sensor NISSAN TERRANO 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 206 of 1767

Preparation

SPECIAL SERVICE TOOLS

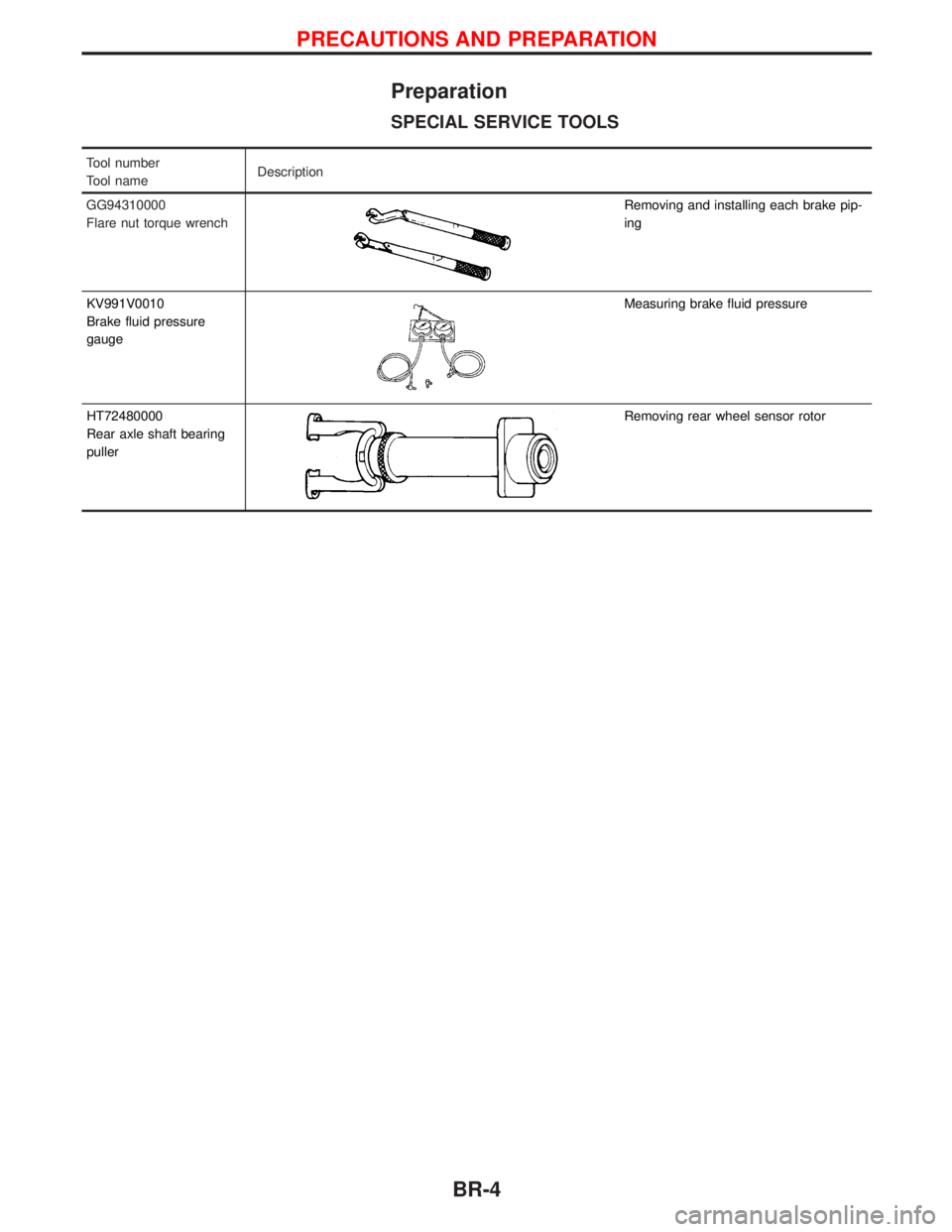

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

Removing and installing each brake pip-

ing

KV991V0010

Brake fluid pressure

gauge

Measuring brake fluid pressure

HT72480000

Rear axle shaft bearing

puller

Removing rear wheel sensor rotor

PRECAUTIONS AND PREPARATION

BR-4

Page 215 of 1767

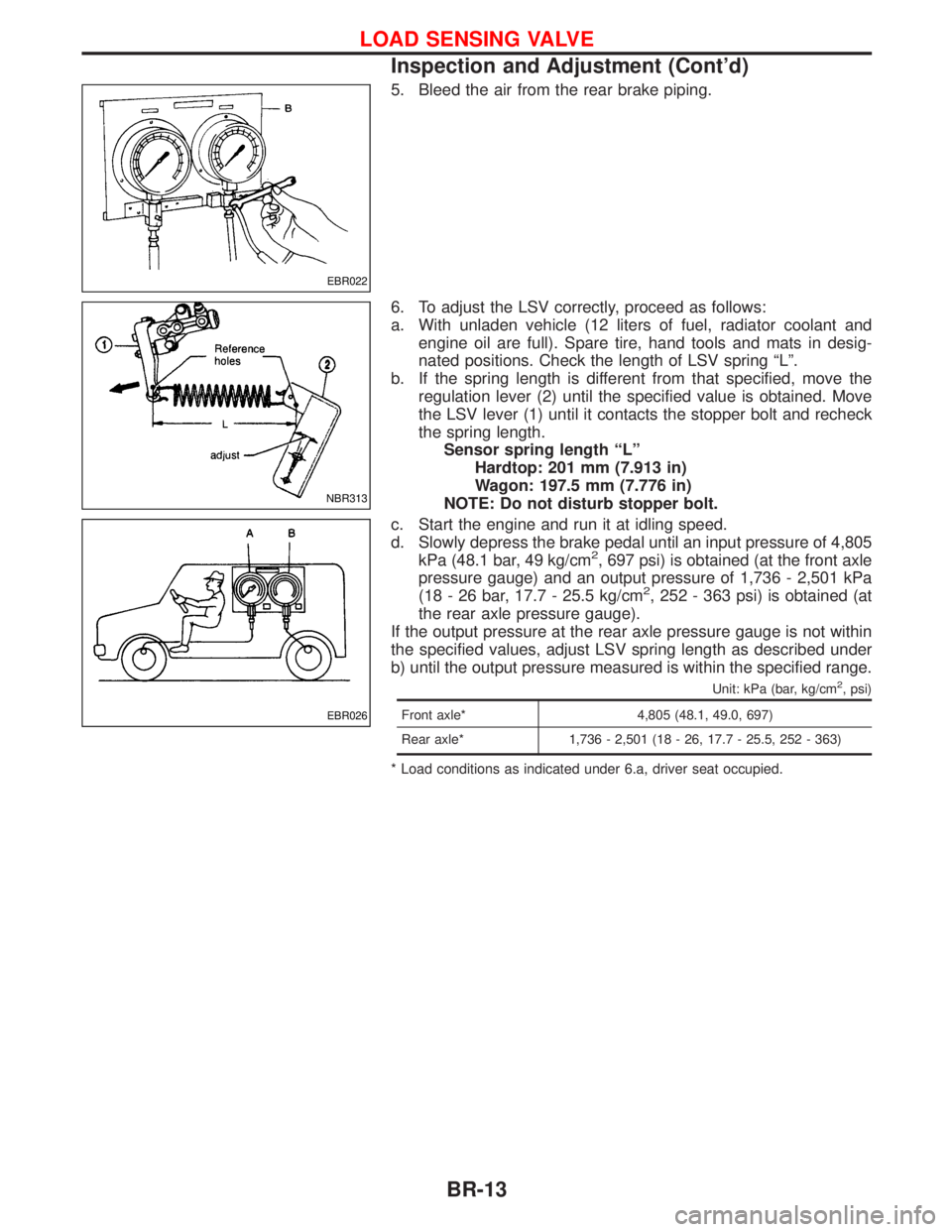

5. Bleed the air from the rear brake piping.

6. To adjust the LSV correctly, proceed as follows:

a. With unladen vehicle (12 liters of fuel, radiator coolant and

engine oil are full). Spare tire, hand tools and mats in desig-

nated positions. Check the length of LSV spring ªLº.

b. If the spring length is different from that specified, move the

regulation lever (2) until the specified value is obtained. Move

the LSV lever (1) until it contacts the stopper bolt and recheck

the spring length.

Sensor spring length ªLº

Hardtop: 201 mm (7.913 in)

Wagon: 197.5 mm (7.776 in)

NOTE: Do not disturb stopper bolt.

c. Start the engine and run it at idling speed.

d. Slowly depress the brake pedal until an input pressure of 4,805

kPa (48.1 bar, 49 kg/cm

2, 697 psi) is obtained (at the front axle

pressure gauge) and an output pressure of 1,736 - 2,501 kPa

(18 - 26 bar, 17.7 - 25.5 kg/cm

2, 252 - 363 psi) is obtained (at

the rear axle pressure gauge).

If the output pressure at the rear axle pressure gauge is not within

the specified values, adjust LSV spring length as described under

b) until the output pressure measured is within the specified range.

Unit: kPa (bar, kg/cm2, psi)

Front axle* 4,805 (48.1, 49.0, 697)

Rear axle* 1,736 - 2,501 (18 - 26, 17.7 - 25.5, 252 - 363)

* Load conditions as indicated under 6.a, driver seat occupied.

