Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1701 of 1767

4. Inspect pinion teeth.

IReplace pinion if teeth are worn or damaged. (Also check

condition of ring gear teeth.)

5. Inspect reduction gear teeth.

IReplace reduction gear if teeth are worn of damaged.

(Also check condition of armature shaft gear teeth.)

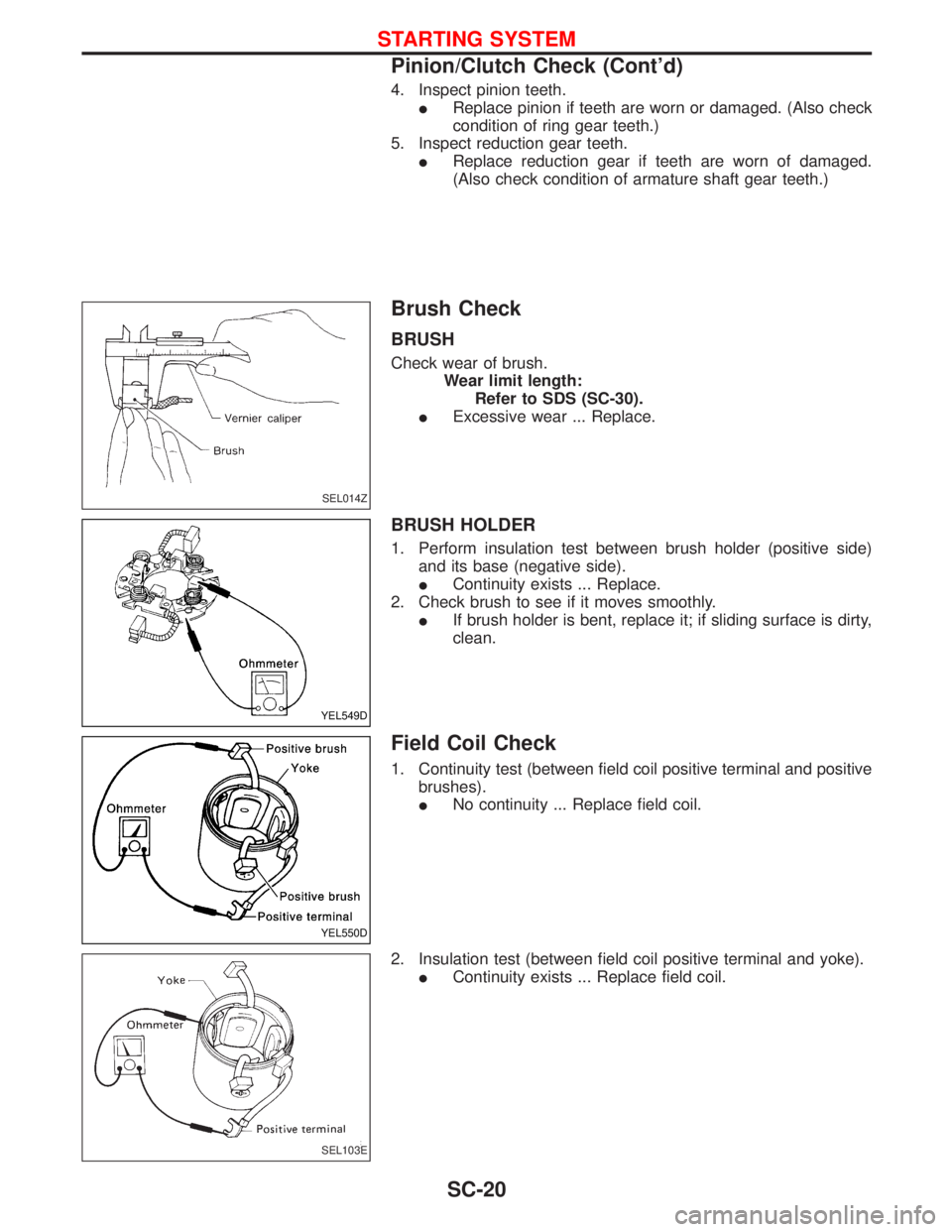

Brush Check

BRUSH

Check wear of brush.

Wear limit length:

Refer to SDS (SC-30).

IExcessive wear ... Replace.

BRUSH HOLDER

1. Perform insulation test between brush holder (positive side)

and its base (negative side).

IContinuity exists ... Replace.

2. Check brush to see if it moves smoothly.

IIf brush holder is bent, replace it; if sliding surface is dirty,

clean.

Field Coil Check

1. Continuity test (between field coil positive terminal and positive

brushes).

INo continuity ... Replace field coil.

2. Insulation test (between field coil positive terminal and yoke).

IContinuity exists ... Replace field coil.

