system NISSAN TERRANO 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 281 of 1767

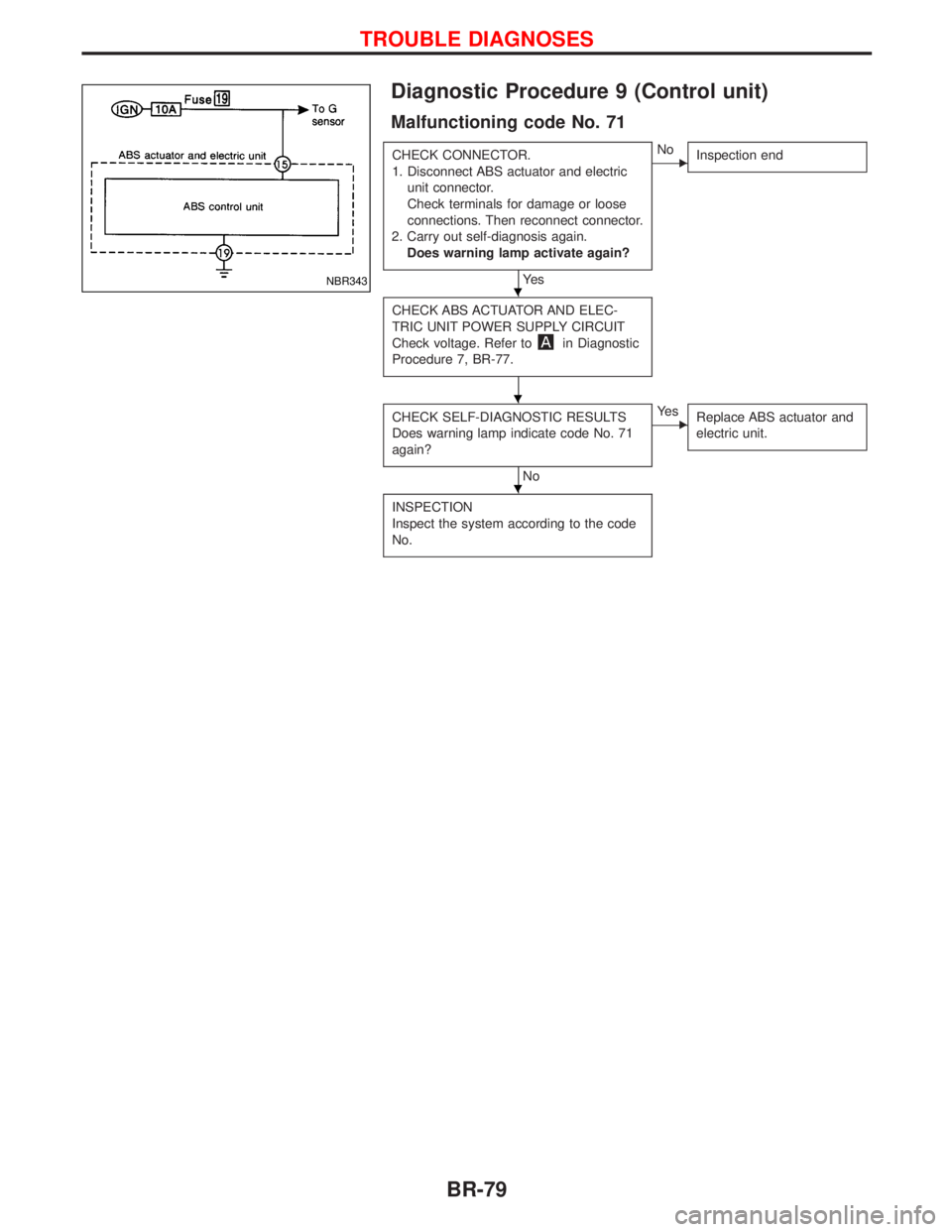

Diagnostic Procedure 9 (Control unit)

Malfunctioning code No. 71

CHECK CONNECTOR.

1. Disconnect ABS actuator and electric

unit connector.

Check terminals for damage or loose

connections. Then reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT POWER SUPPLY CIRCUIT

Check voltage. Refer to

in Diagnostic

Procedure 7, BR-77.