EBR022

NBR313

EBR026

LOAD SENSING VALVE

Inspection and Adjustment (Cont'd)

BR-13

Page 240 of 1767

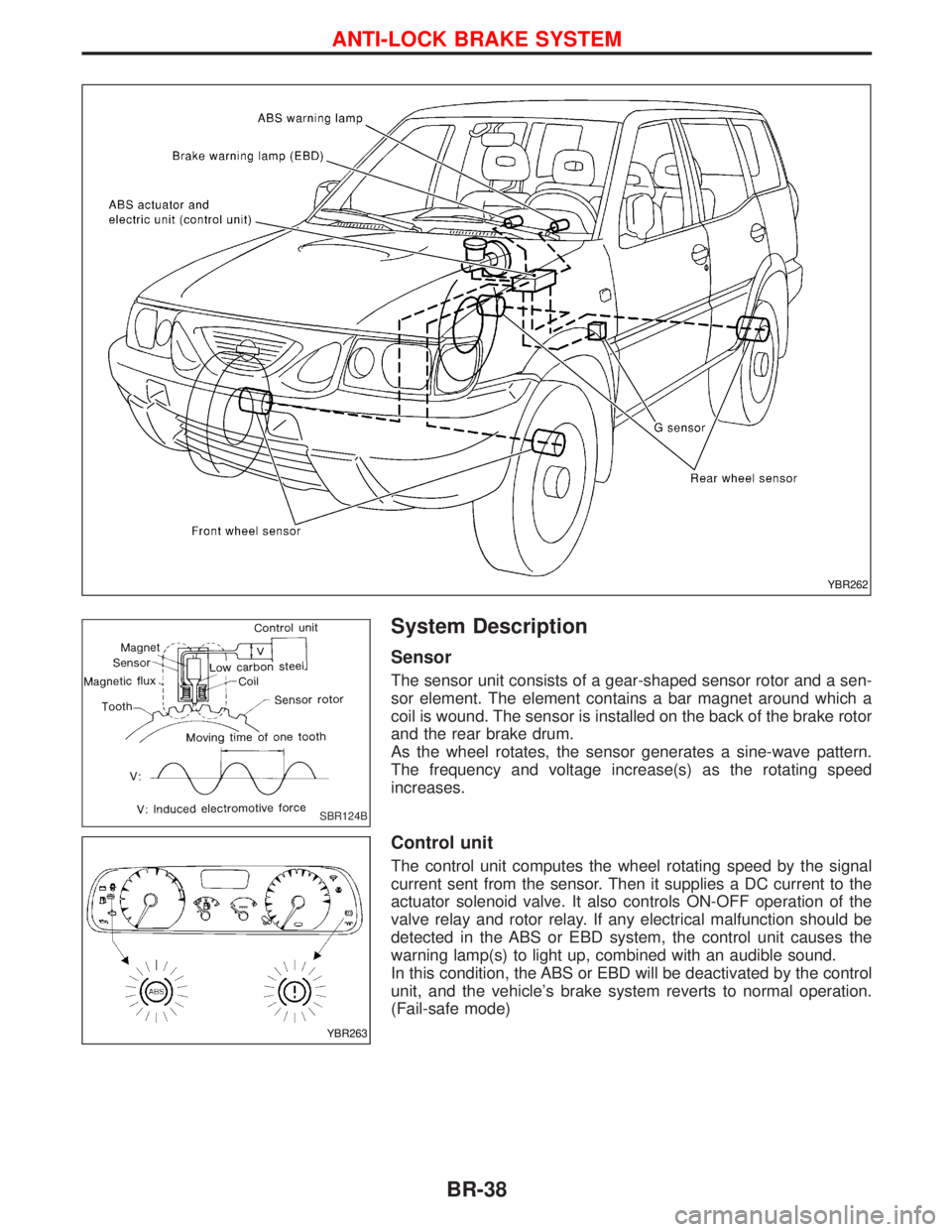

System Description

Sensor

The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back of the brake rotor

and the rear brake drum.

As the wheel rotates, the sensor generates a sine-wave pattern.

The frequency and voltage increase(s) as the rotating speed

increases.

Control unit

The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and rotor relay. If any electrical malfunction should be

detected in the ABS or EBD system, the control unit causes the

warning lamp(s) to light up, combined with an audible sound.

In this condition, the ABS or EBD will be deactivated by the control

unit, and the vehicle's brake system reverts to normal operation.

(Fail-safe mode)

