fuel cap NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 386 of 1767

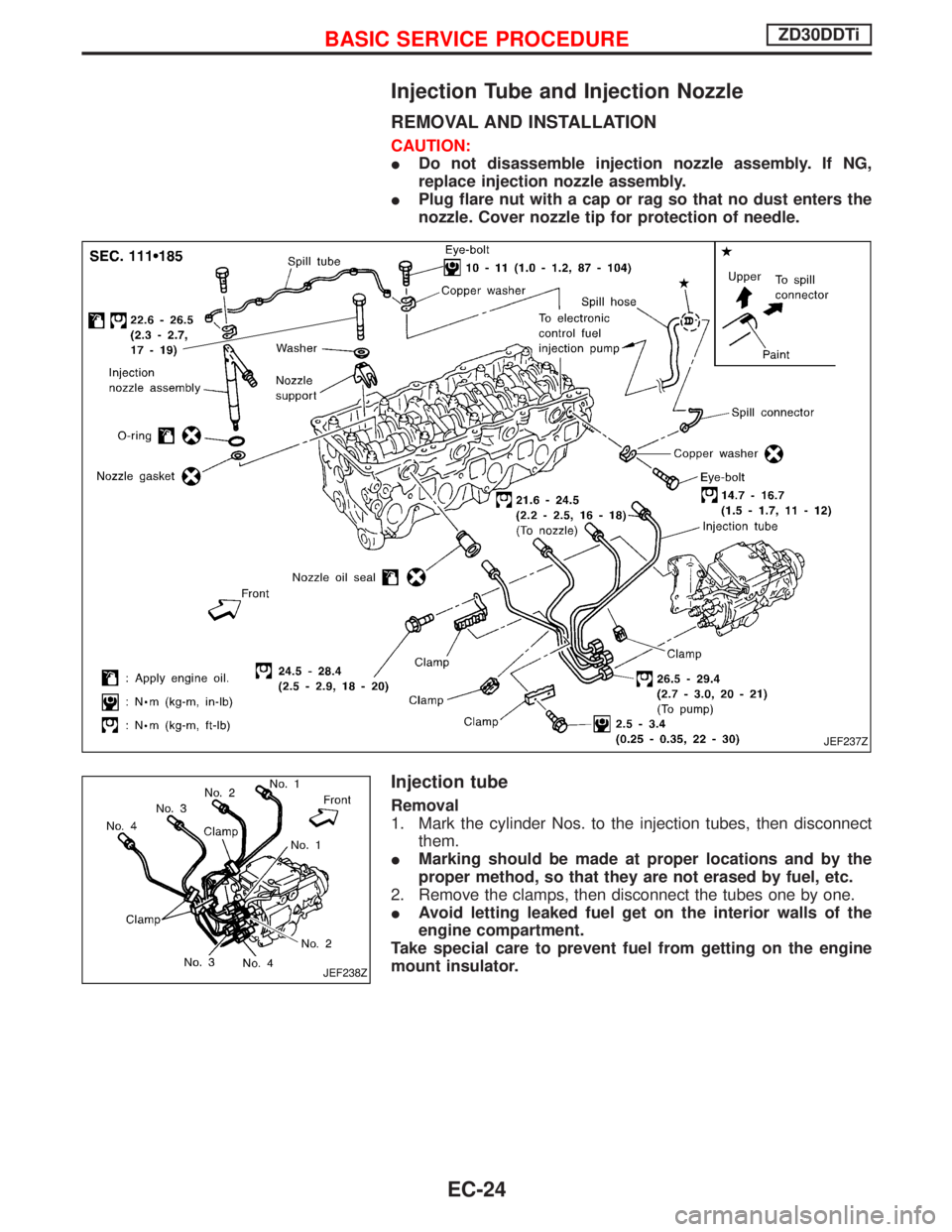

Injection Tube and Injection Nozzle

REMOVAL AND INSTALLATION

CAUTION:

IDo not disassemble injection nozzle assembly. If NG,

replace injection nozzle assembly.

IPlug flare nut with a cap or rag so that no dust enters the

nozzle. Cover nozzle tip for protection of needle.

Injection tube

Removal

1. Mark the cylinder Nos. to the injection tubes, then disconnect

them.

IMarking should be made at proper locations and by the

proper method, so that they are not erased by fuel, etc.

2. Remove the clamps, then disconnect the tubes one by one.

IAvoid letting leaked fuel get on the interior walls of the

engine compartment.

Take special care to prevent fuel from getting on the engine

mount insulator.

