battery NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 20 of 1767

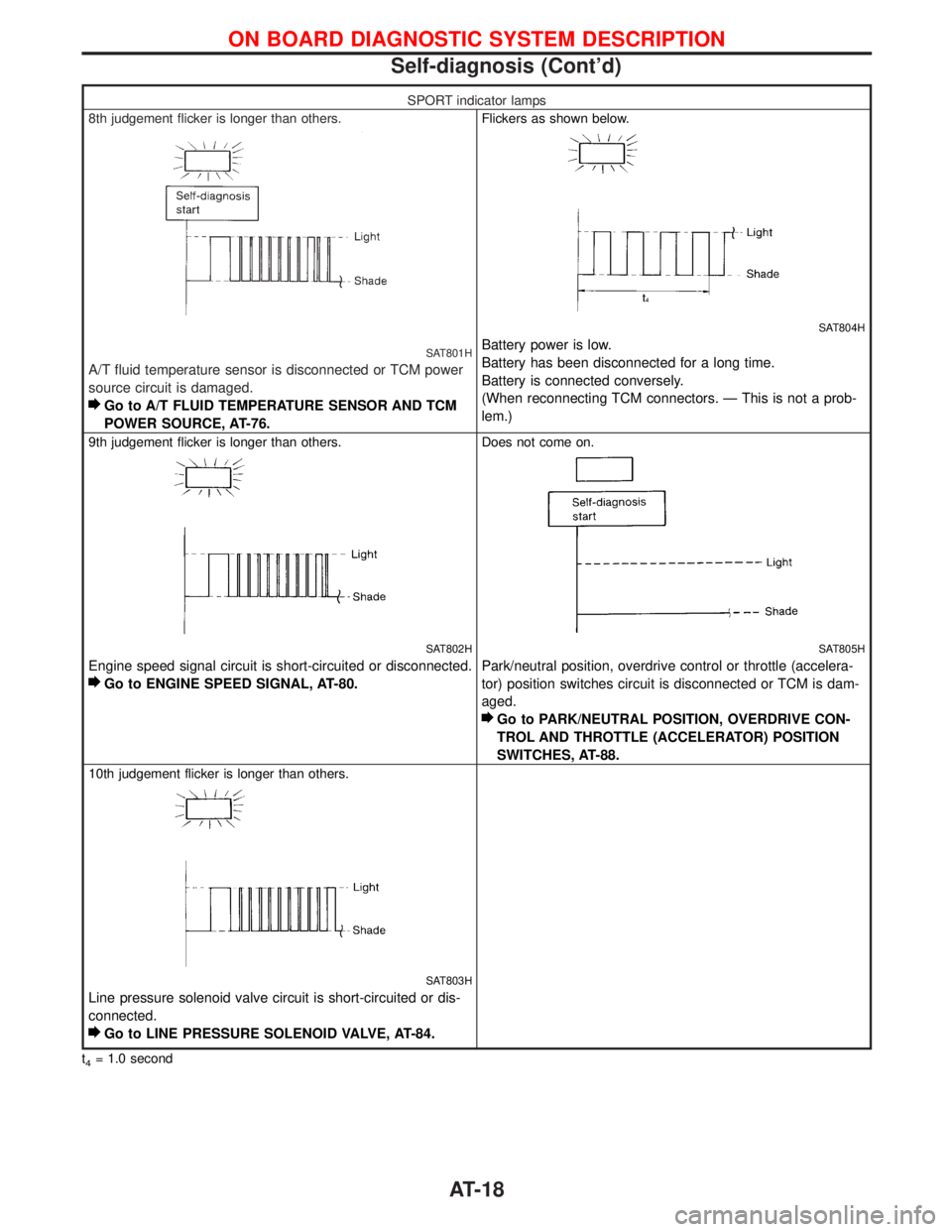

SPORT indicator lamps

8th judgement flicker is longer than others.

SAT801H

A/T fluid temperature sensor is disconnected or TCM power

source circuit is damaged.

Go to A/T FLUID TEMPERATURE SENSOR AND TCM

POWER SOURCE, AT-76.

Flickers as shown below.

SAT804H

Battery power is low.

Battery has been disconnected for a long time.

Battery is connected conversely.

(When reconnecting TCM connectors. Ð This is not a prob-

lem.)

9th judgement flicker is longer than others.

SAT802H

Engine speed signal circuit is short-circuited or disconnected.

Go to ENGINE SPEED SIGNAL, AT-80.

Does not come on.

SAT805H

Park/neutral position, overdrive control or throttle (accelera-

tor) position switches circuit is disconnected or TCM is dam-

aged.

Go to PARK/NEUTRAL POSITION, OVERDRIVE CON-

TROL AND THROTTLE (ACCELERATOR) POSITION

SWITCHES, AT-88.

10th judgement flicker is longer than others.

SAT803H

Line pressure solenoid valve circuit is short-circuited or dis-

connected.

Go to LINE PRESSURE SOLENOID VALVE, AT-84.