SEL014Z

YEL549D

YEL550D

SEL103E

STARTING SYSTEM

Pinion/Clutch Check (Cont'd)

SC-20

Page 1702 of 1767

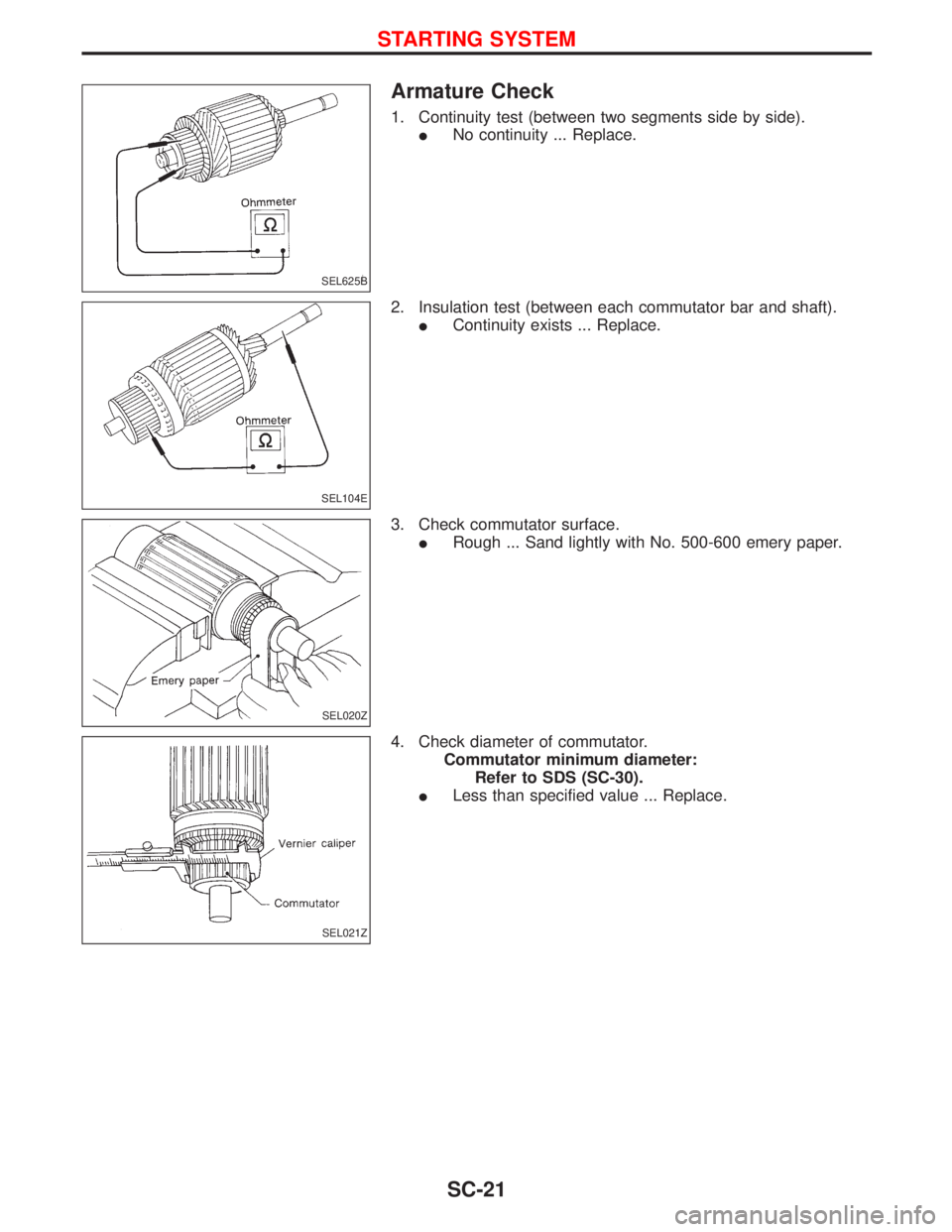

Armature Check

1. Continuity test (between two segments side by side).

INo continuity ... Replace.

2. Insulation test (between each commutator bar and shaft).

IContinuity exists ... Replace.

3. Check commutator surface.

IRough ... Sand lightly with No. 500-600 emery paper.

4. Check diameter of commutator.

Commutator minimum diameter:

Refer to SDS (SC-30).

ILess than specified value ... Replace.

