system NISSAN TERRANO 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 210 of 1767

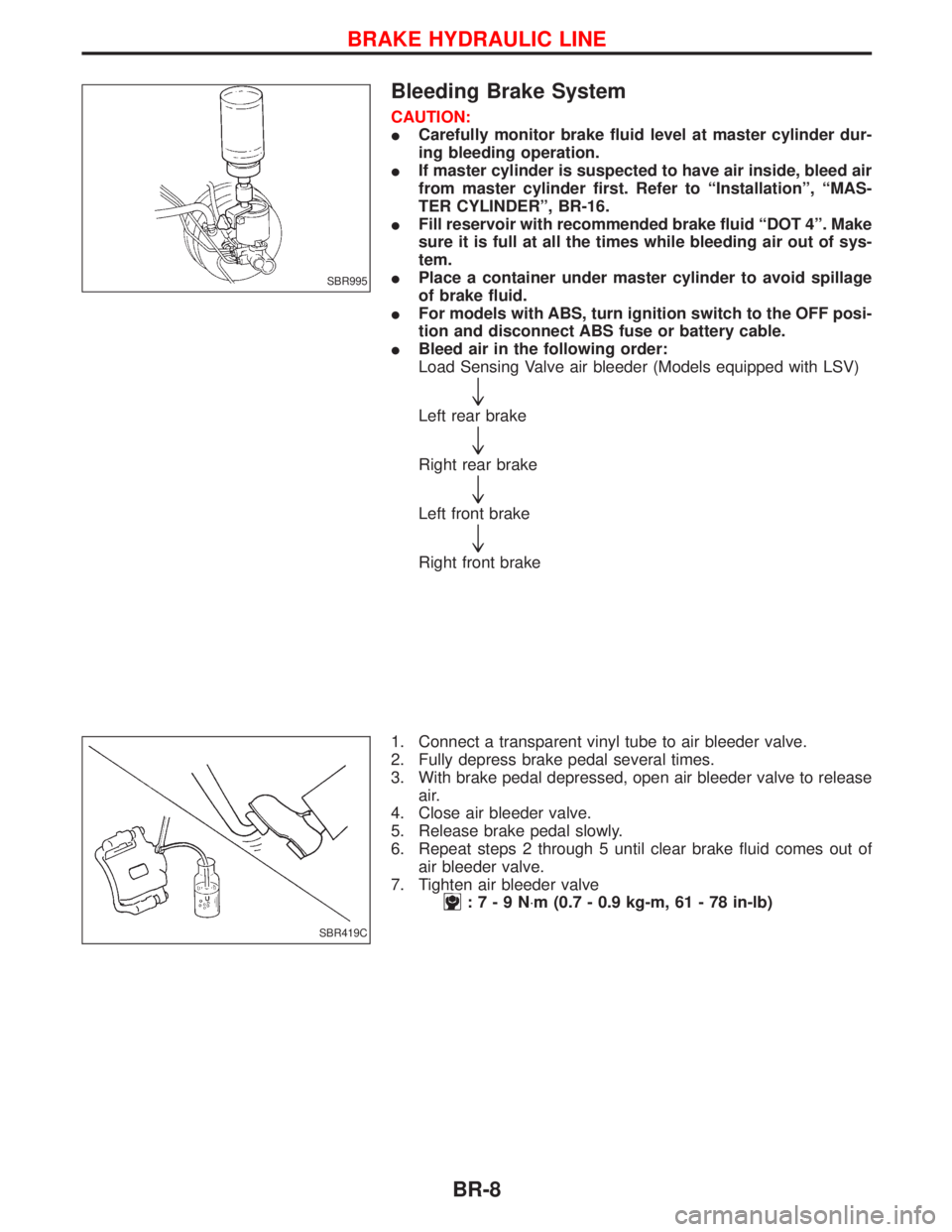

Bleeding Brake System

CAUTION:

ICarefully monitor brake fluid level at master cylinder dur-

ing bleeding operation.

IIf master cylinder is suspected to have air inside, bleed air

from master cylinder first. Refer to ªInstallationº, ªMAS-

TER CYLINDERº, BR-16.

IFill reservoir with recommended brake fluid ªDOT 4º. Make

sure it is full at all the times while bleeding air out of sys-

tem.

IPlace a container under master cylinder to avoid spillage

of brake fluid.

IFor models with ABS, turn ignition switch to the OFF posi-

tion and disconnect ABS fuse or battery cable.

IBleed air in the following order:

Load Sensing Valve air bleeder (Models equipped with LSV)

"

Left rear brake

"

Right rear brake

"

Left front brake

"

Right front brake

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2 through 5 until clear brake fluid comes out of

air bleeder valve.

