Ignition NISSAN TERRANO 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 87 of 1767

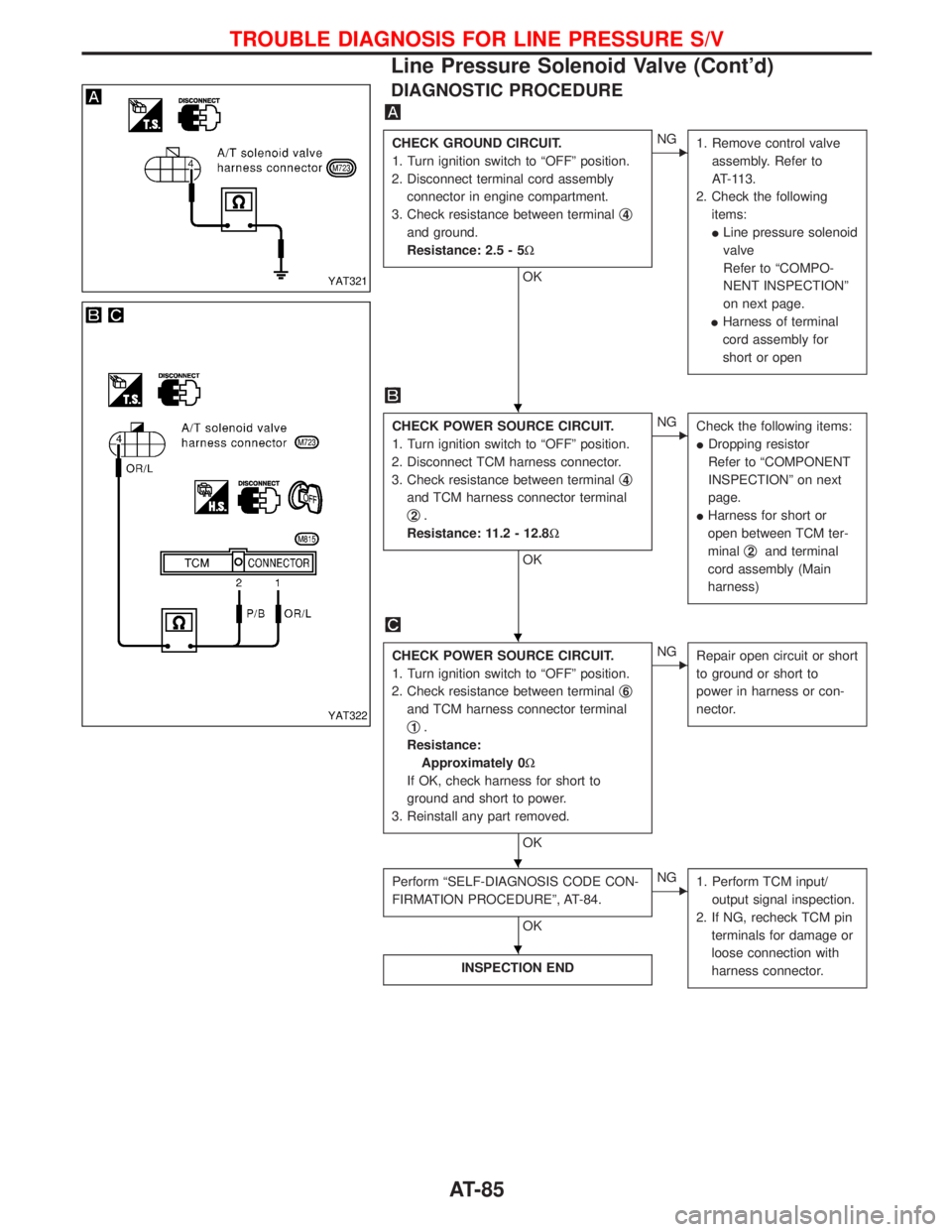

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

4

and ground.

Resistance: 2.5 - 5W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

ILine pressure solenoid

valve

Refer to ªCOMPO-

NENT INSPECTIONº

on next page.

IHarness of terminal

cord assembly for

short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

4

and TCM harness connector terminal

q

2.

Resistance: 11.2 - 12.8W

OK

ENG

Check the following items:

IDropping resistor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness for short or

open between TCM ter-

minalq

2and terminal

cord assembly (Main

harness)

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Check resistance between terminalq

6

and TCM harness connector terminal

q

1.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

3. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-84.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT321

