Start NISSAN TERRANO 2002 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 91 of 1767

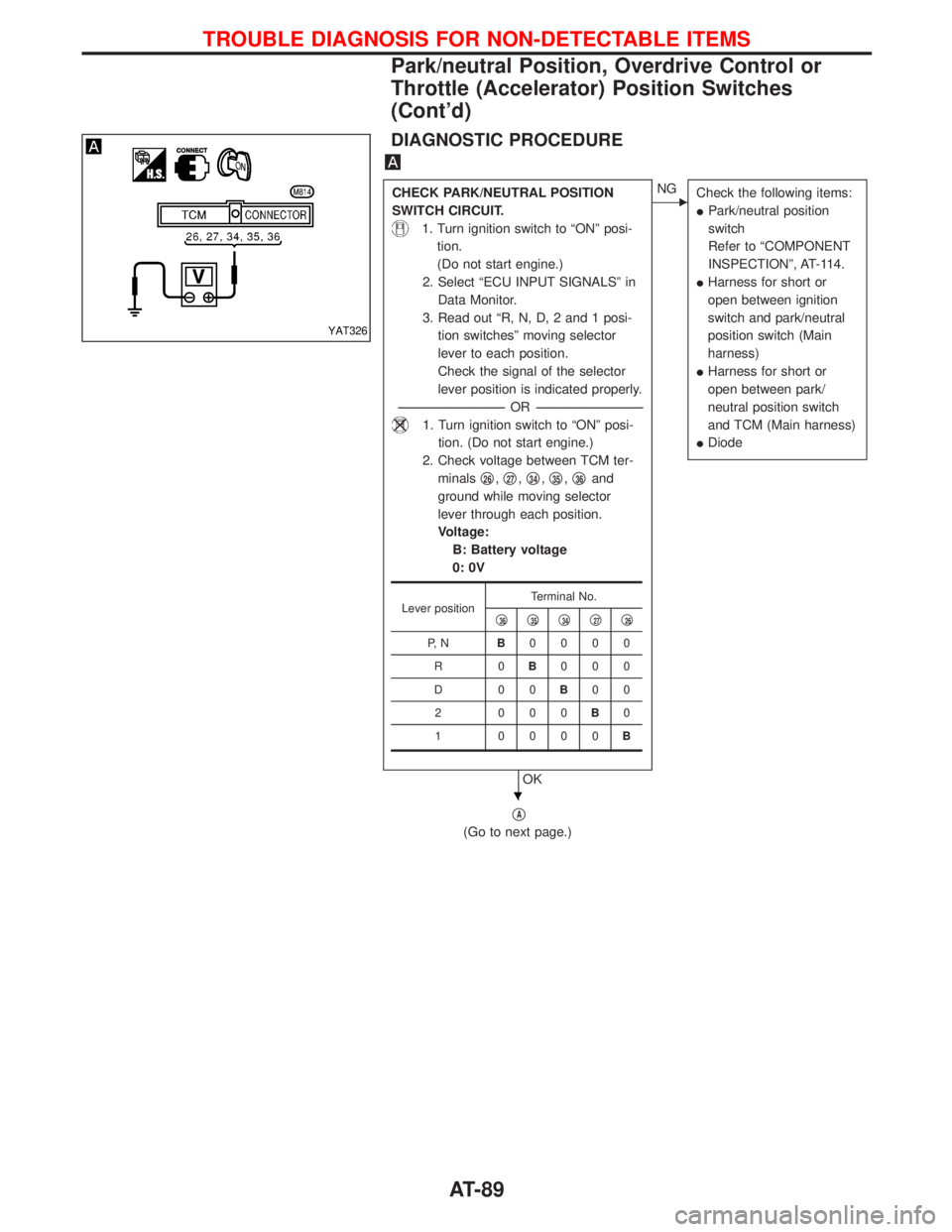

DIAGNOSTIC PROCEDURE

CHECK PARK/NEUTRAL POSITION

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªR, N, D, 2 and 1 posi-

tion switchesº moving selector

lever to each position.

Check the signal of the selector

lever position is indicated properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter-

minalsq

26,q27,q34,q35,q36and

ground while moving selector

lever through each position.

Voltage:

B: Battery voltage

0: 0V

OK

ENG

Check the following items:

IPark/neutral position

switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and park/neutral

position switch (Main

harness)

IHarness for short or

open between park/

neutral position switch

and TCM (Main harness)

IDiode

qA

(Go to next page.)

Lever positionTerminal No.

