Start NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 267 of 1767

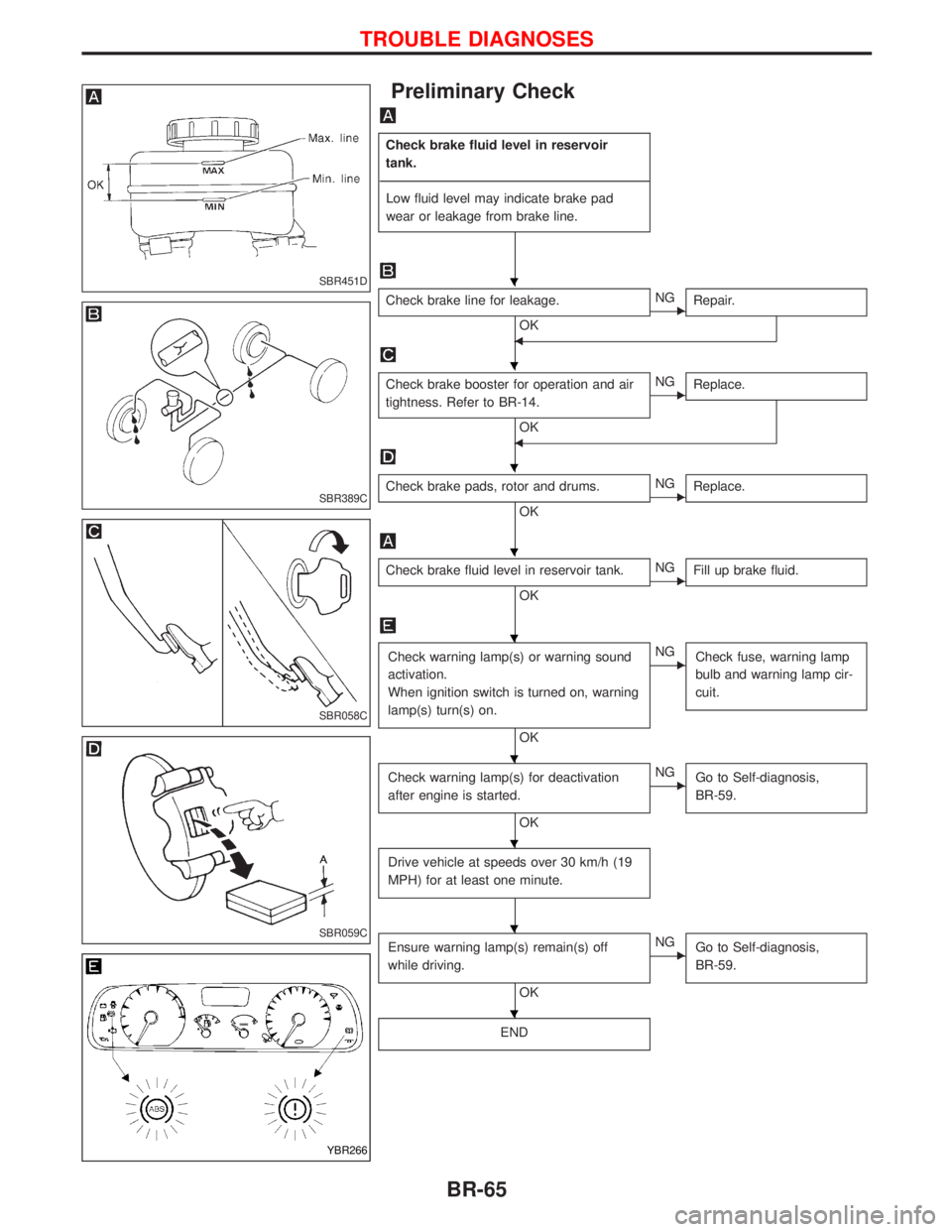

Preliminary Check

Check brake fluid level in reservoir

tank.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low fluid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKENG

Repair.

F

Check brake booster for operation and air

tightness. Refer to BR-14.

OK

ENG

Replace.

F

Check brake pads, rotor and drums.

OKENG

Replace.

Check brake fluid level in reservoir tank.

OKENG

Fill up brake fluid.

Check warning lamp(s) or warning sound

activation.

When ignition switch is turned on, warning

lamp(s) turn(s) on.

OK

ENG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp(s) for deactivation

after engine is started.

OK

ENG

Go to Self-diagnosis,

BR-59.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least one minute.

Ensure warning lamp(s) remain(s) off

while driving.

OK

ENG

Go to Self-diagnosis,

BR-59.