YAT322

H

H

H

H

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-85

Page 91 of 1767

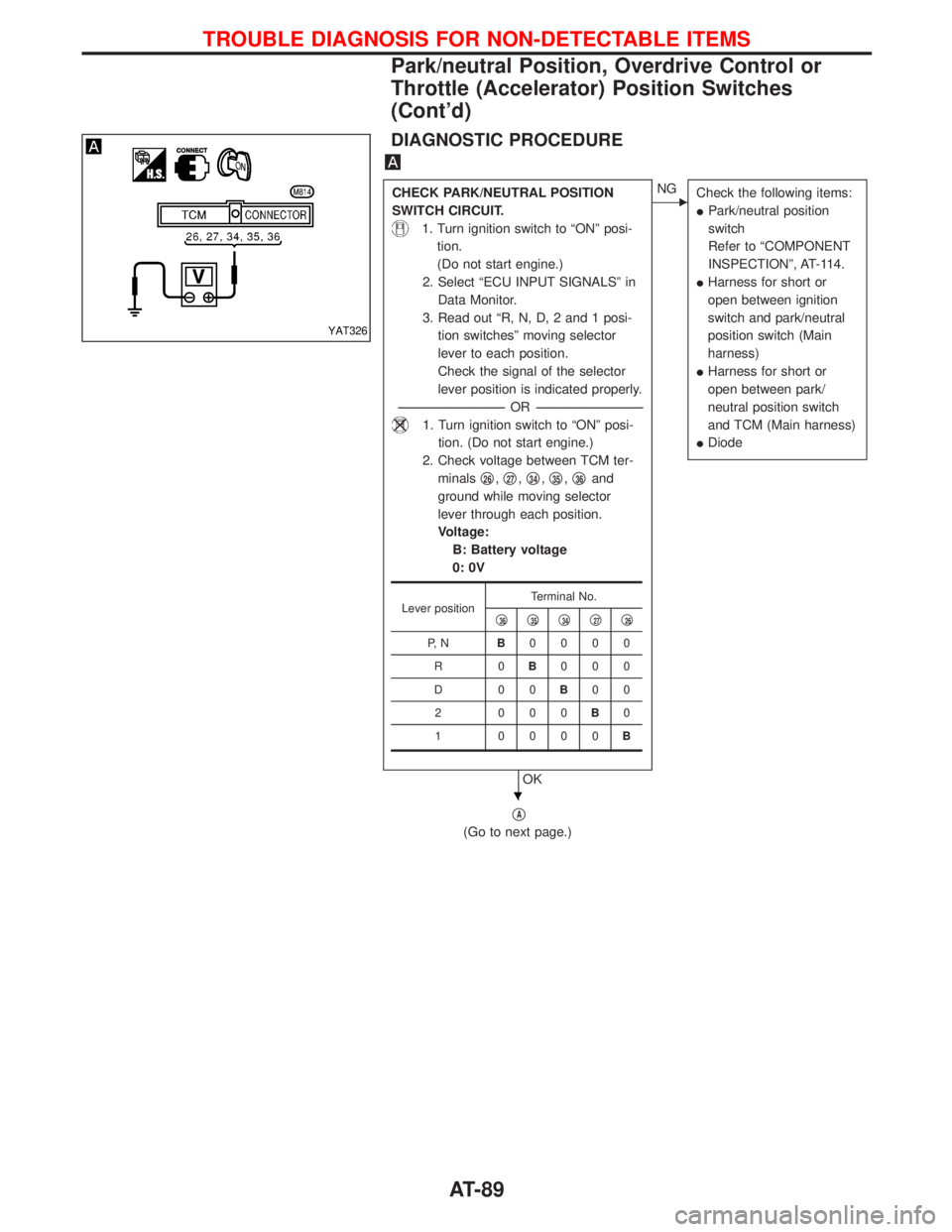

DIAGNOSTIC PROCEDURE

CHECK PARK/NEUTRAL POSITION

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªR, N, D, 2 and 1 posi-

tion switchesº moving selector

lever to each position.

Check the signal of the selector

lever position is indicated properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter-

minalsq

26,q27,q34,q35,q36and

ground while moving selector

lever through each position.

Voltage:

B: Battery voltage

0: 0V

OK

ENG

Check the following items:

IPark/neutral position

switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and park/neutral

position switch (Main

harness)

IHarness for short or

open between park/

neutral position switch

and TCM (Main harness)

IDiode

qA

(Go to next page.)

Lever positionTerminal No.

