battery replacement NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 859 of 1767

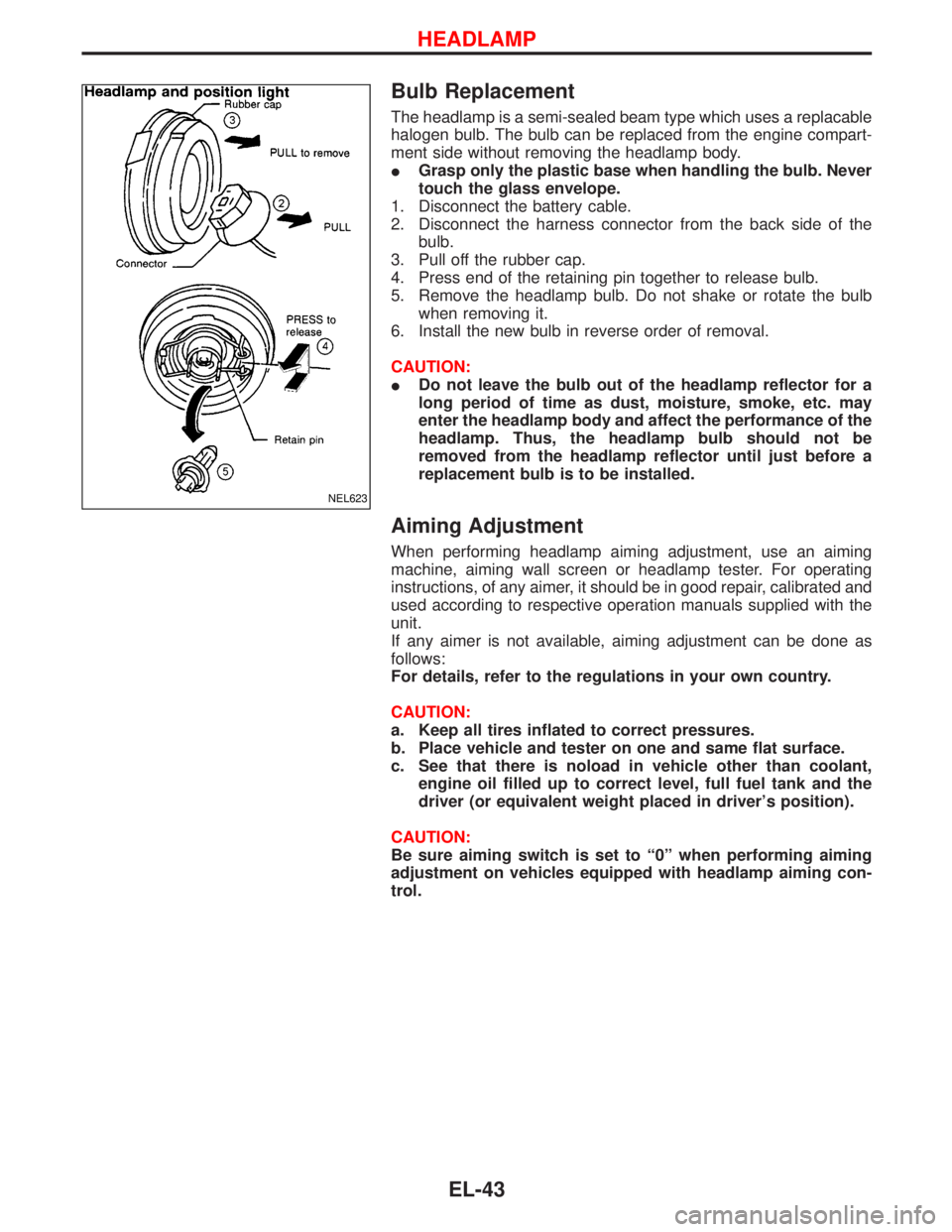

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb

when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

IDo not leave the bulb out of the headlamp reflector for a

long period of time as dust, moisture, smoke, etc. may

enter the headlamp body and affect the performance of the

headlamp. Thus, the headlamp bulb should not be

removed from the headlamp reflector until just before a

replacement bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

CAUTION:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

HEADLAMP

EL-43

Page 927 of 1767

System Description

Refer to Owner's Manual for audio system operating instructions.

NATS AUDIO LINK

Description

The link with the NATS IMMU implies that the audio unit can basically only be operated if connected to the

matching NATS IMMU to which the audio unit was initially fitted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the audio unit is basically

useless since special equipment is required to reset the audio unit.

Initialization process for audio units that are linked to the NATS IMMU

New audio units will be delivered to the factories in the ªNEWº state, i.e. ready to be linked with the vehicle's

NATS. When the audio unit in ªNEWº state is first switched on at the factory, it will start up communication

with the vehicle's immobiliser control unit (IMMU) and send a code (the ªaudio unit Codeº) to the IMMU. The

IMMU will then store this code, which is unique to each audio unit, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will confirm correct receipt of the audio unit code to the audio

unit. Hereafter, the audio unit will operate as normal.

During the initialisation process, ªNEWº is displayed on the audio unit display. Normally though, communica-

tion between audio unit and IMMU takes such a short time that the audio unit seems to switch on directly

without showing ªNEWº on its display.