SEL625B

SEL104E

SEL020Z

SEL021Z

STARTING SYSTEM

SC-21

Page 1703 of 1767

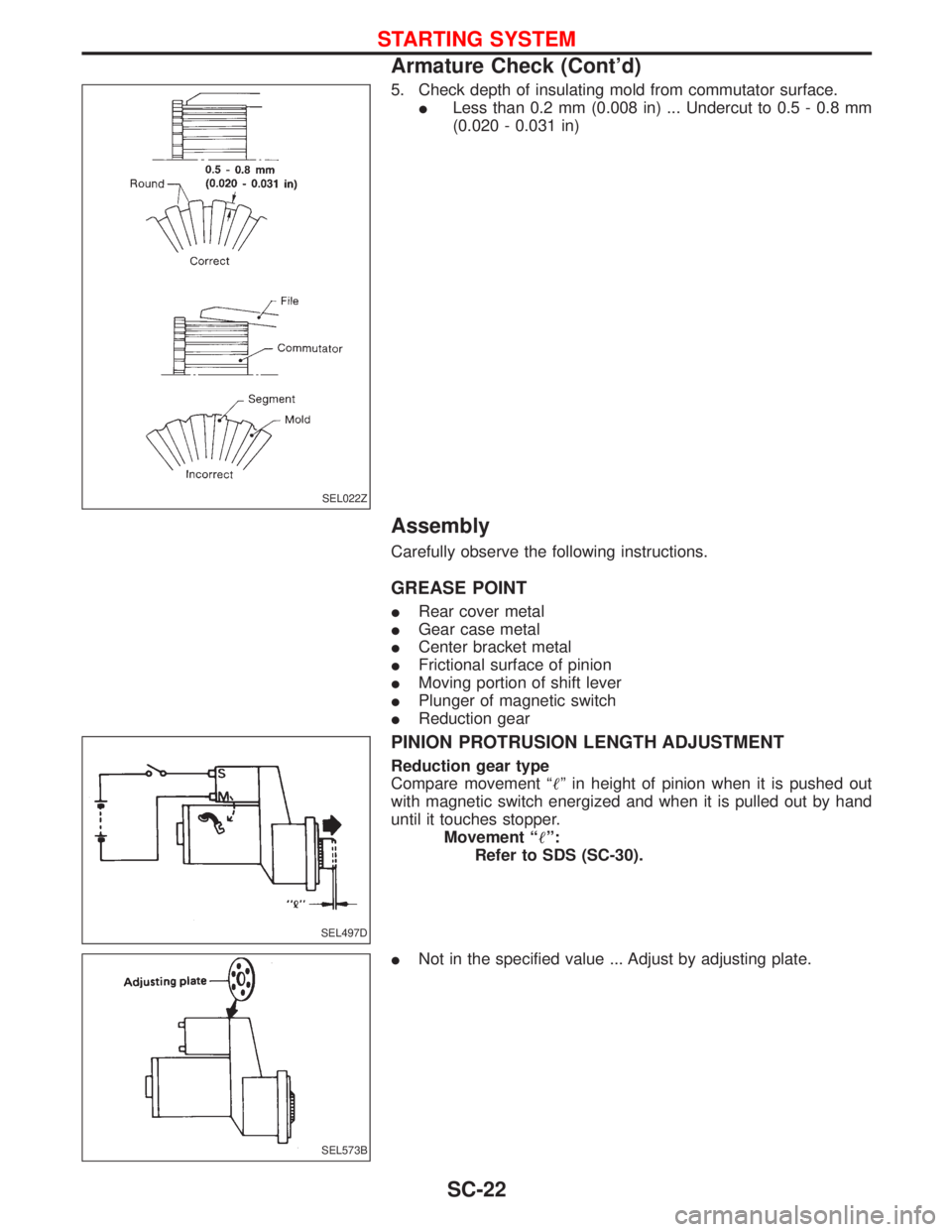

5. Check depth of insulating mold from commutator surface.

ILess than 0.2 mm (0.008 in) ... Undercut to 0.5 - 0.8 mm

(0.020 - 0.031 in)

Assembly

Carefully observe the following instructions.

GREASE POINT

IRear cover metal

IGear case metal

ICenter bracket metal

IFrictional surface of pinion

IMoving portion of shift lever

IPlunger of magnetic switch

IReduction gear

PINION PROTRUSION LENGTH ADJUSTMENT

Reduction gear type

Compare movement ªº in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

Movement ªº:

Refer to SDS (SC-30).

INot in the specified value ... Adjust by adjusting plate.

SEL022Z

SEL497D

SEL573B

STARTING SYSTEM

Armature Check (Cont'd)

SC-22

Page 1704 of 1767

System Description

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

I10A fuse (No. 31, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage (ZD30DDTi engine models). The

charging circuit is protected by the 100A (A/T models) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

Ithrough 10A fuse [No. 12, located in the fuse block (J/B)]

Ito combination meter terminal 28 for the charge warning lamp.