q36q35q34q27q26

P, NB0000

R0B000

D00B00

2 000B0

1 0000B

YAT326

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-89

Page 92 of 1767

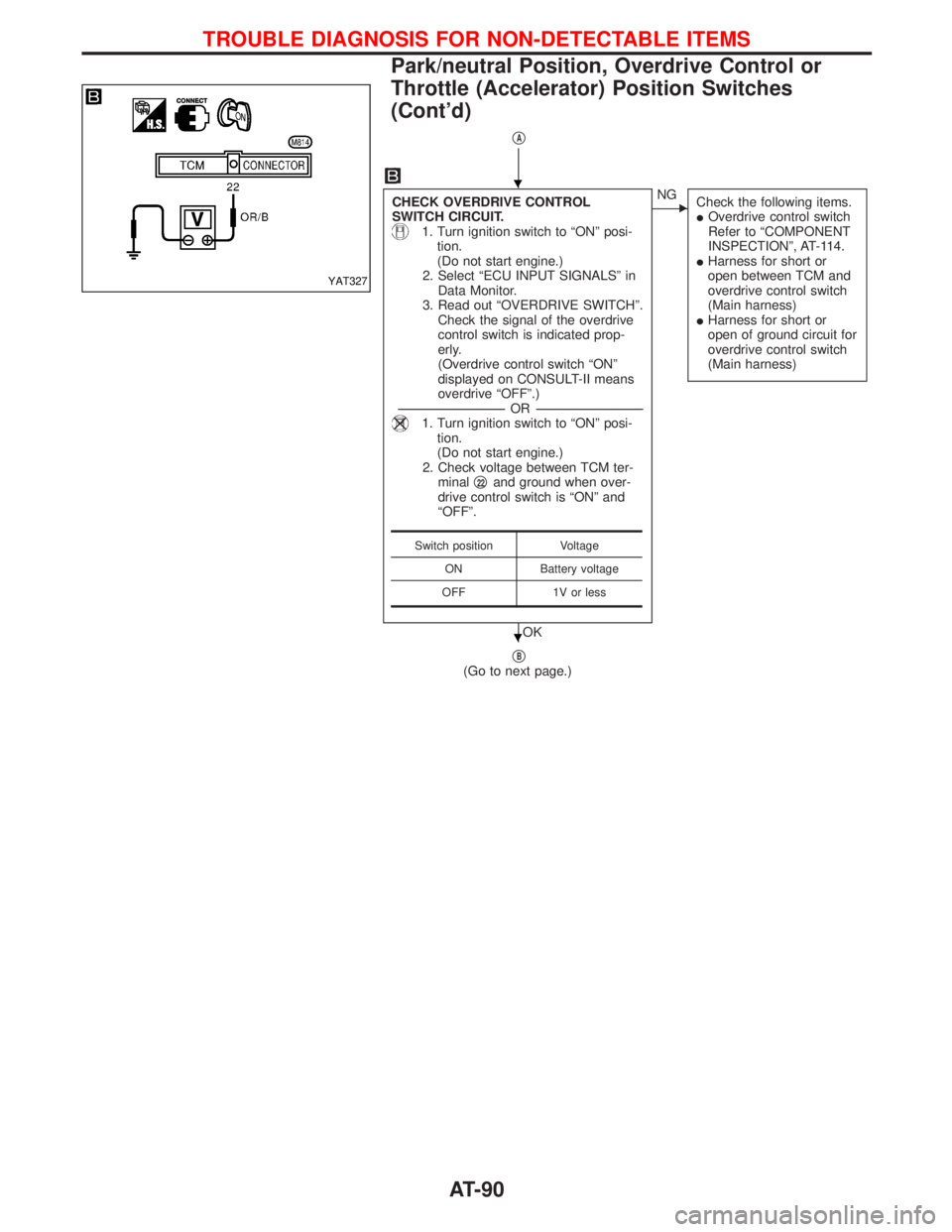

qA

CHECK OVERDRIVE CONTROL

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªOVERDRIVE SWITCHº.

Check the signal of the overdrive

control switch is indicated prop-

erly.

(Overdrive control switch ªONº

displayed on CONSULT-II means

overdrive ªOFFº.)

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalq

22and ground when over-

drive control switch is ªONº and

ªOFFº.

OK

ENG

Check the following items.

IOverdrive control switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between TCM and

overdrive control switch

(Main harness)

IHarness for short or

open of ground circuit for

overdrive control switch

(Main harness)

qB(Go to next page.)