YBR262

SBR124B

YBR263

ANTI-LOCK BRAKE SYSTEM

BR-38

Page 241 of 1767

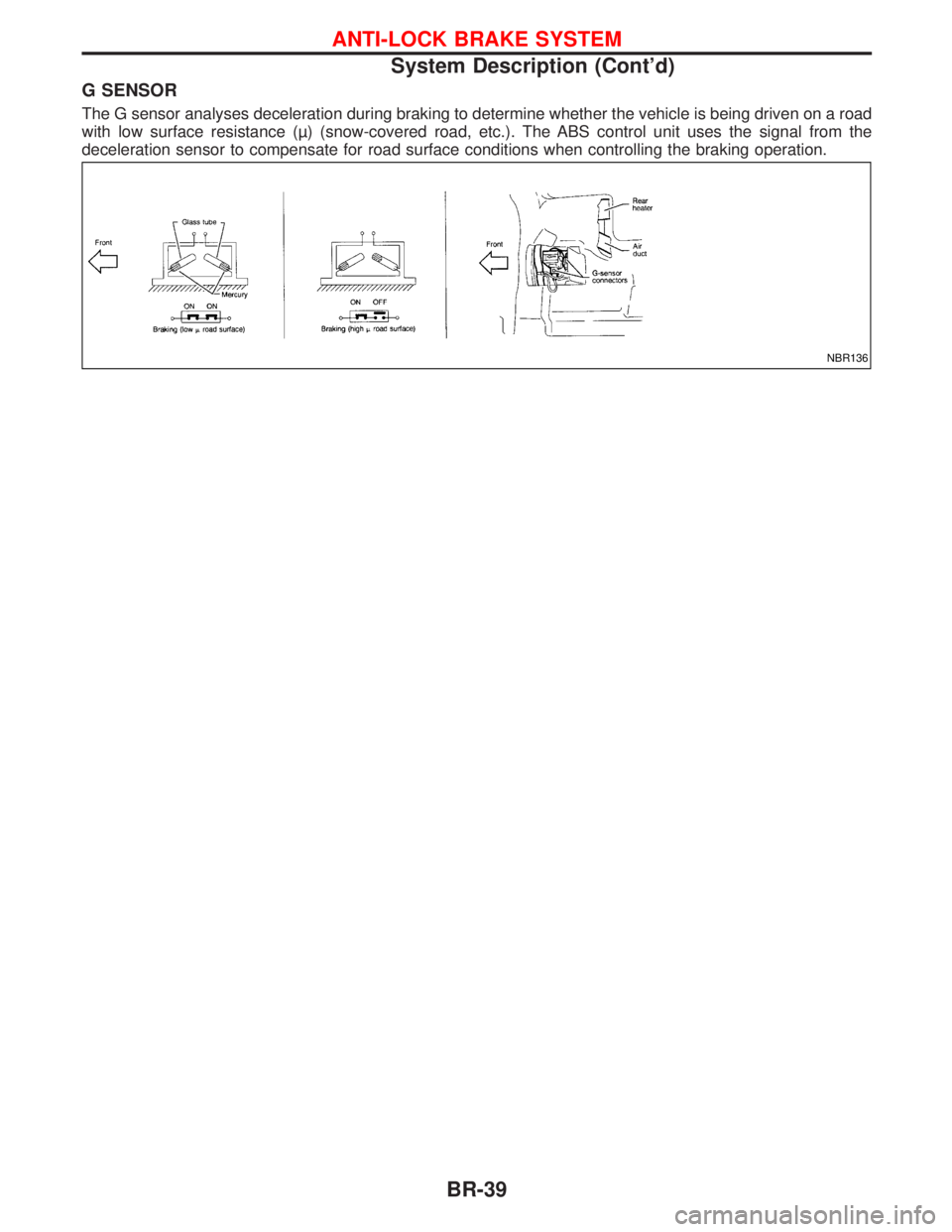

G SENSOR

The G sensor analyses deceleration during braking to determine whether the vehicle is being driven on a road

with low surface resistance () (snow-covered road, etc.). The ABS control unit uses the signal from the

deceleration sensor to compensate for road surface conditions when controlling the braking operation.

NBR136

ANTI-LOCK BRAKE SYSTEM

System Description (Cont'd)