7. Tighten air bleeder valve

:7-9N×m (0.7 - 0.9 kg-m, 61 - 78 in-lb)

SBR995

SBR419C

BRAKE HYDRAULIC LINE

BR-8

Page 211 of 1767

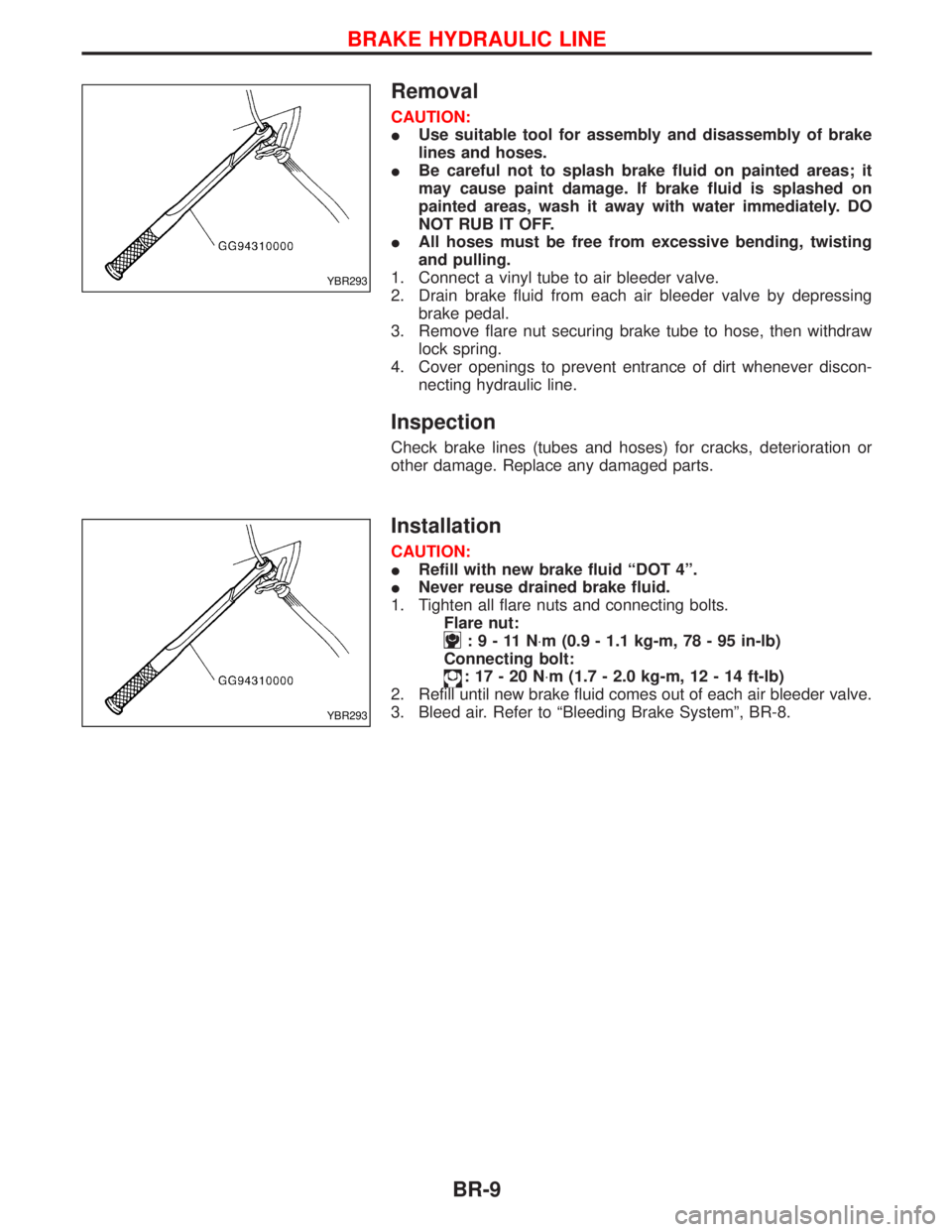

Removal

CAUTION:

IUse suitable tool for assembly and disassembly of brake

lines and hoses.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately. DO

NOT RUB IT OFF.

IAll hoses must be free from excessive bending, twisting

and pulling.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve by depressing

brake pedal.

3. Remove flare nut securing brake tube to hose, then withdraw

lock spring.

4. Cover openings to prevent entrance of dirt whenever discon-

necting hydraulic line.

Inspection

Check brake lines (tubes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Tighten all flare nuts and connecting bolts.

Flare nut:

:9-11N×m (0.9 - 1.1 kg-m, 78 - 95 in-lb)

Connecting bolt:

:17-20N×m (1.7 - 2.0 kg-m, 12 - 14 ft-lb)

2. Refill until new brake fluid comes out of each air bleeder valve.

3. Bleed air. Refer to ªBleeding Brake Systemº, BR-8.

YBR293

YBR293

BRAKE HYDRAULIC LINE

BR-9

Page 213 of 1767

Removal

CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately. DO

NOT RUB IT OFF.

IRemove flare nuts and LSV bolts.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

ICheck level in brake fluid reservoir.

1. Tighten provisionally flare nuts.

2. Tighten LSV bolts.

:20-24N×m (2.0 - 2.4 kg-m, 14 - 17 ft-lb)

3. Tighten flare nuts.

:15-18N×m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

4. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

5. Adjust load sensing valve (LSV). Refer to ªInspection and

Adjustmentº, ªLOAD SENSING VALVEº, BR-12.