Switch position Voltage

ON Battery voltage

OFF 1V or less

YAT327

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-90

Page 93 of 1767

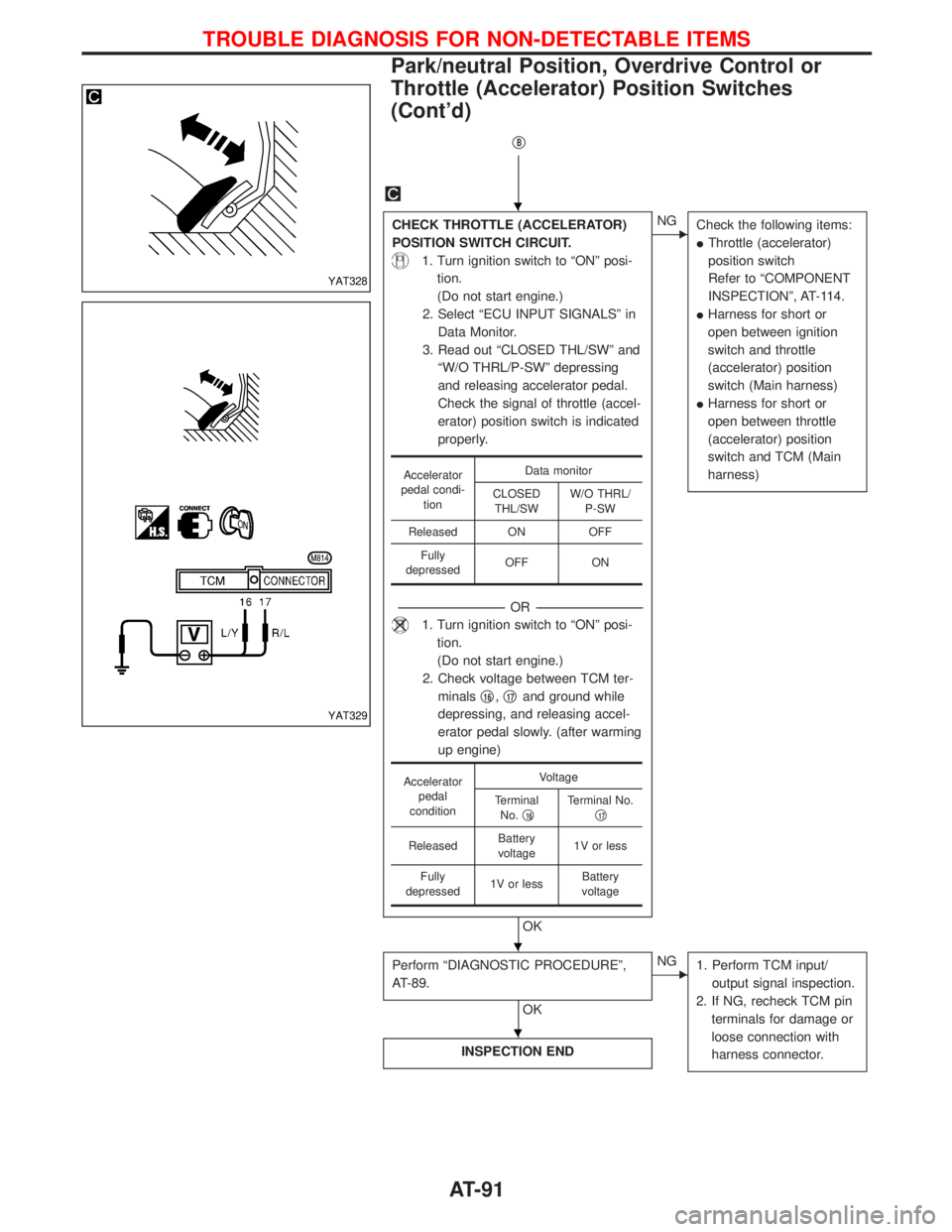

qB

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªCLOSED THL/SWº and

ªW/O THRL/P-SWº depressing

and releasing accelerator pedal.

Check the signal of throttle (accel-

erator) position switch is indicated

properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalsq

16,q17and ground while

depressing, and releasing accel-

erator pedal slowly. (after warming

up engine)

OK

ENG

Check the following items:

IThrottle (accelerator)

position switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and throttle

(accelerator) position

switch (Main harness)

IHarness for short or

open between throttle

(accelerator) position

switch and TCM (Main

harness)

Perform ªDIAGNOSTIC PROCEDUREº,

AT-89.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

Accelerator

pedal condi-

tionData monitor

CLOSED

THL/SWW/O THRL/

P-SW

Released ON OFF

Fully

depressedOFF ON

Accelerator

pedal

conditionVoltage

Terminal

No.q

16Terminal No.

q17

ReleasedBattery

voltage1V or less

Fully

depressed1V or lessBattery

voltage

YAT328

YAT329

H

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-91

Page 95 of 1767

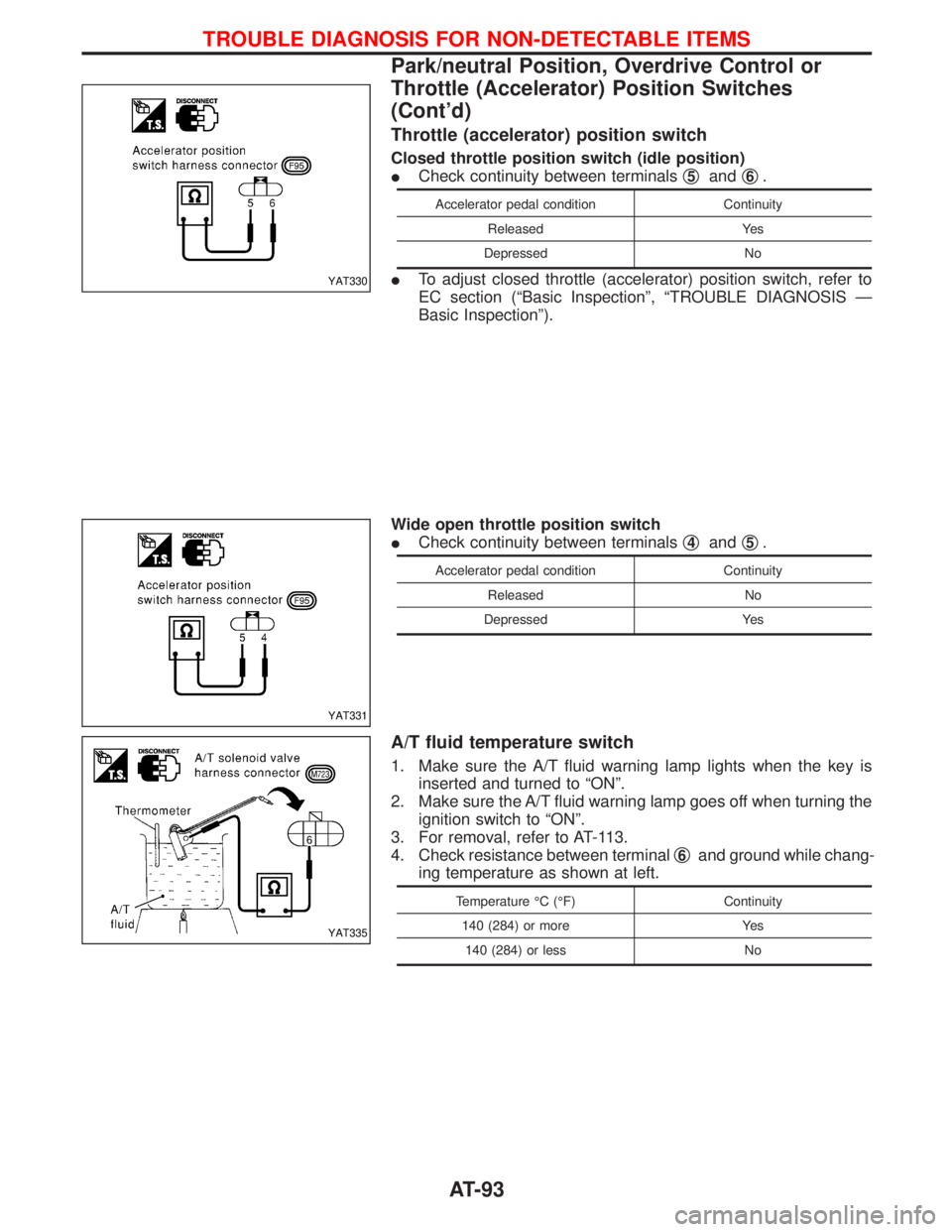

Throttle (accelerator) position switch

Closed throttle position switch (idle position)

ICheck continuity between terminalsq

5andq6.