t4= 1.0 second

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-18

Page 22 of 1767

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed

upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

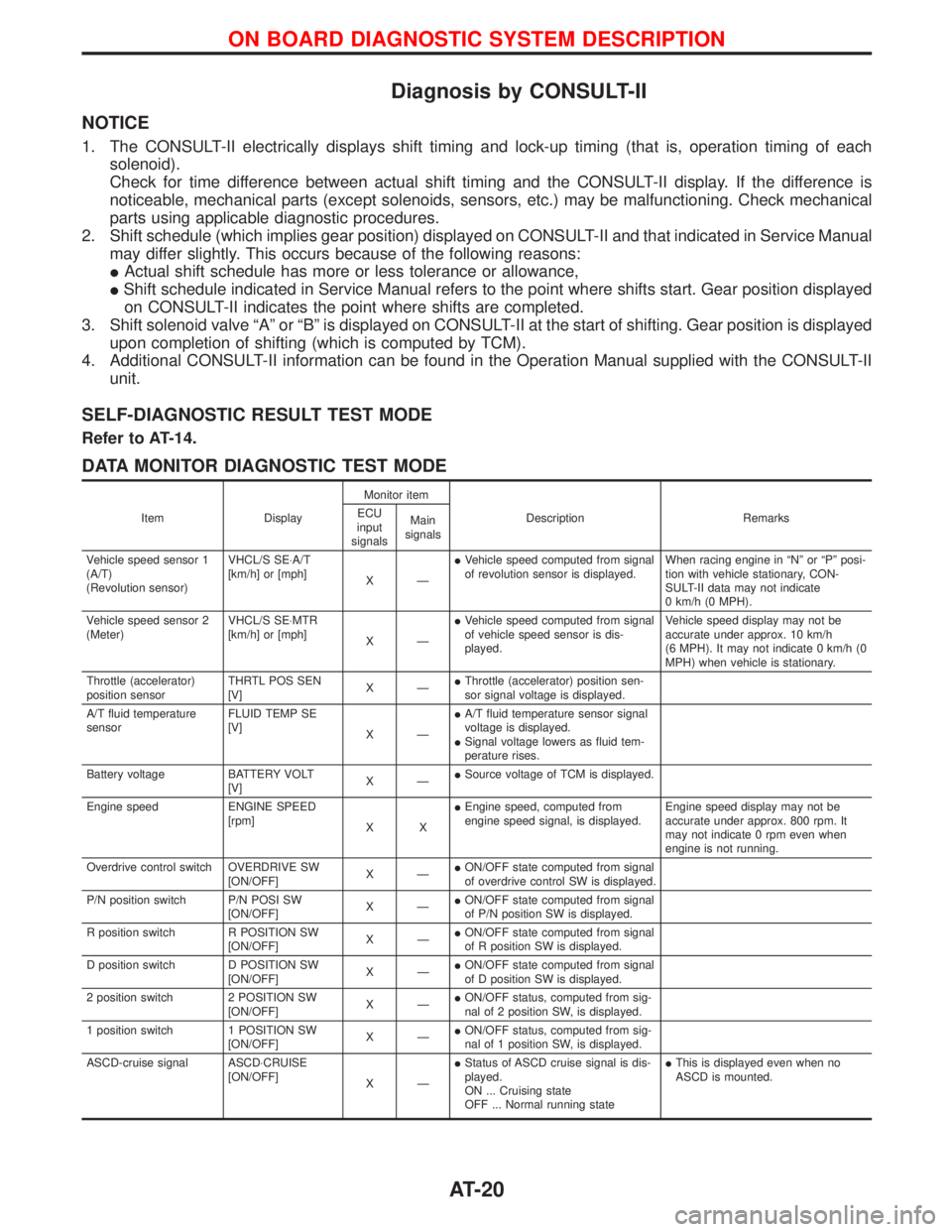

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor)VHCL/S SE×A/T

[km/h] or [mph]

XÐIVehicle speed computed from signal

of revolution sensor is displayed.When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SE×MTR

[km/h] or [mph]

XÐIVehicle speed computed from signal

of vehicle speed sensor is dis-

played.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensorTHRTL POS SEN

[V]XÐIThrottle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensorFLUID TEMP SE

[V]

XÐIA/T fluid temperature sensor signal

voltage is displayed.

ISignal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT

[V]XÐISource voltage of TCM is displayed.

Engine speed ENGINE SPEED

[rpm]

XXIEngine speed, computed from

engine speed signal, is displayed.Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF]XÐION/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW

[ON/OFF]XÐION/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE

[ON/OFF]

XÐIStatus of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running stateIThis is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