END

SBR451D

SBR389C

SBR058C

SBR059C

YBR266

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-65

Page 275 of 1767

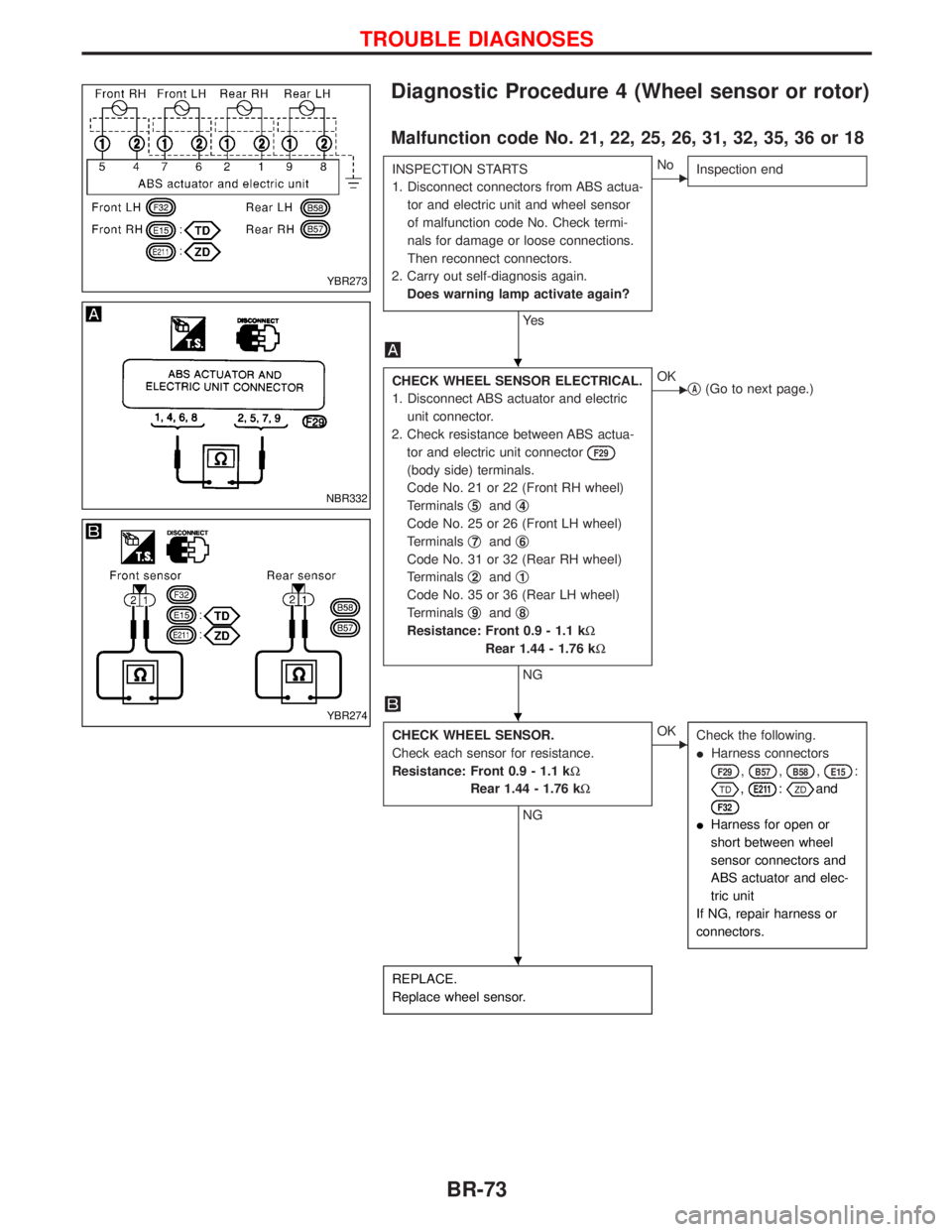

Diagnostic Procedure 4 (Wheel sensor or rotor)

Malfunction code No. 21, 22, 25, 26, 31, 32, 35, 36 or 18

INSPECTION STARTS

1. Disconnect connectors from ABS actua-

tor and electric unit and wheel sensor

of malfunction code No. Check termi-

nals for damage or loose connections.

Then reconnect connectors.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s

ENo

Inspection end

CHECK WHEEL SENSOR ELECTRICAL.

1. Disconnect ABS actuator and electric

unit connector.

2. Check resistance between ABS actua-

tor and electric unit connector

F29

(body side) terminals.

Code No. 21 or 22 (Front RH wheel)

Terminalsq

5andq4

Code No. 25 or 26 (Front LH wheel)

Terminalsq

7andq6

Code No. 31 or 32 (Rear RH wheel)

Terminalsq

2andq1

Code No. 35 or 36 (Rear LH wheel)

Terminalsq

9andq8

Resistance: Front 0.9 - 1.1 kW

Rear 1.44 - 1.76 kW

NG

EOK

qA(Go to next page.)