Ground is supplied to terminal 2 of the combination meter through terminal 1(L) (TD27Ti engine models) or

3(L) (ZD30DDTi engine model) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

CHARGING SYSTEM

SC-23

Page 1707 of 1767

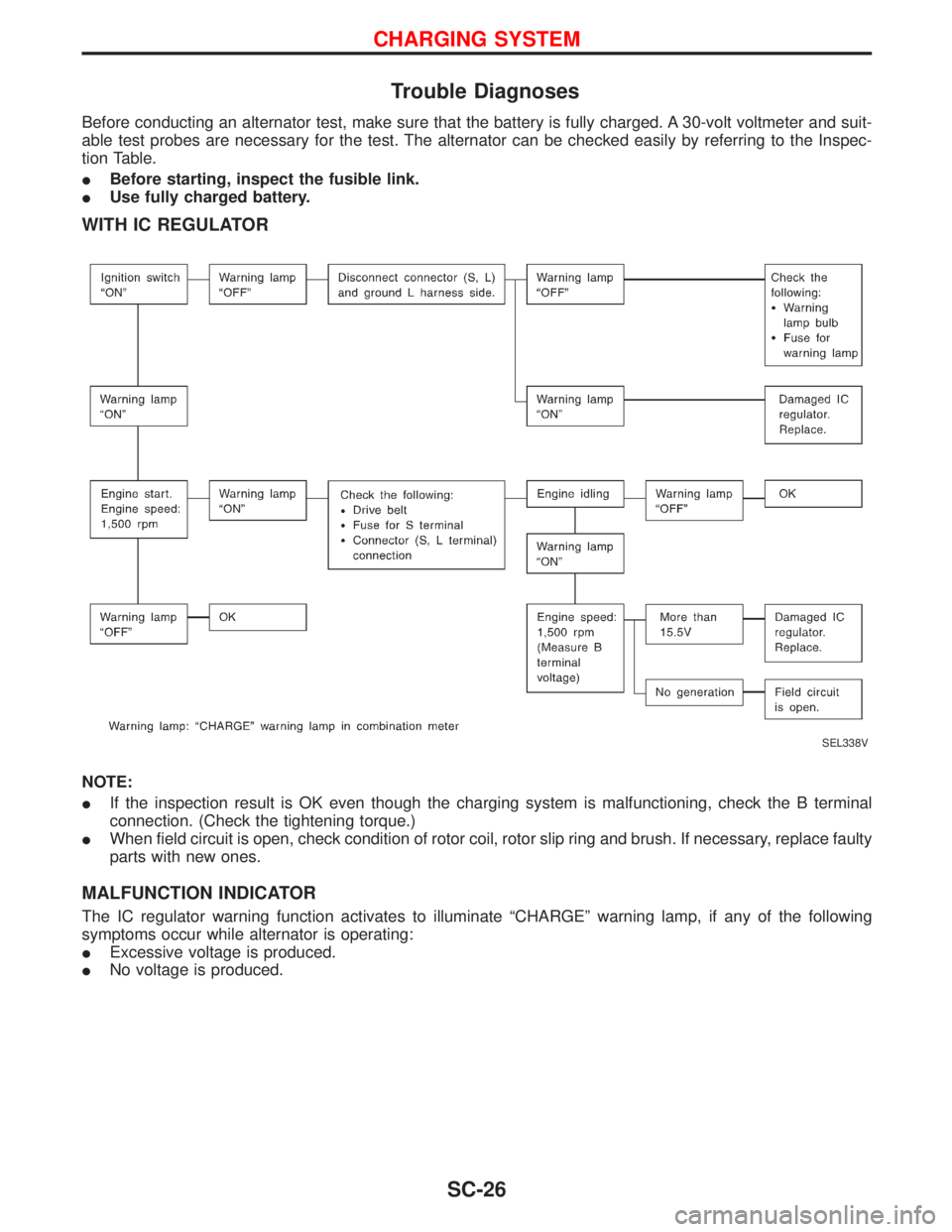

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and suit-

able test probes are necessary for the test. The alternator can be checked easily by referring to the Inspec-

tion Table.

IBefore starting, inspect the fusible link.

IUse fully charged battery.

WITH IC REGULATOR

NOTE:

IIf the inspection result is OK even though the charging system is malfunctioning, check the B terminal

connection. (Check the tightening torque.)

IWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary, replace faulty

parts with new ones.

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate ªCHARGEº warning lamp, if any of the following

symptoms occur while alternator is operating:

IExcessive voltage is produced.

INo voltage is produced.

