Ignition NISSAN TERRANO 2002 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 274 of 1767

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENo

Inspection end

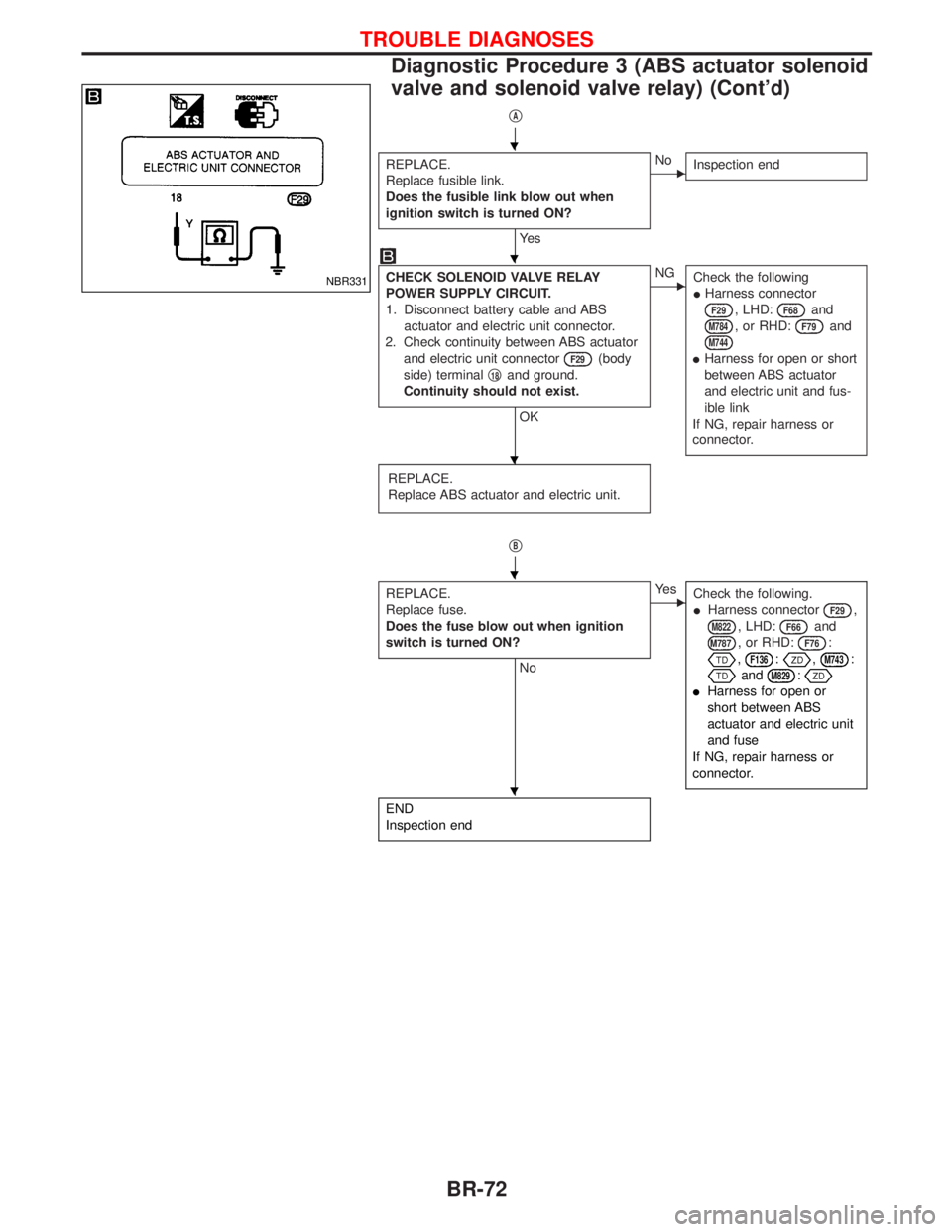

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

18and ground.

Continuity should not exist.

OK

ENG

Check the following

IHarness connector

F29, LHD:F68and

M784, or RHD:F79and

M744

IHarness for open or short

between ABS actuator

and electric unit and fus-

ible link

If NG, repair harness or

connector.

REPLACE.

Replace ABS actuator and electric unit.

qB

REPLACE.

Replace fuse.

Does the fuse blow out when ignition

switch is turned ON?

No

EYe s

Check the following.