CHECK WHEEL SENSOR.

Check each sensor for resistance.

Resistance: Front 0.9 - 1.1 kW

Rear 1.44 - 1.76 kW

NG

EOK

Check the following.

IHarness connectors

F29,B57,B58,E15:

,E211:and

F32

IHarness for open or

short between wheel

sensor connectors and

ABS actuator and elec-

tric unit

If NG, repair harness or

connectors.

REPLACE.

Replace wheel sensor.

YBR273

NBR332

YBR274

H

H

H

TROUBLE DIAGNOSES

BR-73

Page 282 of 1767

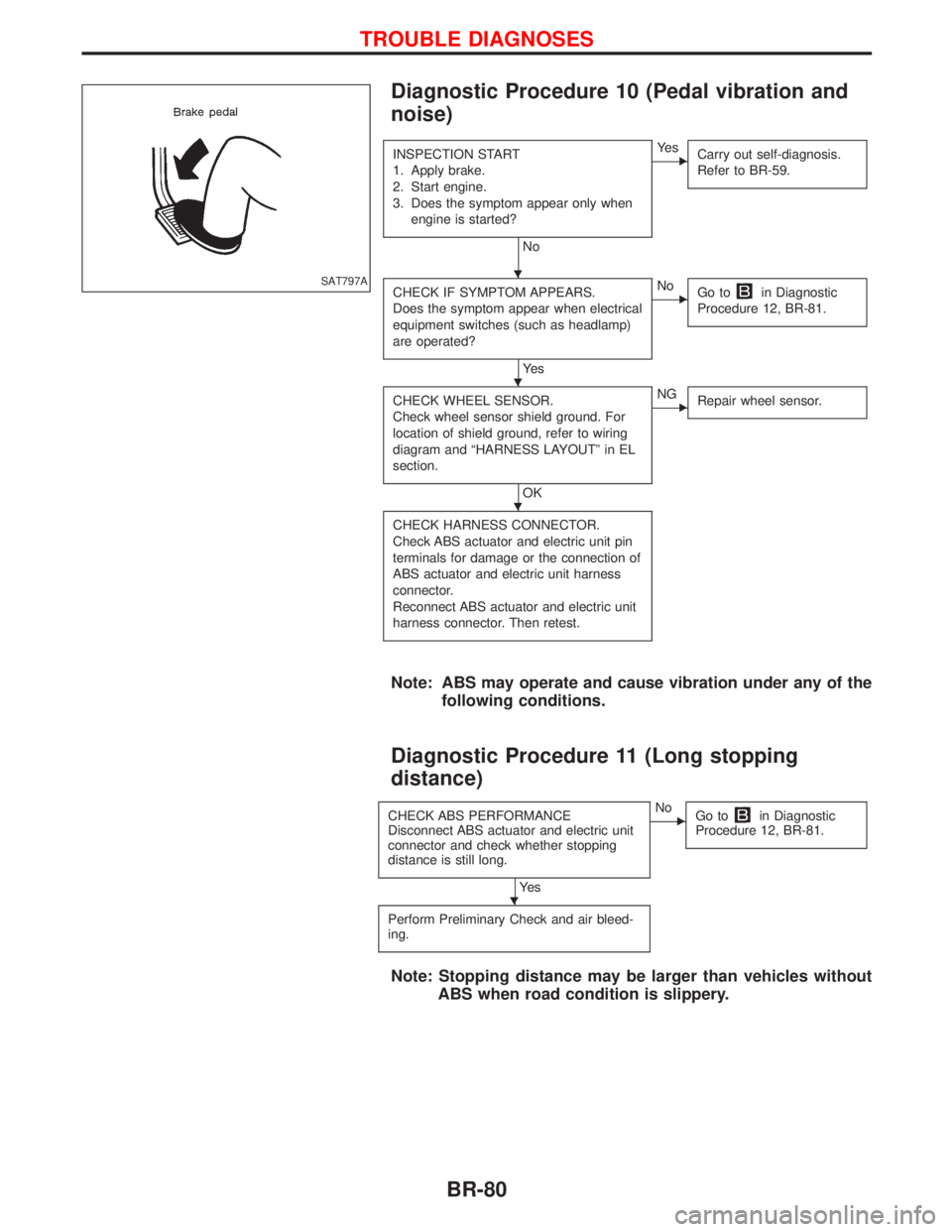

Diagnostic Procedure 10 (Pedal vibration and

noise)

INSPECTION START

1. Apply brake.

2. Start engine.

3. Does the symptom appear only when

engine is started?