CHECK SELF-DIAGNOSTIC RESULTS

Does warning lamp indicate code No. 71

again?

No

EYe s

Replace ABS actuator and

electric unit.

INSPECTION

Inspect the system according to the code

No.

NBR343H

H

H

TROUBLE DIAGNOSES

BR-79

Page 289 of 1767

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS...............................................................2

Service Notice..............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

CLIP AND FASTENER....................................................3

Description ...................................................................3

CHASSIS AND BODY MAINTENANCE.........................5

Checking Body Corrosion ............................................5

BODY FRONT END.........................................................6

Removal and Installation .............................................6

BODY REAR END AND OPENER..................................8

Removal and Installation .............................................8

DOOR.............................................................................10

Removal and Installation ...........................................10

INSTRUMENT PANEL ASSEMBLY..............................16

Removal and Installation ...........................................16

SIDE AND FLOOR TRIM..............................................18

Removal and Installation ...........................................18

DOOR TRIM...................................................................19

Removal and Installation ...........................................19ROOF TRIM...................................................................20

Removal and Installation ...........................................20

EXTERIOR.....................................................................21

Removal and Installation ...........................................21

FRONT SEAT.................................................................34

Removal and Installation ...........................................34

Heated Seat ...............................................................36

Active Head Restraint ................................................36

SECOND SEAT..............................................................37

Removal and Installation ...........................................37

THIRD SEAT..................................................................39

Removal and Installation ...........................................39

SUNROOF......................................................................40

Removal and Installation ...........................................40

WINDSHIELD AND WINDOWS....................................42

Removal and Installation ...........................................42

DOOR MIRROR.............................................................48

Removal and Installation ...........................................48

BODY (ALIGNMENT)....................................................49

Alignment ...................................................................49

Page 290 of 1767

Service Notice

IWhen removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

IHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil

or damage them.

IApply sealing compound where necessary when installing parts.

IWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

IWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL R20 is as follows (The compo-

sition varies according to the destination and optional equipment.):

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRSsection of this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