JEF237Z

JEF238Z

BASIC SERVICE PROCEDUREZD30DDTi

EC-24

Page 675 of 1767

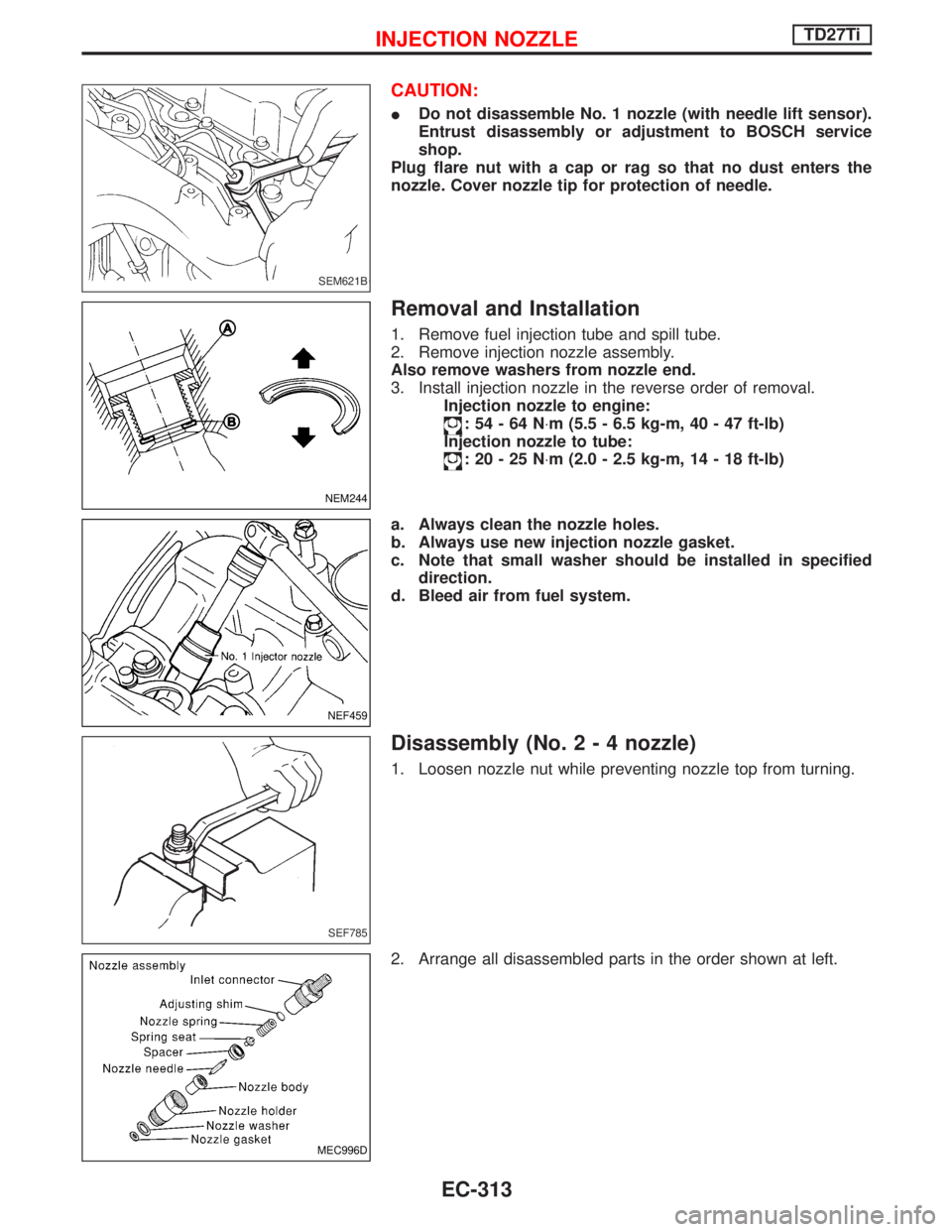

CAUTION:

IDo not disassemble No. 1 nozzle (with needle lift sensor).

Entrust disassembly or adjustment to BOSCH service

shop.

Plug flare nut with a cap or rag so that no dust enters the

nozzle. Cover nozzle tip for protection of needle.

Removal and Installation

1. Remove fuel injection tube and spill tube.

2. Remove injection nozzle assembly.

Also remove washers from nozzle end.

3. Install injection nozzle in the reverse order of removal.

Injection nozzle to engine:

:54-64N×m (5.5 - 6.5 kg-m, 40 - 47 ft-lb)

Injection nozzle to tube:

:20-25N×m (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

a. Always clean the nozzle holes.

b. Always use new injection nozzle gasket.

c. Note that small washer should be installed in specified

direction.

d. Bleed air from fuel system.

Disassembly (No.2-4nozzle)