No

EYe s

Carry out self-diagnosis.

Refer to BR-59.

CHECK IF SYMPTOM APPEARS.

Does the symptom appear when electrical

equipment switches (such as headlamp)

are operated?

Ye s

ENo

Go toin Diagnostic

Procedure 12, BR-81.

CHECK WHEEL SENSOR.

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ªHARNESS LAYOUTº in EL

section.

OK

ENG

Repair wheel sensor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Note: ABS may operate and cause vibration under any of the

following conditions.

Diagnostic Procedure 11 (Long stopping

distance)

CHECK ABS PERFORMANCE

Disconnect ABS actuator and electric unit

connector and check whether stopping

distance is still long.

Ye s

ENo

Go toin Diagnostic

Procedure 12, BR-81.

Perform Preliminary Check and air bleed-

ing.

Note: Stopping distance may be larger than vehicles without

ABS when road condition is slippery.

SAT797AH

H

H

H

TROUBLE DIAGNOSES

BR-80

Page 365 of 1767

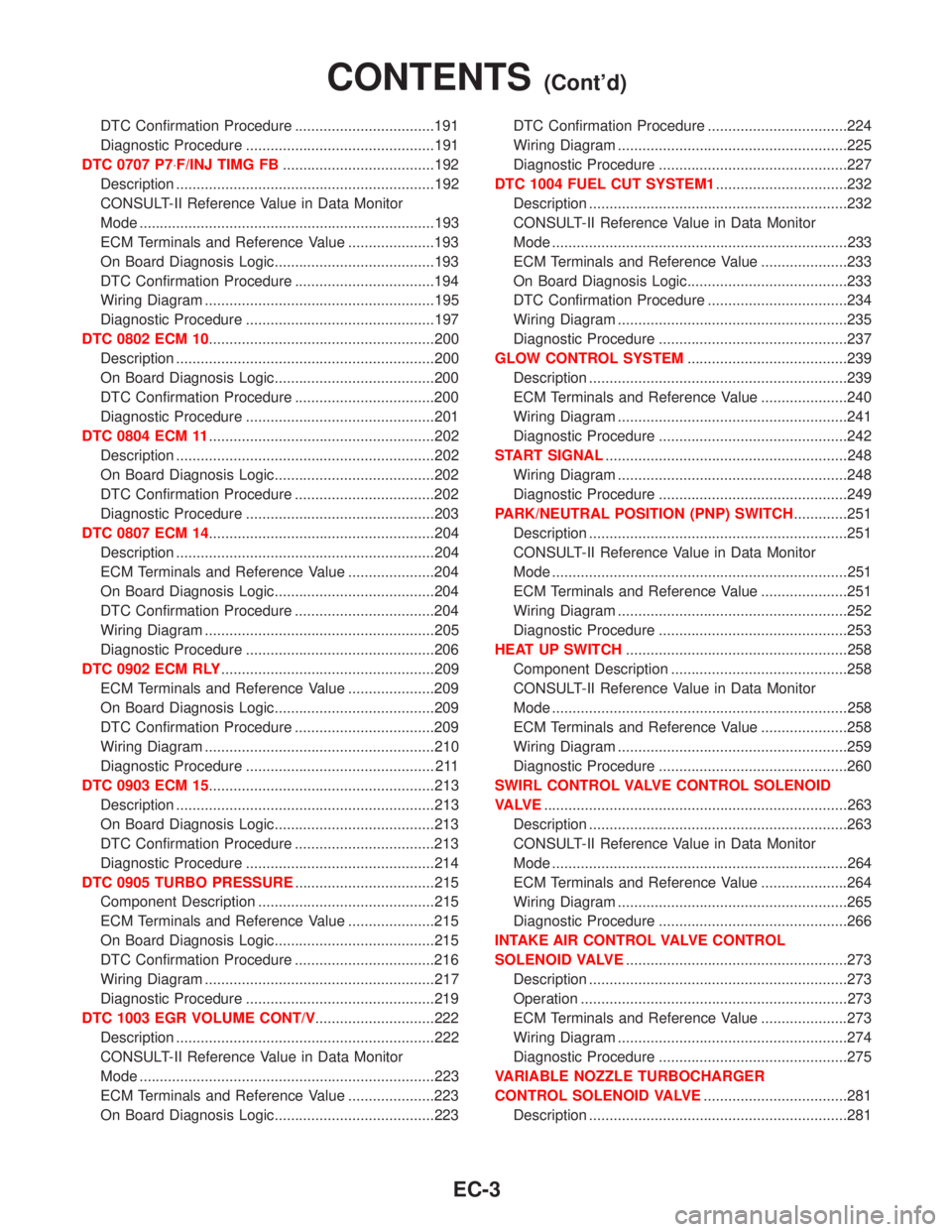

DTC Confirmation Procedure ..................................191

Diagnostic Procedure ..............................................191

DTC 0707 P7×F/INJ TIMG FB.....................................192

Description ...............................................................192

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................193

ECM Terminals and Reference Value .....................193

On Board Diagnosis Logic.......................................193

DTC Confirmation Procedure ..................................194

Wiring Diagram ........................................................195

Diagnostic Procedure ..............................................197

DTC 0802 ECM 10.......................................................200

Description ...............................................................200

On Board Diagnosis Logic.......................................200

DTC Confirmation Procedure ..................................200

Diagnostic Procedure ..............................................201

DTC 0804 ECM 11.......................................................202

Description ...............................................................202

On Board Diagnosis Logic.......................................202

DTC Confirmation Procedure ..................................202

Diagnostic Procedure ..............................................203

DTC 0807 ECM 14.......................................................204

Description ...............................................................204

ECM Terminals and Reference Value .....................204

On Board Diagnosis Logic.......................................204

DTC Confirmation Procedure ..................................204

Wiring Diagram ........................................................205

Diagnostic Procedure ..............................................206

DTC 0902 ECM RLY....................................................209

ECM Terminals and Reference Value .....................209

On Board Diagnosis Logic.......................................209

DTC Confirmation Procedure ..................................209

Wiring Diagram ........................................................210

Diagnostic Procedure .............................................. 211

DTC 0903 ECM 15.......................................................213

Description ...............................................................213

On Board Diagnosis Logic.......................................213

DTC Confirmation Procedure ..................................213

Diagnostic Procedure ..............................................214

DTC 0905 TURBO PRESSURE..................................215

Component Description ...........................................215

ECM Terminals and Reference Value .....................215

On Board Diagnosis Logic.......................................215

DTC Confirmation Procedure ..................................216

Wiring Diagram ........................................................217

Diagnostic Procedure ..............................................219

DTC 1003 EGR VOLUME CONT/V.............................222

Description ...............................................................222

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................223