BT-2

Page 296 of 1767

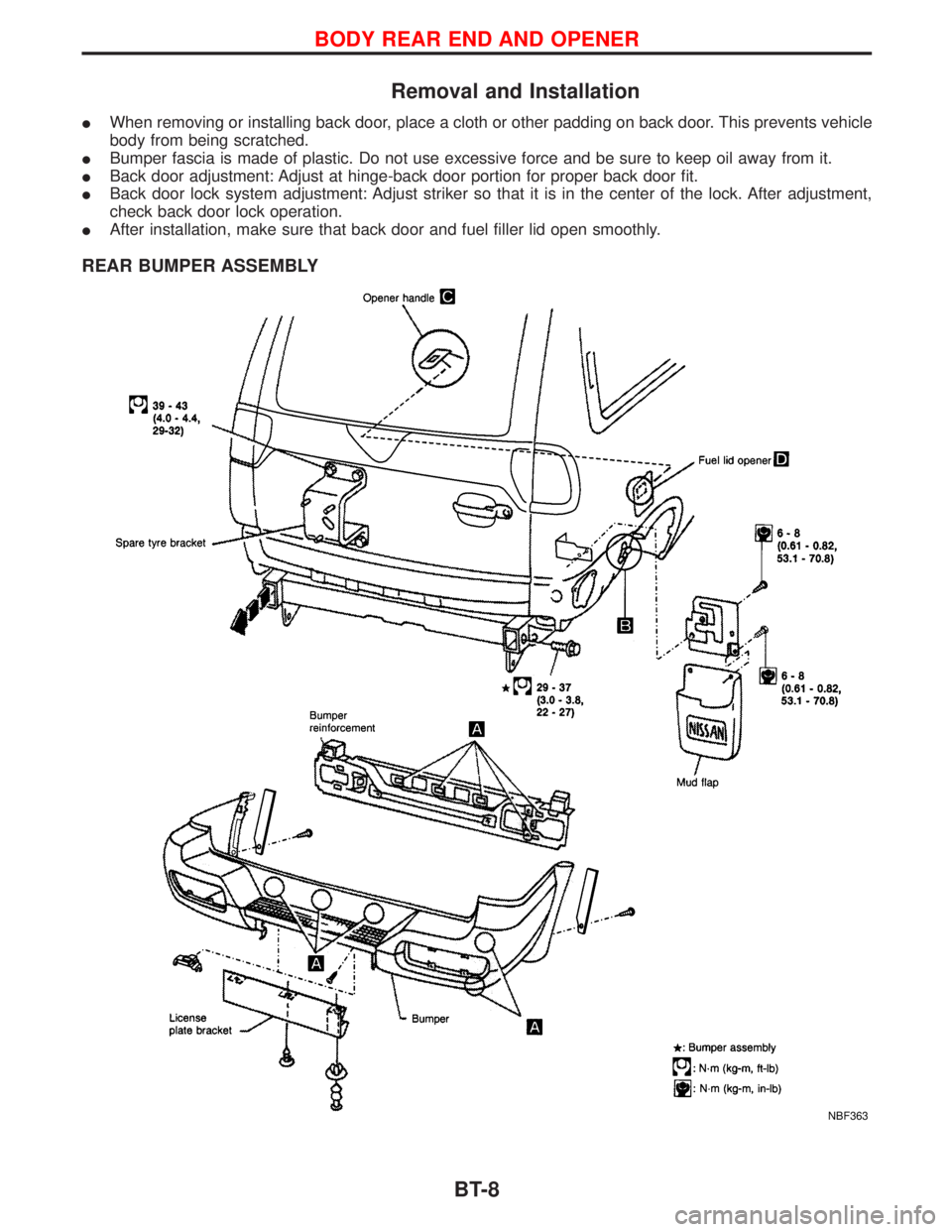

Removal and Installation

IWhen removing or installing back door, place a cloth or other padding on back door. This prevents vehicle

body from being scratched.

IBumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

IBack door adjustment: Adjust at hinge-back door portion for proper back door fit.

IBack door lock system adjustment: Adjust striker so that it is in the center of the lock. After adjustment,

check back door lock operation.

IAfter installation, make sure that back door and fuel filler lid open smoothly.

REAR BUMPER ASSEMBLY

NBF363

BODY REAR END AND OPENER

BT-8

Page 304 of 1767

Removal and Installation

CAUTION:

IDisconnect ground terminal from battery in advance.

IDisconnect air bag system line in advance.

INever tamper with or force air bag lid open, as this may adversely affect air bag performance.

IBe careful not to scratch pad and other parts.

INSTRUMENT PANEL ASSEMBLY

BT-16

Page 324 of 1767

Heated Seat

HFor Wiring Diagram, refer to EL-128, ªHEATED SEATº for details.