1. Loosen nozzle nut while preventing nozzle top from turning.

2. Arrange all disassembled parts in the order shown at left.

SEM621B

NEM244

NEF459

SEF785

MEC996D

INJECTION NOZZLETD27Ti

EC-313

Page 859 of 1767

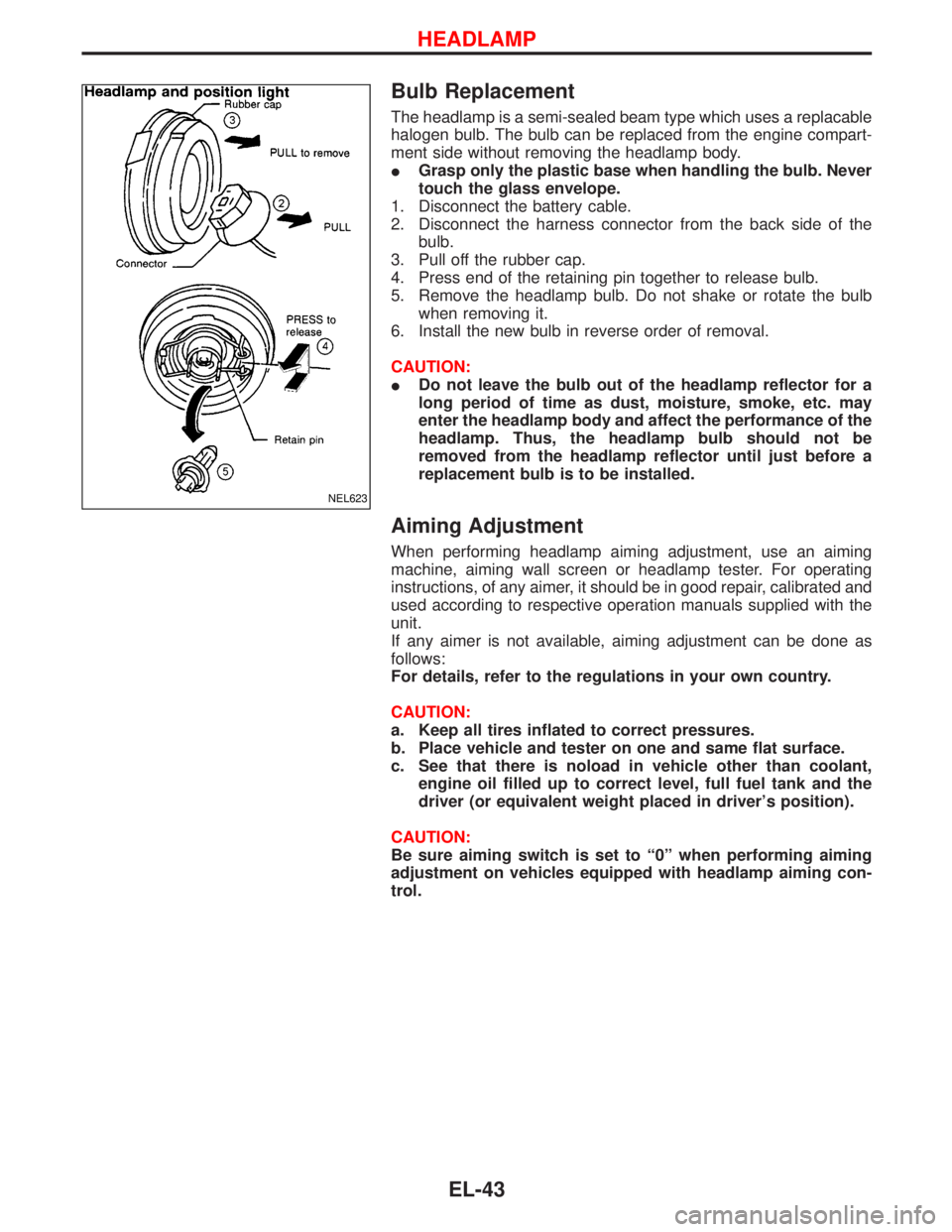

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb

when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

IDo not leave the bulb out of the headlamp reflector for a

long period of time as dust, moisture, smoke, etc. may

enter the headlamp body and affect the performance of the

headlamp. Thus, the headlamp bulb should not be

removed from the headlamp reflector until just before a

replacement bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

CAUTION:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

HEADLAMP

EL-43

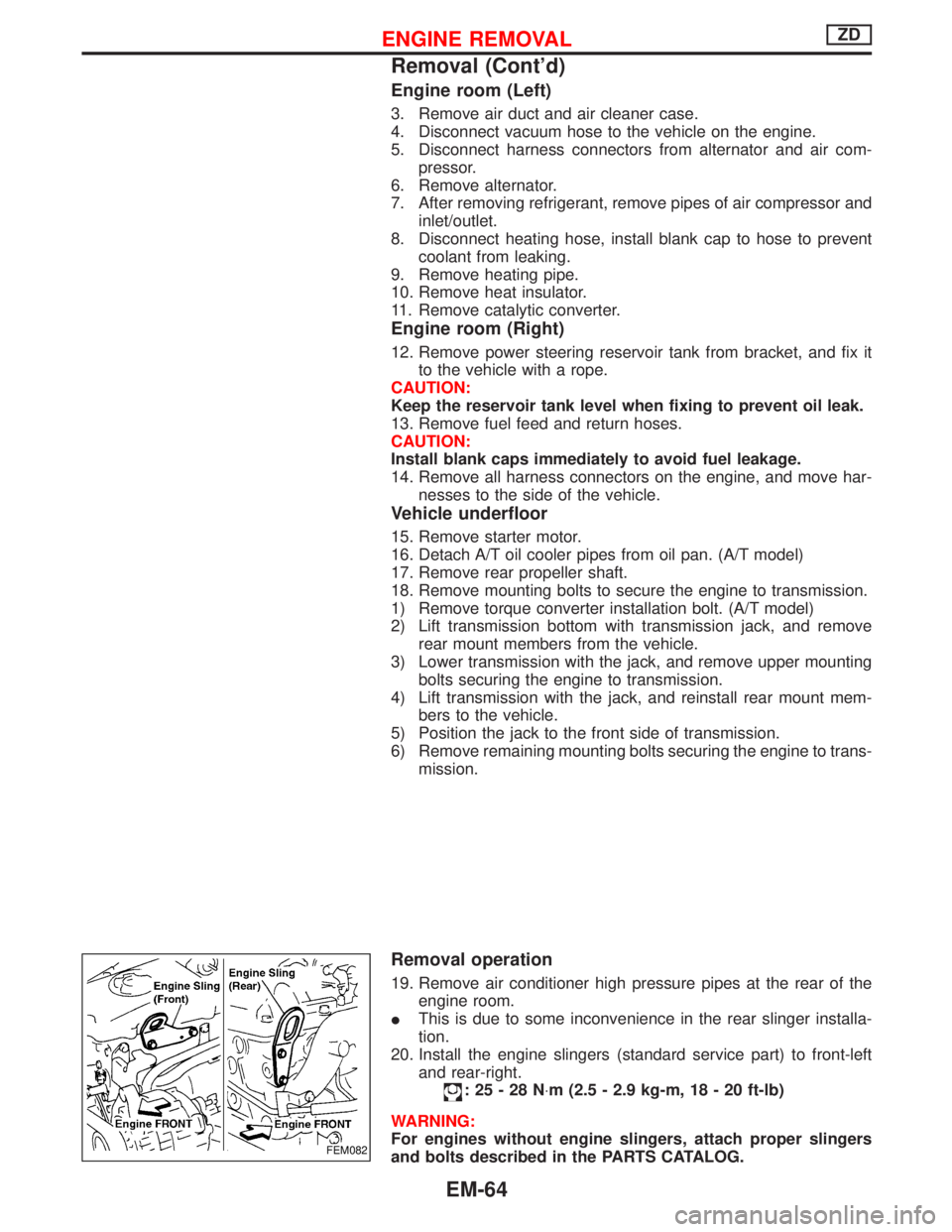

Page 1172 of 1767

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor and

inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix it

to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move har-

nesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mounting

bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to trans-

mission.