SEL338V

CHARGING SYSTEM

SC-26

Page 1711 of 1767

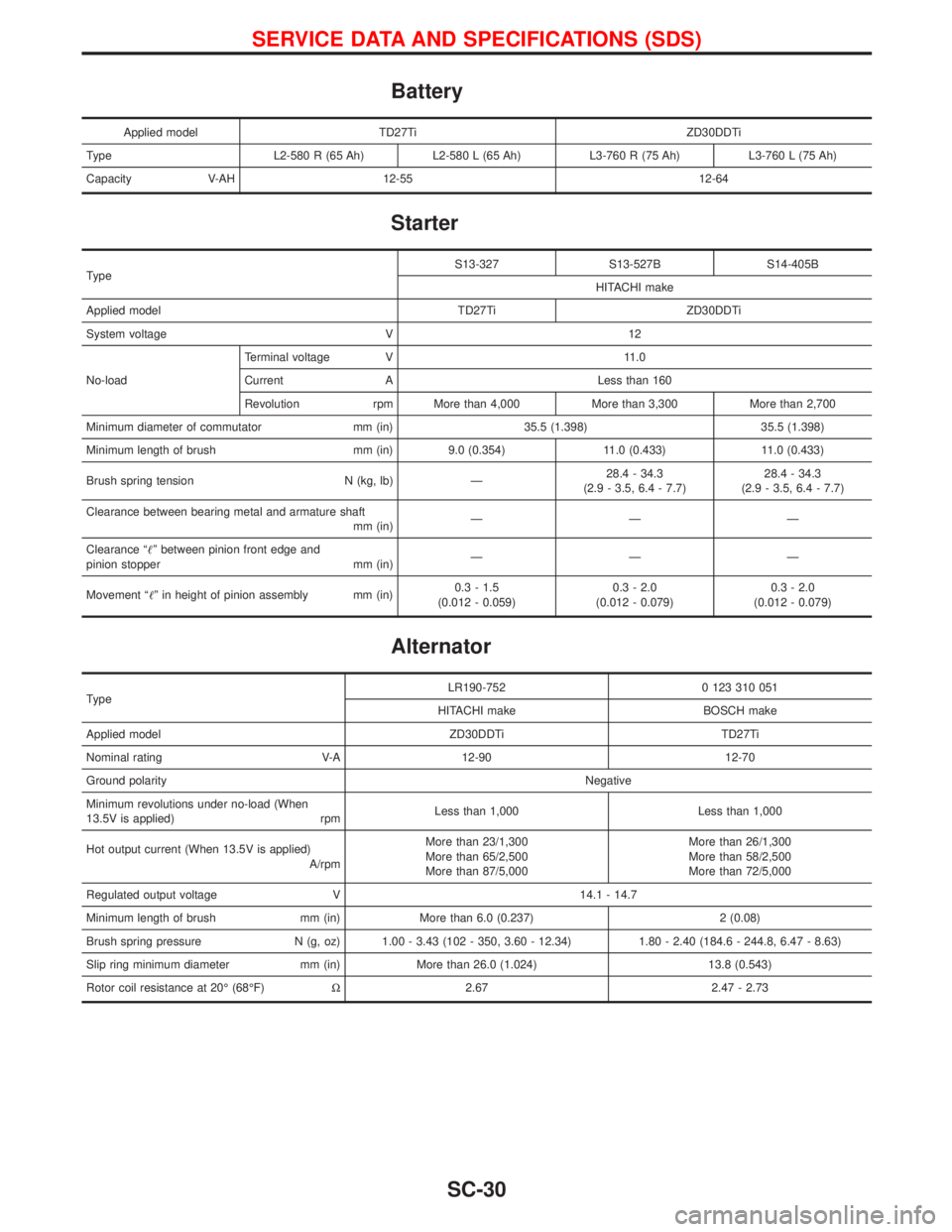

Battery

Applied model TD27Ti ZD30DDTi

Type L2-580 R (65 Ah) L2-580 L (65 Ah) L3-760 R (75 Ah) L3-760 L (75 Ah)

Capacity V-AH 12-55 12-64

Starter

TypeS13-327 S13-527B S14-405B

HITACHI make

Applied model TD27Ti ZD30DDTi

System voltage V 12

No-loadTerminal voltage V 11.0

Current A Less than 160

Revolution rpm More than 4,000 More than 3,300 More than 2,700

Minimum diameter of commutator mm (in) 35.5 (1.398) 35.5 (1.398)

Minimum length of brush mm (in) 9.0 (0.354) 11.0 (0.433) 11.0 (0.433)

Brush spring tension N (kg, lb) Ð28.4 - 34.3

(2.9 - 3.5, 6.4 - 7.7)28.4 - 34.3

(2.9 - 3.5, 6.4 - 7.7)

Clearance between bearing metal and armature shaft

mm (in)ÐÐÐ

Clearance ªº between pinion front edge and

pinion stopper mm (in)ÐÐÐ

Movement ªº in height of pinion assembly mm (in)0.3 - 1.5

(0.012 - 0.059)0.3 - 2.0

(0.012 - 0.079)0.3 - 2.0

(0.012 - 0.079)

Alternator

TypeLR190-752 0 123 310 051

HITACHI make BOSCH make

Applied model ZD30DDTi TD27Ti

Nominal rating V-A 12-90 12-70

Ground polarityNegative

Minimum revolutions under no-load (When

13.5V is applied) rpmLess than 1,000 Less than 1,000

Hot output current (When 13.5V is applied)