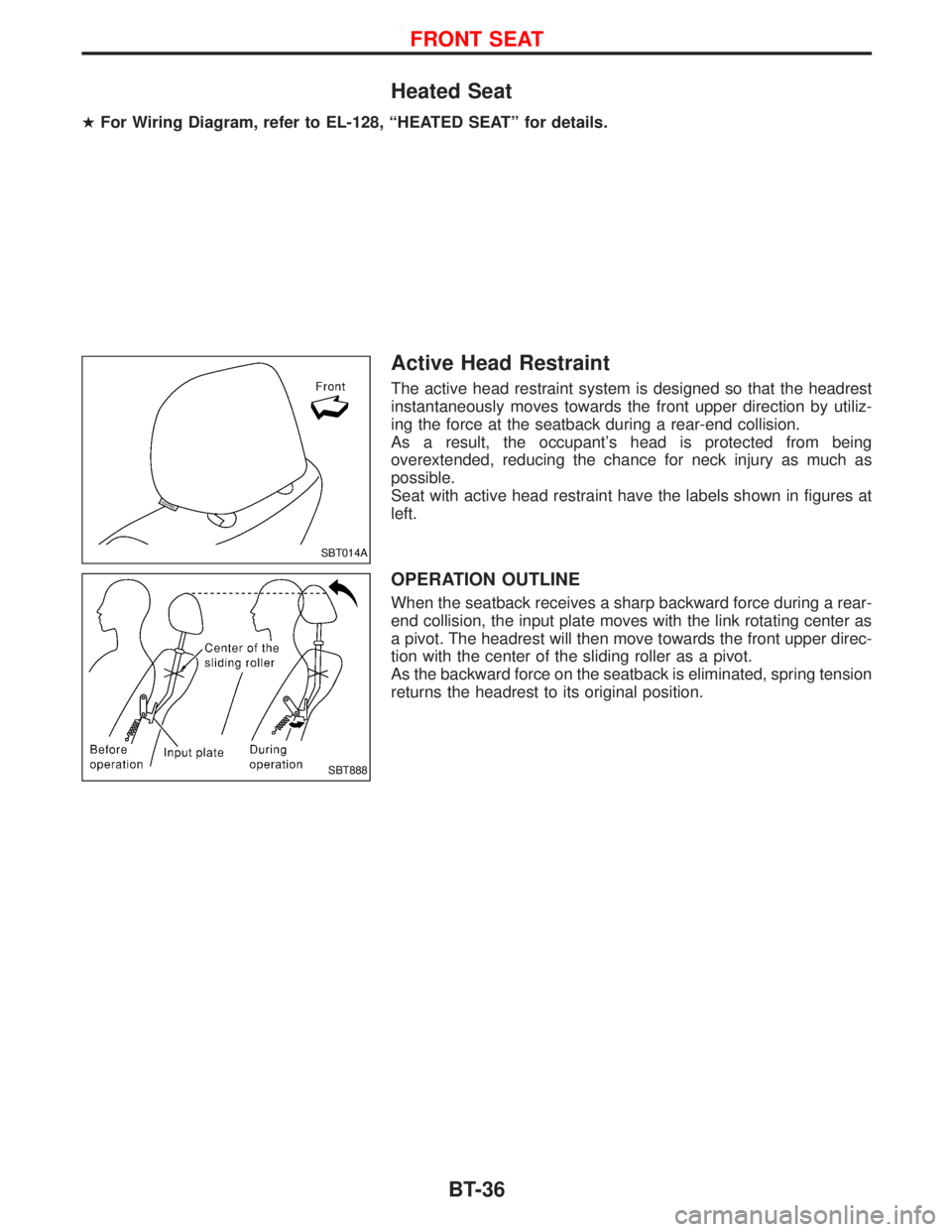

Active Head Restraint

The active head restraint system is designed so that the headrest

instantaneously moves towards the front upper direction by utiliz-

ing the force at the seatback during a rear-end collision.

As a result, the occupant's head is protected from being

overextended, reducing the chance for neck injury as much as

possible.

Seat with active head restraint have the labels shown in figures at

left.

OPERATION OUTLINE

When the seatback receives a sharp backward force during a rear-

end collision, the input plate moves with the link rotating center as

a pivot. The headrest will then move towards the front upper direc-

tion with the center of the sliding roller as a pivot.

As the backward force on the seatback is eliminated, spring tension

returns the headrest to its original position.