Normal operation

Each time the audio unit is switched on afterwards, the audio unit code will be verified between the audio unit

and the NATS before the audio unit becomes operational. During the code verification process, ªWAITº is

shown on the audio unit display. Again, the communication takes such a short time that the audio unit seems

to switch on directly without showing ªWAITº on its display.

When the radio is locked

In case of a audio unit being linked with the vehicle's NATS (immobilizer system), disconnection of the link

between the audio unit and the IMMU will cause the audio unit to switch into the lock (ªSECUREº) mode in

which the audio unit is fully inoperative. Hence, repair of the audio unit is basically impossible, unless the audio

unit is reset to the ªNEWº state for which special decoding equipment is required.

Clarion has provided their authorized service representatives with so called ªdecoder boxesº which can bring

the audio unit back to the ªNEWº state, enabling the audio unit to be switched on after which repair can be

carried out. Subsequently, when the repaired audio unit is delivered to the final user again, it will be in the

ªNEWº state as to enable re-linking the audio unit to the vehicle's immobiliser system. As a result of the above,

repair of the audio unit can only be done by an authorized Clarion representative.

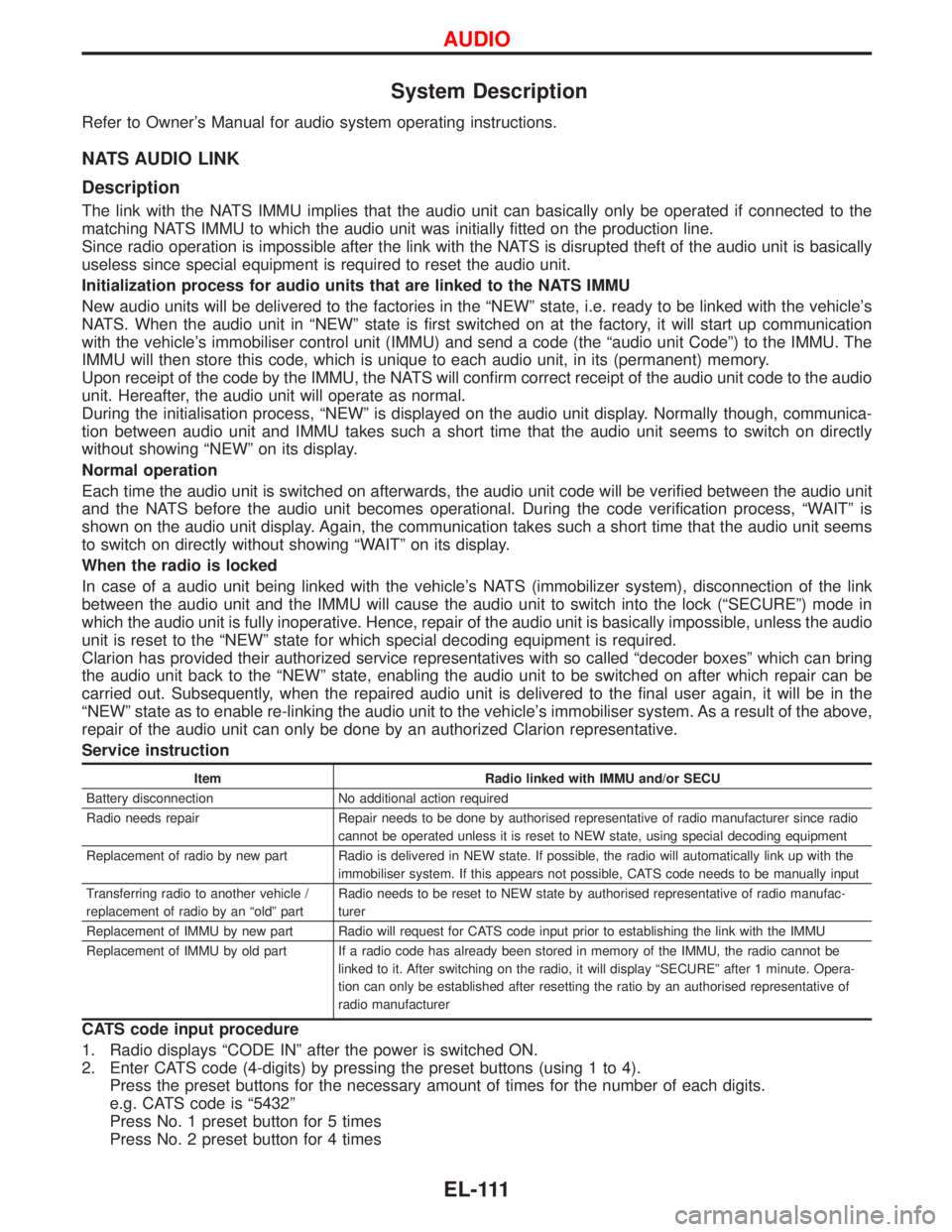

Service instruction

Item Radio linked with IMMU and/or SECU

Battery disconnection No additional action required

Radio needs repair Repair needs to be done by authorised representative of radio manufacturer since radio

cannot be operated unless it is reset to NEW state, using special decoding equipment