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

END

Inspection end

NBR331

H

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) (Cont'd)

BR-72

Page 278 of 1767

qA

REPLACE.

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ON?

Ye s

ENo

Inspection end

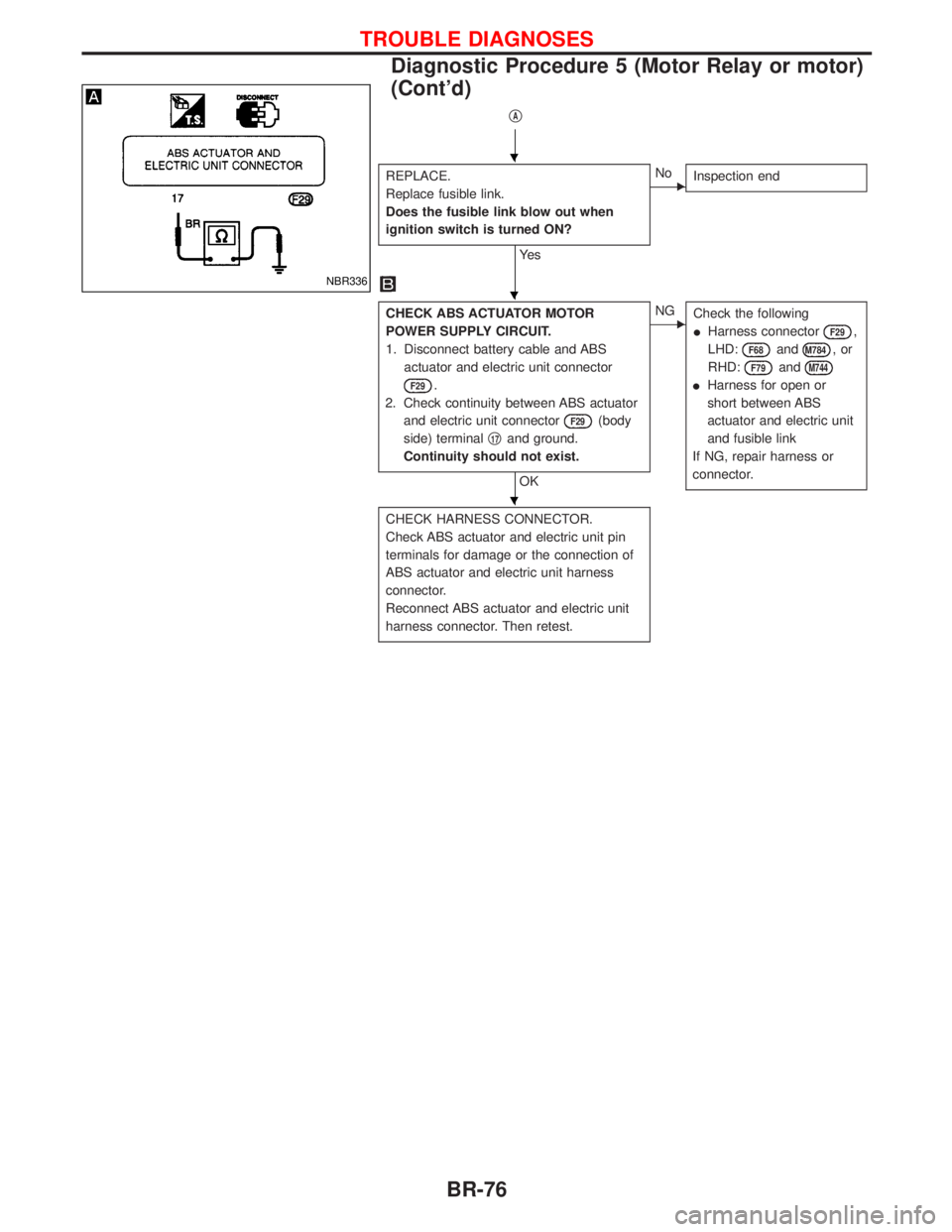

CHECK ABS ACTUATOR MOTOR

POWER SUPPLY CIRCUIT.

1. Disconnect battery cable and ABS

actuator and electric unit connector

F29.

2. Check continuity between ABS actuator

and electric unit connector

F29(body

side) terminalq

17and ground.

Continuity should not exist.

