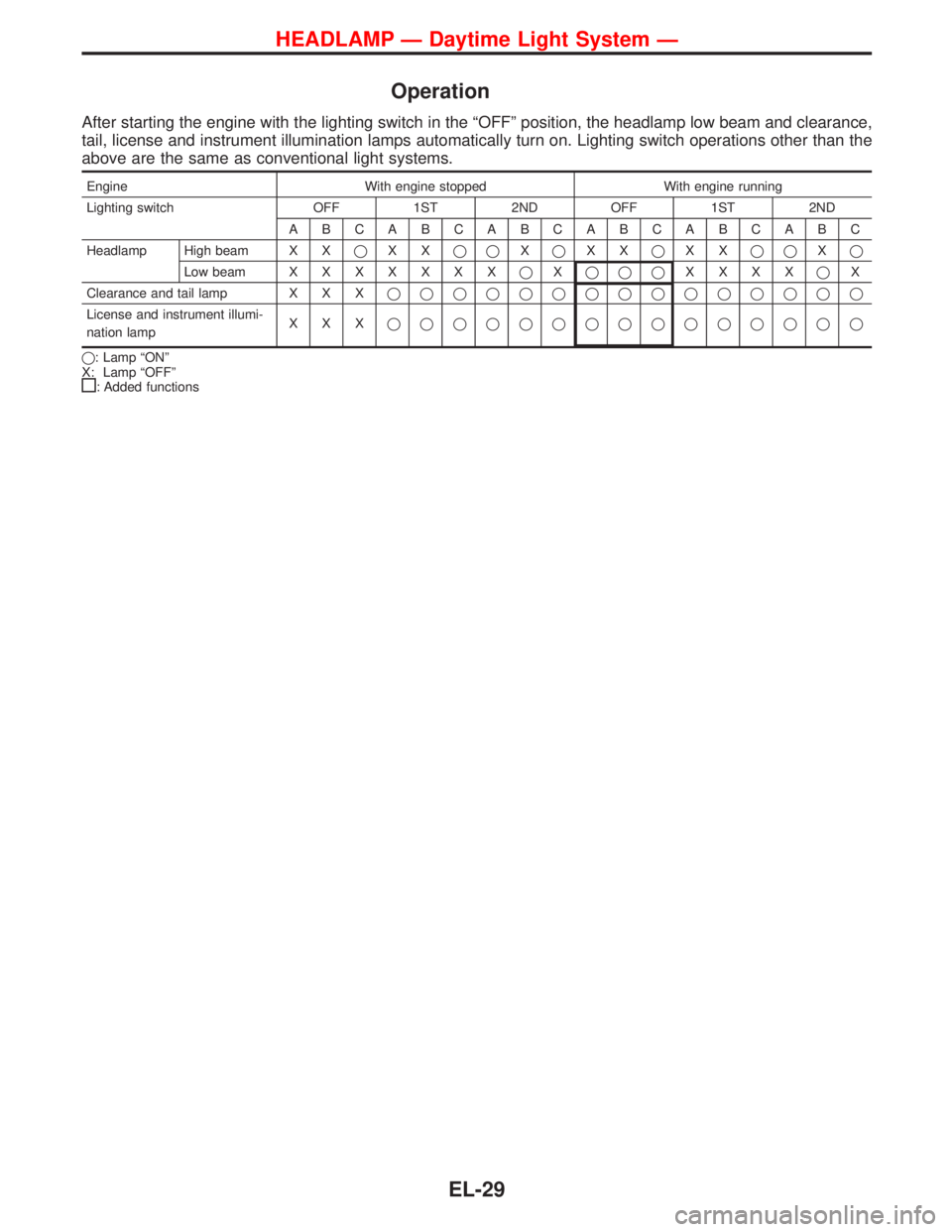

Operation

After starting the engine with the lighting switch in the ªOFFº position, the headlamp low beam and clearance,

tail, license and instrument illumination lamps automatically turn on. Lighting switch operations other than the

above are the same as conventional light systems.