Replacement of radio by new part Radio is delivered in NEW state. If possible, the radio will automatically link up with the

immobiliser system. If this appears not possible, CATS code needs to be manually input

Transferring radio to another vehicle /

replacement of radio by an ªoldº partRadio needs to be reset to NEW state by authorised representative of radio manufac-

turer

Replacement of IMMU by new part Radio will request for CATS code input prior to establishing the link with the IMMU

Replacement of IMMU by old part If a radio code has already been stored in memory of the IMMU, the radio cannot be

linked to it. After switching on the radio, it will display ªSECUREº after 1 minute. Opera-

tion can only be established after resetting the ratio by an authorised representative of

radio manufacturer

CATS code input procedure

1. Radio displays ªCODE INº after the power is switched ON.

2. Enter CATS code (4-digits) by pressing the preset buttons (using 1 to 4).

Press the preset buttons for the necessary amount of times for the number of each digits.

e.g. CATS code is ª5432º

Press No. 1 preset button for 5 times

Press No. 2 preset button for 4 times

AUDIO

EL-111

Page 1316 of 1767

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL........................................8

HOW TO READ WIRING DIAGRAMS..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL.......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT........................................22Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES..................................................................25

CONSULT-II CHECKING SYSTEM...............................26

General ......................................................................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............27

Checking Equipment..................................................27

IDENTIFICATION INFORMATION.................................28

Model Variation ..........................................................28

Identification Number .................................................29

Dimensions ................................................................31

Wheels and Tires .......................................................31

LIFTING POINTS AND TOW TRUCK TOWING...........32

Garage Jack and Safety Stand .................................32

Screw Jack ................................................................32

4-pole Lift ...................................................................33

Tow Truck Towing ......................................................33

ISO 15031-2 TERMINOLOGY LIST..............................35

ISO 15031-2 Terminology List ...................................35

TIGHTENING TORQUE OF STANDARD BOLTS........38

Page 1342 of 1767

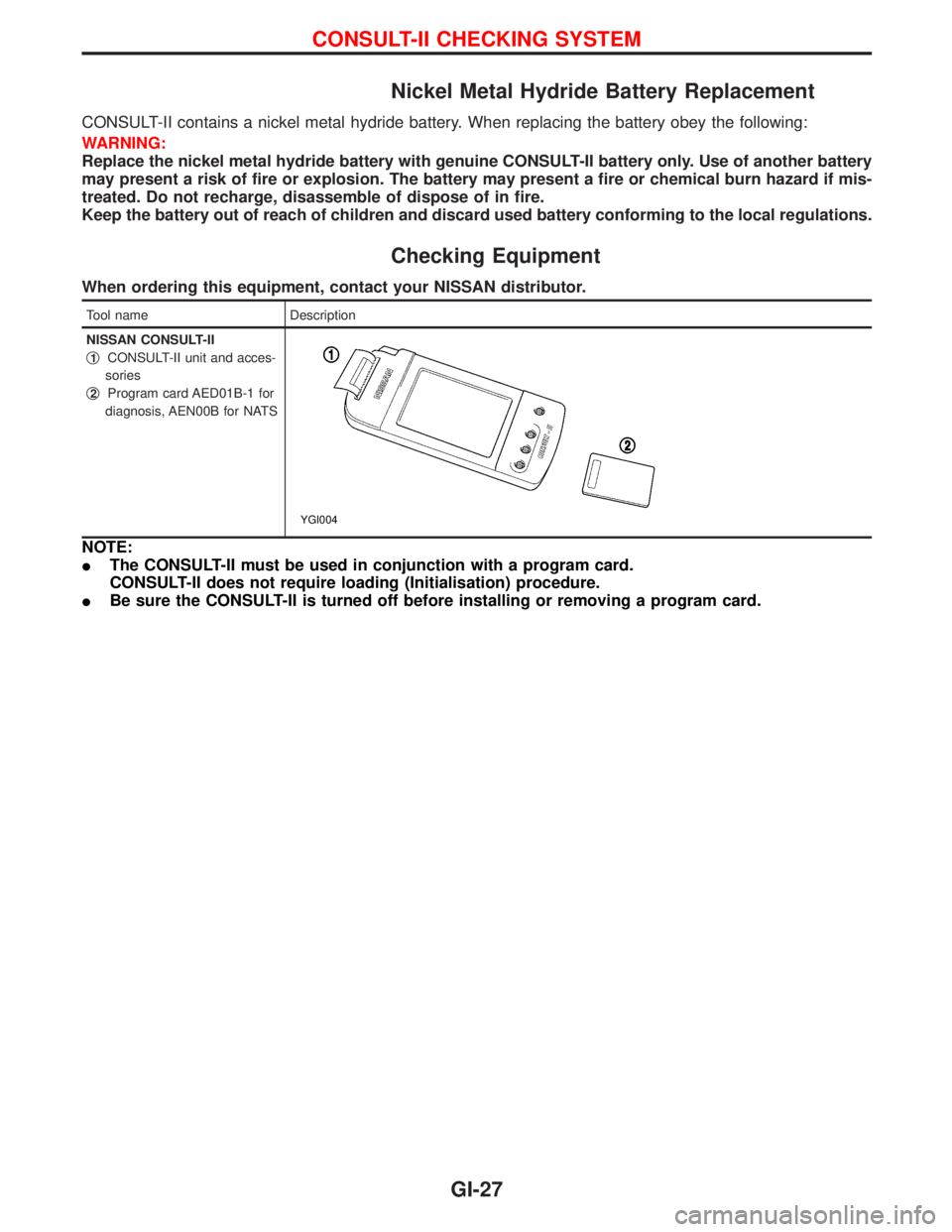

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another battery

may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering this equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

q

1CONSULT-II unit and acces-

sories

q

2Program card AED01B-1 for

diagnosis, AEN00B for NATS

YGI004

NOTE:

IThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

IBe sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II CHECKING SYSTEM

GI-27

Page 1419 of 1767

A

ABS (anti-lock brake system).........................BR-35

ABS - Wiring diagram ....................................BR-50

A/C air flow .......................................................HA-8

A/C compressor precaution..............................HA-5

A/C control operation (manual A/C) .................HA-6

A/C relay.........................................................HA-61

A/C symptom chart (manual A/C) ..................HA-36

A/C trouble diagnoses (manual A/C) .............HA-27

A/C, M - Wiring diagram ................................HA-43

ACC/SW - Wiring diagram ...........................EC-106

Accelerator control system ...........................FE-2, 5

Accelerator position sensor .........EC-130, 368, 371

Accelerator position switch ..................EC-369, 371

Accelerator switch (F/C) ...............................EC-104

Accelerator wire adjustment .............................FE-5

Accelerator work unit....................................EC-365

A/CCUT - Wiring diagram ............................EC-289

Air bag ..............................................................RS-6

Air bag disposal..............................................RS-20

Air bag precautions ...........................................GI-3

Air bleeding (hydraulic clutch) ..........................CL-6

Air bleeding for brake system ..........................BR-8

Air cleaner filter replacement ..............MA-5, 20, 24

Air conditioner cut control ..............EC-22, 311, 440

Air control cable adjustment...........................HA-62

Air flow meter - See Mass air flow

sensor .................................................EC-88, 356

Alternator ........................................................SC-27

Angular tightening application..........................EM-3

Antenna .................................................EL-111, 127

Anti-lock brake system - See ABS .................BR-37

Anti-lock brake system - Wiring

diagram .......................................................BR-50

APS - Wiring diagram ..................................EC-133

ASCD vacuum hose ......................................MA-40

A/T - Wiring diagram .........................................AT-7

A/T - Wiring diagram - AT - PNP/SW .............AT-87

A/T - Wiring diagram - AT - VSS A/T ..............AT-49

A/T control ....................................................EC-155

A/T diagnosis communication line ...............EC-155

A/T fluid checking ............................................AT-27

A/T fluid temperature sensor...........................AT-76

A/T mode switch..............................................AT-94

A/T self-diagnoses ....................................AT-14, 19

A/T Wiring diagram - AT - ENG SS ................AT-79

A/T Wiring diagram AT - BA/FTS ....................AT-75

A/T Wiring diagram AT - LPSV .......................AT-82

A/T Wiring diagram AT - OVRCSV .................AT-68

A/T Wiring diagram AT - SSV/A ......................AT-62

A/T Wiring diagram AT - SSV/B ......................AT-65

A/T Wiring diagram AT - TCV .........................AT-71

A/T Wiring diagram AT - TPS..........................AT-56

A/T Wiring diagram AT - VSSMTR .................AT-52

AT/C - Wiring diagram..................................EC-157

Audio......................................................EL-111, 113

AUDIO - Wiring diagram ...............................EL-115Audio and A/C control removal and