Page 26 of 1767

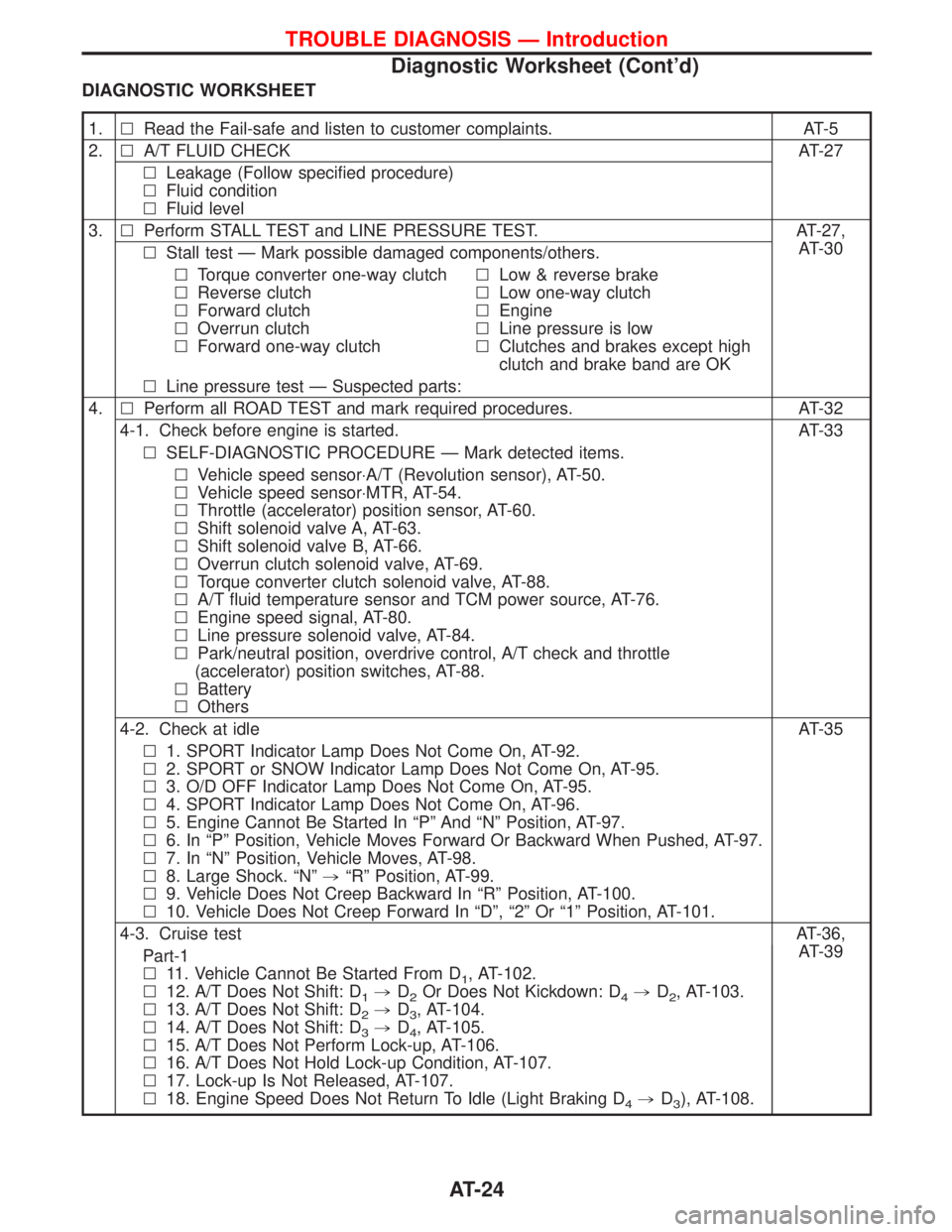

DIAGNOSTIC WORKSHEET

1.lRead the Fail-safe and listen to customer complaints. AT-5

2.lA/T FLUID CHECK AT-27

lLeakage (Follow specified procedure)

lFluid condition

lFluid level

3.lPerform STALL TEST and LINE PRESSURE TEST. AT-27,

AT-30

lStall test Ð Mark possible damaged components/others.

lTorque converter one-way clutch

lReverse clutch

lForward clutch

lOverrun clutch

lForward one-way clutchlLow & reverse brake

lLow one-way clutch

lEngine

lLine pressure is low

lClutches and brakes except high

clutch and brake band are OK

lLine pressure test Ð Suspected parts:

4.lPerform all ROAD TEST and mark required procedures. AT-32

4-1. Check before engine is started. AT-33

lSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

lVehicle speed sensor×A/T (Revolution sensor), AT-50.

lVehicle speed sensor×MTR, AT-54.

lThrottle (accelerator) position sensor, AT-60.

lShift solenoid valve A, AT-63.

lShift solenoid valve B, AT-66.

lOverrun clutch solenoid valve, AT-69.

lTorque converter clutch solenoid valve, AT-88.

lA/T fluid temperature sensor and TCM power source, AT-76.

lEngine speed signal, AT-80.

lLine pressure solenoid valve, AT-84.

lPark/neutral position, overdrive control, A/T check and throttle

(accelerator) position switches, AT-88.

lBattery

lOthers

4-2. Check at idle AT-35

l1. SPORT Indicator Lamp Does Not Come On, AT-92.

l2. SPORT or SNOW Indicator Lamp Does Not Come On, AT-95.

l3. O/D OFF Indicator Lamp Does Not Come On, AT-95.

l4. SPORT Indicator Lamp Does Not Come On, AT-96.

l5. Engine Cannot Be Started In ªPº And ªNº Position, AT-97.

l6. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed, AT-97.

l7. In ªNº Position, Vehicle Moves, AT-98.

l8. Large Shock. ªNº,ªRº Position, AT-99.

l9. Vehicle Does Not Creep Backward In ªRº Position, AT-100.

l10. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-101.

4-3. Cruise testAT-36,

AT-39

Part-1

l11. Vehicle Cannot Be Started From D

1, AT-102.

l12. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-103.

l13. A/T Does Not Shift: D

2,D3, AT-104.

l14. A/T Does Not Shift: D

3,D4, AT-105.

l15. A/T Does Not Perform Lock-up, AT-106.

l16. A/T Does Not Hold Lock-up Condition, AT-107.

l17. Lock-up Is Not Released, AT-107.

l18. Engine Speed Does Not Return To Idle (Light Braking D

4,D3), AT-108.