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

IThis is due to some inconvenience in the rear slinger installa-

tion.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28N×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-64

Page 1248 of 1767

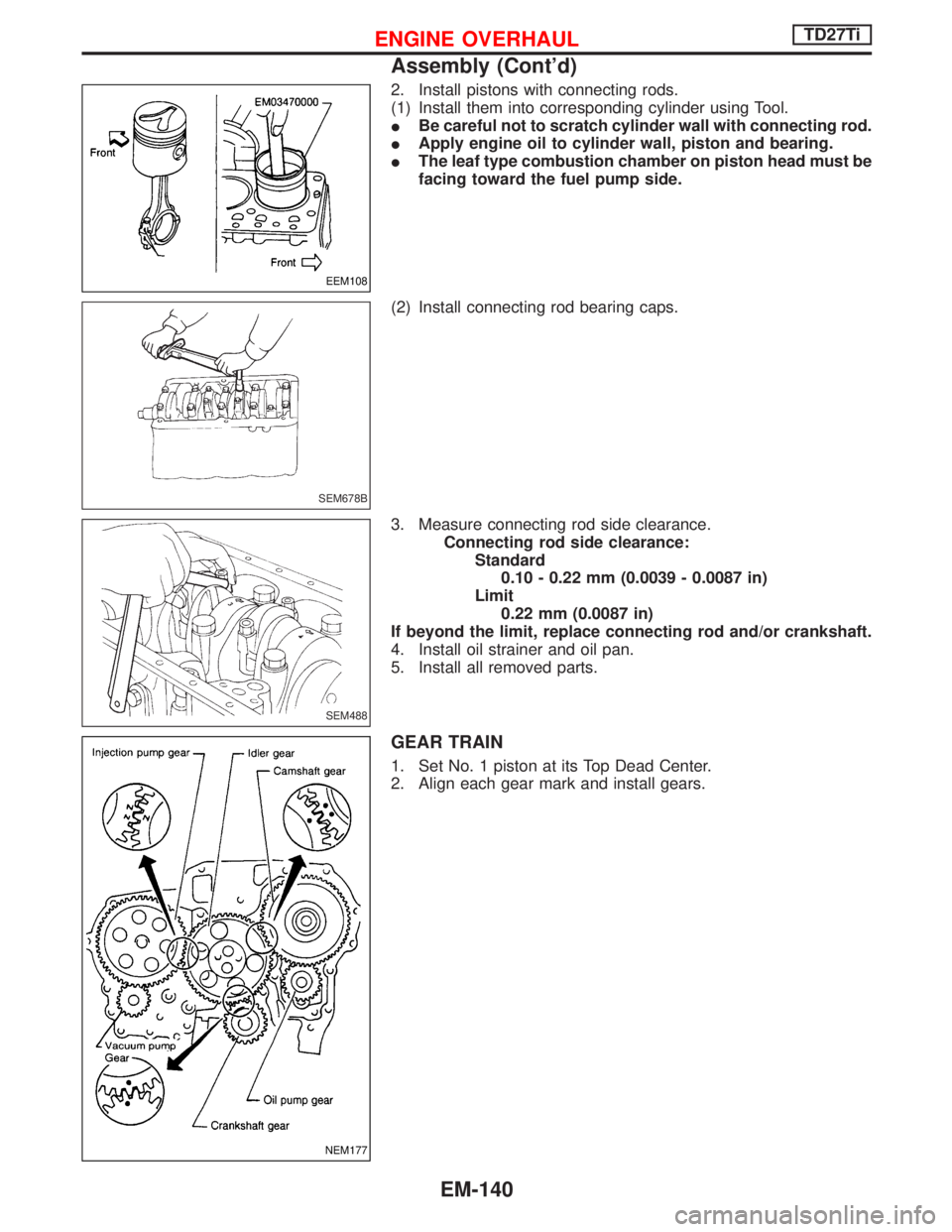

2. Install pistons with connecting rods.

(1) Install them into corresponding cylinder using Tool.

IBe careful not to scratch cylinder wall with connecting rod.

IApply engine oil to cylinder wall, piston and bearing.

IThe leaf type combustion chamber on piston head must be

facing toward the fuel pump side.

(2) Install connecting rod bearing caps.

3. Measure connecting rod side clearance.

Connecting rod side clearance:

Standard

0.10 - 0.22 mm (0.0039 - 0.0087 in)

Limit

0.22 mm (0.0087 in)

If beyond the limit, replace connecting rod and/or crankshaft.