installation - See Instrument panel .............BT-16

Auto lock free running hub .............................FA-14

Automatic transmission number ......................GI-30

Axle housing (rear) ...........................................RA-8

B

Back Door .......................................................BT-14

Back door opener - See Back door ................BT-14

Back door trim.................................................BT-18

Back door window...........................................BT-43

Back-up lamp ..................................................EL-49

Back-up lamp switch (M/T) ........................MT-6, 10

BACK/L - Wiring diagram................................EL-49

Ball joint front axle ..........................................FA-36

Basic inspection .....................................EC-50, 338

Battery ..............................................................SC-3

Battery Voltage .............................................EC-153

Blower motor ..................................................HA-60

Blower resistor................................................HA-60

Body alignment ...............................................BT-49

BOOST - Wiring diagram .............................EC-217

Boring/horning cylinder block.........................EM-74

Brake booster .................................................BR-17

Brake fluid change ...........................................BR-5

Brake fluid level ...........................MA-17, 36, 40, 43

Brake fluid level and line check .......................BR-5

Brake hydraulic line......................................BR-5, 6

Brake inspection ..........................MA-36, 40, 41, 42

Brake lines and cables inspection.....MA-36, 40, 42

Brake lining wear temporary checking ....MA-36, 42

Brake master cylinder ....................................BR-16

Brake pedal ....................................................BR-14

Brake switch .................................................EC-400

BRK/SW - Wiring diagram ...........................EC-205

Bumper, front ....................................................BT-6

Bumper, rear .....................................................BT-8

C

Camshaft ........................................................EM-30

Camshaft position sensor (PUMP)...............EC-161

Center case (Transfer) ......................................TF-9

CHARGE - Wiring diagram ............................SC-24

Charge air pressure sensor .........................EC-215

Charging system ............................................SC-23

Chassis and body maintenance ....................MA-36

CIGAR - Wiring diagram ...............................EL-105

Cigarette lighter.............................................EL-104

Circuit breaker.................................................EL-17

CKPS - Wiring diagram ................................EC-147

Clock .............................................................EL-104

CLOCK - Wiring diagram ..............................EL-106

Clutch cover ..............................................CL-11, 12

Clutch disc ......................................................CL-11

Clutch fluid level ......................................MA-17, 36

Clutch master cylinder ..................................CL-7, 8

ALPHABETICAL INDEX

IDX-2

Page 1632 of 1767

IInstall driver air bag module to steering wheel to check fit or

alignment with the wheel.

ICheck steering wheel for excessive free play.

IInstall front passenger air bag module to instrument panel to

check fit or alignment with the instrument panel.

IInstall front side air bag module to seatback to check fit and

alignment with the seat.

3) Spiral cable

ICheck spiral cable for dents, cracks, or deformities.

ICheck connectors and protective tape for damage.

ICheck steering wheel for noise, binding or heavy operation.

4) Main harness, body harness, side air bag module sub-harness

ICheck connectors for poor connections, damage, and terminals

for deformities.

ICheck harnesses for binding, chafing or cut.

5) Front seat belt pre-tensioner

ICheck harness cover and connectors for damage, terminals for

deformities, and harness for binding.

ICheck belts for damage and anchors for loose mounting.

ICheck retractor for smooth operation.

IPerform self-diagnosis for seat belt pre-tensioner using ªAIR

BAGº warning lamp or CONSULT-II.

Refer to ªSRS Operation Checkº for details. (RS-36)

6) Side air bag (satellite) sensor

ICheck side air bag (satellite) sensor (including bracket portion)

for dents, cracks or deformities.

ICheck connectors for damage, and terminals for deformities.

CAUTION:

Replace previously used special bolts and ground bolt with

new ones.