SBT014A

SBT888

FRONT SEAT

BT-36

Page 349 of 1767

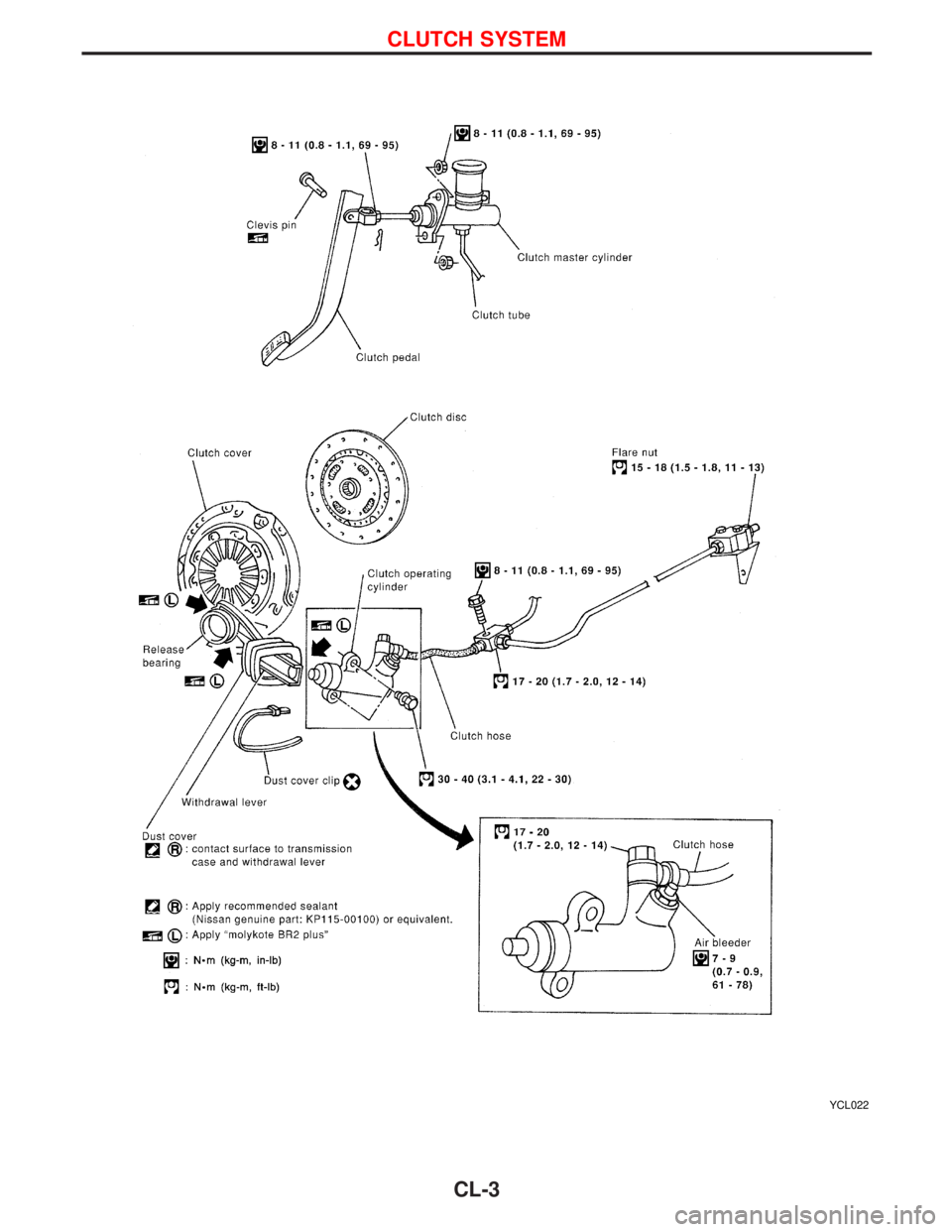

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS AND PREPARATION............................2

Precautions ..................................................................2

Preparation ..................................................................2

CLUTCH SYSTEM...........................................................3

Clutch Pedal ................................................................4

INSPECTION AND ADJUSTMENT.................................5

Adjusting Clutch Pedal ................................................5

Bleeding Procedure .....................................................6

CLUTCH MASTER CYLINDER.......................................7

HYDRAULIC CLUTCH CONTROL.................................8Clutch Master Cylinder ................................................8