4. Install oil strainer and oil pan.

5. Install all removed parts.

GEAR TRAIN

1. Set No. 1 piston at its Top Dead Center.

2. Align each gear mark and install gears.

EEM108

SEM678B

SEM488

NEM177

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-140

Page 1422 of 1767

INT/V - Wiring diagram ................................EC-274

Intake air control valve control solenoid

valve .........................................................EC-273

Intake Air Volume .........................................EC-143

Intake door control linkage adjustment ..........HA-63

Intake manifold...............................................EM-12

Interior .............................................................BT-18

Interior lamp ..............................................EL-61, 66

ISO 15031-2 Terminology................................GI-35

K

Knuckle spindle ...............................................FA-20

L

License lamp ...................................................EL-45

Limited slip diff. adjustment............................PD-45

Limited slip diff. assembly ..............................PD-47

Limited slip diff. disassembly ...................PD-43, 44

Limited slip diff. inspection .............................PD-44

Line pressure solenoid valve ..........................AT-84

Line pressure test (A/T) ..........................AT-30, 196

Liquid gasket application .................................EM-3

Location of electrical units ............EL-241, 242, 244

Lock, door ...........................................BT-10, 12, 14

Low and reverse brake .................................AT-161

LSV (Load sensing valve) ..............................BR-10

Lubricants.......................................................MA-17

Lubrication circuit (engine) .........................LC-3, 20

Lubrication oil A/C ....................................HA-22, 64

Lubrication-locks, hinges and hood

latches ..................................................MA-36, 45

Luggage compartment trim .............................BT-18

M

MAFS - Wiring diagram..................................EC-90

MAIN - Wiring diagram...................................EC-80

Main drive gear (M/T) .....................................MT-11

Main gear (Transfer) .................................TF-10, 21

Mainshaft (M/T) ..............................................MT-11

Mainshaft (Transfer)..................................TF-10, 17

Maintenance ...........MA-5, 8, 11, 14, 20, 36, 48, 49

MAJOR OVERHALL ......................................AT-119

Major overhaul (Transfer) .................................TF-9

Malfunction indicator (MI).......................EC-34, 322

Manifold tightening torque (intake &

exhaust) ...............................................MA-20, 28

Manual transmission number ..........................GI-30

Manual transmission oil replacement ......MA-36, 37

Map lamp ........................................................EL-66

Mass air flow sensor (MAFS) ................EC-88, 356

Master cylinder (brake) ..................................BR-16

Meter .........................................................EL-70, 71

METER - Wiring diagram................................EL-72

MIL/DL - Wiring diagram ..............................EC-291MIRROR - Wiring diagram............................EL-131

Mirror, door......................................................BT-48

Model variation ................................................GI-28

Molding - See Exterior ....................................BT-21

M/T major overhaul ........................................MT-10

M/T removal and installation ........................MT-7, 8

Mud guard - See Exterior ...............................BT-21

MULTI - Wiring diagram................................EL-169

Multi-remote control system .........EL-168, 177, 179

Multiport fuel injection precautions ....................GI-5

N

NATS (Nissan anti-theft

system) .....................EL-186, 187, 188, 195, 208

NATS - Wiring diagram .................................EL-189

NATS V2.0 precautions (For Europe) ...............GI-4

Needle lift sensor .........................................EC-427

NVH troubleshooting (EM) ...............................EM-8

O

Oil change (capacity) ............MA-21, 29, 37, 38, 39

Oil change (interval) ..................................MA-5, 35

Oil cooler (engine) ............................................LC-8

Oil pan (engine) .............................................EM-22

Oil pump (A/T)...............................................AT-134

Oil seal replacement (engine)........................EM-50

Oil seal replacement (front final drive

4WD)...........................................................PD-10

OILPSW - Wiring diagram............................EC-451

On board diagnostic system ..................EC-33, 321

Overdrive control switch..................................AT-95

Overheat .......................................................EC-109

Overrun clutch solenoid valve ..................AT-69, 70

Oversize piston ..............................................EM-74

P

Park/Neutral position switch .........................EC-251

Park/neutral position switch (A/T) ...........AT-88, 114

Parking drum brake ........................................BR-35

Parking lamp ...................................................EL-45

PCV (positive crankcase ventilation) .....EC-23, 312

Periodic maintenance ......................................MA-5

Piston pin inspection ......................................EM-71

Piston ring inspection.....................................EM-72

PNP/SW - Wiring diagram ...........................EC-252

POWER - Wiring diagram.................................EL-8

Power door lock ...EL-137, 138, 145, 146, 148, 158

Power steering fluid level...............MA-36, 44, ST-4

Power steering gear .................................ST-12, 22

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ....................................EL-6, 8