A/rpmMore than 23/1,300

More than 65/2,500

More than 87/5,000More than 26/1,300

More than 58/2,500

More than 72/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 6.0 (0.237) 2 (0.08)

Brush spring pressure N (g, oz) 1.00 - 3.43 (102 - 350, 3.60 - 12.34) 1.80 - 2.40 (184.6 - 244.8, 6.47 - 8.63)

Slip ring minimum diameter mm (in) More than 26.0 (1.024) 13.8 (0.543)

Rotor coil resistance at 20É (68ÉF)W2.67 2.47 - 2.73

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-30

Page 1716 of 1767

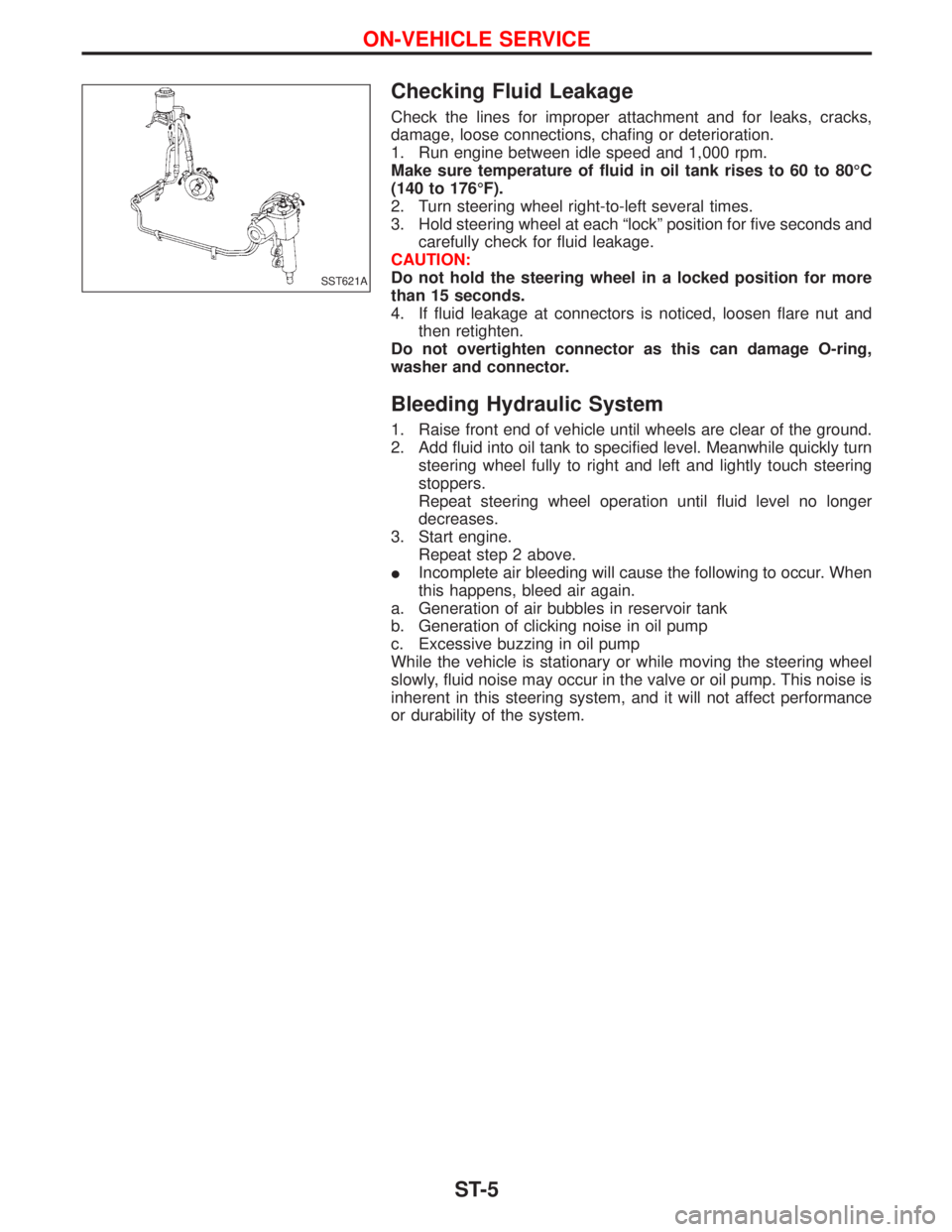

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing or deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds and

carefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Meanwhile quickly turn

steering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

IIncomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a. Generation of air bubbles in reservoir tank

b. Generation of clicking noise in oil pump

c. Excessive buzzing in oil pump

While the vehicle is stationary or while moving the steering wheel

slowly, fluid noise may occur in the valve or oil pump. This noise is

inherent in this steering system, and it will not affect performance

or durability of the system.