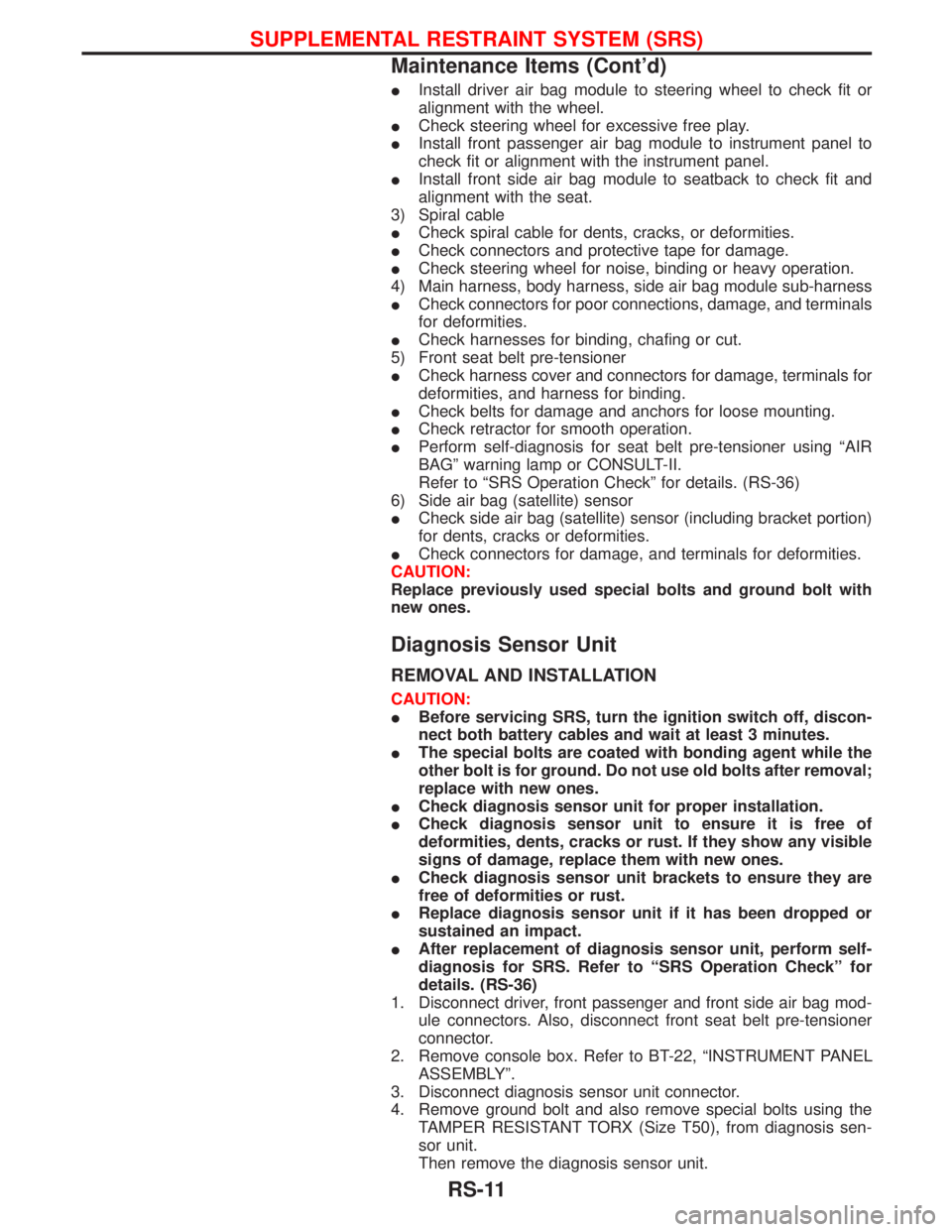

Diagnosis Sensor Unit

REMOVAL AND INSTALLATION

CAUTION:

IBefore servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait at least 3 minutes.

IThe special bolts are coated with bonding agent while the

other bolt is for ground. Do not use old bolts after removal;

replace with new ones.

ICheck diagnosis sensor unit for proper installation.

ICheck diagnosis sensor unit to ensure it is free of

deformities, dents, cracks or rust. If they show any visible

signs of damage, replace them with new ones.

ICheck diagnosis sensor unit brackets to ensure they are

free of deformities or rust.

IReplace diagnosis sensor unit if it has been dropped or

sustained an impact.

IAfter replacement of diagnosis sensor unit, perform self-

diagnosis for SRS. Refer to ªSRS Operation Checkº for

details. (RS-36)

1. Disconnect driver, front passenger and front side air bag mod-

ule connectors. Also, disconnect front seat belt pre-tensioner

connector.

2. Remove console box. Refer to BT-22, ªINSTRUMENT PANEL

ASSEMBLYº.

3. Disconnect diagnosis sensor unit connector.

4. Remove ground bolt and also remove special bolts using the

TAMPER RESISTANT TORX (Size T50), from diagnosis sen-

sor unit.

Then remove the diagnosis sensor unit.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Maintenance Items (Cont'd)

RS-11

Page 1633 of 1767

NOTE:

ITo install, reverse the removal procedure sequence.