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-24

Page 27 of 1767

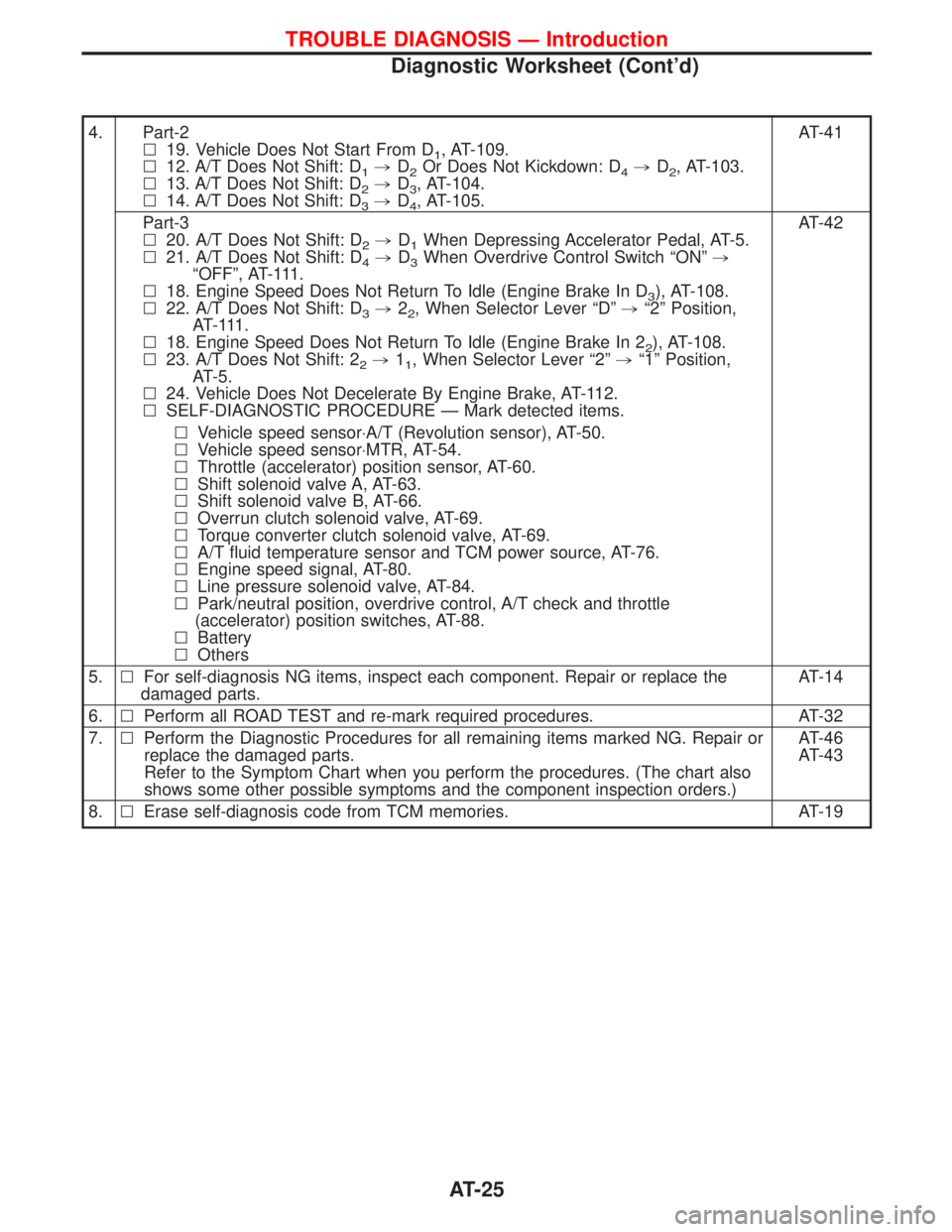

4. Part-2

l19. Vehicle Does Not Start From D

1, AT-109.

l12. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-103.

l13. A/T Does Not Shift: D

2,D3, AT-104.

l14. A/T Does Not Shift: D

3,D4, AT-105.AT-41

Part-3

l20. A/T Does Not Shift: D

2,D1When Depressing Accelerator Pedal, AT-5.

l21. A/T Does Not Shift: D

4,D3When Overdrive Control Switch ªONº,

ªOFFº, AT-111.

l18. Engine Speed Does Not Return To Idle (Engine Brake In D

3), AT-108.

l22. A/T Does Not Shift: D

3,22, When Selector Lever ªDº,ª2º Position,

AT- 111 .

l18. Engine Speed Does Not Return To Idle (Engine Brake In 2

2), AT-108.

l23. A/T Does Not Shift: 2

2,11, When Selector Lever ª2º,ª1º Position,

AT-5.

l24. Vehicle Does Not Decelerate By Engine Brake, AT-112.

lSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.AT-42

lVehicle speed sensor×A/T (Revolution sensor), AT-50.

lVehicle speed sensor×MTR, AT-54.

lThrottle (accelerator) position sensor, AT-60.

lShift solenoid valve A, AT-63.

lShift solenoid valve B, AT-66.

lOverrun clutch solenoid valve, AT-69.

lTorque converter clutch solenoid valve, AT-69.

lA/T fluid temperature sensor and TCM power source, AT-76.

lEngine speed signal, AT-80.

lLine pressure solenoid valve, AT-84.

lPark/neutral position, overdrive control, A/T check and throttle

(accelerator) position switches, AT-88.

lBattery

lOthers

5.lFor self-diagnosis NG items, inspect each component. Repair or replace the

damaged parts.AT-14

6.lPerform all ROAD TEST and re-mark required procedures. AT-32

7.lPerform the Diagnostic Procedures for all remaining items marked NG. Repair or

replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also

shows some other possible symptoms and the component inspection orders.)AT-46

AT-43

8.lErase self-diagnosis code from TCM memories. AT-19

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-25

Page 49 of 1767

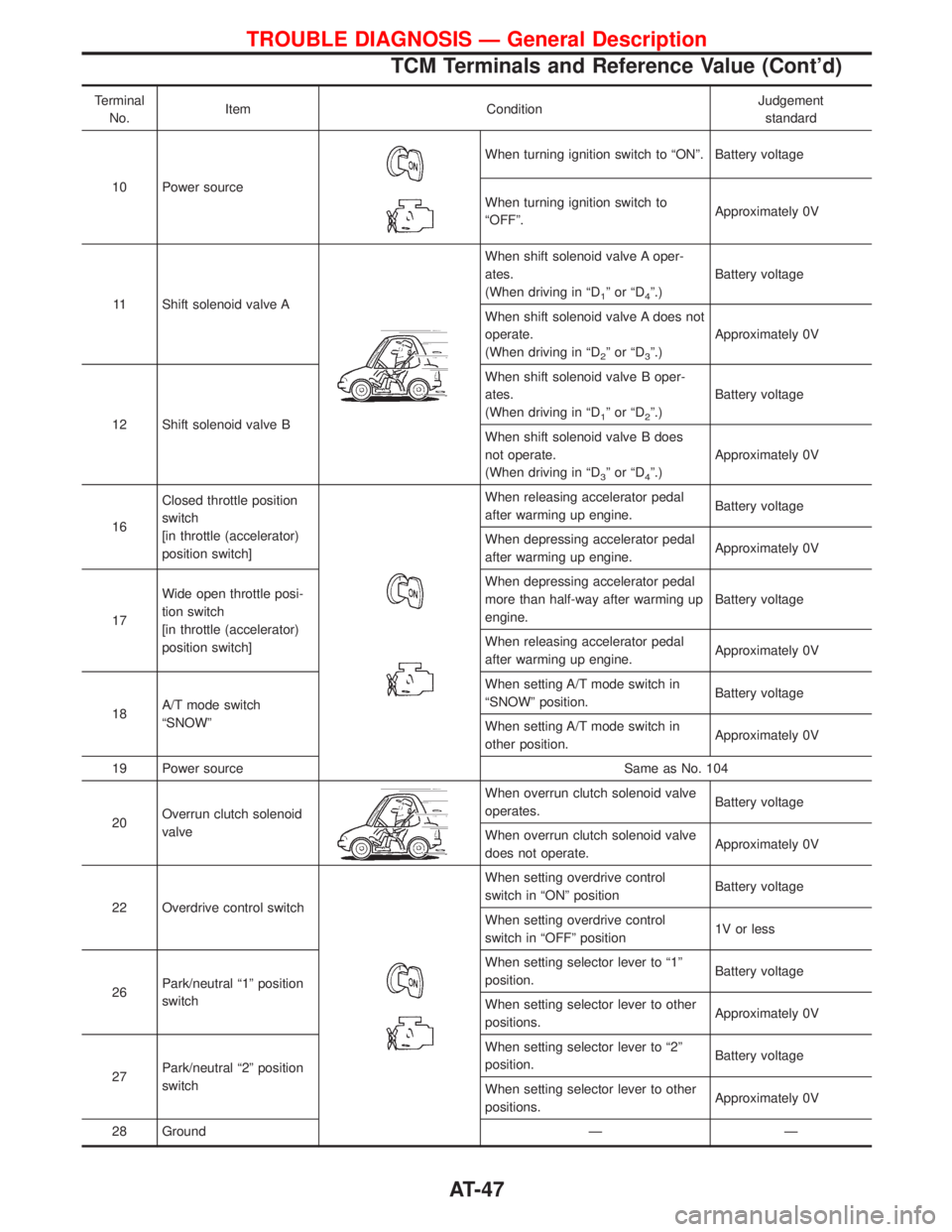

Terminal

No.Item ConditionJudgement

standard

10 Power source

When turning ignition switch to ªONº. Battery voltage

When turning ignition switch to

ªOFFº.Approximately 0V

11 Shift solenoid valve A

When shift solenoid valve A oper-

ates.

(When driving in ªD

1ºorªD4º.)Battery voltage

When shift solenoid valve A does not

operate.

(When driving in ªD

2ºorªD3º.)Approximately 0V

12 Shift solenoid valve BWhen shift solenoid valve B oper-

ates.

(When driving in ªD

1ºorªD2º.)Battery voltage

When shift solenoid valve B does

not operate.

(When driving in ªD

3ºorªD4º.)Approximately 0V

16Closed throttle position

switch

[in throttle (accelerator)

position switch]

When releasing accelerator pedal

after warming up engine.Battery voltage

When depressing accelerator pedal

after warming up engine.Approximately 0V

17Wide open throttle posi-

tion switch

[in throttle (accelerator)

position switch]When depressing accelerator pedal

more than half-way after warming up

engine.Battery voltage

When releasing accelerator pedal

after warming up engine.Approximately 0V

18A/T mode switch

ªSNOWºWhen setting A/T mode switch in

ªSNOWº position.Battery voltage

When setting A/T mode switch in

other position.Approximately 0V

19 Power source Same as No. 104

20Overrun clutch solenoid

valve

When overrun clutch solenoid valve

operates.Battery voltage

When overrun clutch solenoid valve

does not operate.Approximately 0V

22 Overdrive control switch

When setting overdrive control

switch in ªONº positionBattery voltage

When setting overdrive control

switch in ªOFFº position1V or less

26Park/neutral ª1º position

switchWhen setting selector lever to ª1º

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

27Park/neutral ª2º position

switchWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

28 Ground Ð Ð

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-47

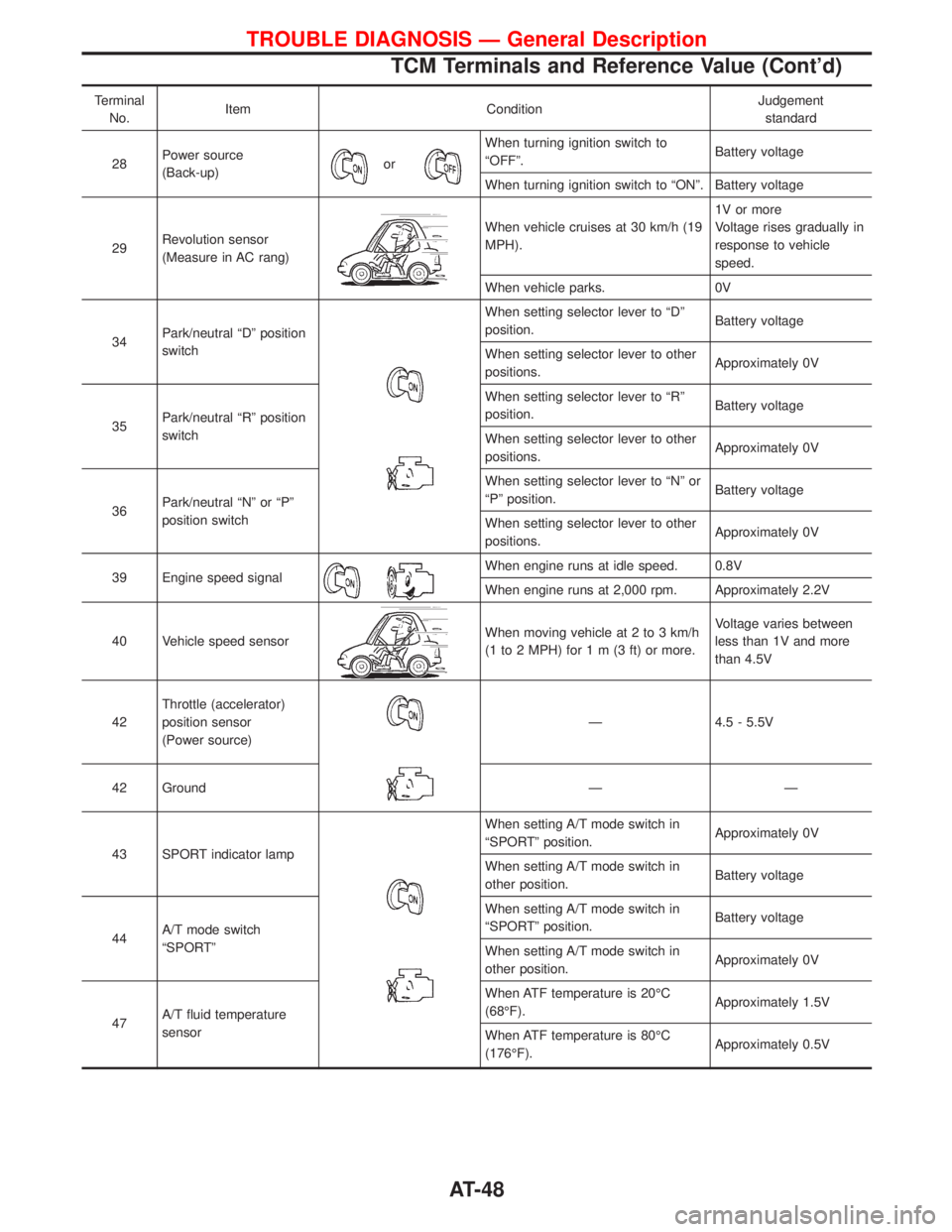

Page 50 of 1767

Terminal

No.Item ConditionJudgement

standard

28Power source

(Back-up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to ªONº. Battery voltage

29Revolution sensor

(Measure in AC rang)

When vehicle cruises at 30 km/h (19

MPH).1V or more

Voltage rises gradually in

response to vehicle

speed.