YBR293

LOAD SENSING VALVE

BR-11

Page 217 of 1767

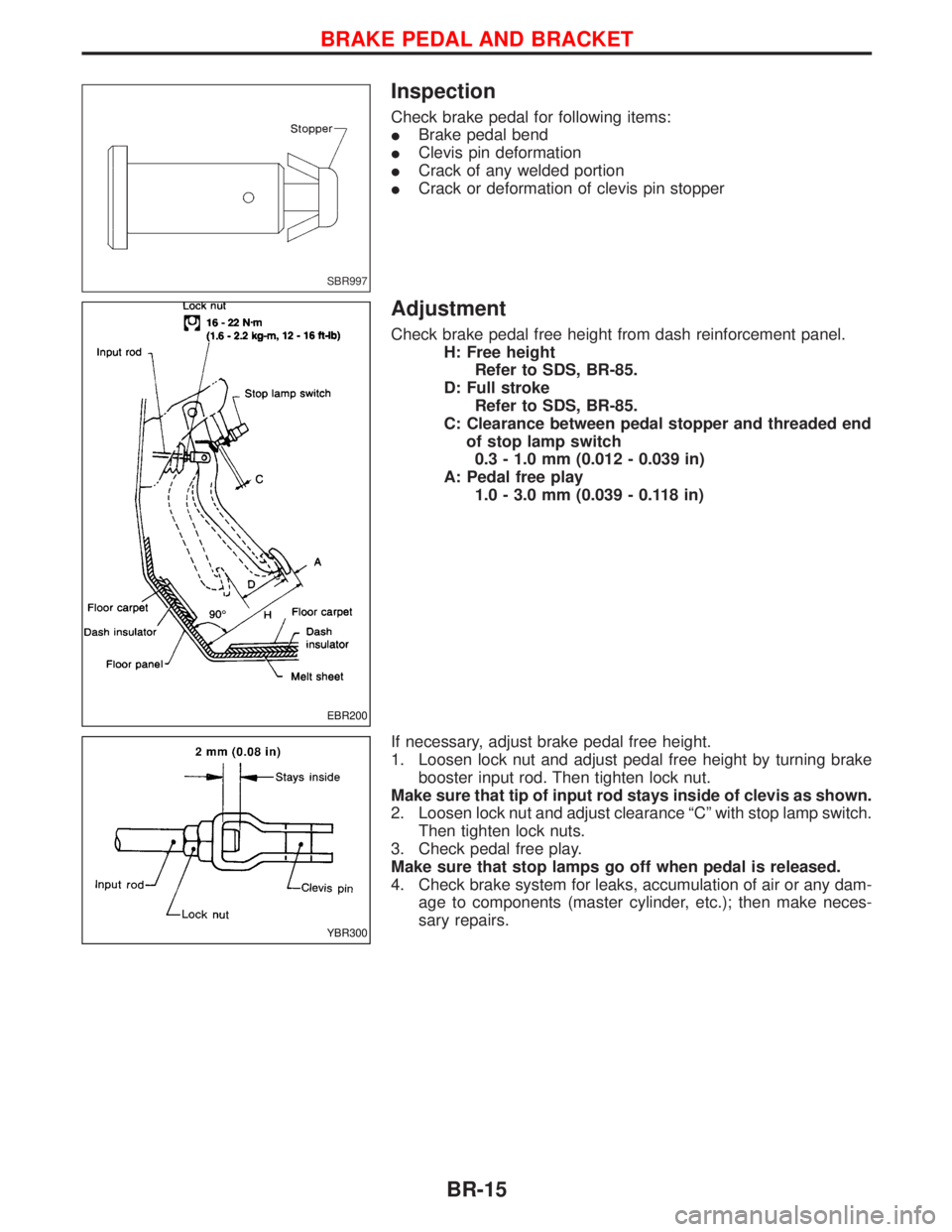

Inspection

Check brake pedal for following items:

IBrake pedal bend

IClevis pin deformation

ICrack of any welded portion

ICrack or deformation of clevis pin stopper

Adjustment

Check brake pedal free height from dash reinforcement panel.

H: Free height

Refer to SDS, BR-85.

D: Full stroke

Refer to SDS, BR-85.

C: Clearance between pedal stopper and threaded end

of stop lamp switch

0.3 - 1.0 mm (0.012 - 0.039 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust brake pedal free height.

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside of clevis as shown.

2. Loosen lock nut and adjust clearance ªCº with stop lamp switch.

Then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

4. Check brake system for leaks, accumulation of air or any dam-

age to components (master cylinder, etc.); then make neces-

sary repairs.