q36q35q34q27q26

P, NB0000

R0B000

D00B00

2 000B0

1 0000B

YAT326

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-89

Page 92 of 1767

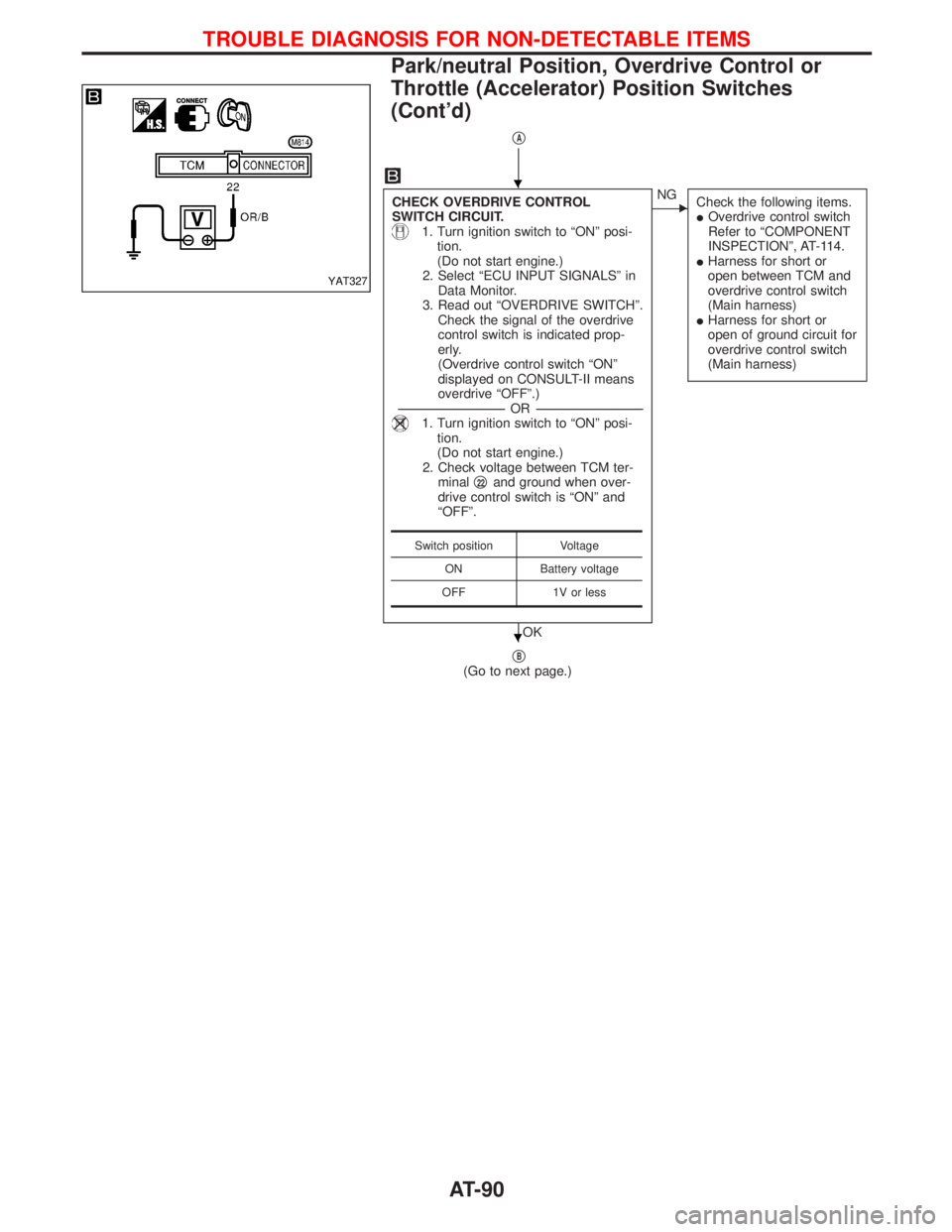

qA

CHECK OVERDRIVE CONTROL

SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªOVERDRIVE SWITCHº.

Check the signal of the overdrive

control switch is indicated prop-

erly.

(Overdrive control switch ªONº

displayed on CONSULT-II means

overdrive ªOFFº.)

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalq

22and ground when over-

drive control switch is ªONº and

ªOFFº.

OK

ENG

Check the following items.

IOverdrive control switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between TCM and

overdrive control switch

(Main harness)

IHarness for short or

open of ground circuit for

overdrive control switch

(Main harness)

qB(Go to next page.)