SST621A

ON-VEHICLE SERVICE

ST-5

Page 1717 of 1767

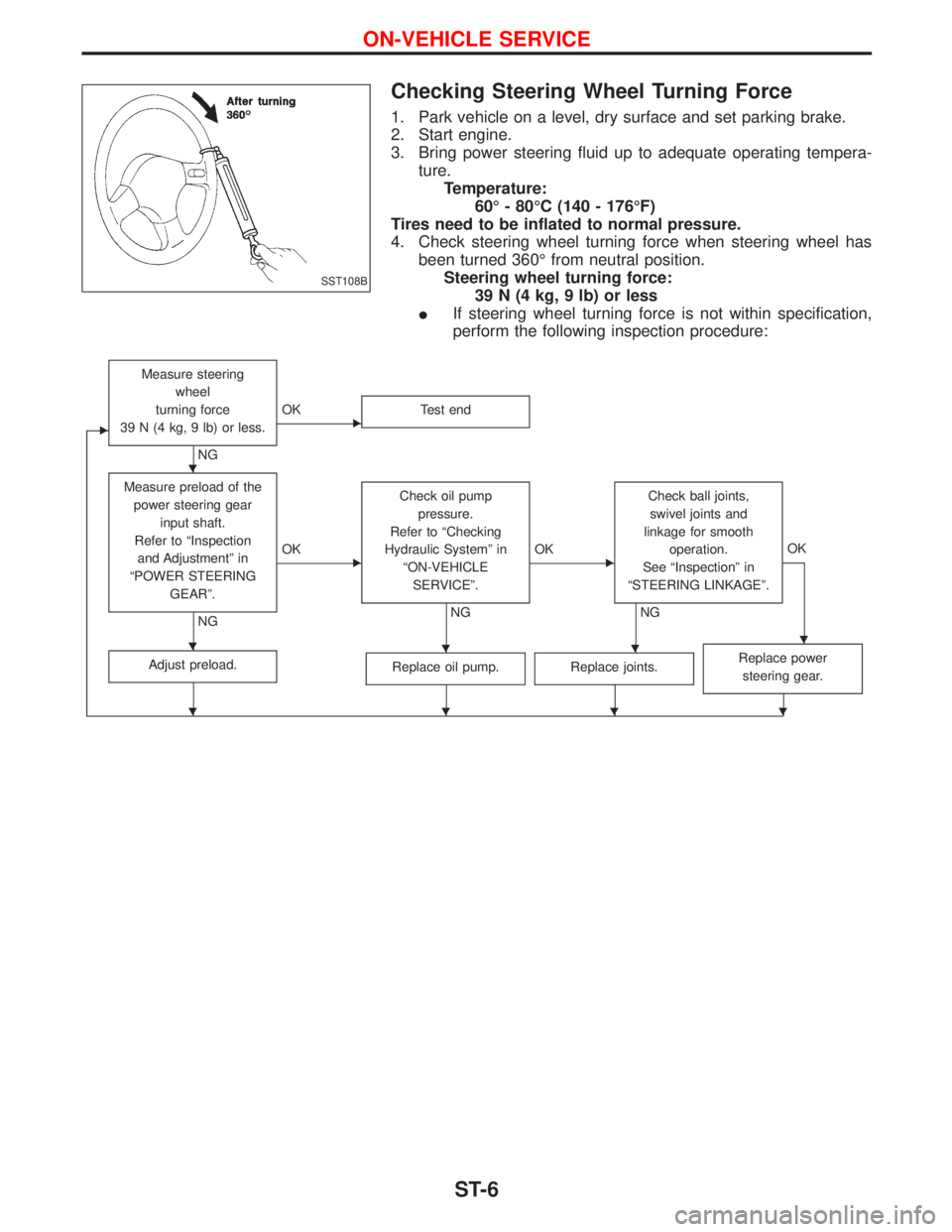

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture.

Temperature:

60É - 80ÉC (140 - 176ÉF)

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

IIf steering wheel turning force is not within specification,

perform the following inspection procedure:

E

Measure steering

wheel

turning force

39 N (4 kg, 9 lb) or less.

NG

EOK Test end

Measure preload of the

power steering gear

input shaft.

Refer to ªInspection

and Adjustmentº in

ªPOWER STEERING

GEARº.

NG

EOKCheck oil pump

pressure.

Refer to ªChecking

Hydraulic Systemº in

ªON-VEHICLE

SERVICEº.

NG

EOKCheck ball joints,

swivel joints and

linkage for smooth

operation.

See ªInspectionº in

ªSTEERING LINKAGEº.

NGOK

Adjust preload.Replace oil pump.Replace joints.Replace power

steering gear.