When vehicle parks. 0V

34Park/neutral ªDº position

switch

When setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

35Park/neutral ªRº position

switchWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

36Park/neutral ªNº or ªPº

position switchWhen setting selector lever to ªNº or

ªPº position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

39 Engine speed signal

When engine runs at idle speed. 0.8V

When engine runs at 2,000 rpm. Approximately 2.2V

40 Vehicle speed sensor

When moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for1m(3ft)ormore.Voltage varies between

less than 1V and more

than 4.5V

42Throttle (accelerator)

position sensor

(Power source)

Ð 4.5 - 5.5V

42 Ground Ð Ð

43 SPORT indicator lamp

When setting A/T mode switch in

ªSPORTº position.Approximately 0V

When setting A/T mode switch in

other position.Battery voltage

44A/T mode switch

ªSPORTºWhen setting A/T mode switch in

ªSPORTº position.Battery voltage

When setting A/T mode switch in

other position.Approximately 0V

47A/T fluid temperature

sensorWhen ATF temperature is 20ÉC

(68ÉF).Approximately 1.5V

When ATF temperature is 80ÉC

(176ÉF).Approximately 0.5V

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-48

Page 66 of 1767

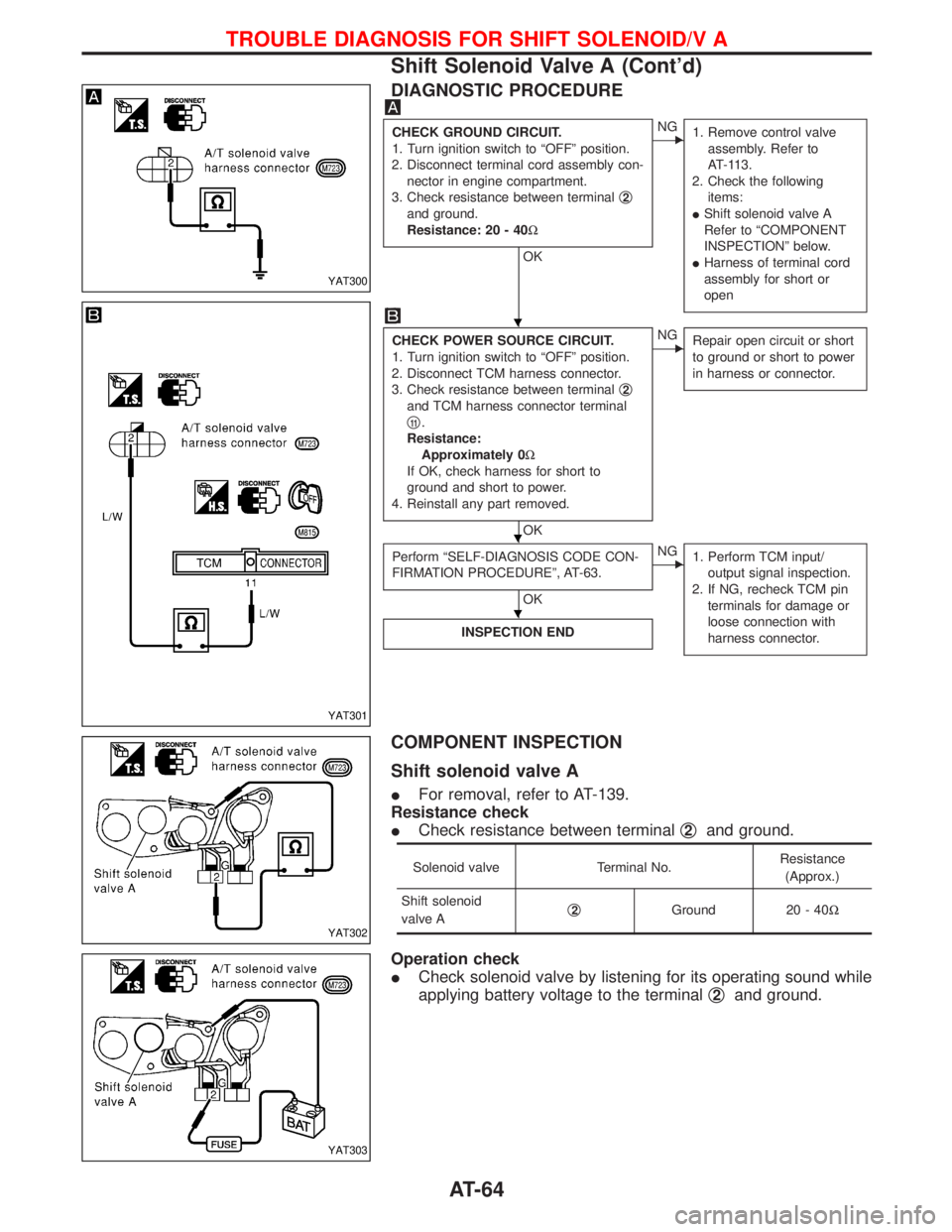

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly con-

nector in engine compartment.

3. Check resistance between terminalq

2

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift solenoid valve A

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

2

and TCM harness connector terminal

q

11.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-63.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve A

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

2and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve Aq

2Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

2and ground.