SBR997

EBR200

YBR300

BRAKE PEDAL AND BRACKET

BR-15

Page 218 of 1767

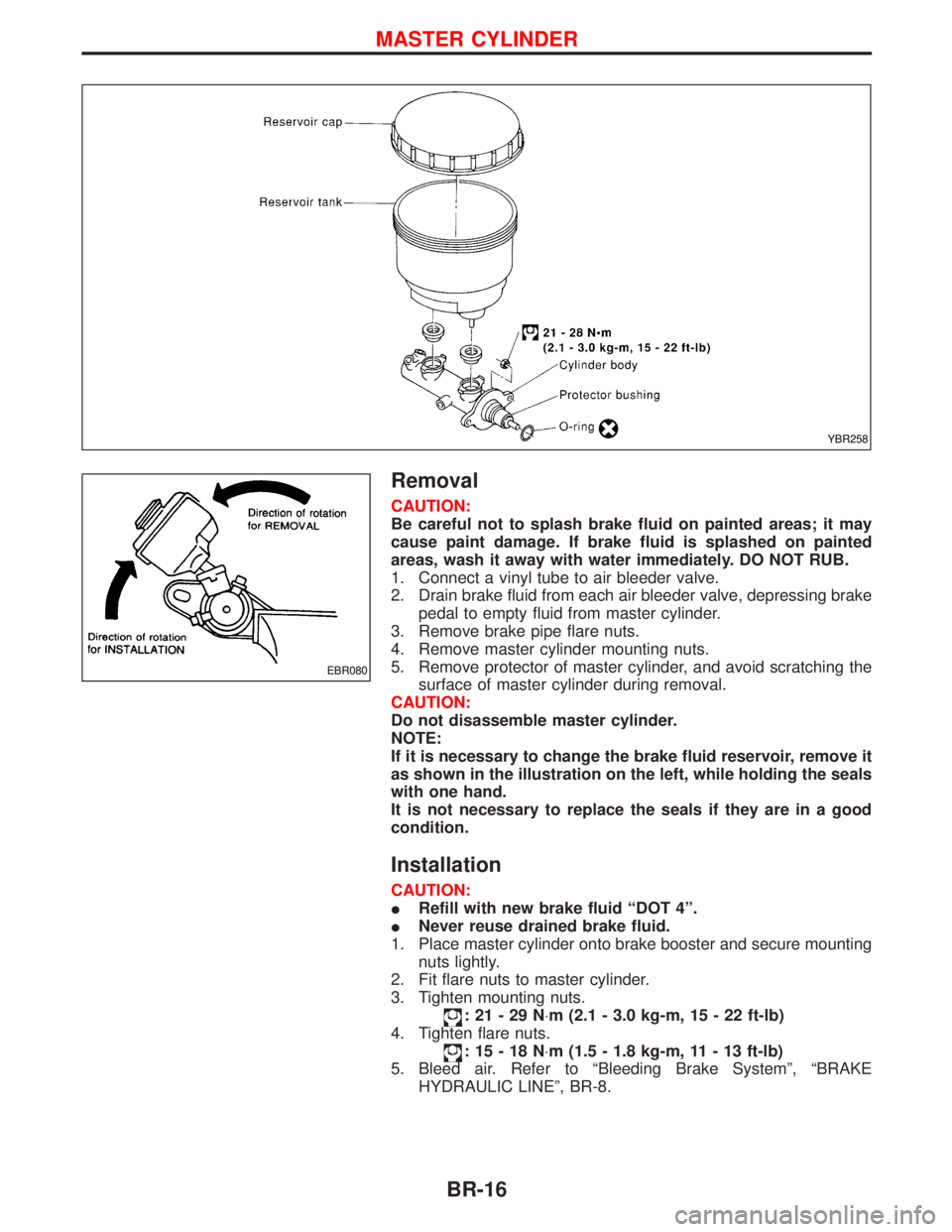

Removal

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately. DO NOT RUB.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve, depressing brake

pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

5. Remove protector of master cylinder, and avoid scratching the

surface of master cylinder during removal.

CAUTION:

Do not disassemble master cylinder.

NOTE:

If it is necessary to change the brake fluid reservoir, remove it

as shown in the illustration on the left, while holding the seals

with one hand.

It is not necessary to replace the seals if they are in a good

condition.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mounting

nuts lightly.

2. Fit flare nuts to master cylinder.

3. Tighten mounting nuts.

:21-29N×m (2.1 - 3.0 kg-m, 15 - 22 ft-lb)