Switch position Voltage

ON Battery voltage

OFF 1V or less

YAT327

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-90

Page 93 of 1767

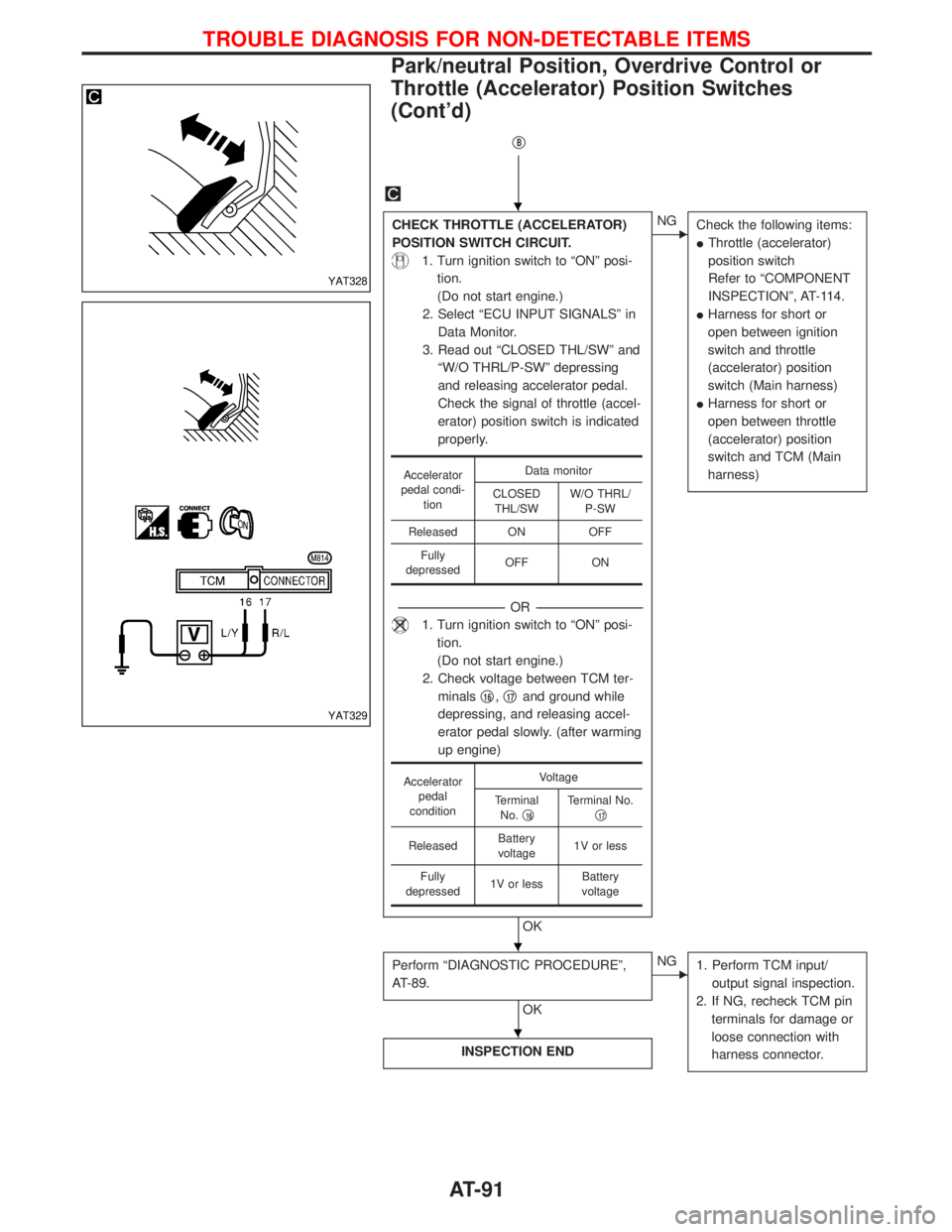

qB

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH CIRCUIT.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out ªCLOSED THL/SWº and

ªW/O THRL/P-SWº depressing

and releasing accelerator pedal.

Check the signal of throttle (accel-

erator) position switch is indicated

properly.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Check voltage between TCM ter-

minalsq

16,q17and ground while

depressing, and releasing accel-

erator pedal slowly. (after warming

up engine)

OK

ENG

Check the following items:

IThrottle (accelerator)

position switch

Refer to ªCOMPONENT

INSPECTIONº, AT-114.

IHarness for short or

open between ignition

switch and throttle

(accelerator) position

switch (Main harness)

IHarness for short or

open between throttle

(accelerator) position

switch and TCM (Main

harness)

Perform ªDIAGNOSTIC PROCEDUREº,

AT-89.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

Accelerator

pedal condi-

tionData monitor

CLOSED

THL/SWW/O THRL/

P-SW

Released ON OFF

Fully

depressedOFF ON

Accelerator

pedal

conditionVoltage

Terminal

No.q

16Terminal No.

q17

ReleasedBattery

voltage1V or less

Fully

depressed1V or lessBattery

voltage

YAT328

YAT329

H

H

H

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches

(Cont'd)