YAT300

YAT301

YAT302

YAT303

H

H

H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V A

Shift Solenoid Valve A (Cont'd)

AT-64

Page 69 of 1767

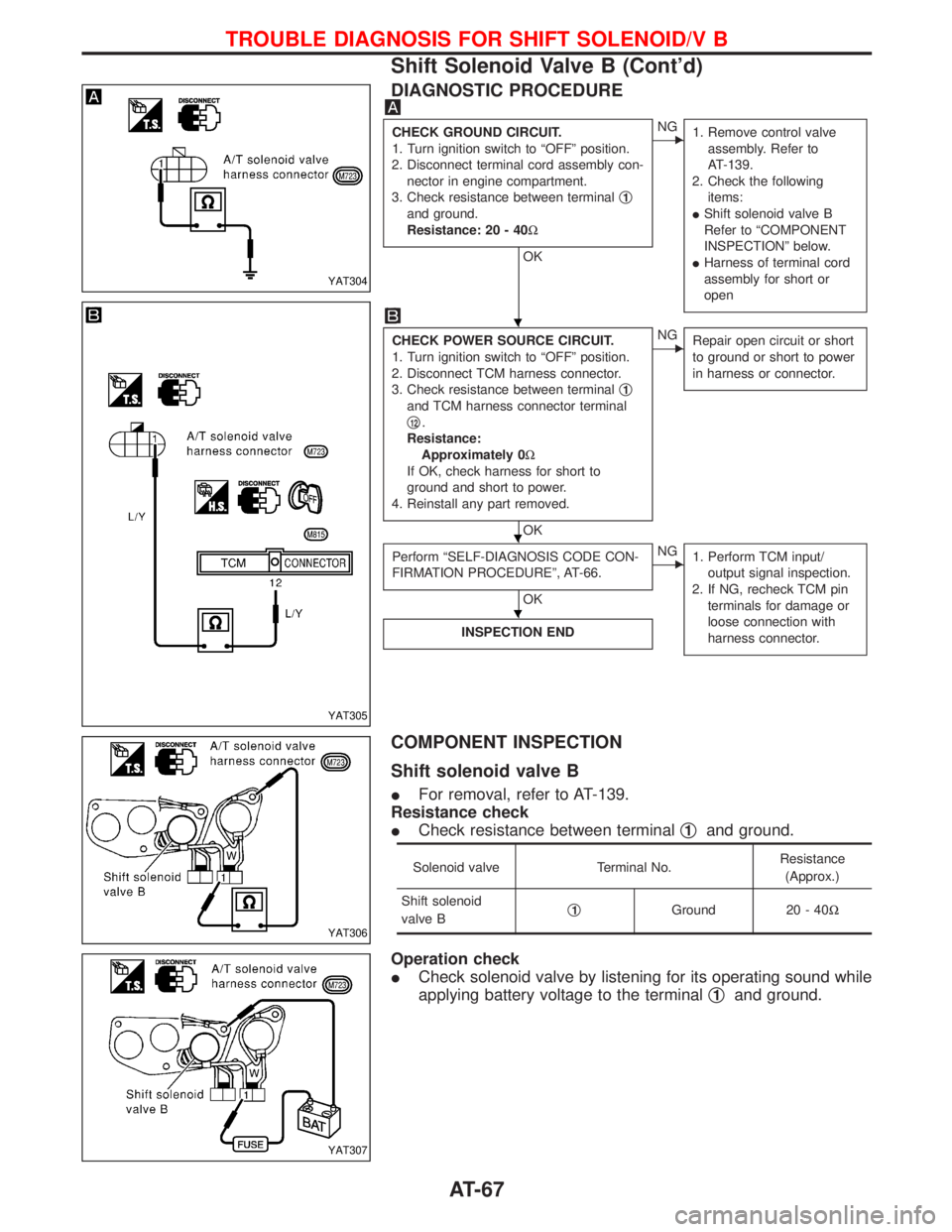

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly con-

nector in engine compartment.

3. Check resistance between terminalq

1

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-139.

2. Check the following

items:

IShift solenoid valve B

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

1

and TCM harness connector terminal

q

12.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-66.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve B

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

1and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve Bq

1Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

1and ground.

YAT304

YAT305

YAT306

YAT307

H

H

H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V B

Shift Solenoid Valve B (Cont'd)