BR-39

Page 244 of 1767

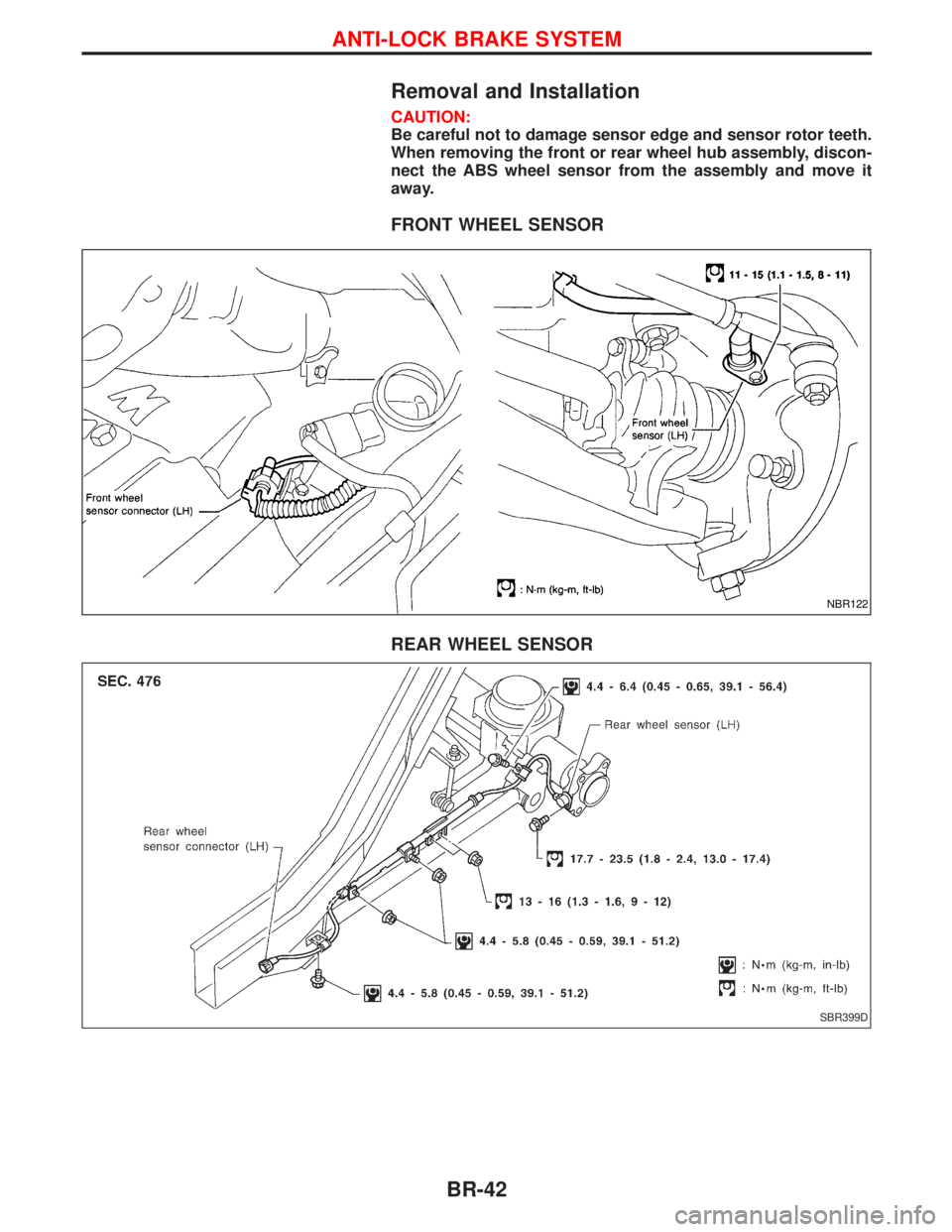

Removal and Installation

CAUTION:

Be careful not to damage sensor edge and sensor rotor teeth.

When removing the front or rear wheel hub assembly, discon-

nect the ABS wheel sensor from the assembly and move it

away.