OK

ENG

Check the following

IHarness connector

F29,

LHD:

F68andM784,or

RHD:

F79andM744

IHarness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

NBR336

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 5 (Motor Relay or motor)

(Cont'd)

BR-76

Page 279 of 1767

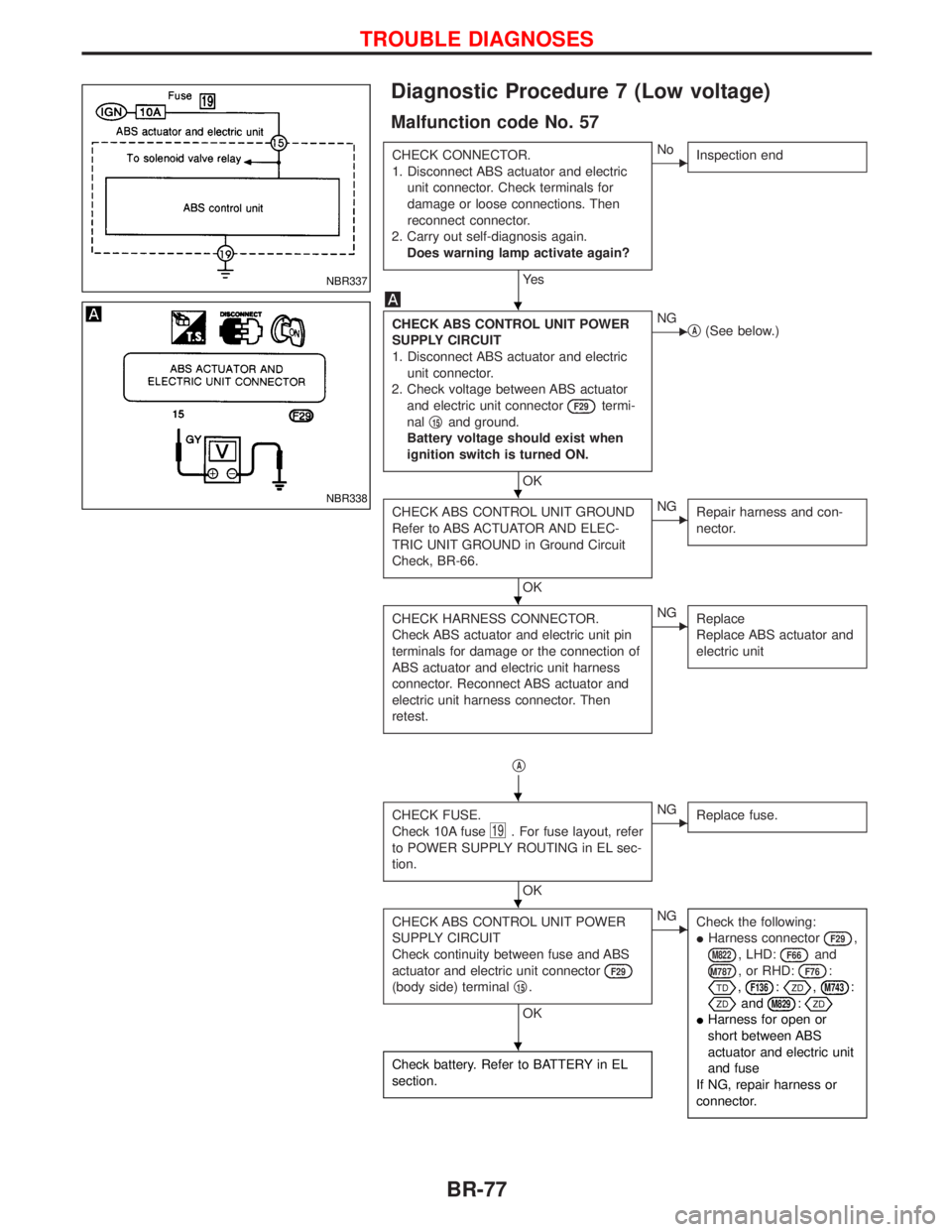

Diagnostic Procedure 7 (Low voltage)

Malfunction code No. 57

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connections. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29termi-

nalq

15and ground.

Battery voltage should exist when

ignition switch is turned ON.

OK

ENG

qA(See below.)

CHECK ABS CONTROL UNIT GROUND

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-66.

OK

ENG

Repair harness and con-

nector.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.ENG

Replace

Replace ABS actuator and

electric unit

qA

CHECK FUSE.