ECM Terminals and Reference Value .....................223

On Board Diagnosis Logic.......................................223DTC Confirmation Procedure ..................................224

Wiring Diagram ........................................................225

Diagnostic Procedure ..............................................227

DTC 1004 FUEL CUT SYSTEM1................................232

Description ...............................................................232

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................233

ECM Terminals and Reference Value .....................233

On Board Diagnosis Logic.......................................233

DTC Confirmation Procedure ..................................234

Wiring Diagram ........................................................235

Diagnostic Procedure ..............................................237

GLOW CONTROL SYSTEM.......................................239

Description ...............................................................239

ECM Terminals and Reference Value .....................240

Wiring Diagram ........................................................241

Diagnostic Procedure ..............................................242

START SIGNAL...........................................................248

Wiring Diagram ........................................................248

Diagnostic Procedure ..............................................249

PARK/NEUTRAL POSITION (PNP) SWITCH.............251

Description ...............................................................251

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................251

ECM Terminals and Reference Value .....................251

Wiring Diagram ........................................................252

Diagnostic Procedure ..............................................253

HEAT UP SWITCH......................................................258

Component Description ...........................................258

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................258

ECM Terminals and Reference Value .....................258

Wiring Diagram ........................................................259

Diagnostic Procedure ..............................................260

SWIRL CONTROL VALVE CONTROL SOLENOID

VA LV E..........................................................................263

Description ...............................................................263

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................264

ECM Terminals and Reference Value .....................264

Wiring Diagram ........................................................265

Diagnostic Procedure ..............................................266

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVE......................................................273

Description ...............................................................273

Operation .................................................................273

ECM Terminals and Reference Value .....................273

Wiring Diagram ........................................................274

Diagnostic Procedure ..............................................275

VARIABLE NOZZLE TURBOCHARGER

CONTROL SOLENOID VALVE...................................281

Description ...............................................................281

CONTENTS(Cont'd)

EC-3

Page 368 of 1767

Diagnostic Procedure ..............................................443

DTC PD1603 ECM 12, DTC P1607 ECM2.................444

Description ...............................................................444

On Board Diagnosis Logic.......................................444

DTC Confirmation Procedure ..................................444

Diagnostic Procedure ..............................................445

DTC P1620 ECM RLY.................................................446

On Board Diagnosis Logic.......................................446

DTC Confirmation Procedure ..................................446

Wiring Diagram ........................................................447

Diagnostic Procedure ..............................................448START SIGNAL...........................................................449