FRONT WHEEL SENSOR

REAR WHEEL SENSOR

NBR122

SBR399D

ANTI-LOCK BRAKE SYSTEM

BR-42

Page 245 of 1767

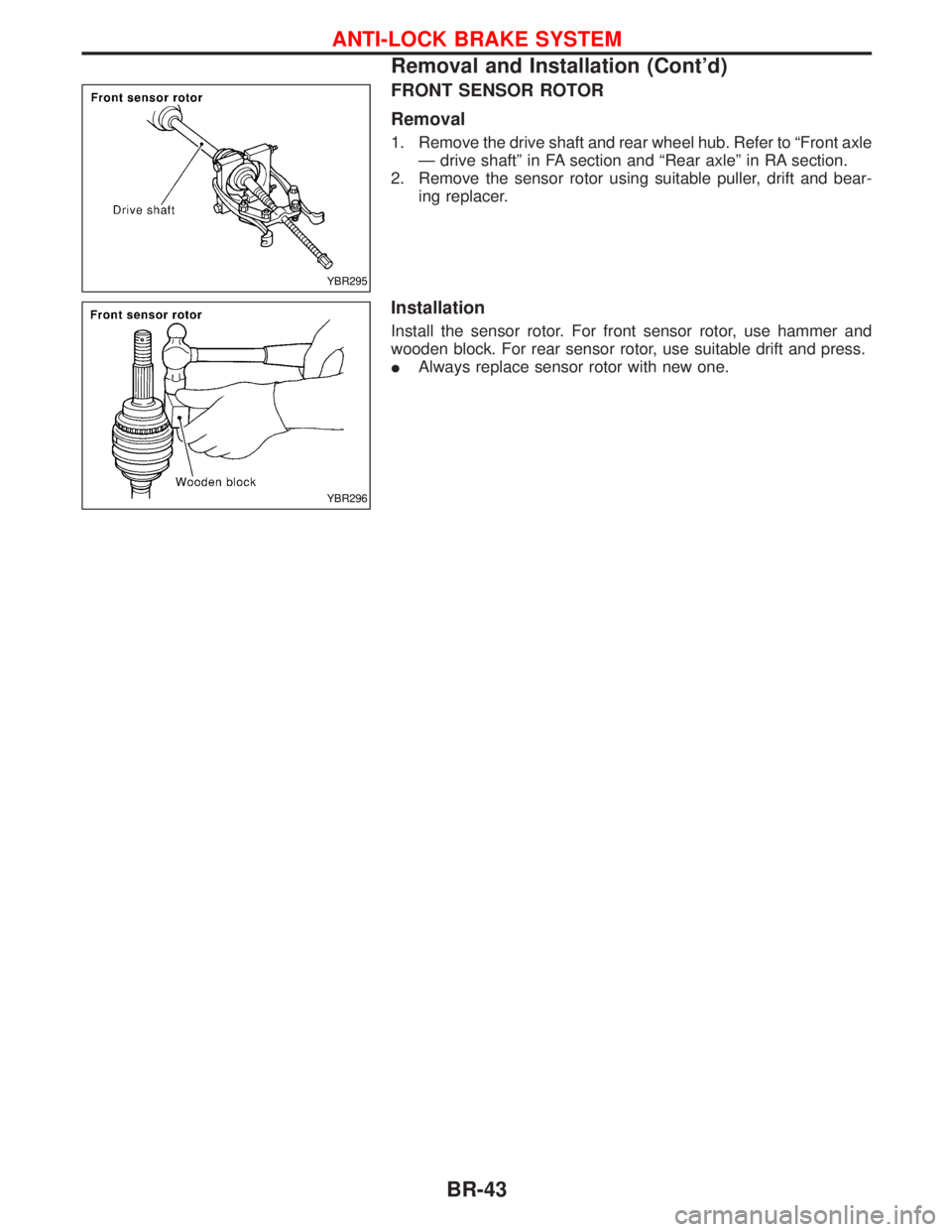

FRONT SENSOR ROTOR

Removal

1. Remove the drive shaft and rear wheel hub. Refer to ªFront axle

Ð drive shaftº in FA section and ªRear axleº in RA section.

2. Remove the sensor rotor using suitable puller, drift and bear-

ing replacer.

Installation

Install the sensor rotor. For front sensor rotor, use hammer and

wooden block. For rear sensor rotor, use suitable drift and press.

IAlways replace sensor rotor with new one.

YBR295

YBR296

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)

BR-43

Page 246 of 1767

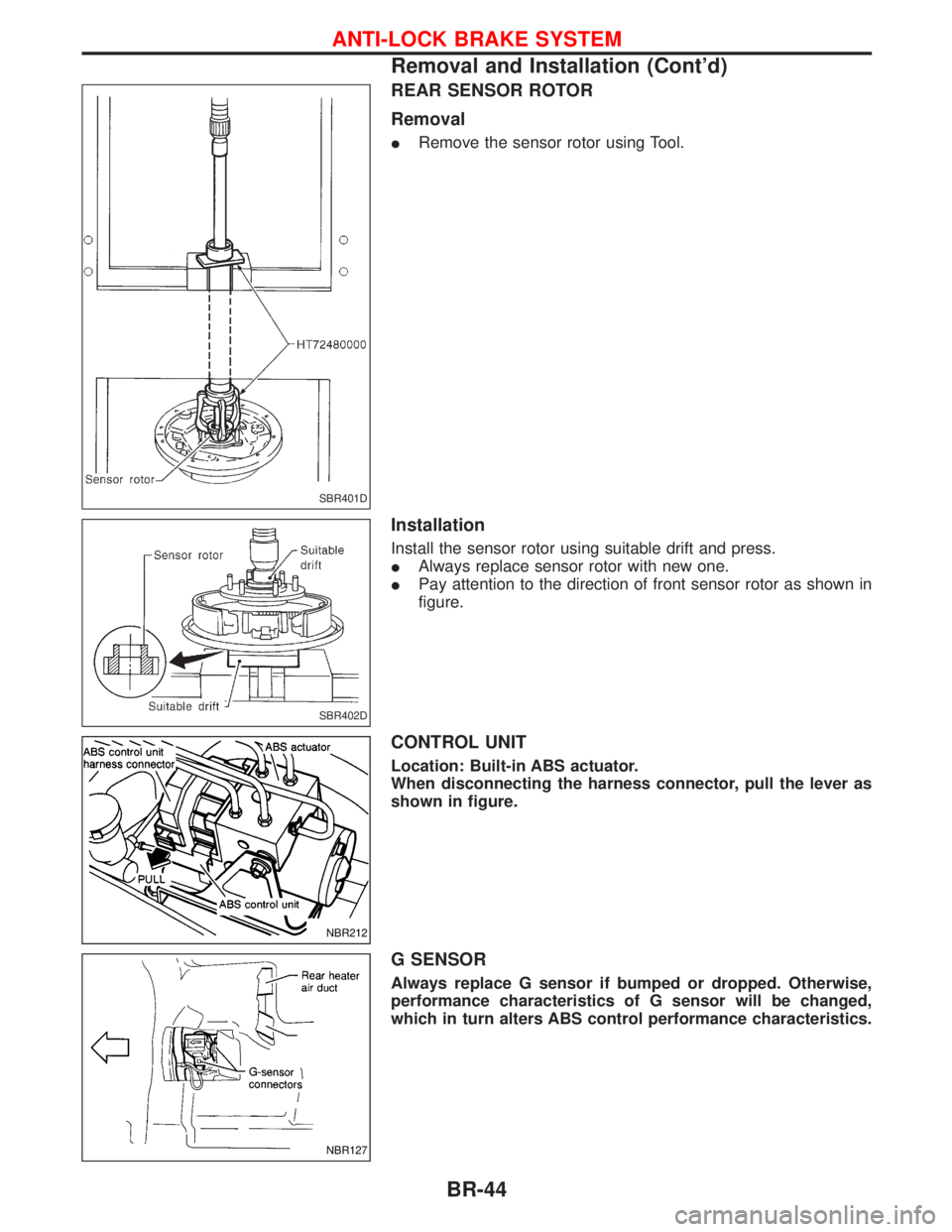

REAR SENSOR ROTOR

Removal

IRemove the sensor rotor using Tool.