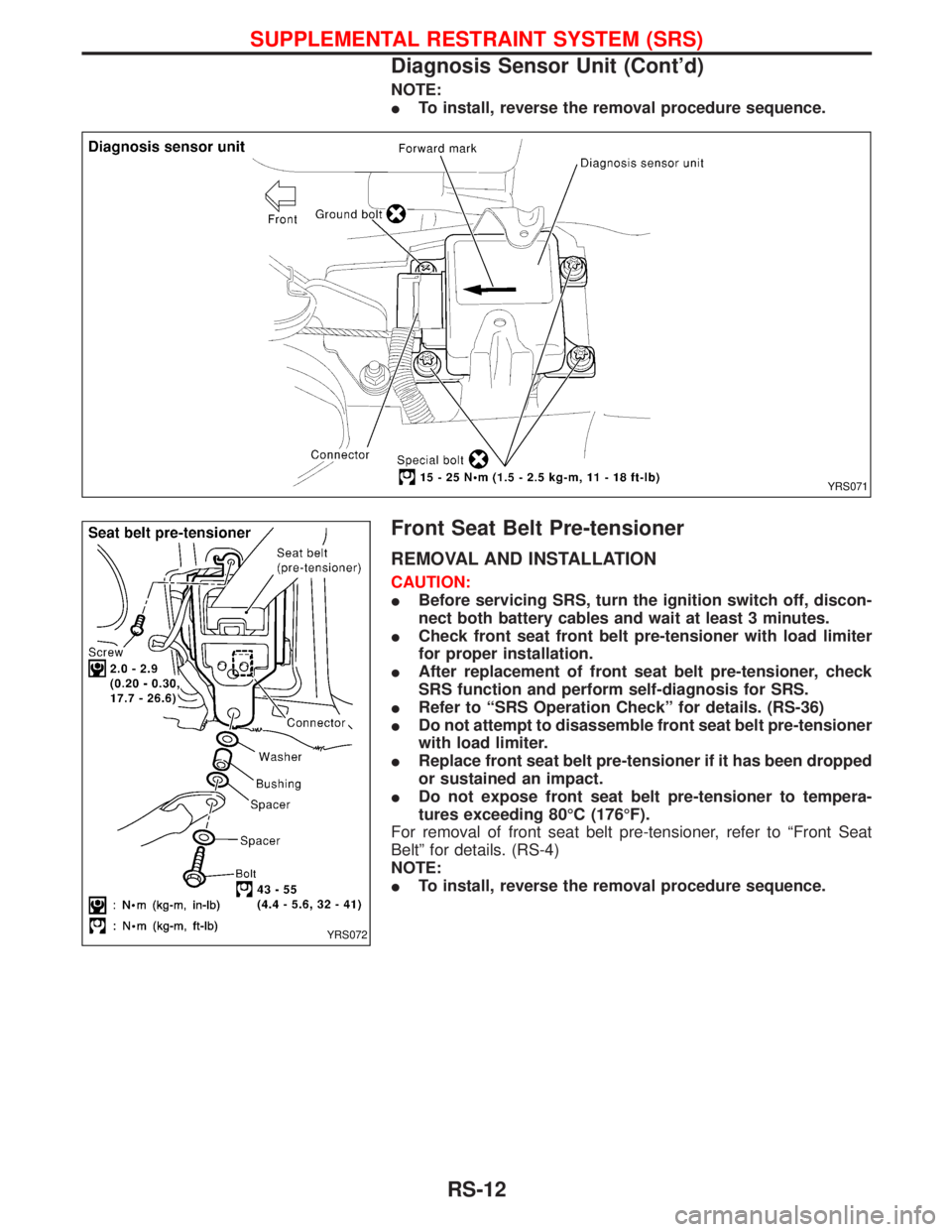

Front Seat Belt Pre-tensioner

REMOVAL AND INSTALLATION

CAUTION:

IBefore servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait at least 3 minutes.

ICheck front seat front belt pre-tensioner with load limiter

for proper installation.

IAfter replacement of front seat belt pre-tensioner, check

SRS function and perform self-diagnosis for SRS.

IRefer to ªSRS Operation Checkº for details. (RS-36)

IDo not attempt to disassemble front seat belt pre-tensioner

with load limiter.

IReplace front seat belt pre-tensioner if it has been dropped

or sustained an impact.

IDo not expose front seat belt pre-tensioner to tempera-

tures exceeding 80ÉC (176ÉF).

For removal of front seat belt pre-tensioner, refer to ªFront Seat

Beltº for details. (RS-4)

NOTE:

ITo install, reverse the removal procedure sequence.

YRS071

YRS072

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Diagnosis Sensor Unit (Cont'd)

RS-12

Page 1634 of 1767

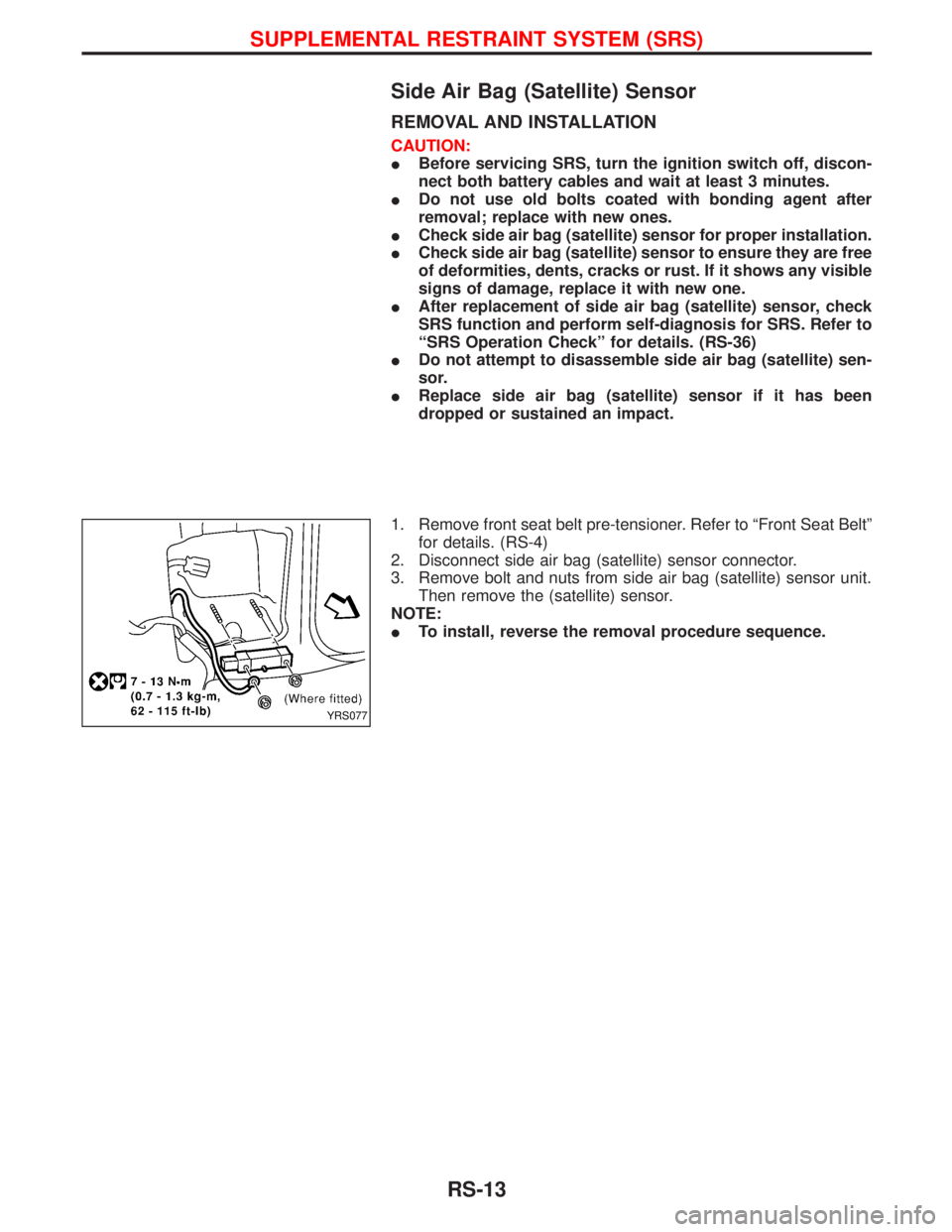

Side Air Bag (Satellite) Sensor

REMOVAL AND INSTALLATION

CAUTION:

IBefore servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait at least 3 minutes.