Wiring Diagram ........................................................449

Diagnostic Procedure ..............................................450

OIL PRESSURE SWITCH...........................................451

Wiring Diagram ........................................................451

MI & DATA LINK CONNECTORS...............................452

Wiring Diagram ........................................................452

SERVICE DATA AND SPECIFICATIONS (SDS)........453

General Specifications .............................................453

Injection Nozzle .......................................................453

Inspection and Adjustment ......................................453

CONTENTS(Cont'd)

EC-6

Page 371 of 1767

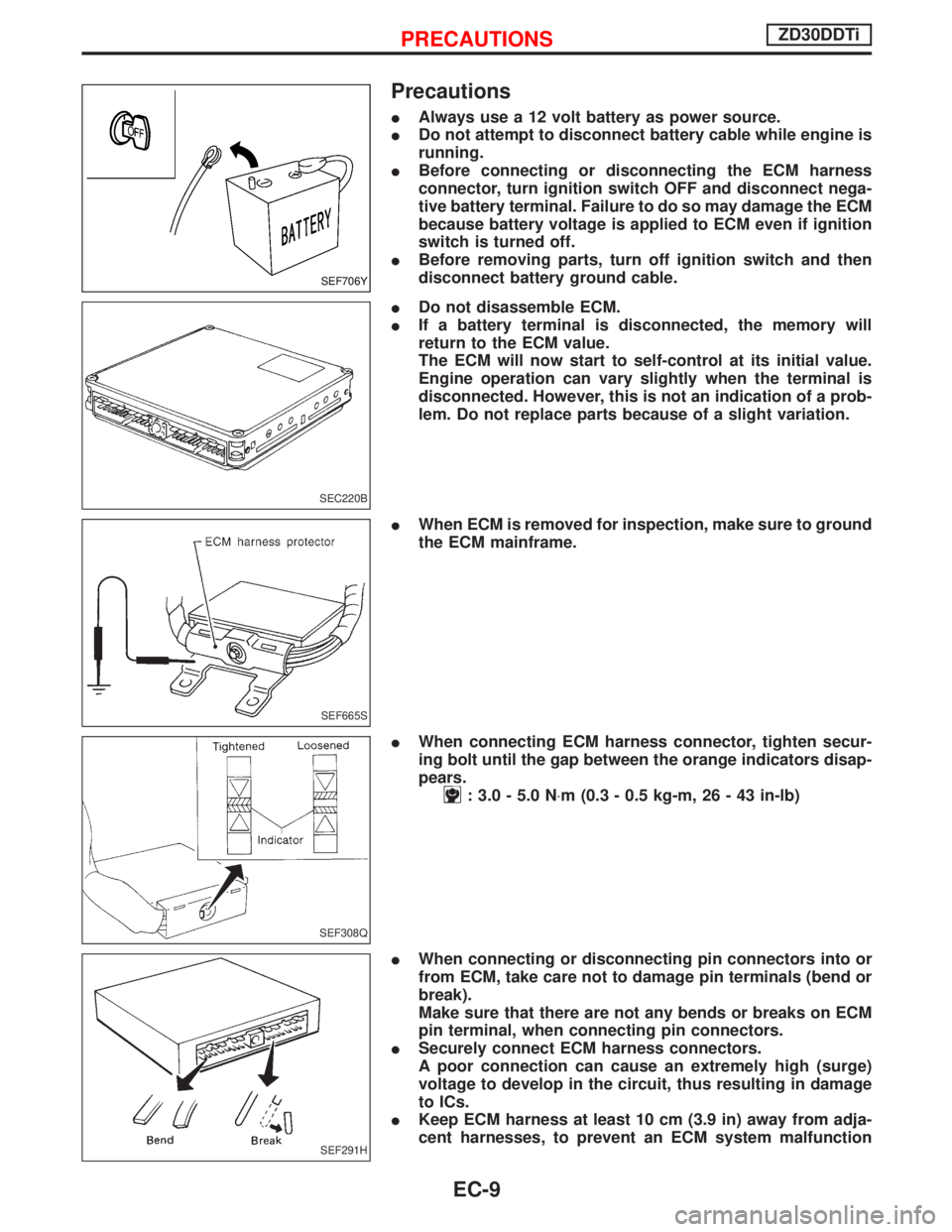

Precautions

IAlways use a 12 volt battery as power source.

IDo not attempt to disconnect battery cable while engine is

running.

IBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

IBefore removing parts, turn off ignition switch and then

disconnect battery ground cable.

IDo not disassemble ECM.

IIf a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

IWhen ECM is removed for inspection, make sure to ground

the ECM mainframe.

IWhen connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

IWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

ISecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

IKeep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

Page 373 of 1767

IDo not disconnect pump harness connector with engine

running.

IDo not disassemble electronic fuel injection pump.

If NG, take proper action.