Check 10A fuse

19. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT

Check continuity between fuse and ABS

actuator and electric unit connector

F29

(body side) terminalq15.

OK

ENG

Check the following:

IHarness connector

F29,

M822, LHD:F66and

M787, or RHD:F76:

,F136:,M743:

andM829:

IHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

Check battery. Refer to BATTERY in EL

section.

NBR337

NBR338

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-77

Page 322 of 1767

Removal and Installation

IWhen removing or installing the seat trim, carefully handle it to keep dirt out and avoid damage.

CAUTION:

IBefore removing the front seat, turn the ignition switch off, disconnect both battery cables and wait

at least 3 minutes (models with side air bag).

IDo not drop, tilt, or bump the side air bag module installed in the seat. Always handle it with care.

IDisconnect the side air bag harness connector and heated seat harness connector from under the

seat before removing the seat.

IDisconnect the side air bag harness connector before removing the seatback. Refer to RS-27,

ªFront Side Air Bag Moduleº for details.

FRONT SEAT

BT-34

Page 371 of 1767

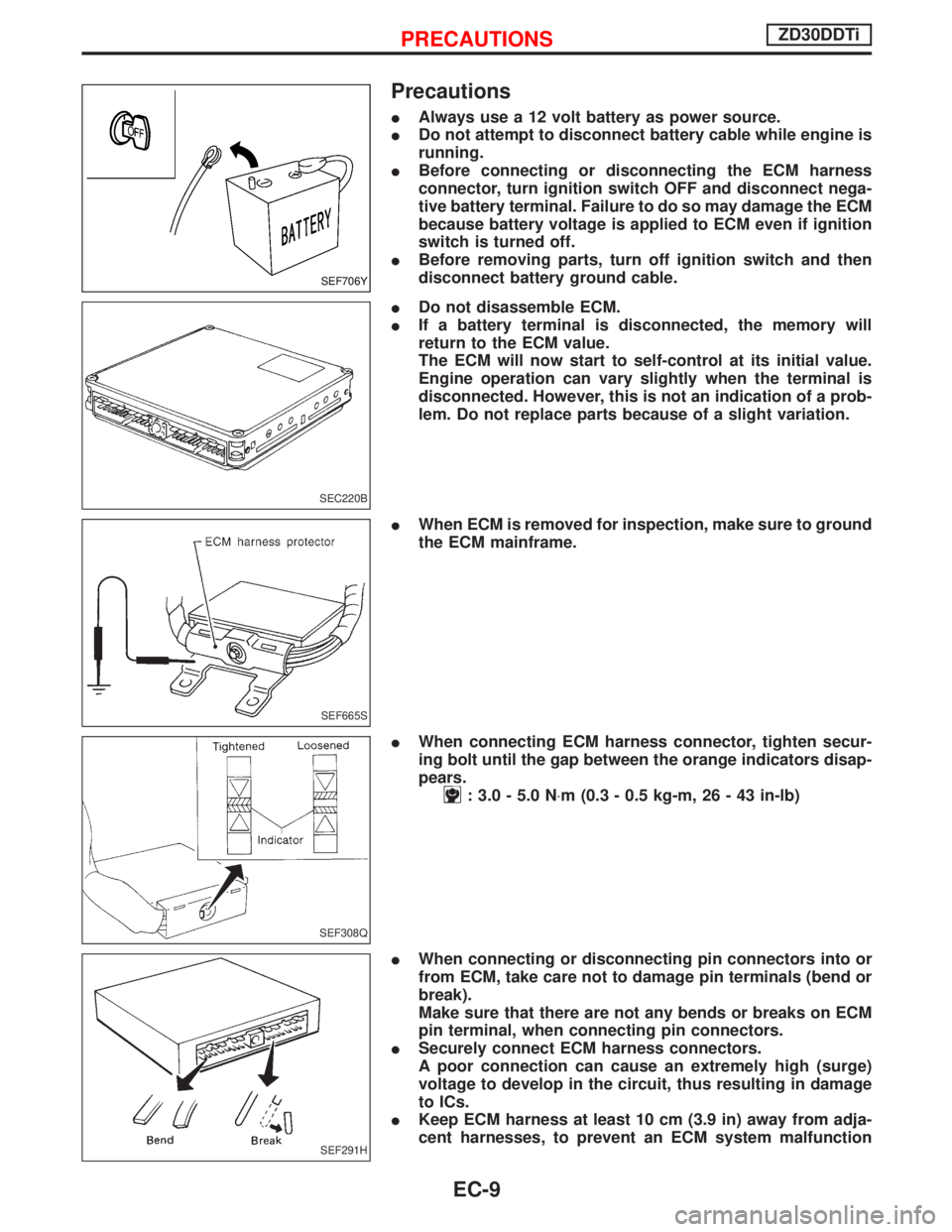

Precautions

IAlways use a 12 volt battery as power source.