Accelerator pedal condition Continuity

Released Yes

Depressed No

ITo adjust closed throttle (accelerator) position switch, refer to

EC section (ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð

Basic Inspectionº).

Wide open throttle position switch

ICheck continuity between terminalsq

4andq5.

Accelerator pedal condition Continuity

Released No

Depressed Yes

A/T fluid temperature switch

1. Make sure the A/T fluid warning lamp lights when the key is

inserted and turned to ªONº.

2. Make sure the A/T fluid warning lamp goes off when turning the

ignition switch to ªONº.

3. For removal, refer to AT-113.

4. Check resistance between terminalq

6and ground while chang-

ing temperature as shown at left.

Temperature ÉC (ÉF) Continuity

140 (284) or more Yes

140 (284) or less No

YAT330

YAT331

YAT335

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-93

Page 96 of 1767

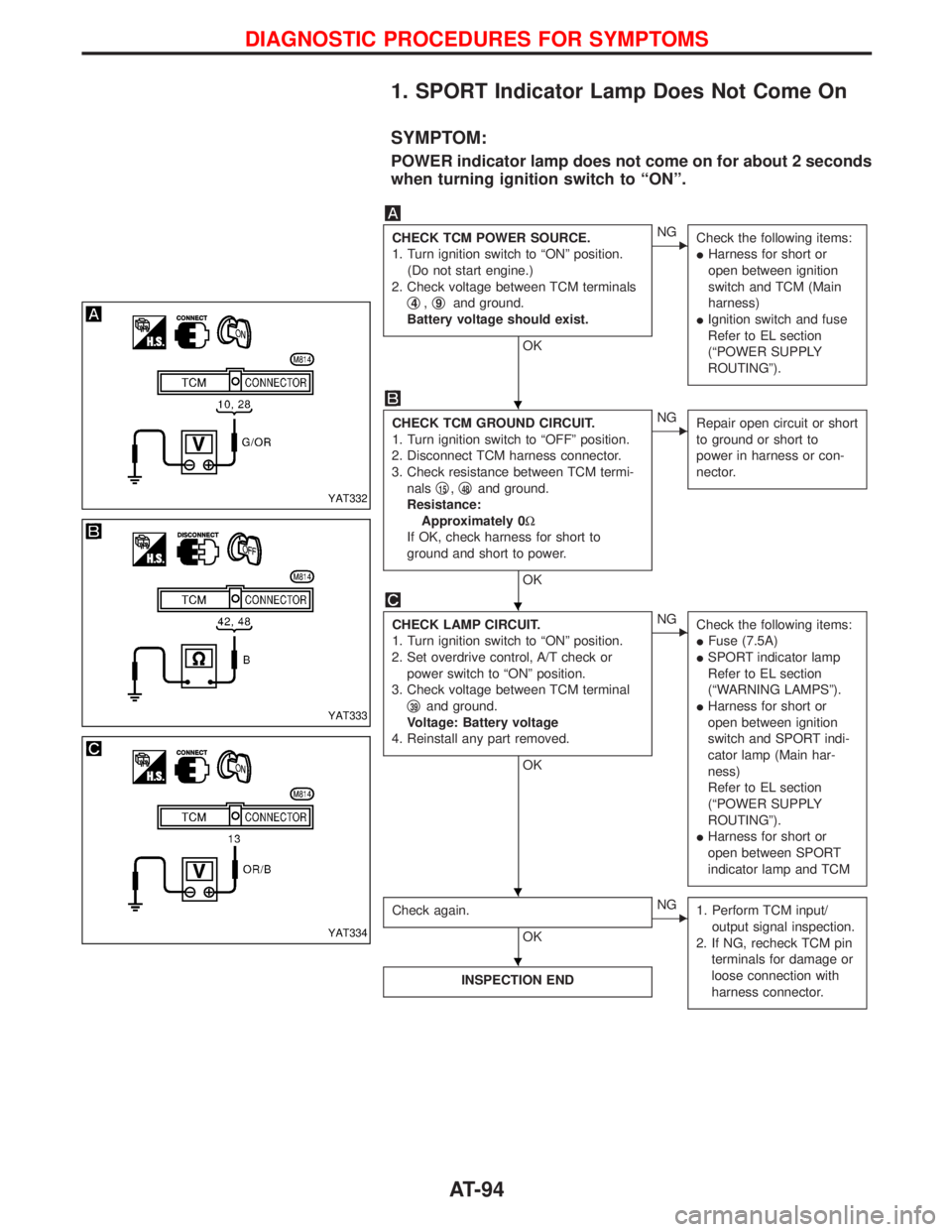

1. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

POWER indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

4,q9and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK TCM GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between TCM termi-

nalsq

15,q48and ground.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

CHECK LAMP CIRCUIT.

1. Turn ignition switch to ªONº position.

2. Set overdrive control, A/T check or

power switch to ªONº position.

3. Check voltage between TCM terminal

q

39and ground.

Voltage: Battery voltage

4. Reinstall any part removed.

OK

ENG

Check the following items:

IFuse (7.5A)

ISPORT indicator lamp

Refer to EL section

(ªWARNING LAMPSº).