IDo not disassemble injection nozzle.

If NG, replace injection nozzle.

IEven a slight leak in the air intake system can cause seri-

ous problems.

IDo not shock or jar the crankshaft position sensor (TDC).

IDo not depress accelerator pedal when starting.

IImmediately after starting, do not rev up engine unneces-

sarily.

IDo not rev up engine just prior to shutdown.

IWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on its installation loca-

tion.

1) Keep the antenna as far as possible away from the ECM.

2) Keep the antenna feeder line more than 20 cm (7.9 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

3) Adjust the antenna and feeder line so that the standing-

wave ratio can be kept smaller.

4) Be sure to ground the radio to vehicle body.

SEF437Y

SEF709Y

SEF708Y

PRECAUTIONSZD30DDTi

Precautions (Cont'd)

EC-11

Page 382 of 1767

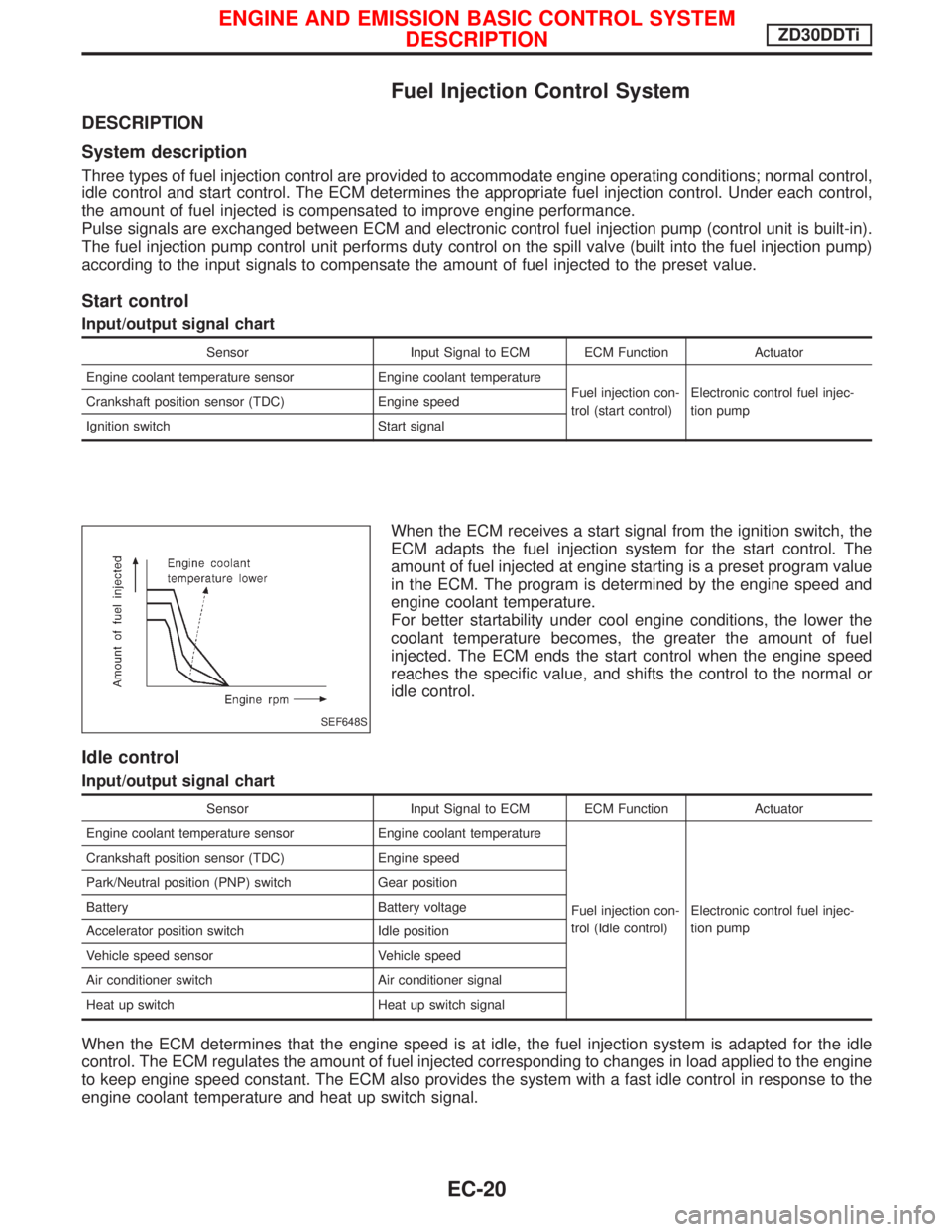

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-in).