IDo not attempt to disconnect battery cable while engine is

running.

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

IBefore removing parts, turn off ignition switch and then

disconnect battery ground cable.

IDo not disassemble ECM.

IIf a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

IWhen ECM is removed for inspection, make sure to ground

the ECM mainframe.

IWhen connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

ISecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

IKeep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

Page 381 of 1767

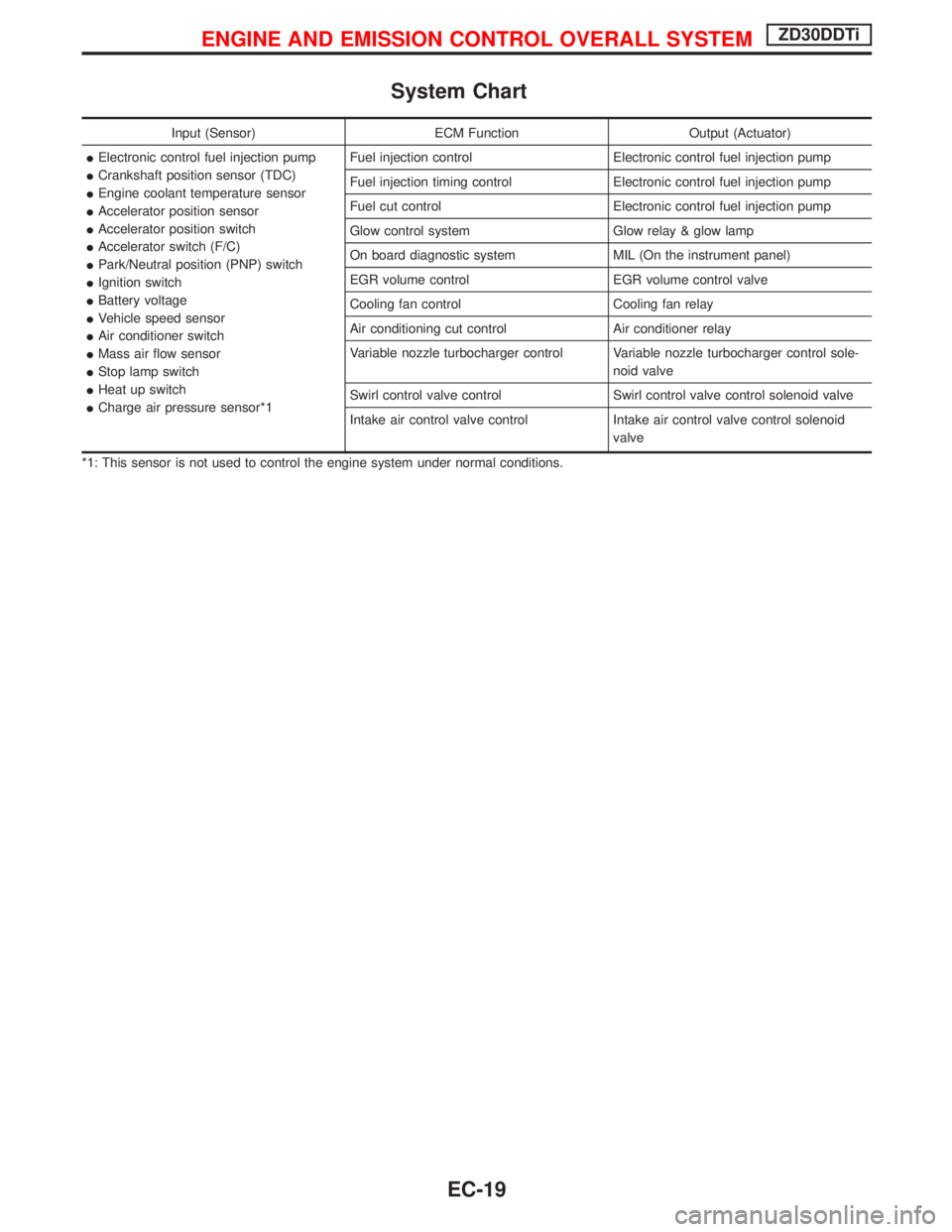

System Chart

Input (Sensor) ECM Function Output (Actuator)