Engine With engine stopped With engine running

Lighting switch OFF 1ST 2ND OFF 1ST 2ND

ABCABCABCABCABCABC

Headlamp High beam X XqXXqqXqXXqXXqqXq

Low beamXXXXXXXqXqqqXXXXqX

Clearance and tail lamp X X Xqqqqqqqqqqqqqqq

License and instrument illumi-

nation lampXXXqqqqqqqqqqqqqqq

q: Lamp ªONº

X: Lamp ªOFFº

: Added functions

HEADLAMP Ð Daytime Light System Ð

EL-29

Page 859 of 1767

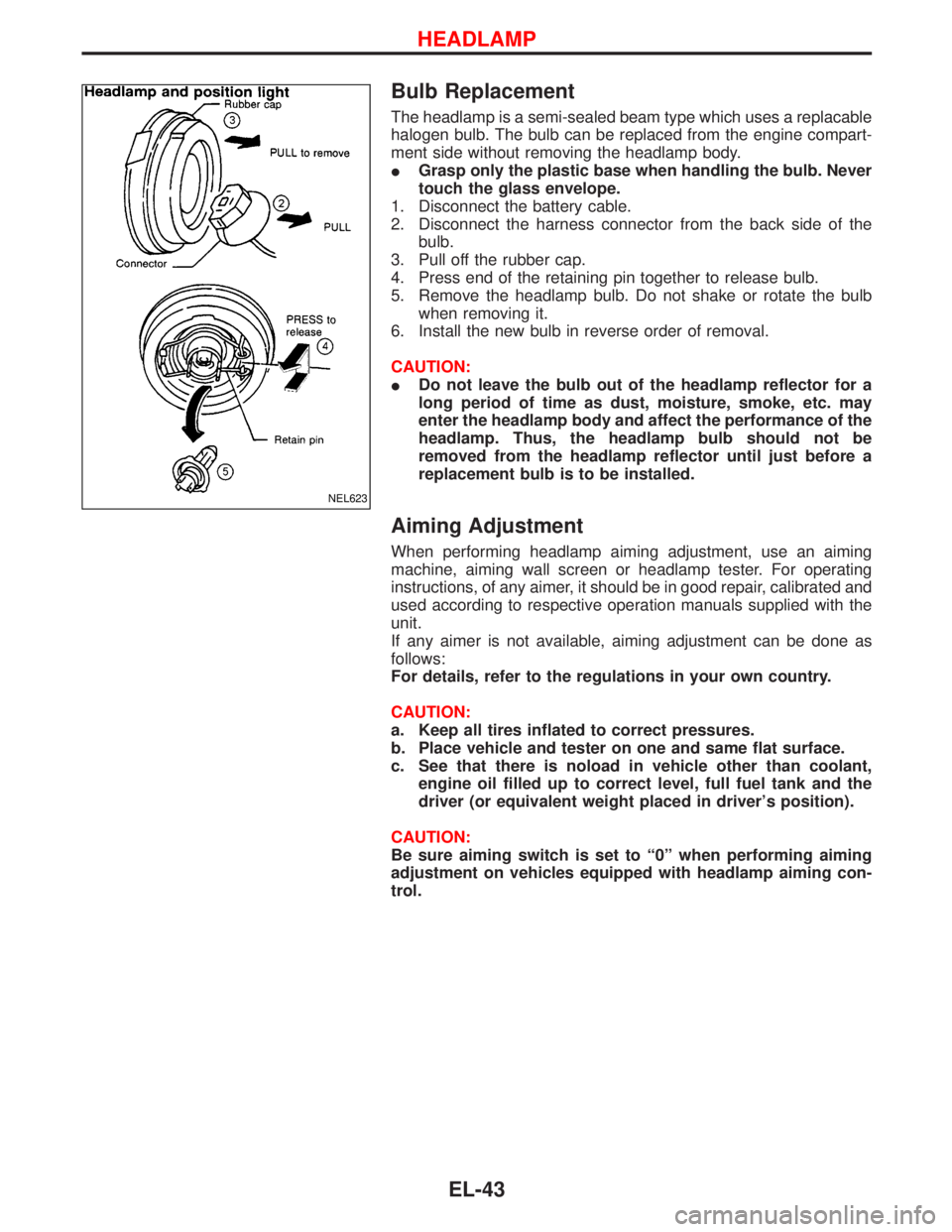

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb

when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

IDo not leave the bulb out of the headlamp reflector for a