Installation

Install the sensor rotor using suitable drift and press.

IAlways replace sensor rotor with new one.

IPay attention to the direction of front sensor rotor as shown in

figure.

CONTROL UNIT

Location: Built-in ABS actuator.

When disconnecting the harness connector, pull the lever as

shown in figure.

G SENSOR

Always replace G sensor if bumped or dropped. Otherwise,

performance characteristics of G sensor will be changed,

which in turn alters ABS control performance characteristics.

SBR401D

SBR402D

NBR212

NBR127

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)

BR-44

Page 249 of 1767

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

INTRODUCTION

The ABS system has an electronic control unit to control major

functions. The control unit accepts input signals from sensors and

uses this data to compute control characteristics to instantly drive

the actuators. It is essential that both kinds of signal are accurate

and stable. It is also important to check for conventional brake

system problems: such as air leaks in booster lines, lack of brake

fluid, or other problems with the brake system.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than catastrophically. Most intermittent problems are

caused by poor electric connections or faulty wiring. In this case,

careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check may not be sufficient to determine the cause of the

problems, so a road test should also be conducted.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with an ABS complaint. The customer

is a very good source of information on such problems; especially

intermittent ones. Through the talks with the customer, find out what

symptoms are present and under what conditions they occur.

Start your diagnosis by looking for ªconventionalº problems first.

This is one of the best ways to troubleshoot brake problems on an

ABS controlled vehicle.