4. Tighten flare nuts.

:15-18N×m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

5. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR258

EBR080

MASTER CYLINDER

BR-16

Page 220 of 1767

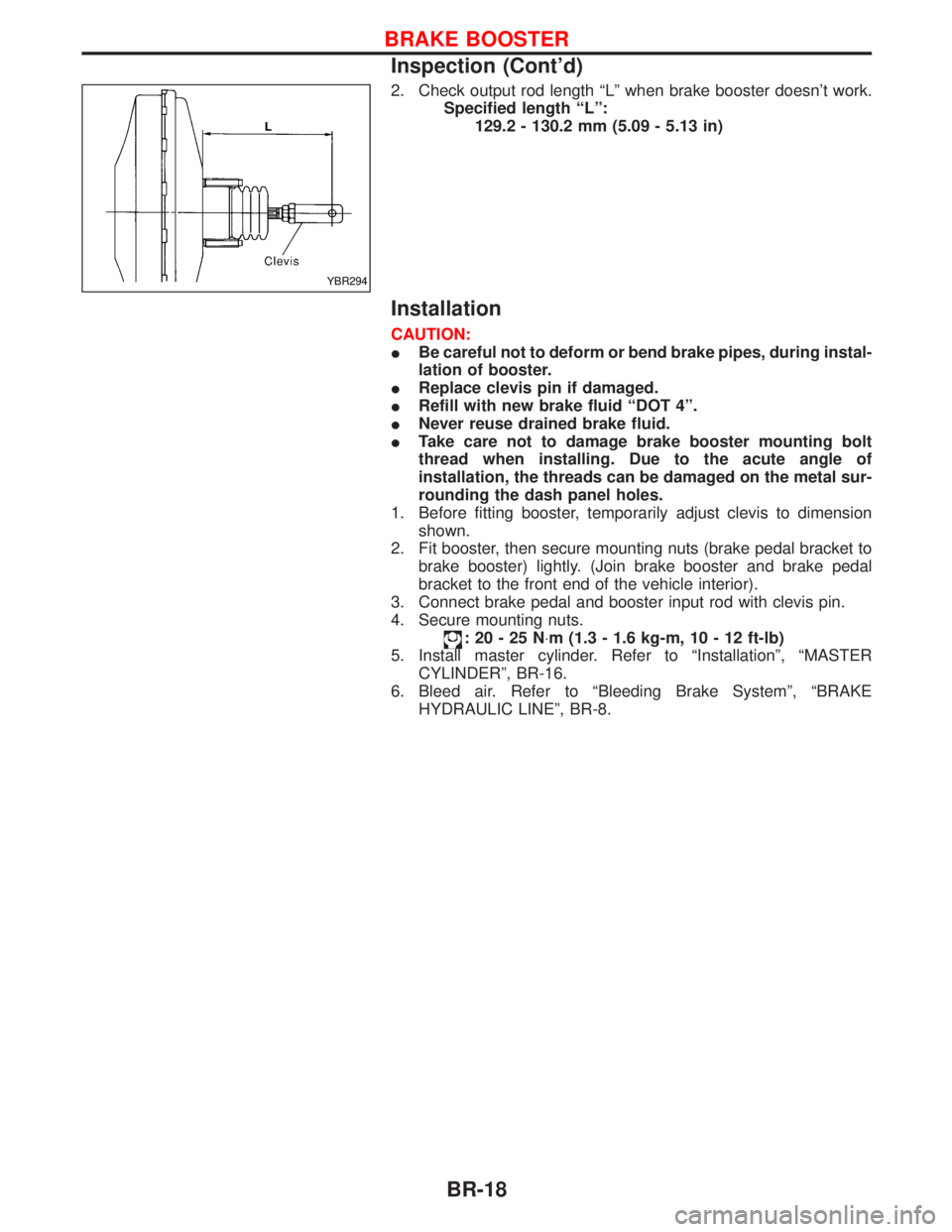

2. Check output rod length ªLº when brake booster doesn't work.

Specified length ªLº:

129.2 - 130.2 mm (5.09 - 5.13 in)

Installation

CAUTION:

IBe careful not to deform or bend brake pipes, during instal-

lation of booster.

IReplace clevis pin if damaged.

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

ITake care not to damage brake booster mounting bolt

thread when installing. Due to the acute angle of

installation, the threads can be damaged on the metal sur-

rounding the dash panel holes.

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

2. Fit booster, then secure mounting nuts (brake pedal bracket to

brake booster) lightly. (Join brake booster and brake pedal

bracket to the front end of the vehicle interior).

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure mounting nuts.

:20-25N×m (1.3 - 1.6 kg-m, 10 - 12 ft-lb)

5. Install master cylinder. Refer to ªInstallationº, ªMASTER

CYLINDERº, BR-16.

6. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR294

BRAKE BOOSTER

Inspection (Cont'd)