long period of time as dust, moisture, smoke, etc. may

enter the headlamp body and affect the performance of the

headlamp. Thus, the headlamp bulb should not be

removed from the headlamp reflector until just before a

replacement bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

CAUTION:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

HEADLAMP

EL-43

Page 860 of 1767

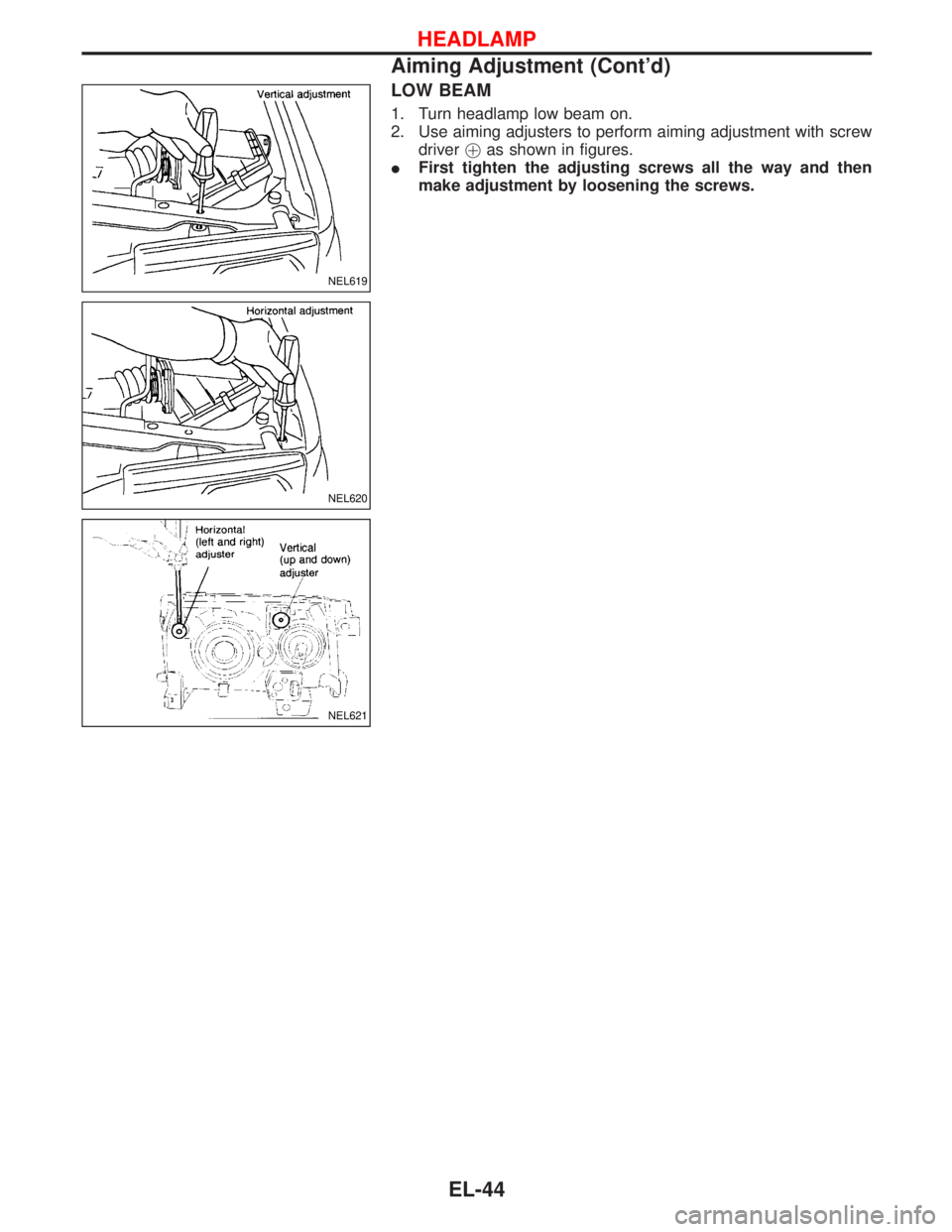

LOW BEAM

1. Turn headlamp low beam on.

2. Use aiming adjusters to perform aiming adjustment with screw

driver!as shown in figures.

IFirst tighten the adjusting screws all the way and then

make adjustment by loosening the screws.