AT-91

Page 96 of 1767

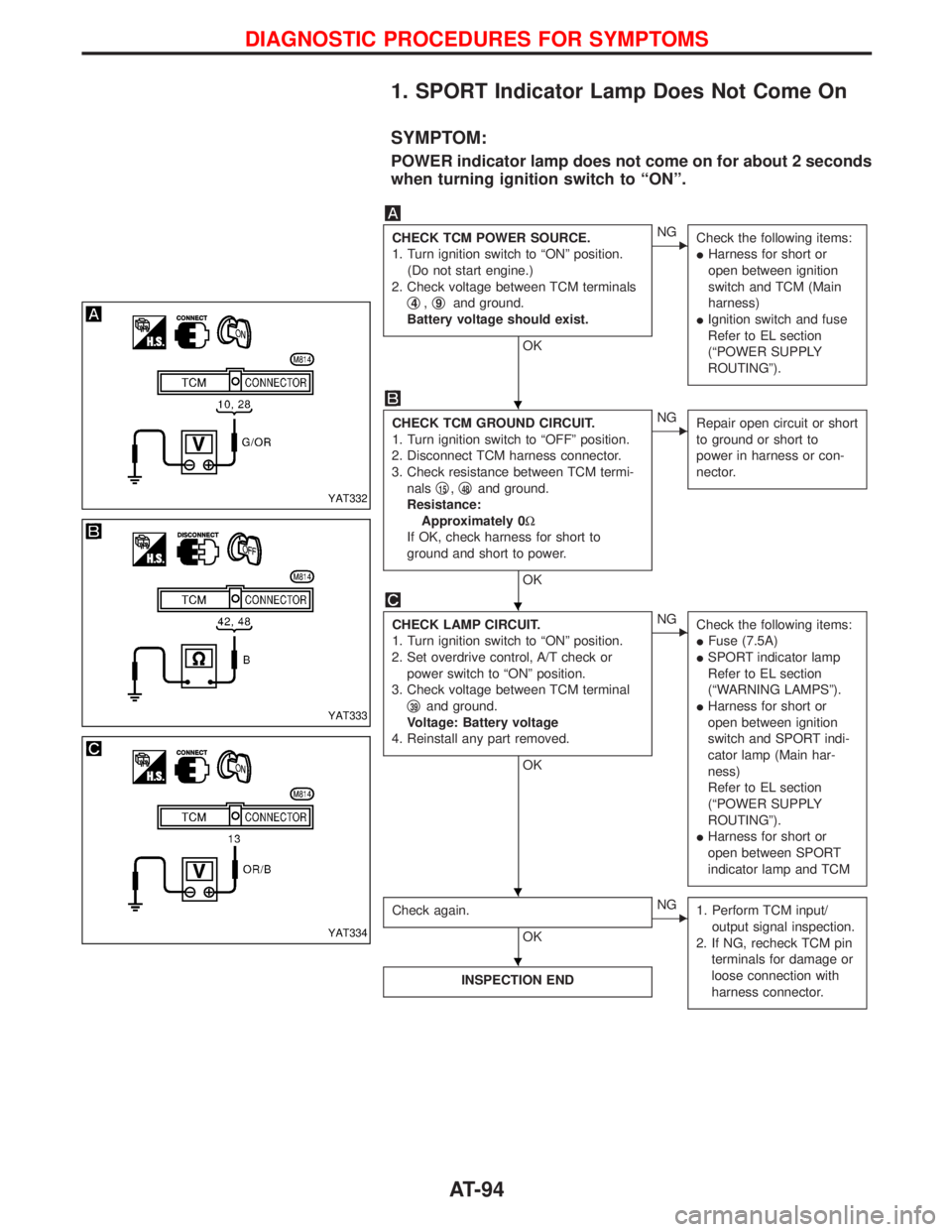

1. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

POWER indicator lamp does not come on for about 2 seconds

when turning ignition switch to ªONº.

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

4,q9and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK TCM GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between TCM termi-

nalsq

15,q48and ground.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

CHECK LAMP CIRCUIT.

1. Turn ignition switch to ªONº position.

2. Set overdrive control, A/T check or

power switch to ªONº position.

3. Check voltage between TCM terminal

q

39and ground.

Voltage: Battery voltage

4. Reinstall any part removed.

OK

ENG

Check the following items:

IFuse (7.5A)

ISPORT indicator lamp

Refer to EL section

(ªWARNING LAMPSº).

IHarness for short or

open between ignition

switch and SPORT indi-

cator lamp (Main har-

ness)

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

IHarness for short or

open between SPORT

indicator lamp and TCM

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT332

YAT333

YAT334

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-94

Page 99 of 1767

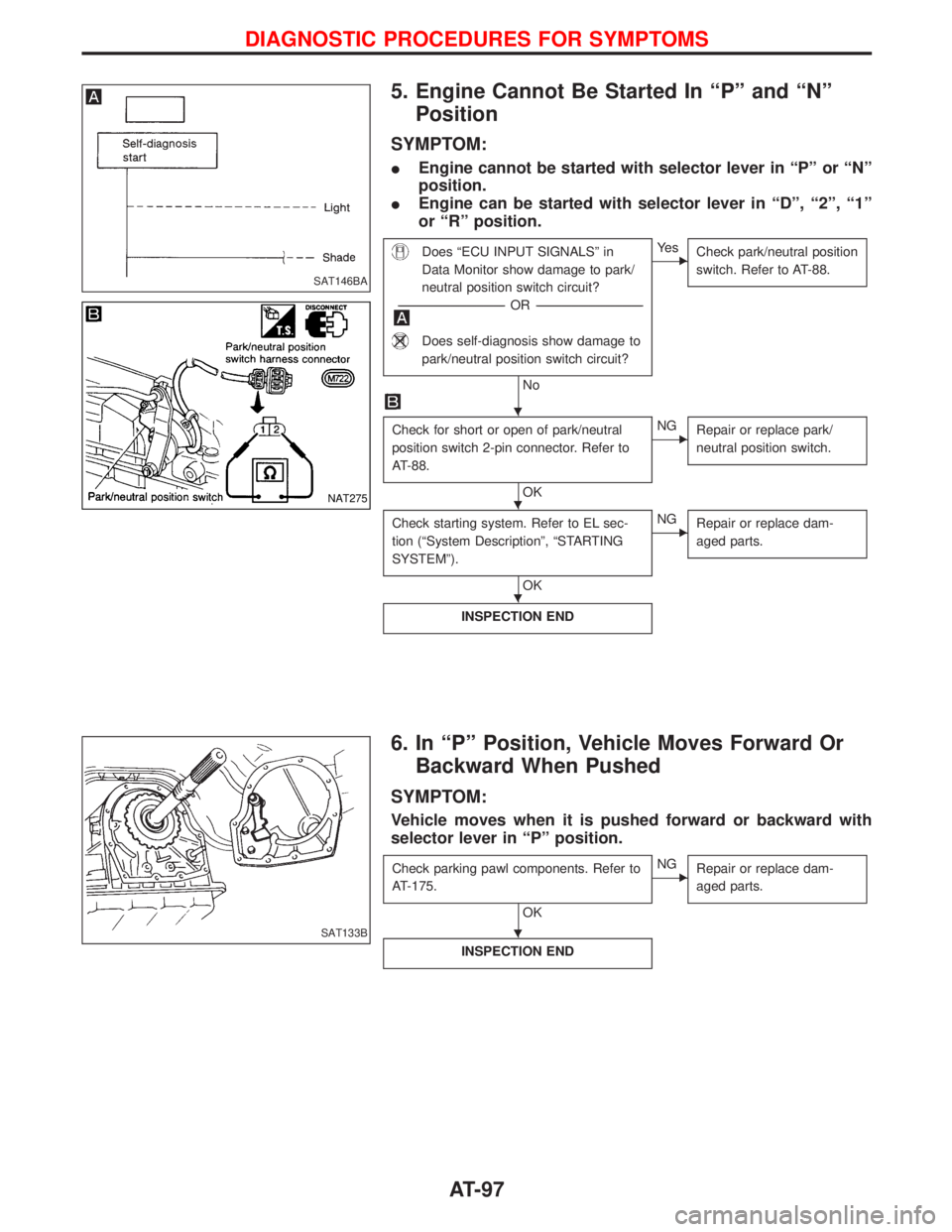

5. Engine Cannot Be Started In ªPº and ªNº

Position

SYMPTOM:

IEngine cannot be started with selector lever in ªPº or ªNº

position.