BR-18

Page 232 of 1767

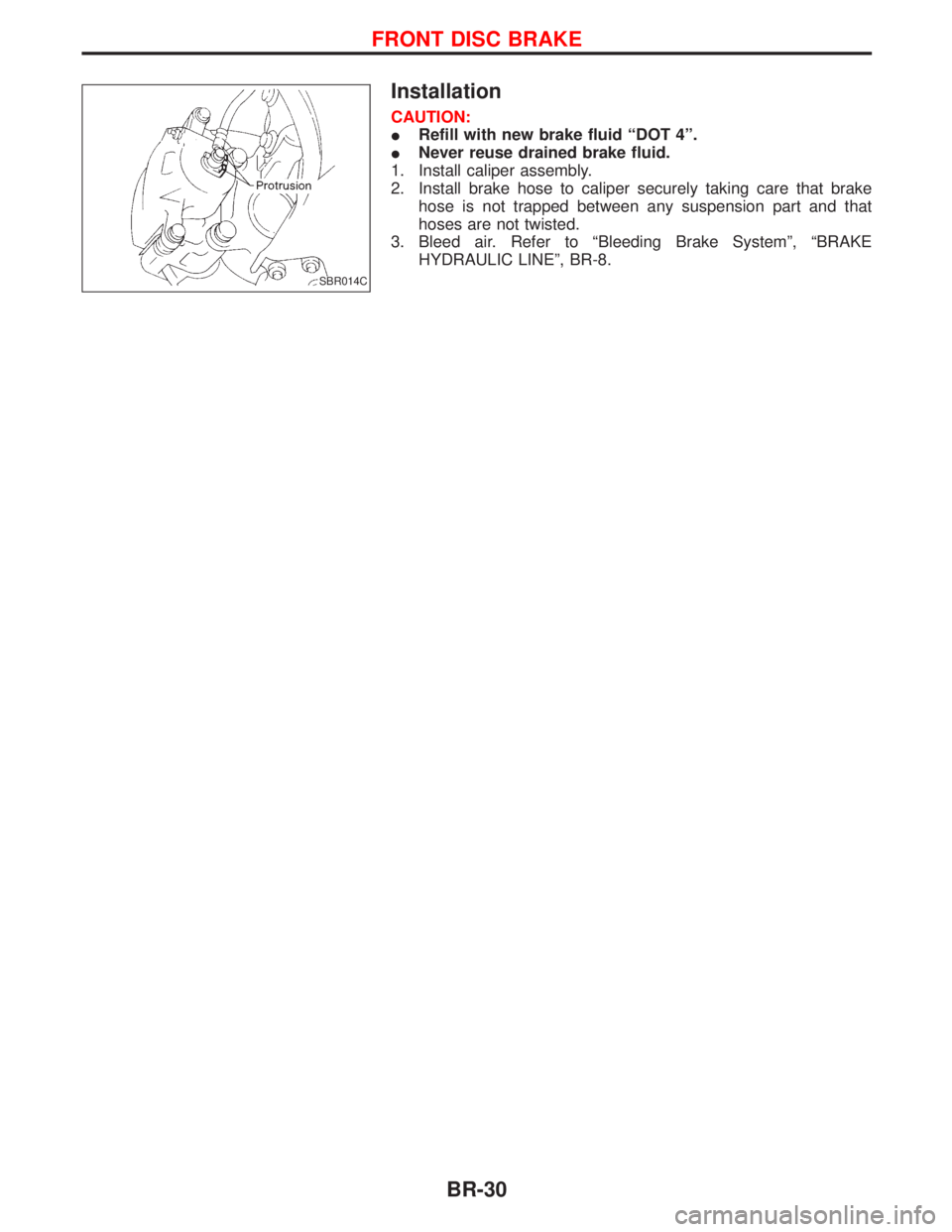

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Install caliper assembly.

2. Install brake hose to caliper securely taking care that brake

hose is not trapped between any suspension part and that

hoses are not twisted.

3. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

SBR014C

FRONT DISC BRAKE

BR-30

Page 236 of 1767

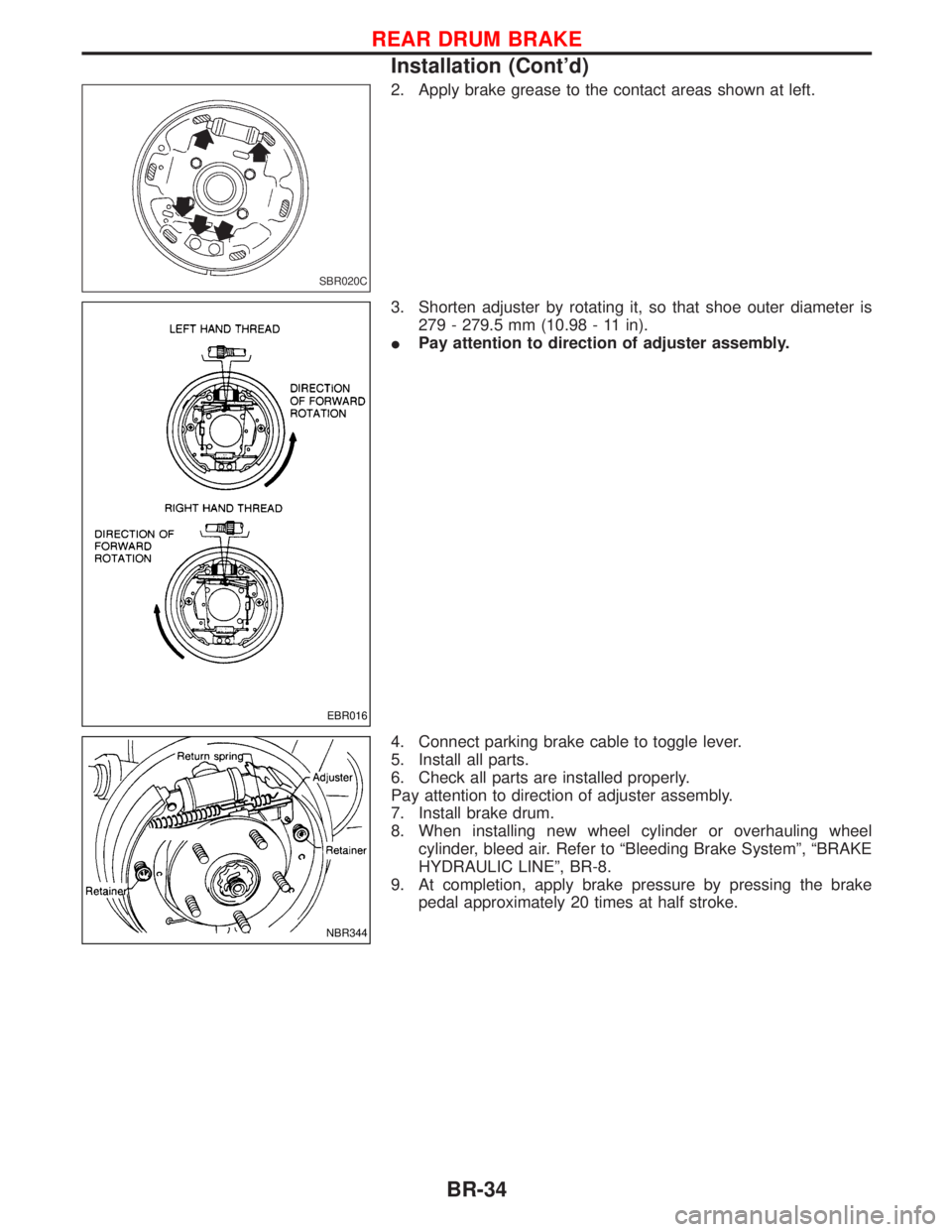

2. Apply brake grease to the contact areas shown at left.

3. Shorten adjuster by rotating it, so that shoe outer diameter is

279 - 279.5 mm (10.98 - 11 in).