Power window ...............................................EL-133

ALPHABETICAL INDEX

IDX-5

Page 1482 of 1767

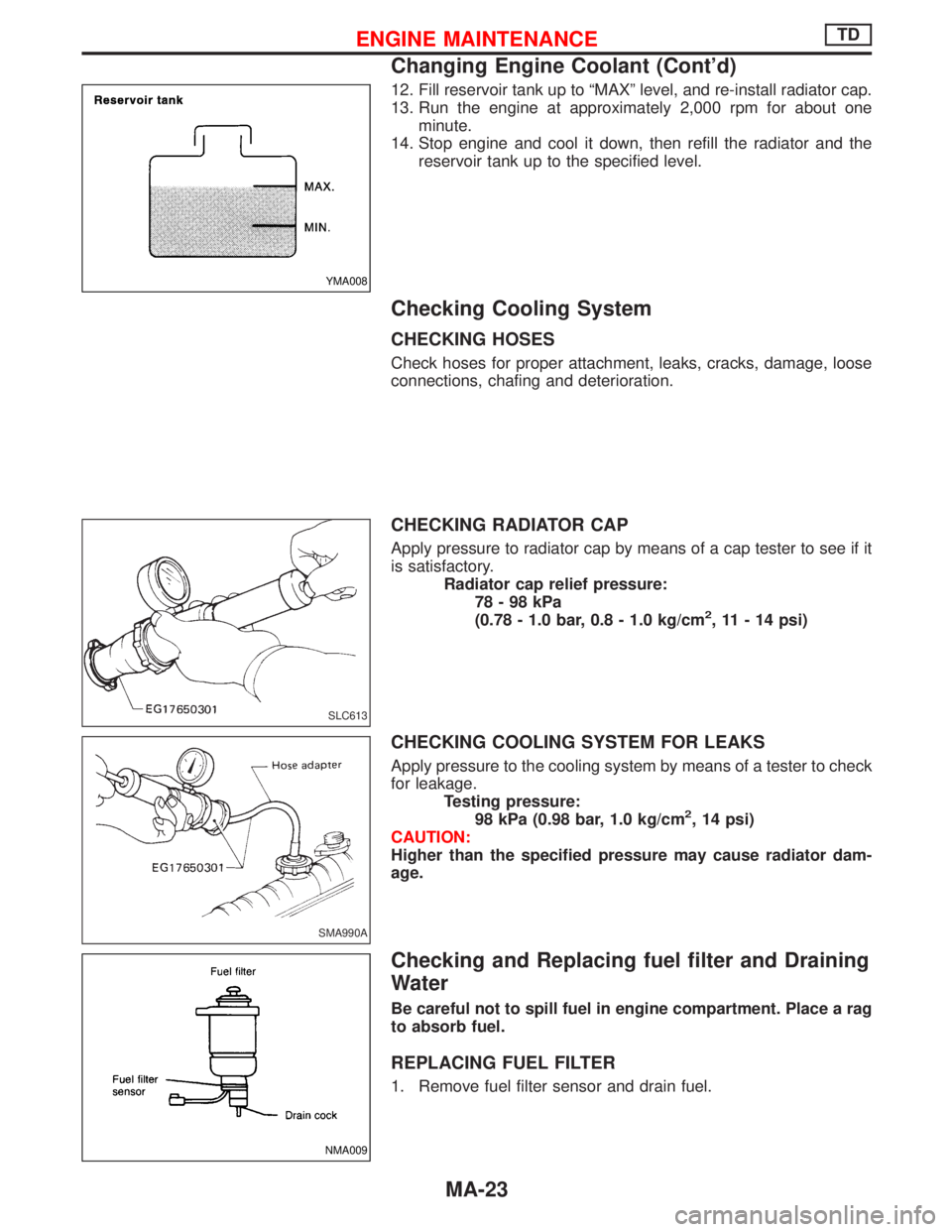

12. Fill reservoir tank up to ªMAXº level, and re-install radiator cap.

13. Run the engine at approximately 2,000 rpm for about one

minute.

14. Stop engine and cool it down, then refill the radiator and the

reservoir tank up to the specified level.

Checking Cooling System

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage, loose

connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see if it

is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 1.0 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Higher than the specified pressure may cause radiator dam-

age.

Checking and Replacing fuel filter and Draining

Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

REPLACING FUEL FILTER

1. Remove fuel filter sensor and drain fuel.

YMA008

SLC613

SMA990A

NMA009

ENGINE MAINTENANCETD

Changing Engine Coolant (Cont'd)