The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection pump)

according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or

idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Heat up switch Heat up switch signal

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONZD30DDTi

EC-20

Page 388 of 1767

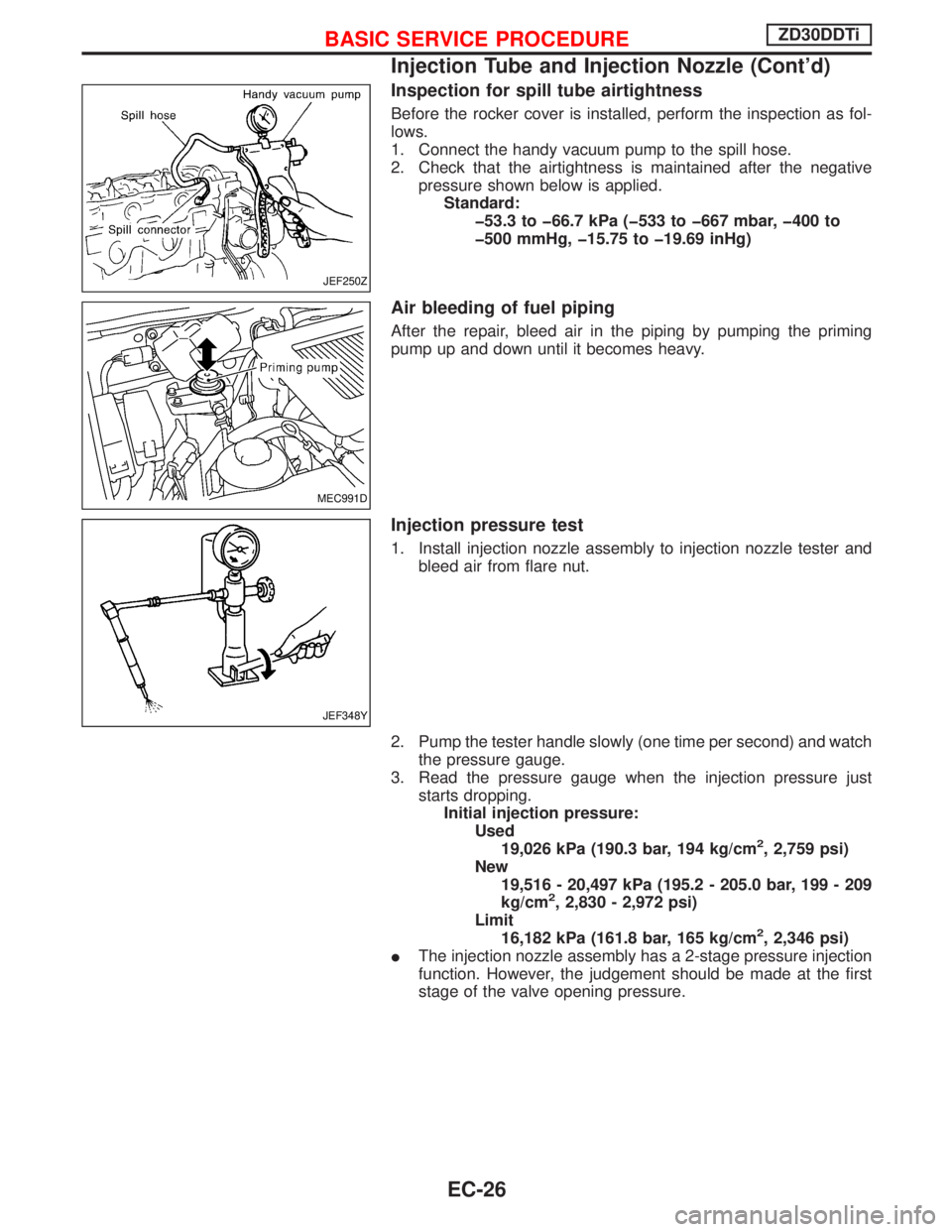

Inspection for spill tube airtightness

Before the rocker cover is installed, perform the inspection as fol-

lows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negative

pressure shown below is applied.

Standard:

þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air bleeding of fuel piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy.

Injection pressure test

1. Install injection nozzle assembly to injection nozzle tester and

bleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and watch

the pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

Used

19,026 kPa (190.3 bar, 194 kg/cm

2, 2,759 psi)

New

19,516 - 20,497 kPa (195.2 - 205.0 bar, 199 - 209

kg/cm

2, 2,830 - 2,972 psi)

Limit

16,182 kPa (161.8 bar, 165 kg/cm

2, 2,346 psi)

IThe injection nozzle assembly has a 2-stage pressure injection

function. However, the judgement should be made at the first

stage of the valve opening pressure.

JEF250Z

MEC991D

JEF348Y

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-26

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34