NEL619

NEL620

NEL621

HEADLAMP

Aiming Adjustment (Cont'd)

EL-44

Page 869 of 1767

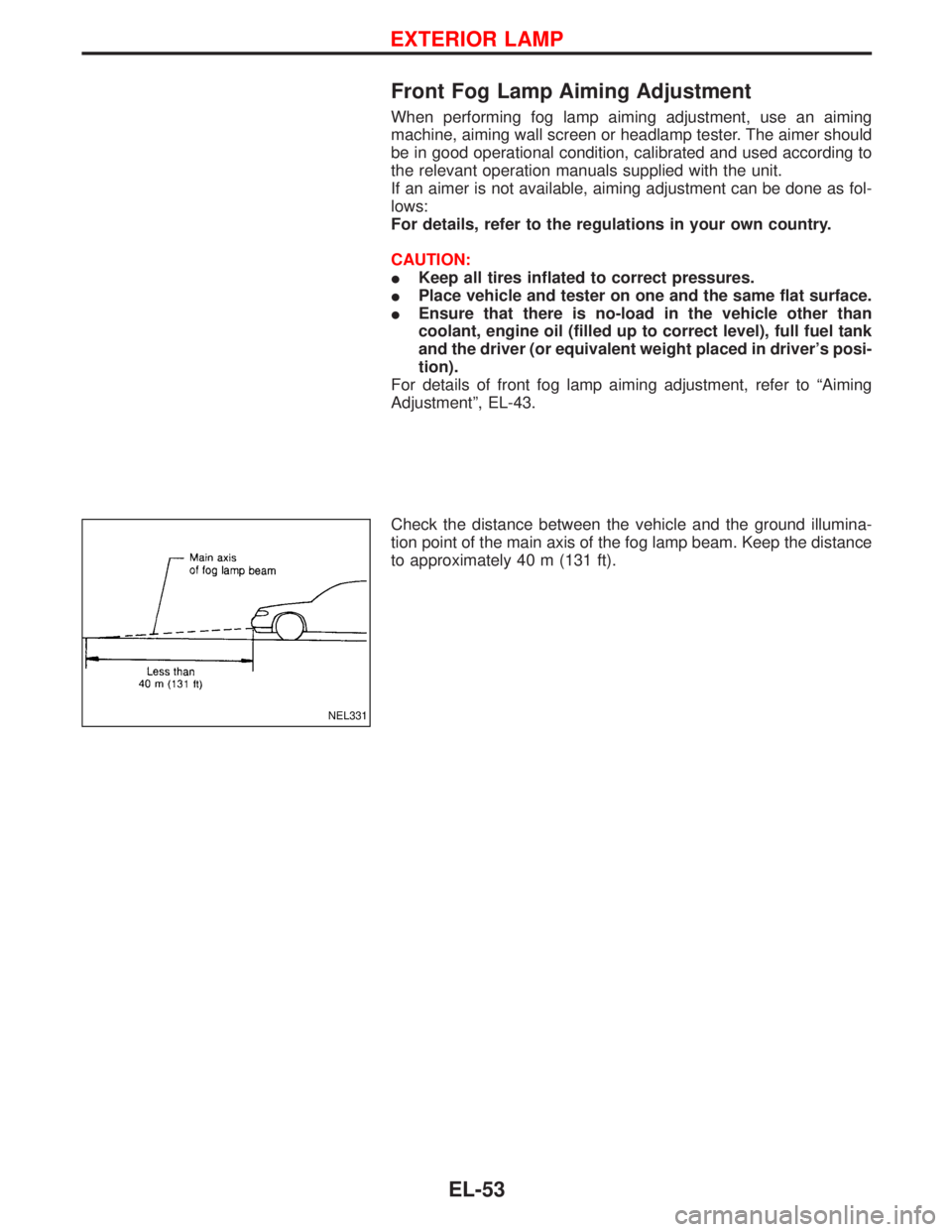

Front Fog Lamp Aiming Adjustment

When performing fog lamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. The aimer should

be in good operational condition, calibrated and used according to

the relevant operation manuals supplied with the unit.

If an aimer is not available, aiming adjustment can be done as fol-

lows:

For details, refer to the regulations in your own country.

CAUTION:

IKeep all tires inflated to correct pressures.

IPlace vehicle and tester on one and the same flat surface.

IEnsure that there is no-load in the vehicle other than

coolant, engine oil (filled up to correct level), full fuel tank

and the driver (or equivalent weight placed in driver's posi-

tion).

For details of front fog lamp aiming adjustment, refer to ªAiming

Adjustmentº, EL-43.

Check the distance between the vehicle and the ground illumina-

tion point of the main axis of the fog lamp beam. Keep the distance

to approximately 40 m (131 ft).