IHarness for short or

open between ignition

switch and SPORT indi-

cator lamp (Main har-

ness)

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

IHarness for short or

open between SPORT

indicator lamp and TCM

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT332

YAT333

YAT334

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-94

Page 97 of 1767

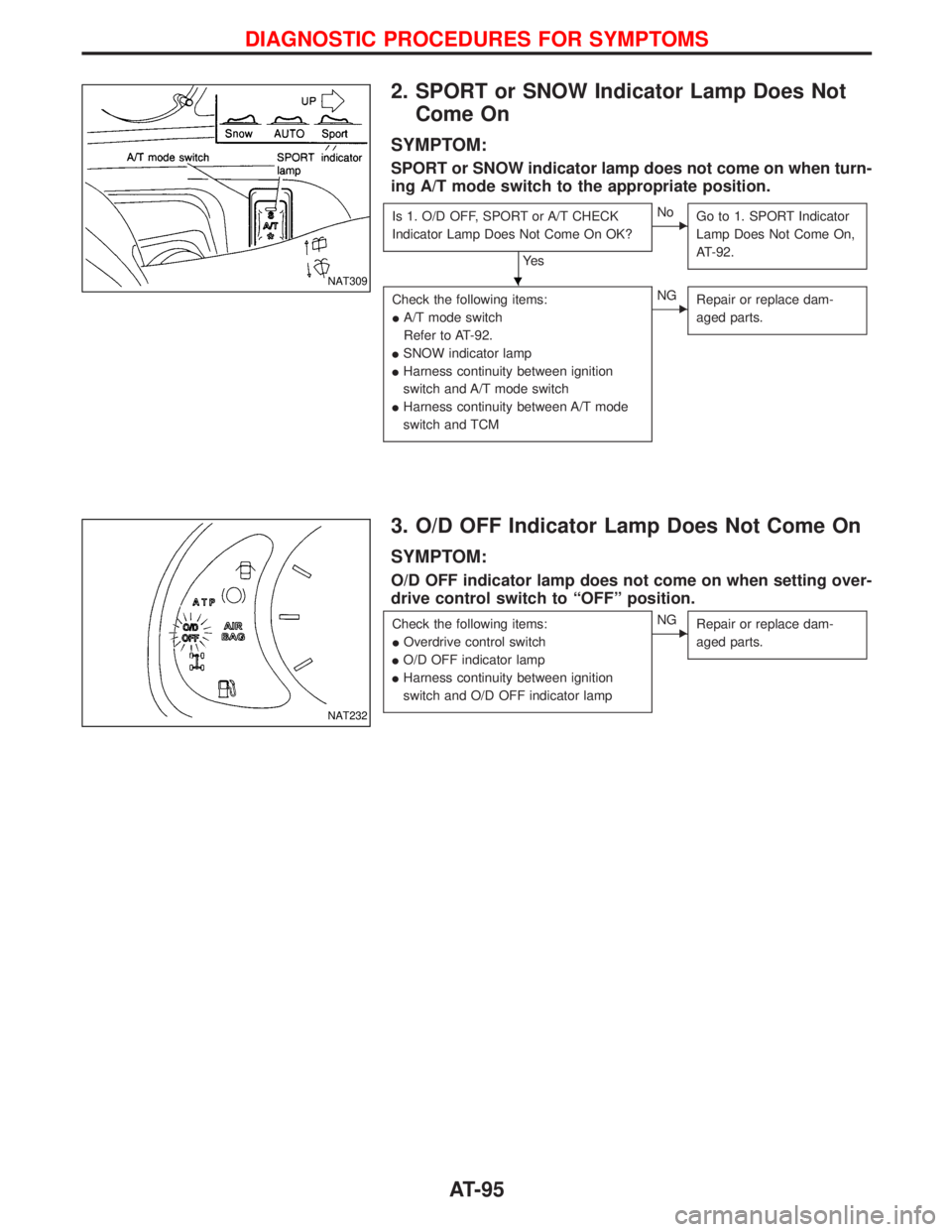

2. SPORT or SNOW Indicator Lamp Does Not

Come On

SYMPTOM:

SPORT or SNOW indicator lamp does not come on when turn-

ing A/T mode switch to the appropriate position.

Is 1. O/D OFF, SPORT or A/T CHECK

Indicator Lamp Does Not Come On OK?

Ye s

ENo

Go to 1. SPORT Indicator

Lamp Does Not Come On,

AT-92.

Check the following items:

IA/T mode switch

Refer to AT-92.

ISNOW indicator lamp

IHarness continuity between ignition

switch and A/T mode switch

IHarness continuity between A/T mode

switch and TCMENG

Repair or replace dam-

aged parts.

3. O/D OFF Indicator Lamp Does Not Come On

SYMPTOM:

O/D OFF indicator lamp does not come on when setting over-

drive control switch to ªOFFº position.

Check the following items:

IOverdrive control switch

IO/D OFF indicator lamp

IHarness continuity between ignition

switch and O/D OFF indicator lampENG

Repair or replace dam-

aged parts.