IEngine can be started with selector lever in ªDº, ª2º, ª1º

or ªRº position.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-88.

Check for short or open of park/neutral

position switch 2-pin connector. Refer to

AT-88.

OK

ENG

Repair or replace park/

neutral position switch.

Check starting system. Refer to EL sec-

tion (ªSystem Descriptionº, ªSTARTING

SYSTEMº).

OK

ENG

Repair or replace dam-

aged parts.

INSPECTION END

6. In ªPº Position, Vehicle Moves Forward Or

Backward When Pushed

SYMPTOM:

Vehicle moves when it is pushed forward or backward with

selector lever in ªPº position.

Check parking pawl components. Refer to

AT-175.

OK

ENG

Repair or replace dam-

aged parts.

INSPECTION END

SAT146BA

NAT275

SAT133B

H

H

H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-97

Page 104 of 1767

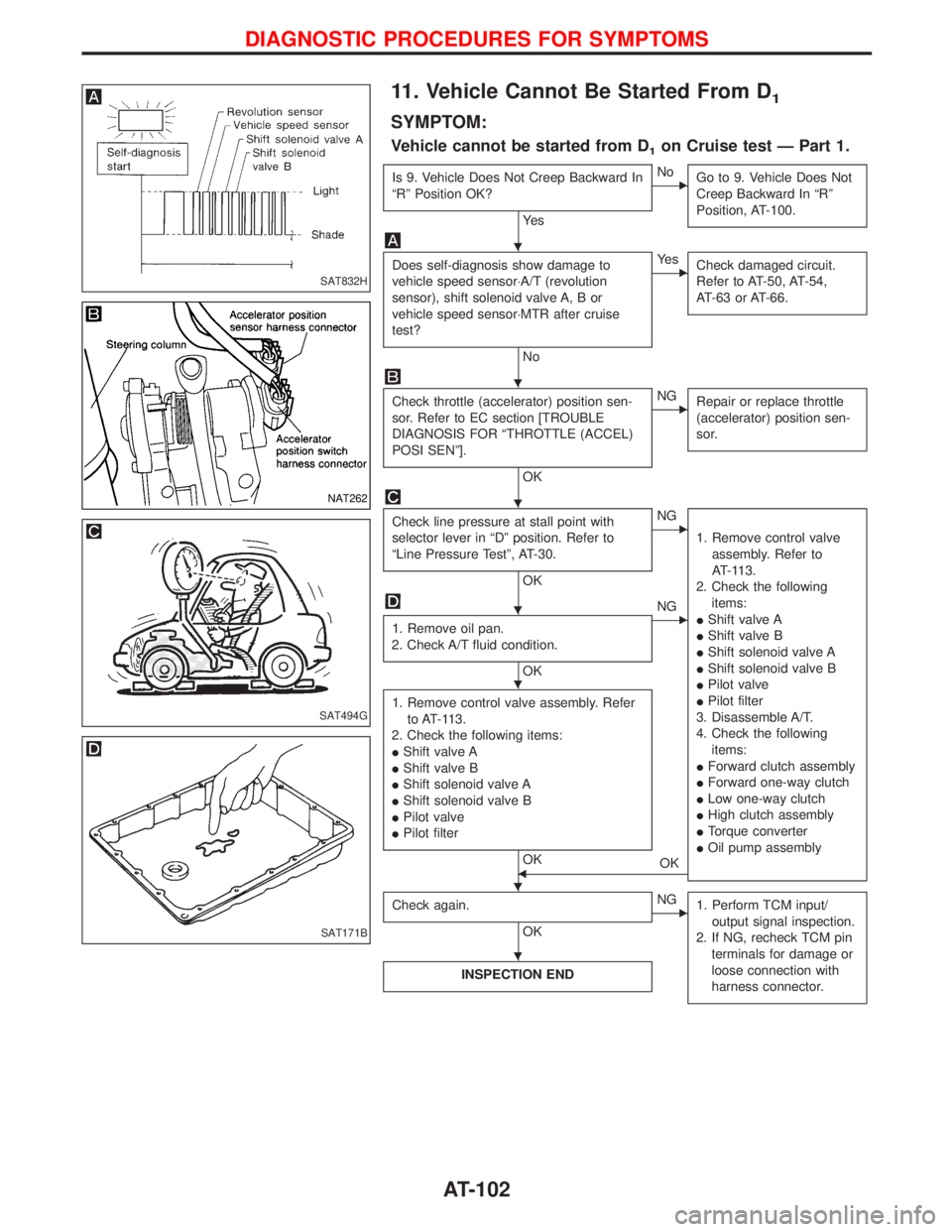

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward In

ªRº Position OK?

Ye s

ENo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-100.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-30.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

OKFOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

NAT262

SAT494G

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-102

Page 105 of 1767

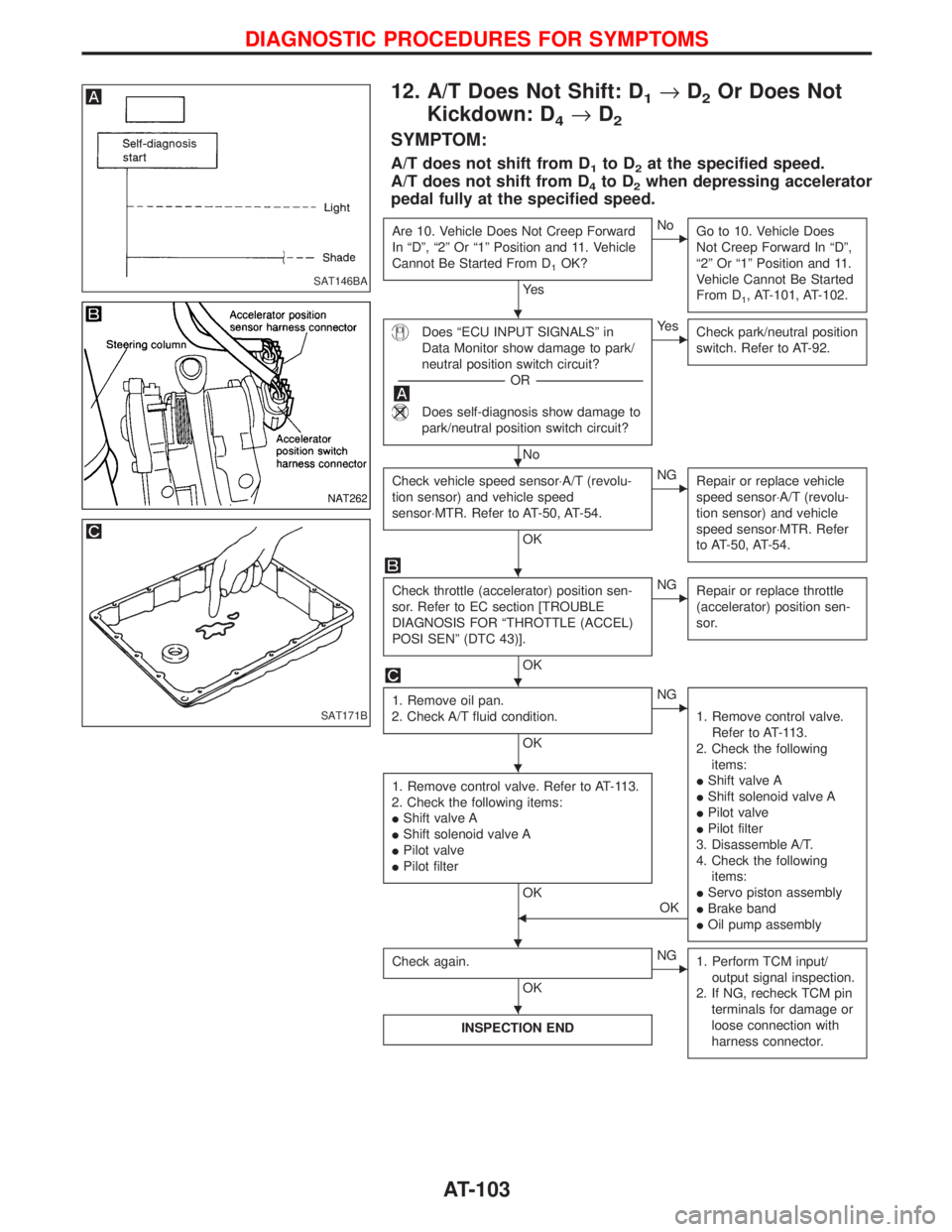

12. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2

SYMPTOM:

A/T does not shift from D1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelerator

pedal fully at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check vehicle speed sensor×A/T (revolu-

tion sensor) and vehicle speed

sensor×MTR. Refer to AT-50, AT-54.

OK

ENG

Repair or replace vehicle

speed sensor×A/T (revolu-

tion sensor) and vehicle

speed sensor×MTR. Refer

to AT-50, AT-54.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº (DTC 43)].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve.

Refer to AT-113.