IElectronic control fuel injection pump

ICrankshaft position sensor (TDC)

IEngine coolant temperature sensor

IAccelerator position sensor

IAccelerator position switch

IAccelerator switch (F/C)

IPark/Neutral position (PNP) switch

IIgnition switch

IBattery voltage

IVehicle speed sensor

IAir conditioner switch

IMass air flow sensor

IStop lamp switch

IHeat up switch

ICharge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

*1: This sensor is not used to control the engine system under normal conditions.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-19

Page 382 of 1767

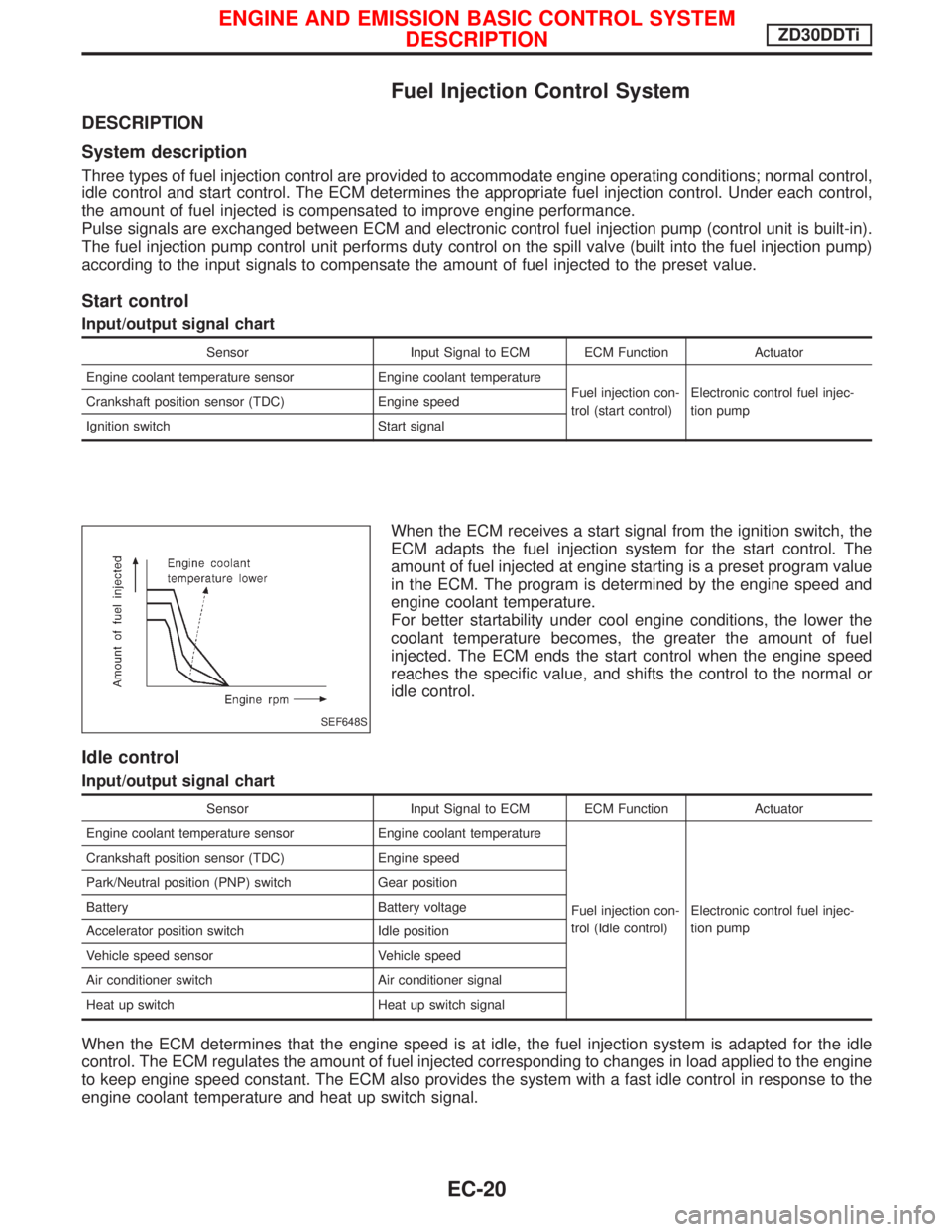

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-in).