NAT309

NAT232

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-95

Page 204 of 1767

Diagnostic Procedure 2 (Warning lamp stays on

when ignition switch is turned ON)............................69

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) .................................71

Diagnostic Procedure 4 (Wheel sensor or rotor) ......73

Diagnostic Procedure 5 (Motor Relay or motor) .......75

Diagnostic Procedure 7 (Low voltage) ......................77

Diagnostic Procedure 8 (G sensor) ...........................78

Diagnostic Procedure 9 (Control unit) .......................79

Diagnostic Procedure 10 (Pedal vibration and

noise) .........................................................................80Diagnostic Procedure 11 (Long stopping

distance) ....................................................................80

Diagnostic Procedure 12 (Unexpected pedal

action) ........................................................................81

Diagnostic Procedure 13 ...........................................82

Diagnostic Procedure 14 ...........................................82

Electrical Components Inspection .............................83

SERVICE DATA AND SPECIFICATIONS (SDS)..........84

General Specifications ...............................................84

Inspection and Adjustment ........................................85

CONTENTS(Cont'd)

BR-2

Page 210 of 1767

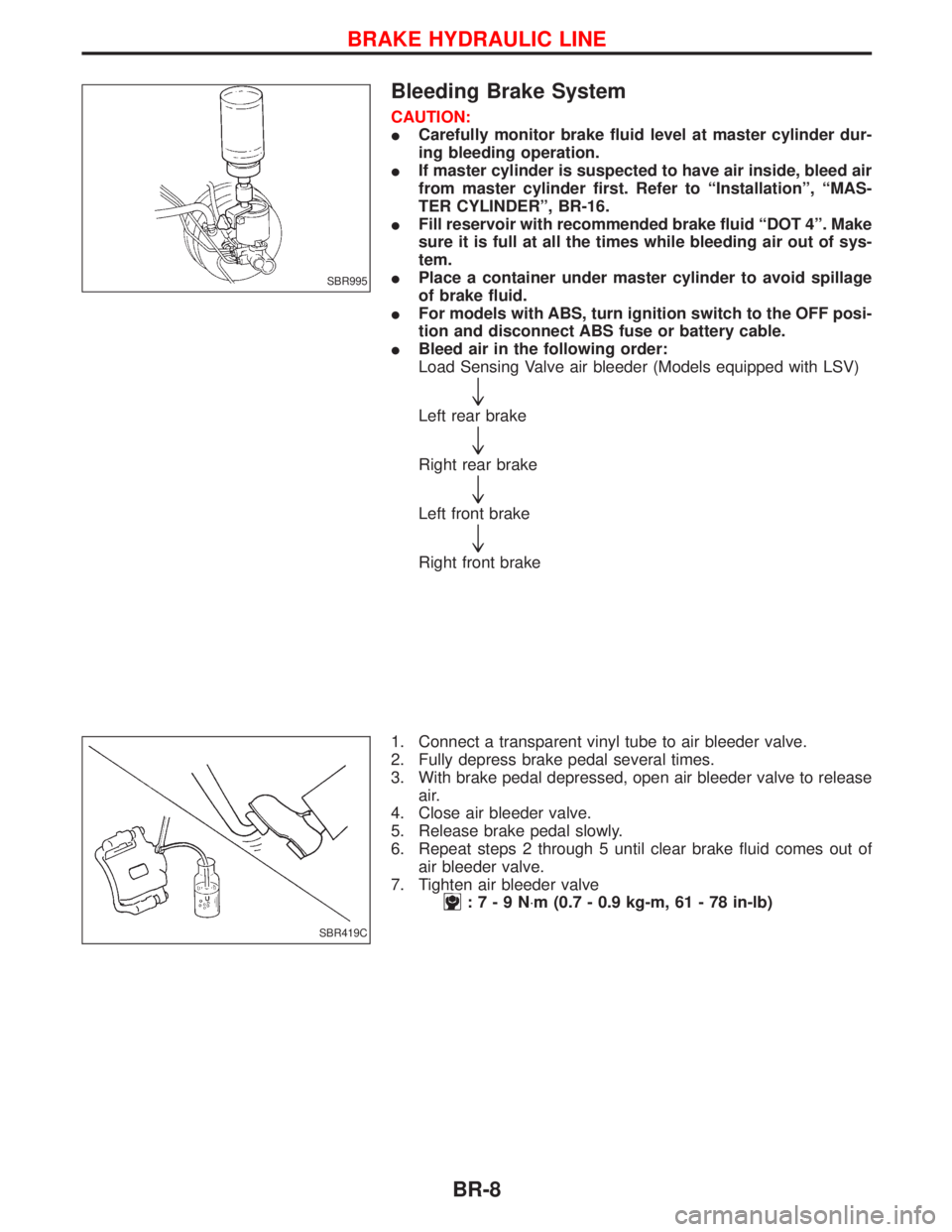

Bleeding Brake System

CAUTION:

ICarefully monitor brake fluid level at master cylinder dur-

ing bleeding operation.

IIf master cylinder is suspected to have air inside, bleed air

from master cylinder first. Refer to ªInstallationº, ªMAS-

TER CYLINDERº, BR-16.

IFill reservoir with recommended brake fluid ªDOT 4º. Make

sure it is full at all the times while bleeding air out of sys-

tem.

IPlace a container under master cylinder to avoid spillage

of brake fluid.

IFor models with ABS, turn ignition switch to the OFF posi-

tion and disconnect ABS fuse or battery cable.

IBleed air in the following order:

Load Sensing Valve air bleeder (Models equipped with LSV)

"

Left rear brake

"

Right rear brake

"

Left front brake

"

Right front brake

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2 through 5 until clear brake fluid comes out of

air bleeder valve.