NEL331

EXTERIOR LAMP

EL-53

Page 876 of 1767

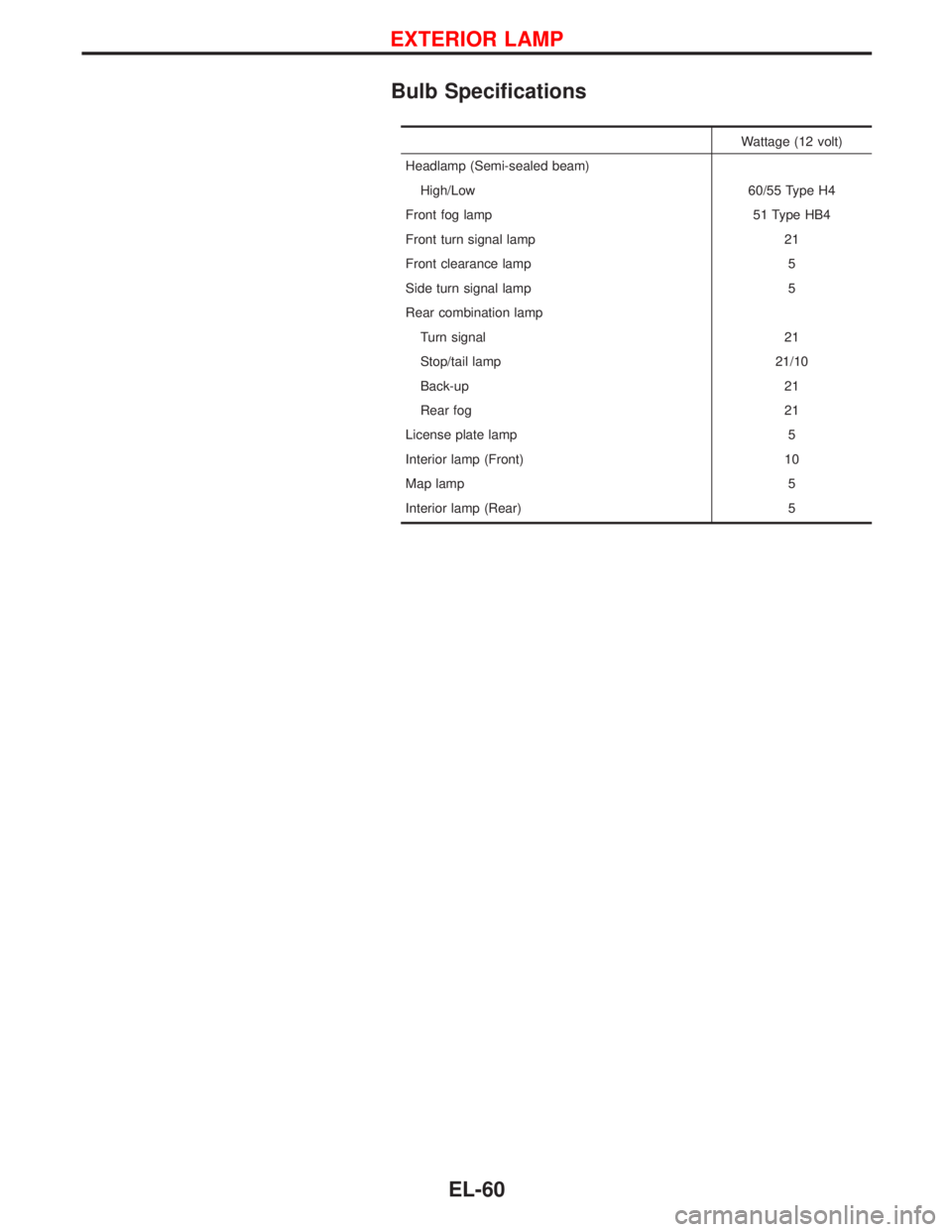

Bulb Specifications

Wattage (12 volt)

Headlamp (Semi-sealed beam)