IPay attention to direction of adjuster assembly.

4. Connect parking brake cable to toggle lever.

5. Install all parts.

6. Check all parts are installed properly.

Pay attention to direction of adjuster assembly.

7. Install brake drum.

8. When installing new wheel cylinder or overhauling wheel

cylinder, bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

9. At completion, apply brake pressure by pressing the brake

pedal approximately 20 times at half stroke.

SBR020C

EBR016

NBR344

REAR DRUM BRAKE

Installation (Cont'd)

BR-34

Page 239 of 1767

Purpose

The Anti-lock Brake System (ABS) with an integrated Electronic Brake force Distribution (EBD) system con-

sists of electronic and hydraulic components. It allows you to control the braking force so that wheel lock can

be avoided during braking.

The advantages of ABS with EBD

1) Better tracking performance through improved steering wheel control.

2) Improved maneuverability and safer vehicle control.

3) Improved vehicle stability by preventing flat spins.

4) Shorter stopping distance and optimal utilisation of the rear brakes under many different circumstances.

Operation

IABS with EBD has self-test capabilities. The ABS warning lamp is illuminated for 1 second each time the

ignition switch is turned ªONº. After the engine is started, the ABS warning lamp turns off. An ABS self-test

is performed the first time the vehicle reaches 6 km/h (4 MPH) to ensure the system is operational. A

mechanical noise may be heard as the ABS performs this self-test and is a normal part of the self-test

feature. If a malfunction is detected during this check, the ABS warning lamp will stay on.

During the self-test, it also performs a EBD check when it detects a failure the ABS warning light will go

on simultaneously with the brake warning light and an audible sound will sound constantly.

IEBD system will only operate when the ABS is not in active status and it uses the inlet valves of ABS con-

trol unit to limit the pressure to the rear wheels when they tend to go into slip.

IWhen the vehicle speed is less than 10 km/h (6 MPH) the ABS system does not operate.

IWhile driving, a mechanical noise may be heard during ABS operation, this is a normal system condition.