MA-23

Page 1484 of 1767

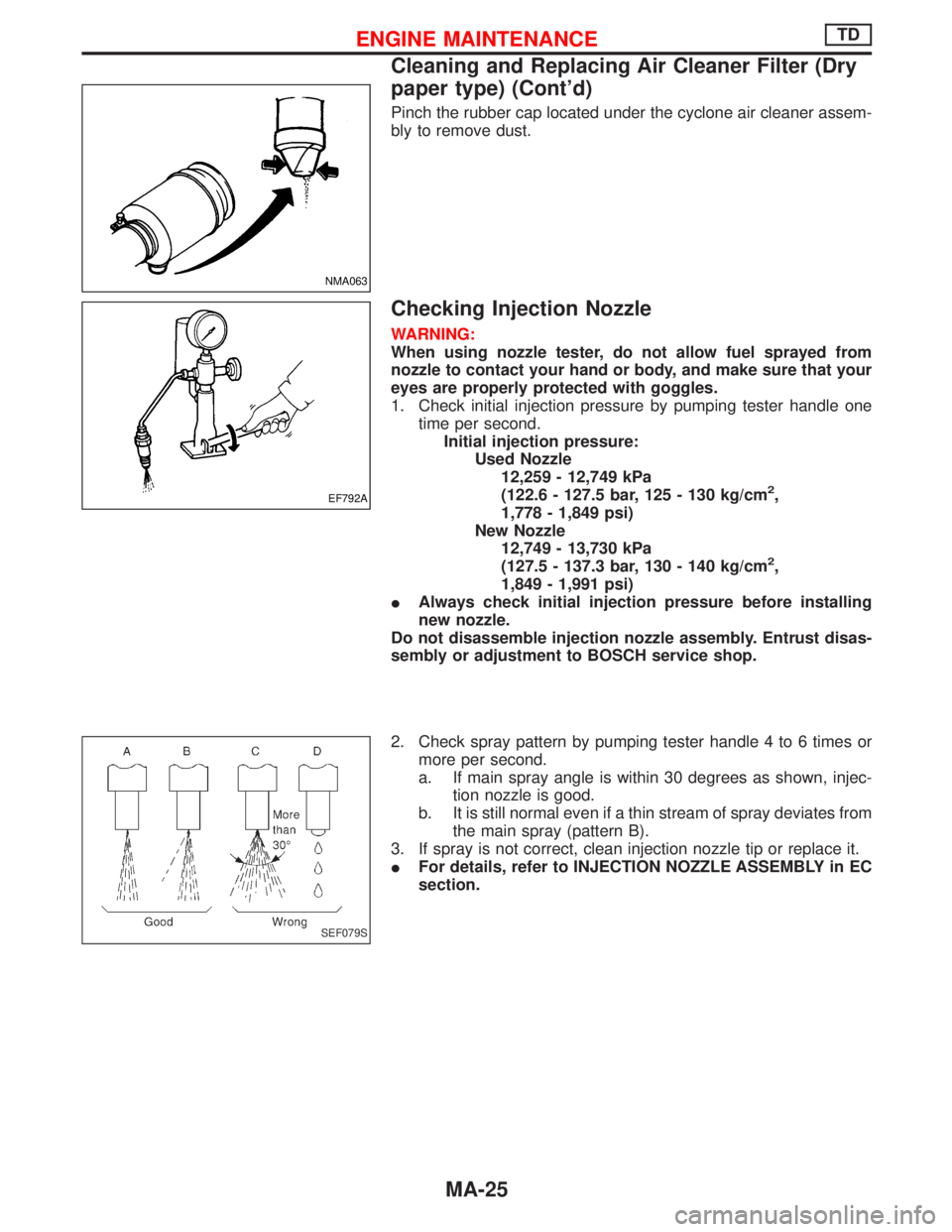

Pinch the rubber cap located under the cyclone air cleaner assem-

bly to remove dust.

Checking Injection Nozzle

WARNING:

When using nozzle tester, do not allow fuel sprayed from

nozzle to contact your hand or body, and make sure that your

eyes are properly protected with goggles.

1. Check initial injection pressure by pumping tester handle one

time per second.

Initial injection pressure:

Used Nozzle

12,259 - 12,749 kPa

(122.6 - 127.5 bar, 125 - 130 kg/cm

2,

1,778 - 1,849 psi)

New Nozzle

12,749 - 13,730 kPa

(127.5 - 137.3 bar, 130 - 140 kg/cm

2,

1,849 - 1,991 psi)

IAlways check initial injection pressure before installing

new nozzle.

Do not disassemble injection nozzle assembly. Entrust disas-

sembly or adjustment to BOSCH service shop.

2. Check spray pattern by pumping tester handle 4 to 6 times or

more per second.

a. If main spray angle is within 30 degrees as shown, injec-

tion nozzle is good.

b. It is still normal even if a thin stream of spray deviates from

the main spray (pattern B).

3. If spray is not correct, clean injection nozzle tip or replace it.

IFor details, refer to INJECTION NOZZLE ASSEMBLY in EC

section.

NMA063

EF792A

SEF079S

ENGINE MAINTENANCETD

Cleaning and Replacing Air Cleaner Filter (Dry

paper type) (Cont'd)