SST108B

H

HHHH

HHHH

ON-VEHICLE SERVICE

ST-6

Page 1718 of 1767

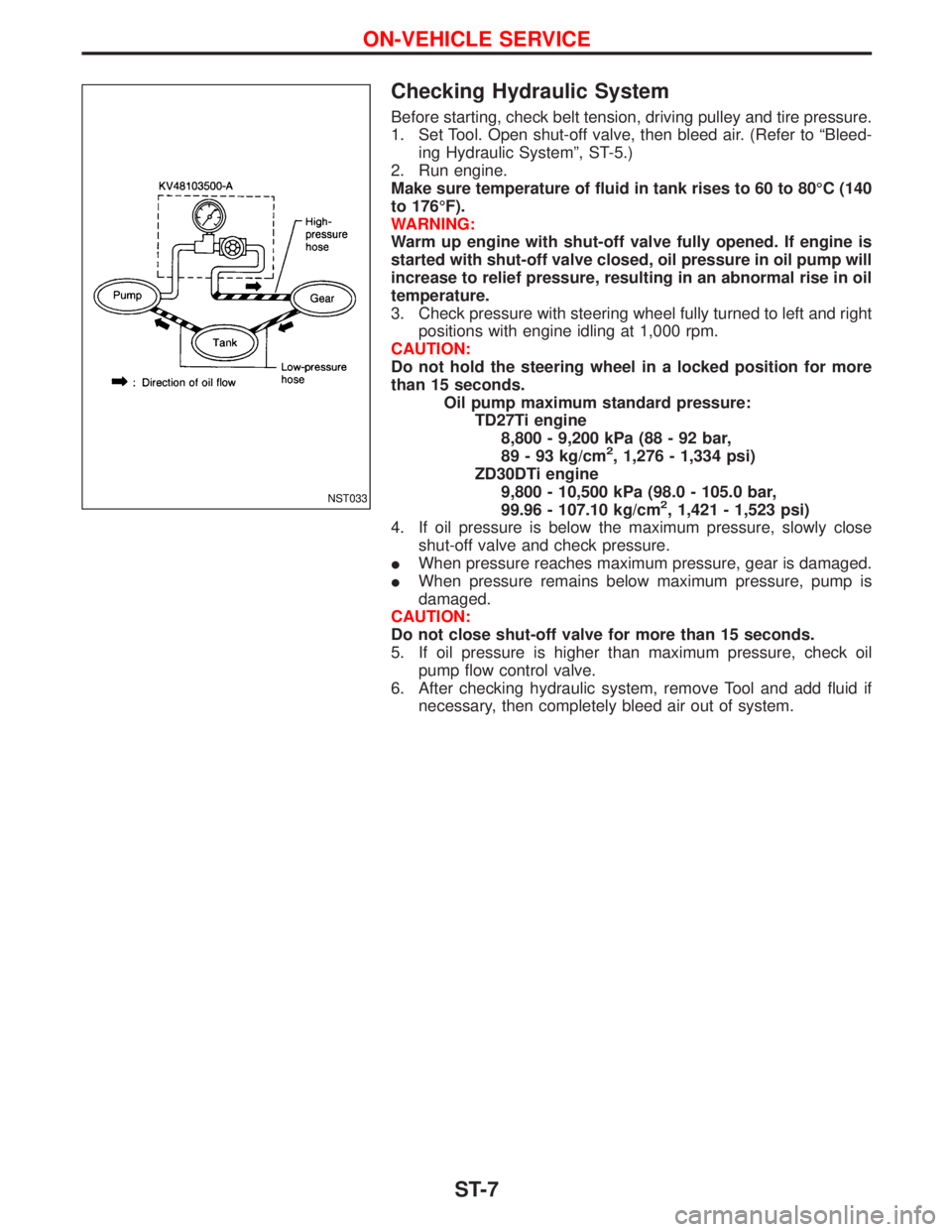

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve, then bleed air. (Refer to ªBleed-

ing Hydraulic Systemº, ST-5.)

2. Run engine.

Make sure temperature of fluid in tank rises to 60 to 80ÉC (140

to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, oil pressure in oil pump will

increase to relief pressure, resulting in an abnormal rise in oil

temperature.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Oil pump maximum standard pressure:

TD27Ti engine

8,800 - 9,200 kPa (88 - 92 bar,

89 - 93 kg/cm

2, 1,276 - 1,334 psi)

ZD30DTi engine

9,800 - 10,500 kPa (98.0 - 105.0 bar,

99.96 - 107.10 kg/cm

2, 1,421 - 1,523 psi)

4. If oil pressure is below the maximum pressure, slowly close

shut-off valve and check pressure.

IWhen pressure reaches maximum pressure, gear is damaged.

IWhen pressure remains below maximum pressure, pump is

damaged.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

5. If oil pressure is higher than maximum pressure, check oil

pump flow control valve.

6. After checking hydraulic system, remove Tool and add fluid if

necessary, then completely bleed air out of system.NST033

ON-VEHICLE SERVICE

ST-7