The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection pump)

according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or

idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-20

Page 395 of 1767

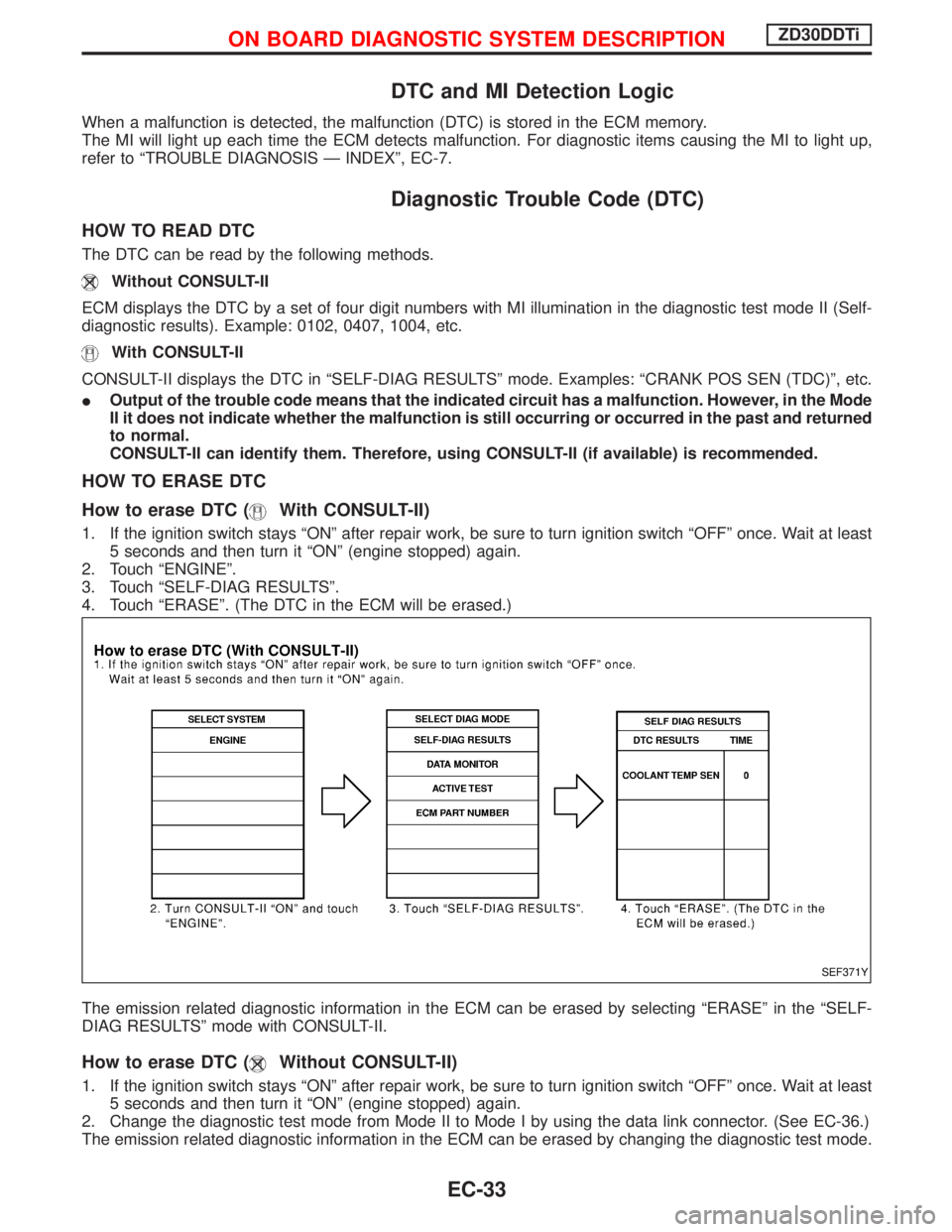

DTC and MI Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

IOutput of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

HOW TO ERASE DTC

How to erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-36.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

SEF371Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-33

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

Page 397 of 1767

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-291.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35