Clutch Operating Cylinder ...........................................8

CLUTCH RELEASE MECHANISM.................................9

CLUTCH DISC AND CLUTCH COVER........................ 11

Clutch Disc................................................................. 11

Clutch Cover and Flywheel .......................................12

SERVICE DATA AND SPECIFICATIONS (SDS)..........14

General Specifications ...............................................14

Inspection and Adjustment ........................................14

Page 350 of 1767

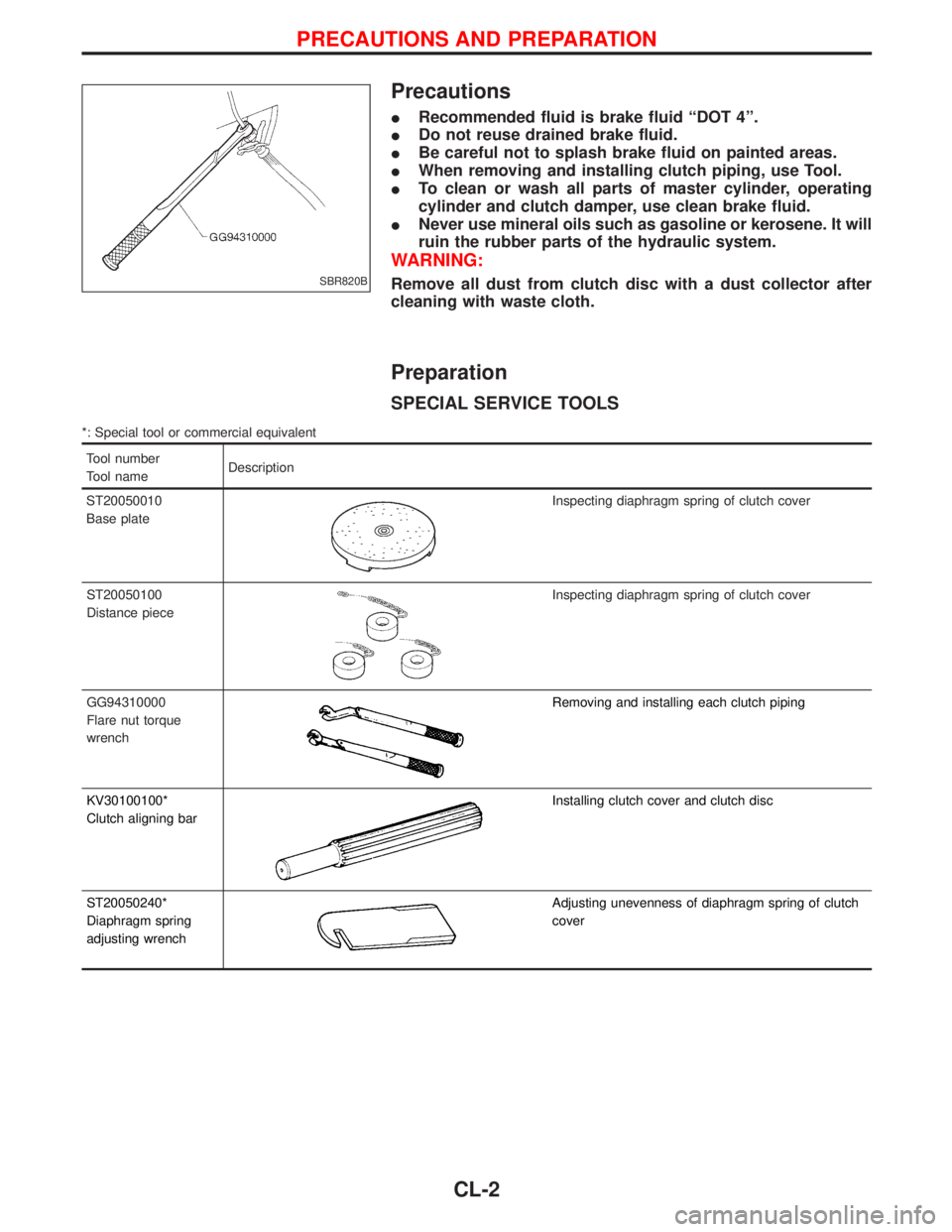

Precautions

IRecommended fluid is brake fluid ªDOT 4º.

IDo not reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas.

IWhen removing and installing clutch piping, use Tool.

ITo clean or wash all parts of master cylinder, operating

cylinder and clutch damper, use clean brake fluid.