MA-25

Page 1485 of 1767

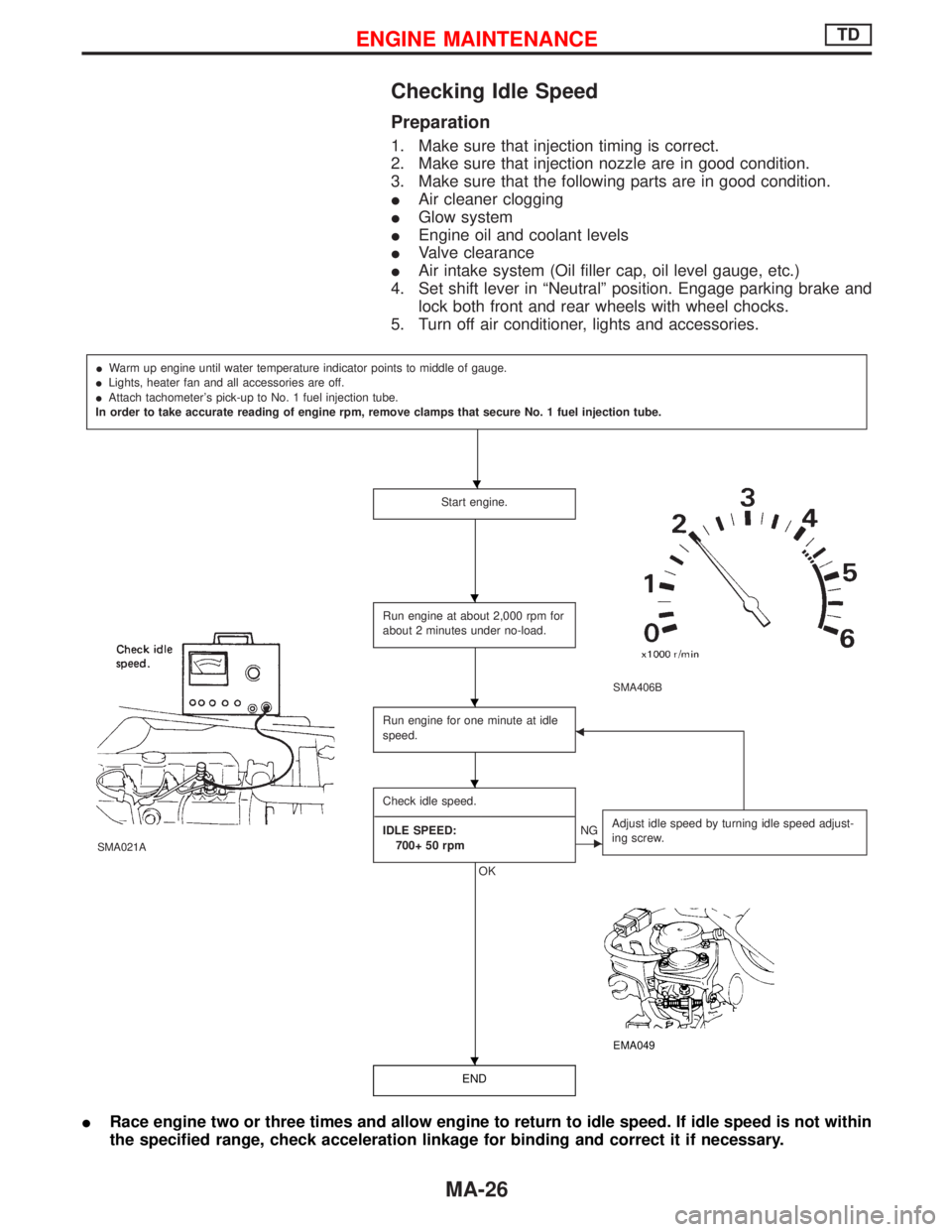

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

IGlow system

IEngine oil and coolant levels

IValve clearance

IAir intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and

lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

IWarm up engine until water temperature indicator points to middle of gauge.

ILights, heater fan and all accessories are off.

IAttach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

IDLE SPEED:

700+ 50 rpm

OK

ENGAdjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

IRace engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

Page 1492 of 1767

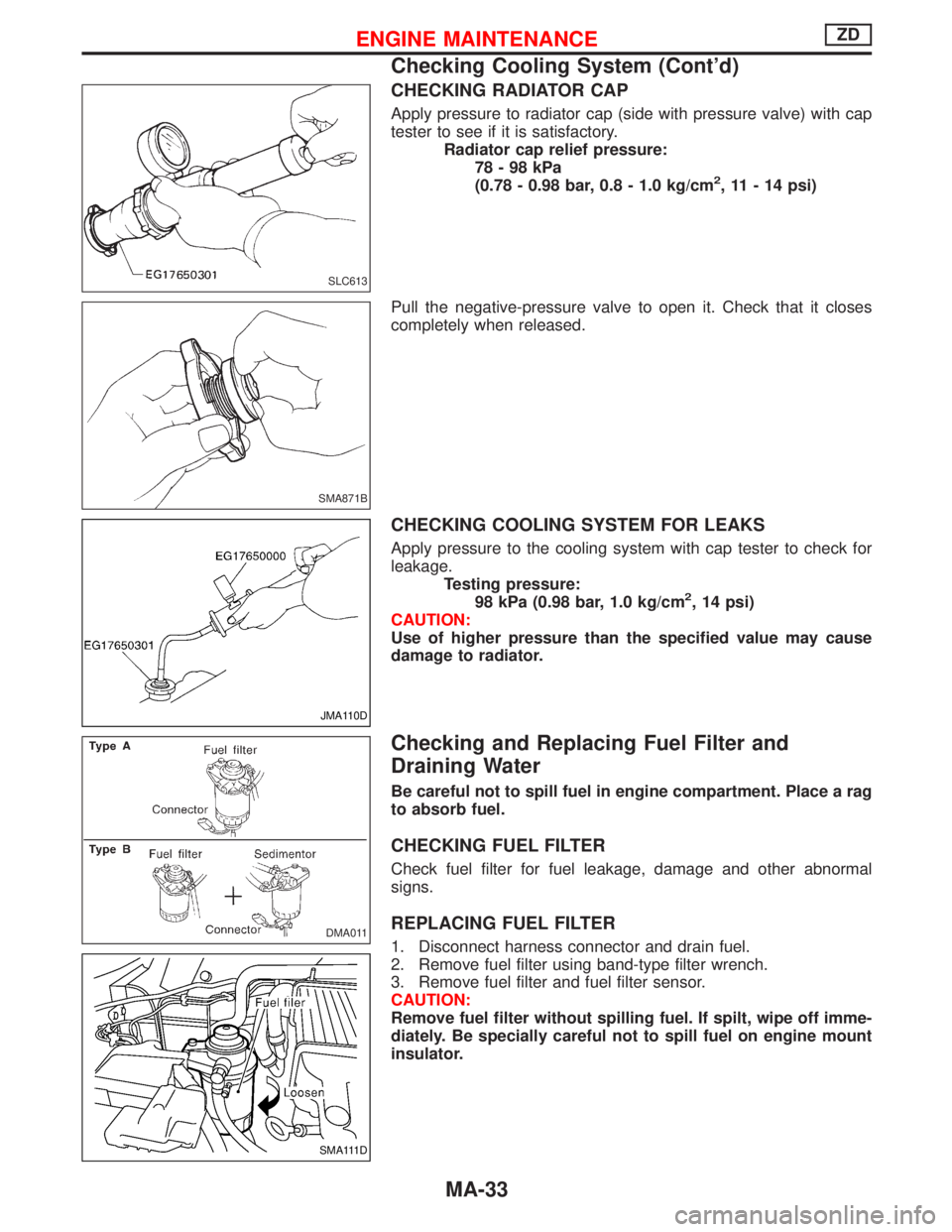

CHECKING RADIATOR CAP

Apply pressure to radiator cap (side with pressure valve) with cap

tester to see if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the specified value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel filter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

2. Remove fuel filter using band-type filter wrench.

3. Remove fuel filter and fuel filter sensor.

CAUTION:

Remove fuel filter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

SLC613

SMA871B

JMA110D

DMA011

SMA111D

ENGINE MAINTENANCEZD

Checking Cooling System (Cont'd)

MA-33