2. Check the following

items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

IOil pump assembly

1. Remove control valve. Refer to AT-113.

2. Check the following items:

IShift valve A

IShift solenoid valve A

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-103

Page 106 of 1767

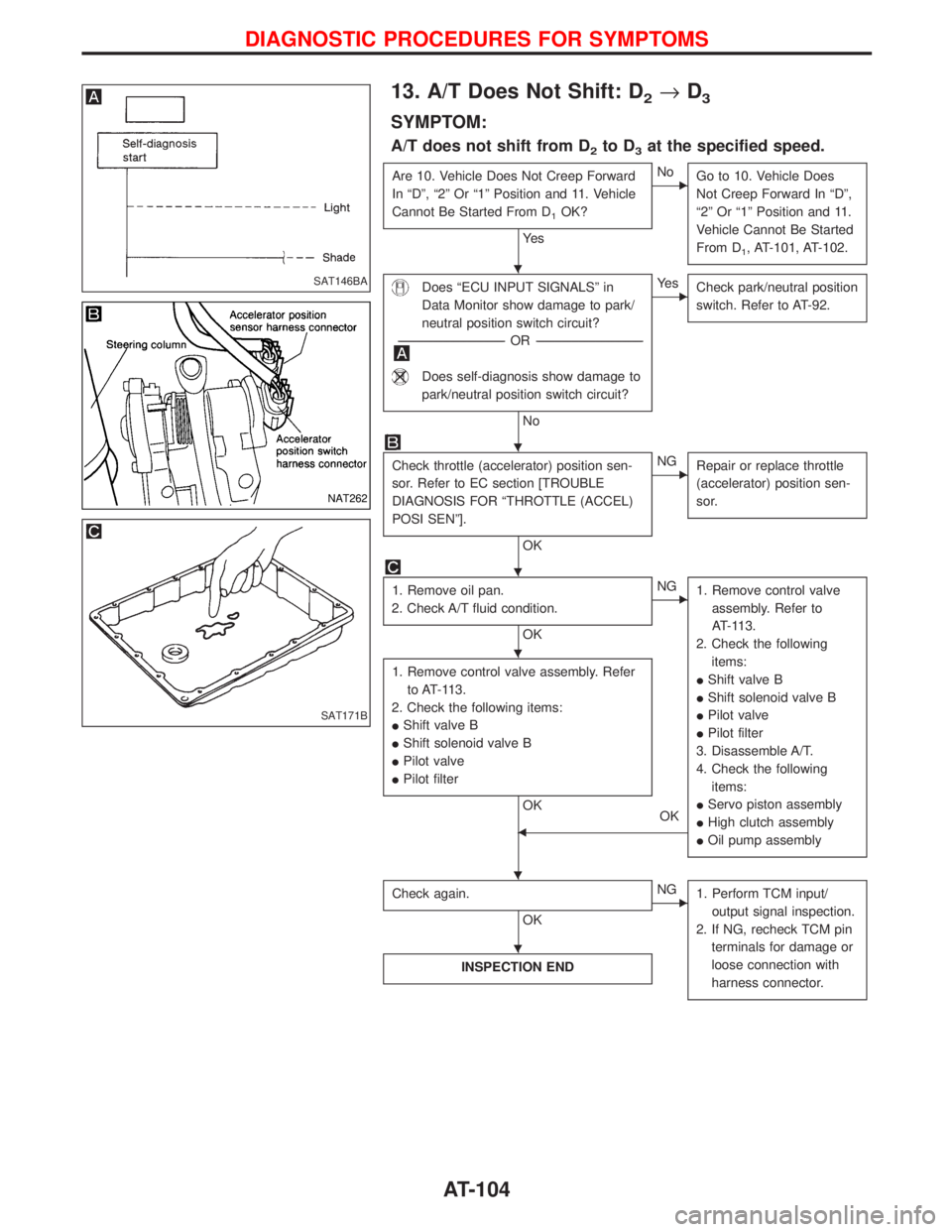

13. A/T Does Not Shift: D2®D3

SYMPTOM:

A/T does not shift from D2to D3at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does ªECU INPUT SIGNALSº in

Data Monitor show damage to park/

neutral position switch circuit?

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage to

park/neutral position switch circuit?

No

EYe s

Check park/neutral position

switch. Refer to AT-92.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IHigh clutch assembly

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

OK

OK

F

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-104

Page 107 of 1767

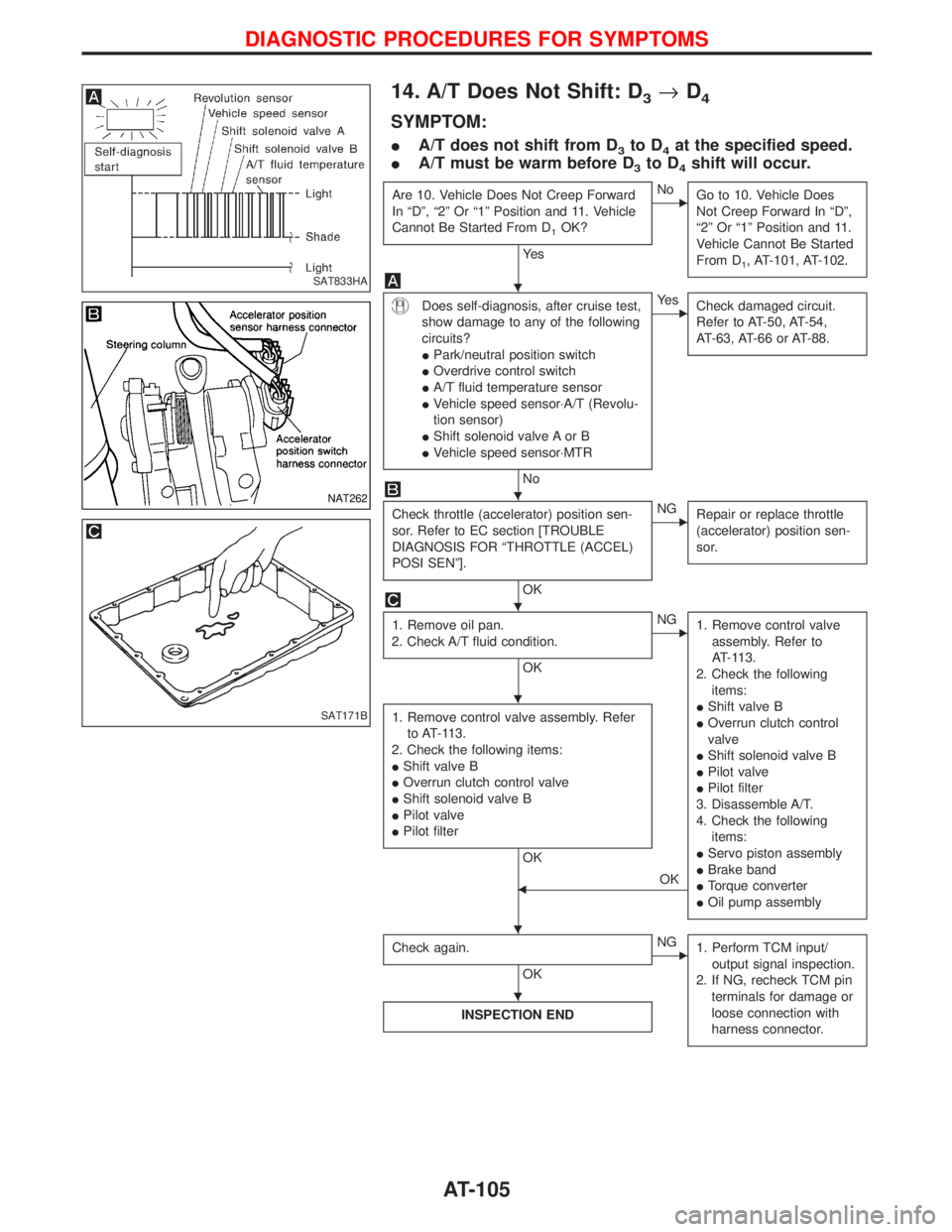

14. A/T Does Not Shift: D3®D4

SYMPTOM:

IA/T does not shift from D3to D4at the specified speed.