INever use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

Remove all dust from clutch disc with a dust collector after

cleaning with waste cloth.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST20050010

Base plate

Inspecting diaphragm spring of clutch cover

ST20050100

Distance piece

Inspecting diaphragm spring of clutch cover

GG94310000

Flare nut torque

wrench

Removing and installing each clutch piping

KV30100100*

Clutch aligning bar

Installing clutch cover and clutch disc

ST20050240*

Diaphragm spring

adjusting wrench

Adjusting unevenness of diaphragm spring of clutch

cover

SBR820B

PRECAUTIONS AND PREPARATION

CL-2

Page 351 of 1767

YCL022

CLUTCH SYSTEM

CL-3

Page 352 of 1767

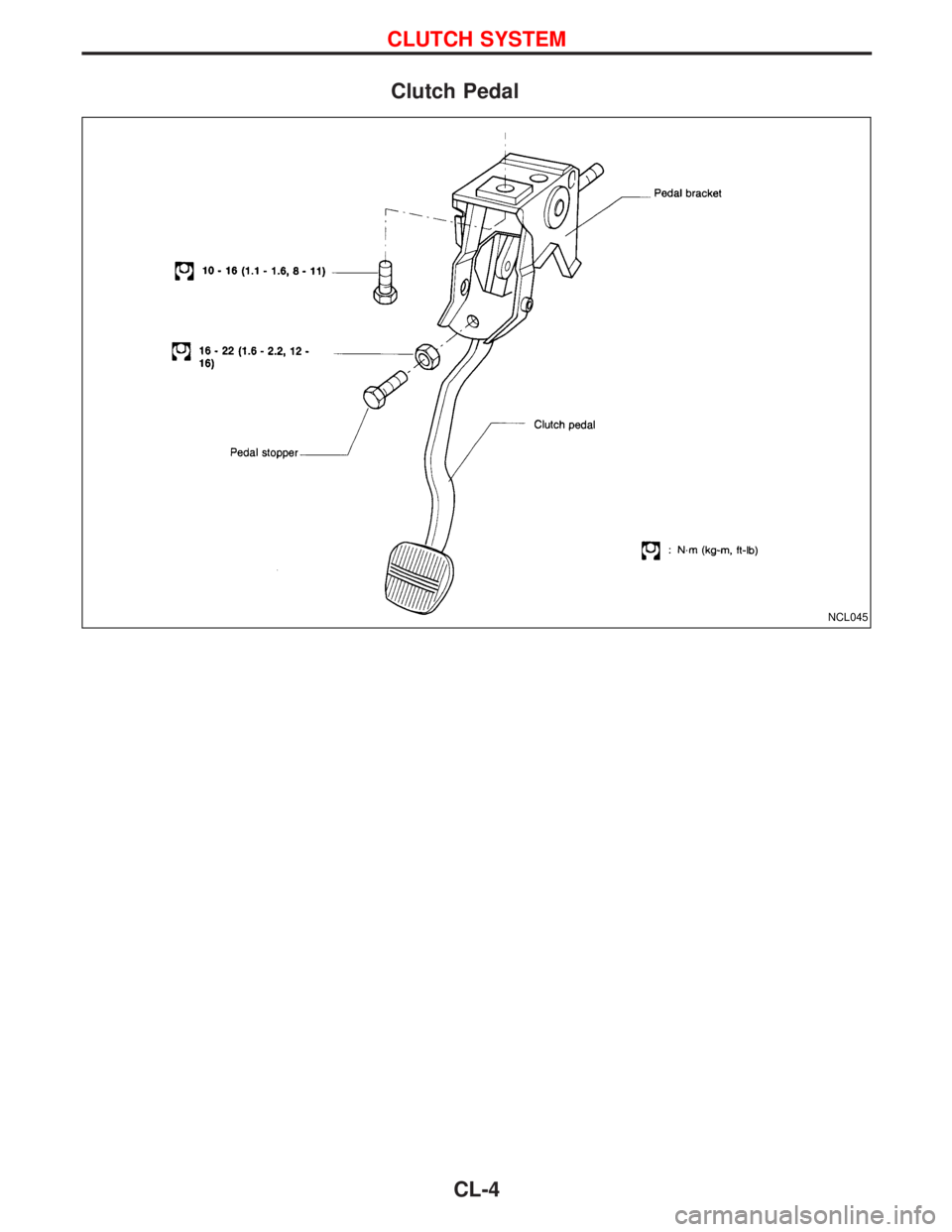

Clutch Pedal

NCL045

CLUTCH SYSTEM

CL-4