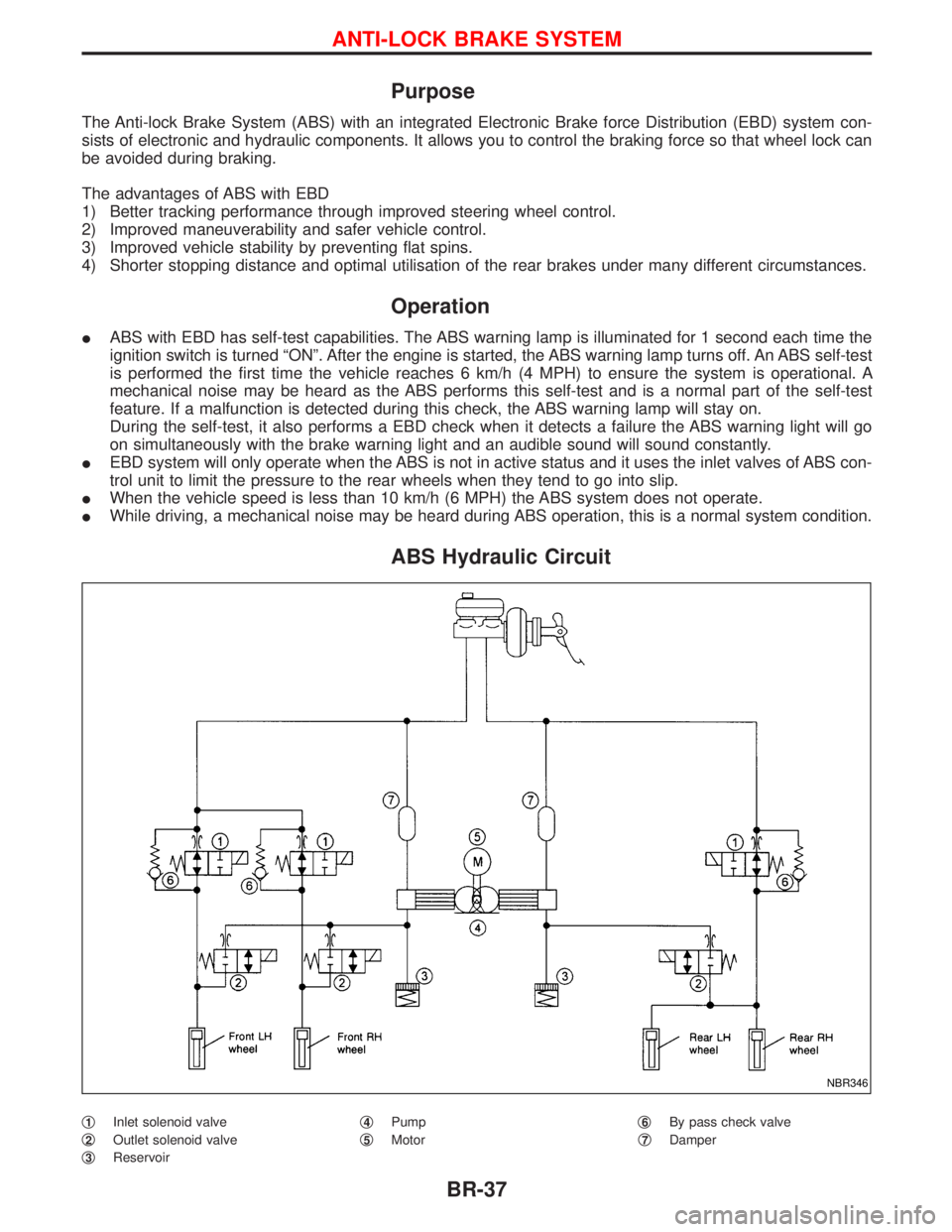

ABS Hydraulic Circuit

q1Inlet solenoid valve

q

2Outlet solenoid valve

q

3Reservoirq

4Pump

q

5Motorq

6By pass check valve

q

7Damper

NBR346

ANTI-LOCK BRAKE SYSTEM

BR-37

Page 240 of 1767

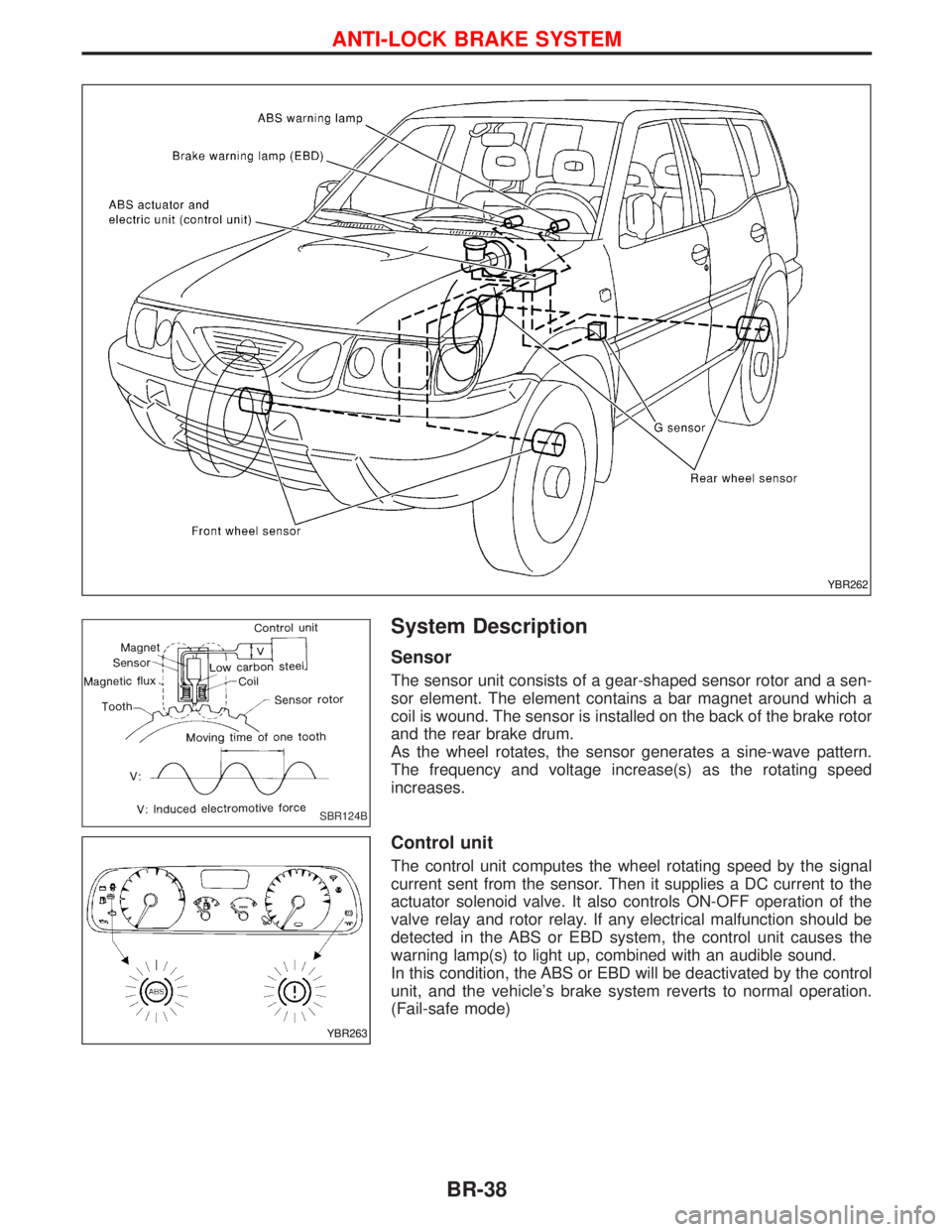

System Description

Sensor

The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back of the brake rotor

and the rear brake drum.

As the wheel rotates, the sensor generates a sine-wave pattern.

The frequency and voltage increase(s) as the rotating speed

increases.

Control unit

The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and rotor relay. If any electrical malfunction should be

detected in the ABS or EBD system, the control unit causes the

warning lamp(s) to light up, combined with an audible sound.

In this condition, the ABS or EBD will be deactivated by the control

unit, and the vehicle's brake system reverts to normal operation.

(Fail-safe mode)

YBR262

SBR124B

YBR263

ANTI-LOCK BRAKE SYSTEM

BR-38