High/Low 60/55 Type H4

Front fog lamp 51 Type HB4

Front turn signal lamp 21

Front clearance lamp 5

Side turn signal lamp 5

Rear combination lamp

Turn signal 21

Stop/tail lamp 21/10

Back-up 21

Rear fog 21

License plate lamp 5

Interior lamp (Front) 10

Map lamp 5

Interior lamp (Rear) 5

EXTERIOR LAMP

EL-60

Page 1178 of 1767

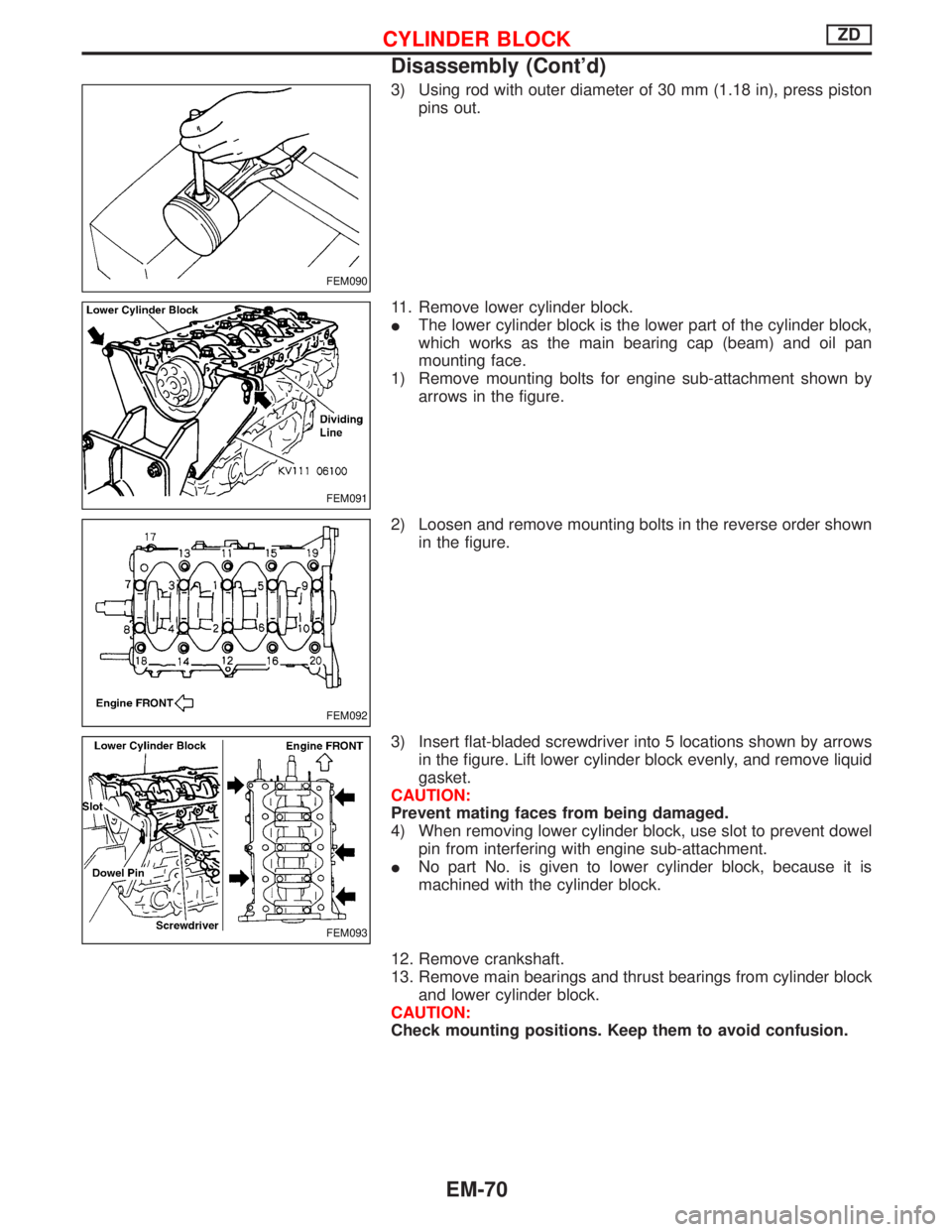

3) Using rod with outer diameter of 30 mm (1.18 in), press piston

pins out.

11. Remove lower cylinder block.

IThe lower cylinder block is the lower part of the cylinder block,

which works as the main bearing cap (beam) and oil pan

mounting face.

1) Remove mounting bolts for engine sub-attachment shown by

arrows in the figure.

2) Loosen and remove mounting bolts in the reverse order shown

in the figure.

3) Insert flat-bladed screwdriver into 5 locations shown by arrows

in the figure. Lift lower cylinder block evenly, and remove liquid

gasket.

CAUTION:

Prevent mating faces from being damaged.

4) When removing lower cylinder block, use slot to prevent dowel

pin from interfering with engine sub-attachment.

INo part No. is given to lower cylinder block, because it is

machined with the cylinder block.

12. Remove crankshaft.

13. Remove main bearings and thrust bearings from cylinder block

and lower cylinder block.

CAUTION:

Check mounting positions. Keep them to avoid confusion.

FEM090

FEM091

FEM092

FEM093

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-70