AT-67

Page 72 of 1767

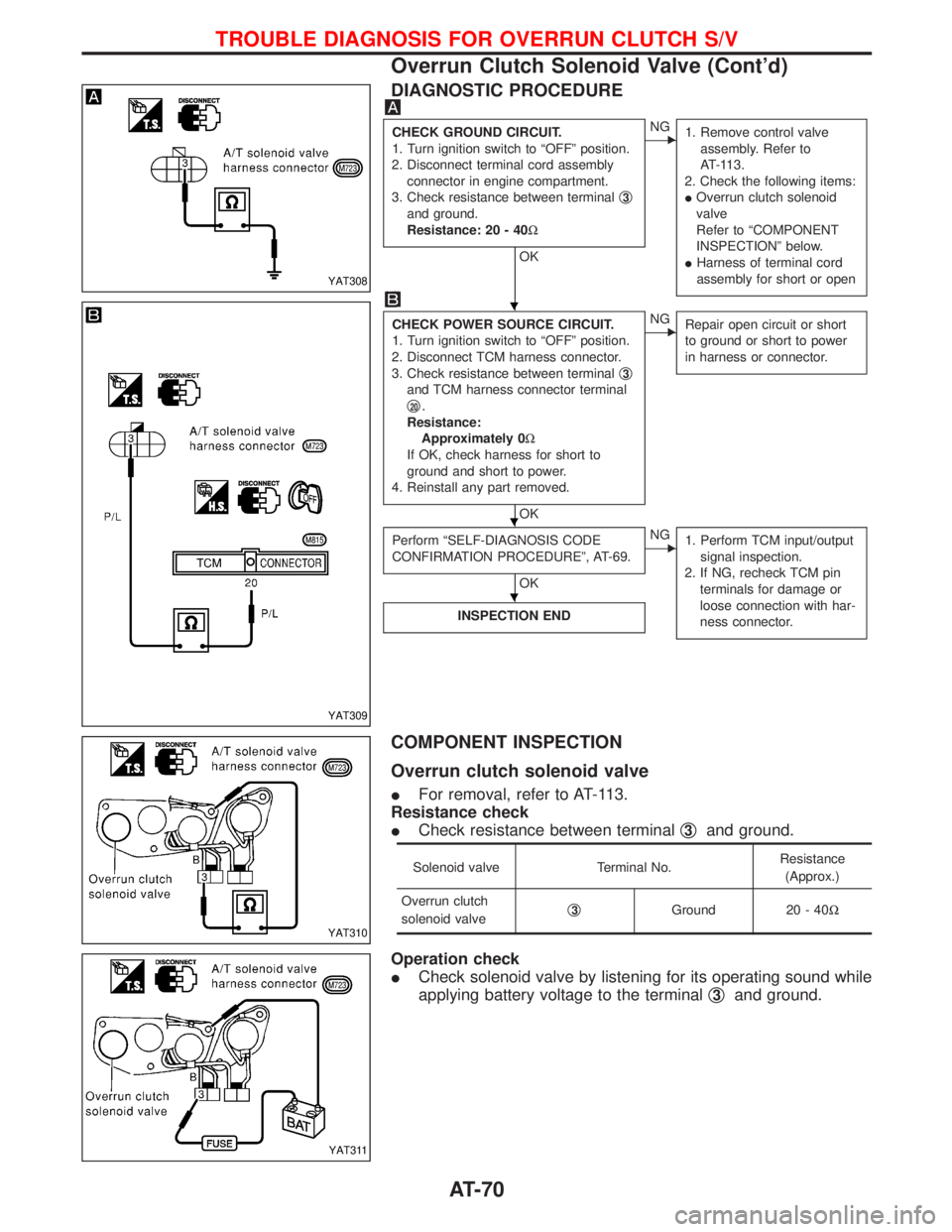

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

3

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following items:

IOverrun clutch solenoid

valve

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

3

and TCM harness connector terminal

q

20.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE

CONFIRMATION PROCEDUREº, AT-69.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with har-

ness connector.

INSPECTION END

COMPONENT INSPECTION

Overrun clutch solenoid valve

IFor removal, refer to AT-113.

Resistance check

ICheck resistance between terminalq

3and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Overrun clutch

solenoid valveq

3Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

3and ground.

YAT308

YAT309

YAT310

YAT311

H

H

H

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH S/V

Overrun Clutch Solenoid Valve (Cont'd)

AT-70

Page 76 of 1767

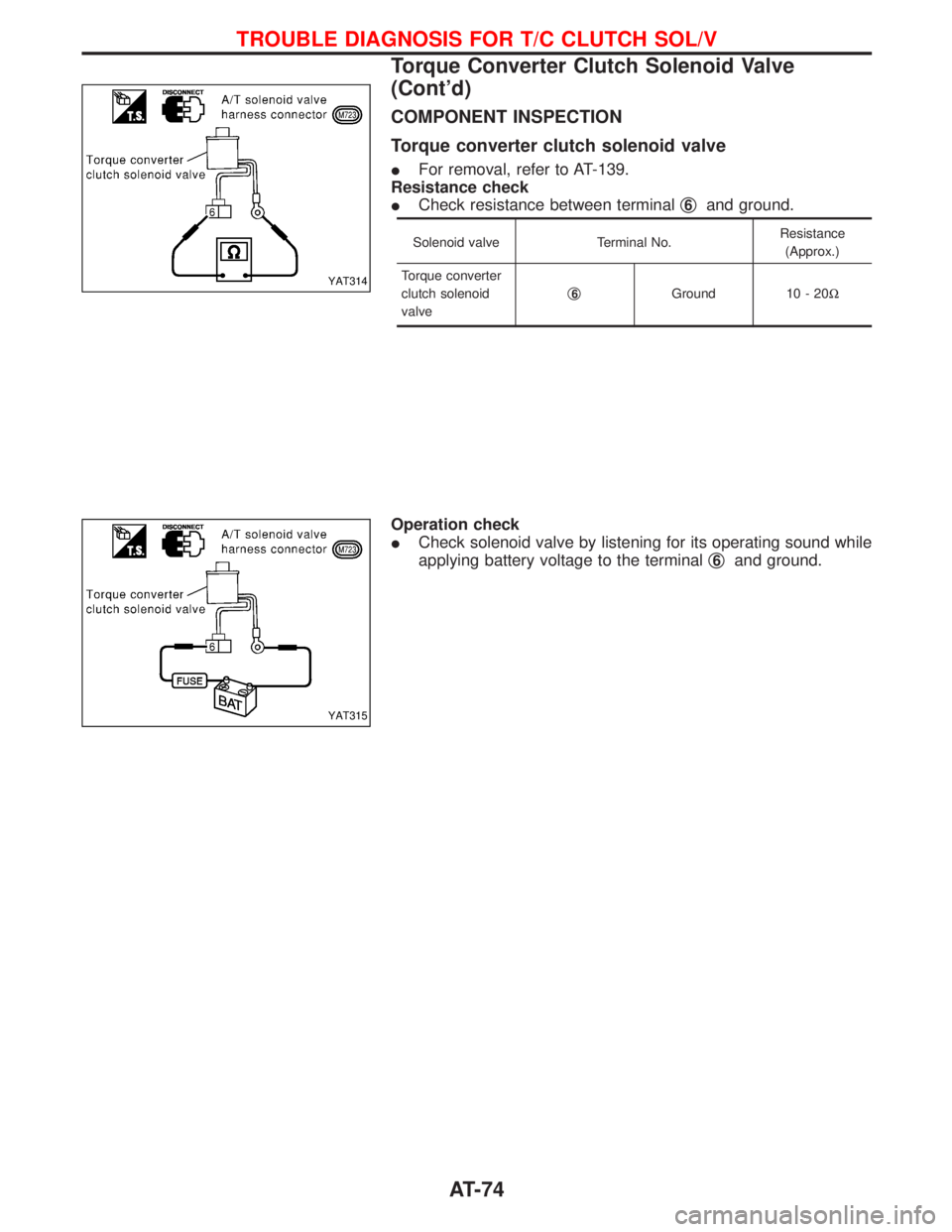

COMPONENT INSPECTION

Torque converter clutch solenoid valve

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

6and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valveq

6Ground 10 - 20W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

6and ground.

YAT314

YAT315

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-74