SEF233G

SEF234G

TROUBLE DIAGNOSES

BR-47

Page 260 of 1767

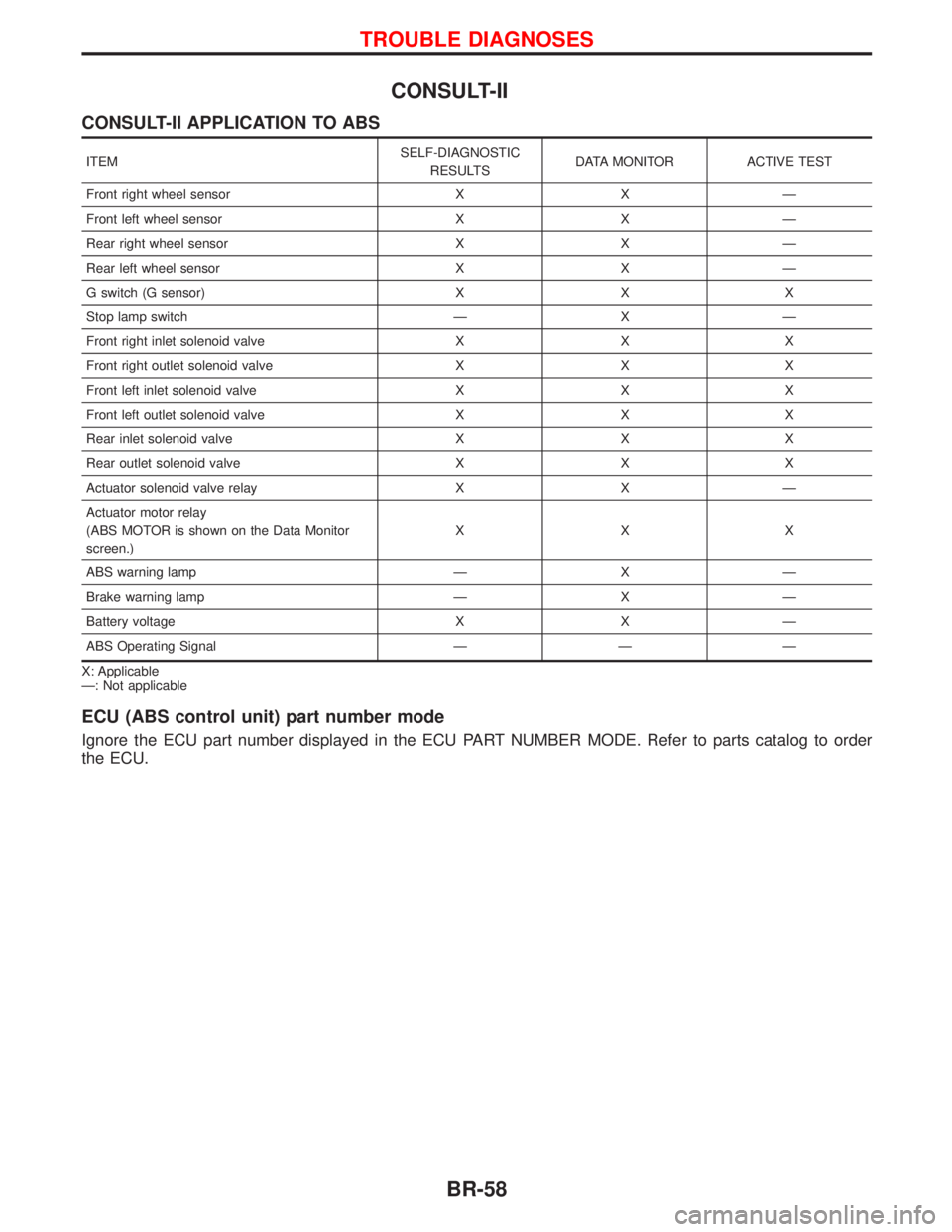

CONSULT-II

CONSULT-II APPLICATION TO ABS

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X Ð

Front left wheel sensor X X Ð

Rear right wheel sensor X X Ð

Rear left wheel sensor X X Ð

G switch (G sensor) X X X

Stop lamp switch Ð X Ð

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear inlet solenoid valve X X X

Rear outlet solenoid valve X X X

Actuator solenoid valve relay X X Ð

Actuator motor relay

(ABS MOTOR is shown on the Data Monitor

screen.)XXX

ABS warning lamp Ð X Ð

Brake warning lamp Ð X Ð

Battery voltage X X Ð

ABS Operating Signal Ð Ð Ð

X: Applicable

Ð: Not applicable

ECU (ABS control unit) part number mode

Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ECU.

TROUBLE DIAGNOSES

BR-58

Page 262 of 1767

![NISSAN TERRANO 2002 Service Workshop Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]ICircuit for front right wheel sensor is open.

(An abnormally high input voltag NISSAN TERRANO 2002 Service Workshop Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]ICircuit for front right wheel sensor is open.

(An abnormally high input voltag](/img/5/57393/w960_57393-261.png)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]ICircuit for front right wheel sensor is open.

(An abnormally high input voltage is entered.)4

FR LH SENSORH

[OPEN]ICircuit for front left wheel sensor is open.

(An abnormally high input voltage is entered.)4

RR RH SENSORH

[OPEN]ICircuit for rear right sensor is open.

(An abnormally high input voltage is entered.)4

RR LH SENSORH

[OPEN]ICircuit for rear left sensor is open.

(An abnormally high input voltage is entered.)4

FR RH SENSORH

[SHORT]ICircuit for front right wheel sensor is shorted.

(An abnormally low input voltage is entered.)4

FR LH SENSORH

[SHORT]ICircuit for front left wheel sensor is shorted.

(An abnormally low input voltage is entered.)4

RR RH SENSORH

[SHORT]ICircuit for rear right sensor is shorted.

(An abnormally low input voltage is entered.)4

RR LH SENSORH

[SHORT]ICircuit for rear left sensor is shorted.

(An abnormally low input voltage is entered.)4

ABS SENSORH

[ABNORMAL SIGNAL]ITeeth damage on sensor rotor or misalignment of wheel sensor.

(Abnormal wheel sensor signal is entered.)4

FR RH IN ABS SOL

[OPEN, SHORT]ICircuit for front right inlet solenoid valve is open or shorted.

(An abnormally low output voltage is entered.)3

FR LH IN ABS SOL

[OPEN, SHORT]ICircuit for front left inlet solenoid valve is open or shorted.

(An abnormally low output voltage is entered.)3

FR RH OUT ABS SOL

[OPEN, SHORT]ICircuit for front right outlet solenoid valve is open or shorted.

(An abnormally low output voltage is entered.)3

FR LH OUT ABS SOL

[OPEN, SHORT]ICircuit for front left outlet solenoid valve is open or shorted.

(An abnormally low output voltage is entered.)3

RR IN ABS SOL

[OPEN, SHORT]ICircuit for rear right outlet solenoid valve is open or shorted.

(An abnormally high output voltage is entered.)3

RR OUT ABS SOL

[OPEN, SHORT]ICircuit for rear left outlet solenoid valve is open or shorted.

(An abnormally high output voltage is entered.)3

ABS ACTUATOR RELAY

[ABNORMAL]IActuator solenoid valve relay is ON, even if control unit sends OFF signal.

IActuator solenoid valve relay is OFF, even if control unit sends ON signal.6

ABS MOTOR RELAY

[ABNORMAL]ICircuit for ABS motor relay is open or shorted.

ICircuit for actuator motor is open or shorted.

IActuator motor relay is stuck.5

BATTERY VOLT

[VB-LOW]IPower source voltage supplied to ABS control unit is abnormally low. 7

CONTROL UNITIFunction of calculation in ABS control unit has failed. 9

G-SENSOR

[ABNORMAL]IG sensor is open.8

HIf a tire slips on rough roads for more than 10 seconds, the ABS warning lamp may come on. In this case, the malfunctioning code

regarding the wheel sensors may be memorized. Turn off the ignition switch, restart the engine and drive the vehicle at speeds

above 30 km/h (19 MPH).

TROUBLE DIAGNOSES

CONSULT-II Inspection Procedure (Cont'd)

BR-60