IA/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Ye s

ENo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-101, AT-102.

Does self-diagnosis, after cruise test,

show damage to any of the following

circuits?

IPark/neutral position switch

IOverdrive control switch

IA/T fluid temperature sensor

IVehicle speed sensor×A/T (Revolu-

tion sensor)

IShift solenoid valve A or B

IVehicle speed sensor×MTR

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63, AT-66 or AT-88.

Check throttle (accelerator) position sen-

sor. Refer to EC section [TROUBLE

DIAGNOSIS FOR ªTHROTTLE (ACCEL)

POSI SENº].

OK

ENG

Repair or replace throttle

(accelerator) position sen-

sor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift valve B

IOverrun clutch control

valve

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following

items:

IServo piston assembly

IBrake band

ITorque converter

IOil pump assembly

1. Remove control valve assembly. Refer

to AT-113.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK

FOK

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

NAT262

SAT171B

H

H

H

H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-105

Page 111 of 1767

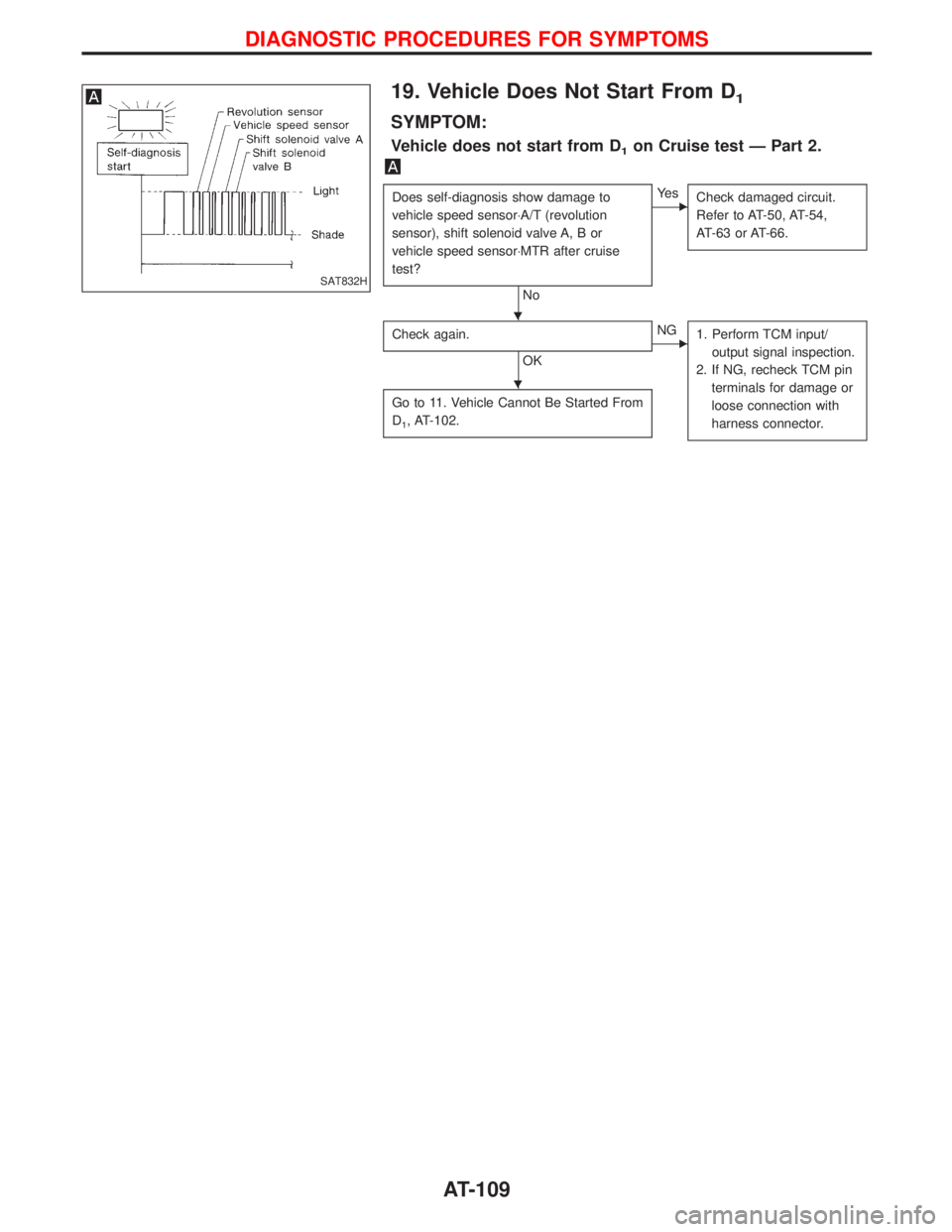

19. Vehicle Does Not Start From D1

SYMPTOM:

Vehicle does not start from D1on Cruise test Ð Part 2.

Does self-diagnosis show damage to

vehicle speed sensor×A/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensor×MTR after cruise

test?

No

EYe s

Check damaged circuit.

Refer to AT-50, AT-54,

AT-63 or AT-66.

Check again.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

Go to 11. Vehicle Cannot Be Started From

D

1, AT-102.

SAT832H

H H

H

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-109