7. Tighten air bleeder valve

:7-9N×m (0.7 - 0.9 kg-m, 61 - 78 in-lb)

SBR995

SBR419C

BRAKE HYDRAULIC LINE

BR-8

Page 239 of 1767

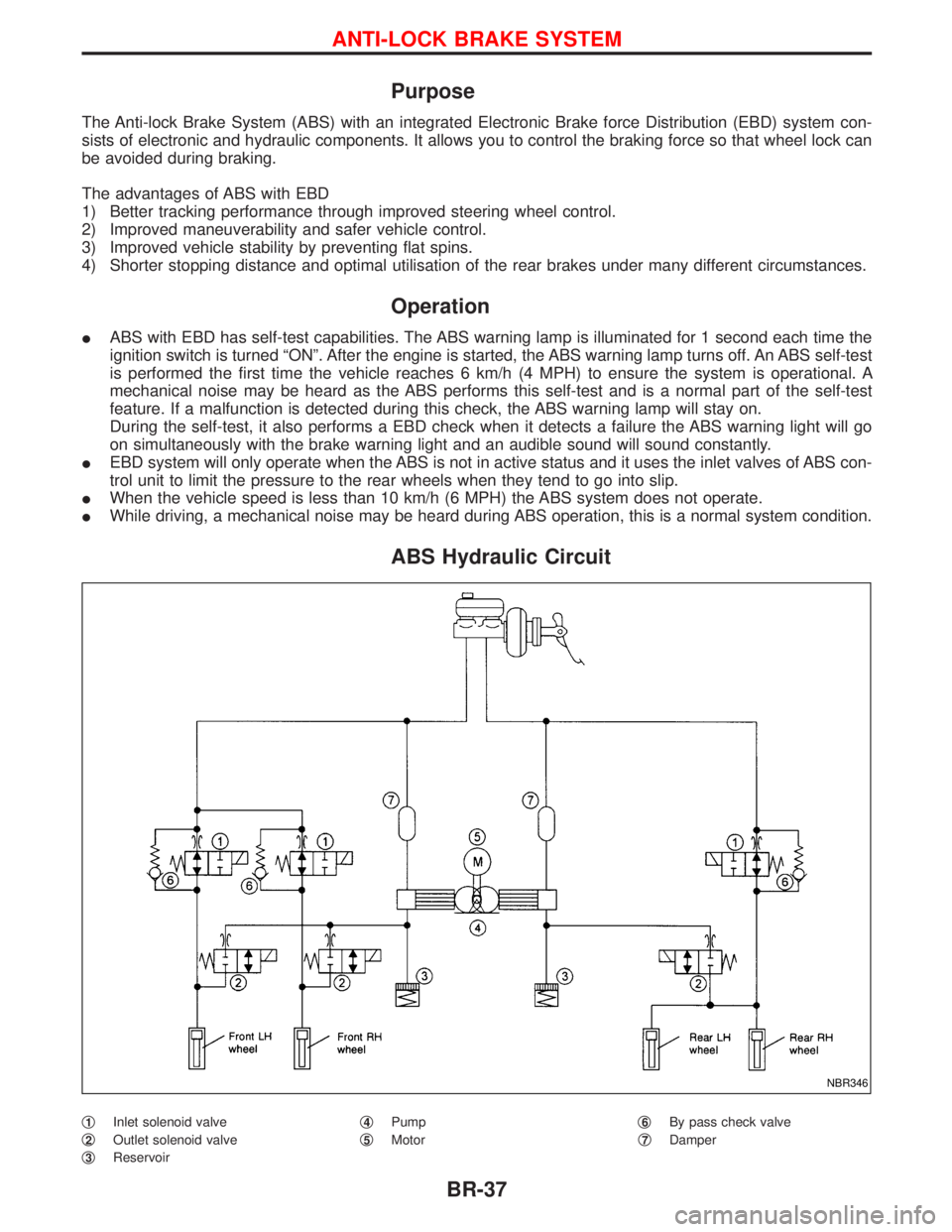

Purpose

The Anti-lock Brake System (ABS) with an integrated Electronic Brake force Distribution (EBD) system con-

sists of electronic and hydraulic components. It allows you to control the braking force so that wheel lock can

be avoided during braking.

The advantages of ABS with EBD

1) Better tracking performance through improved steering wheel control.

2) Improved maneuverability and safer vehicle control.

3) Improved vehicle stability by preventing flat spins.

4) Shorter stopping distance and optimal utilisation of the rear brakes under many different circumstances.

Operation

IABS with EBD has self-test capabilities. The ABS warning lamp is illuminated for 1 second each time the

ignition switch is turned ªONº. After the engine is started, the ABS warning lamp turns off. An ABS self-test

is performed the first time the vehicle reaches 6 km/h (4 MPH) to ensure the system is operational. A

mechanical noise may be heard as the ABS performs this self-test and is a normal part of the self-test

feature. If a malfunction is detected during this check, the ABS warning lamp will stay on.

During the self-test, it also performs a EBD check when it detects a failure the ABS warning light will go

on simultaneously with the brake warning light and an audible sound will sound constantly.

IEBD system will only operate when the ABS is not in active status and it uses the inlet valves of ABS con-

trol unit to limit the pressure to the rear wheels when they tend to go into slip.

IWhen the vehicle speed is less than 10 km/h (6 MPH) the ABS system does not operate.

IWhile driving, a mechanical noise may be heard during ABS operation, this is a normal system condition.

ABS Hydraulic Circuit

q1Inlet solenoid valve

q

2Outlet solenoid valve

q

3Reservoirq

4Pump

q

5Motorq

6By pass check valve

q

7Damper

NBR346

ANTI-LOCK BRAKE SYSTEM

BR-37