IDo not use old bolts coated with bonding agent after

removal; replace with new ones.

ICheck side air bag (satellite) sensor for proper installation.

ICheck side air bag (satellite) sensor to ensure they are free

of deformities, dents, cracks or rust. If it shows any visible

signs of damage, replace it with new one.

IAfter replacement of side air bag (satellite) sensor, check

SRS function and perform self-diagnosis for SRS. Refer to

ªSRS Operation Checkº for details. (RS-36)

IDo not attempt to disassemble side air bag (satellite) sen-

sor.

IReplace side air bag (satellite) sensor if it has been

dropped or sustained an impact.

1. Remove front seat belt pre-tensioner. Refer to ªFront Seat Beltº

for details. (RS-4)

2. Disconnect side air bag (satellite) sensor connector.

3. Remove bolt and nuts from side air bag (satellite) sensor unit.

Then remove the (satellite) sensor.

NOTE:

ITo install, reverse the removal procedure sequence.

YRS077

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-13

Page 1659 of 1767

![NISSAN TERRANO 2002 Service Repair Manual If no malfunction is detected on ªSELF-DIAG [CURRENT]º but mal-

function is indicated by the ªAIR BAGº warning lamp, go to DIAG-

NOSTIC PROCEDURE 4, page RS-42, to diagnose the following

situation NISSAN TERRANO 2002 Service Repair Manual If no malfunction is detected on ªSELF-DIAG [CURRENT]º but mal-

function is indicated by the ªAIR BAGº warning lamp, go to DIAG-

NOSTIC PROCEDURE 4, page RS-42, to diagnose the following

situation](/img/5/57393/w960_57393-1658.png)

If no malfunction is detected on ªSELF-DIAG [CURRENT]º but mal-

function is indicated by the ªAIR BAGº warning lamp, go to DIAG-

NOSTIC PROCEDURE 4, page RS-42, to diagnose the following

situations:

ISelf-diagnostic result ªSELF-DIAG [PAST]º (previously stored

in the memory) might not be erased after repair.

IThe SRS system malfunctions intermittently.

8. Touch ªPRINTº.

9. Compare diagnostic codes to ªCONSULT-II Diagnostic Code

Chartº, page RS-38.

10. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

11. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

12. Repair the system as outlined by the ªRepair orderº in ªCON-

SULT-II Diagnostic Code Chartº, that corresponds to the self-

diagnostic result. For replacement procedure of component

parts, refer to RS-11.

13. After repairing the system, go to DIAGNOSTIC PROCEDURE

3, page RS-40 for final checking.

CONSULT-II DIAGNOSTIC CODE CHART (ªSELF-DIAG

[CURRENT]º)

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp is

user mode.ISelf-diagnostic result ªSELF-DIAG

[PAST]º (previously stored in the

memory) might not be erased after

repair.

IIntermittent malfunction has been

detected in the past.IGo to DIAGNOSTIC PROCEDURE 4

(RS-40) after charging battery.

INo malfunction is detected.IGo to DIAGNOSTIC PROCEDURE 3

(RS-40).

AIRBAG MODULE

[OPEN]IDriver air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace the spiral cable.

4. Replace driver air bag module.

(Before disposal, it must be

deployed.)

5. Replace the diagnosis sensor unit.

6. Replace the related harness. AIRBAG MODULE

[VB-SHORT]IDriver air bag module circuit is shorted to a power supply cir-

cuit. (including the spiral cable)

AIRBAG MODULE

[GND-SHORT]IDriver air bag module circuit is shorted to ground. (including

the spiral cable)

AIRBAG MODULE

[SHORT]IDriver air bag module circuit is shorted between wires.

SRS701

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-38

Page 1661 of 1767

![NISSAN TERRANO 2002 Service Repair Manual Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circ NISSAN TERRANO 2002 Service Repair Manual Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circ](/img/5/57393/w960_57393-1660.png)

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replacement.º

PRE-TEN FRONT RH

[OPEN/VB-SHORT]IThe circuit for front RH seat belt pre-tensioner is open or

shorted to a power supply circuit.1. Visually check the wiring harness

connections.

2. Replace the harness if it has visible

damage.

3. Replace front RH seat belt.

(Before disposal, it must be deacti-

vated.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. PRE-TEN FRONT RH

[GND-SHORT]IThe circuit for front RH seat belt pre-tensioner is shorted to

ground.

INDEFINITE FAIL-

URES (AIR BAG)IA problem which cannot be specified occurs because more

than two parts are out of order.1. Visually check wiring harness con-

nections.

2. Replace diagnosis sensor unit.

3. Replace spiral cable and air bag

modules.

4. Replace air bag and pre-tensioner

harness.

5. Replace main harness.

INDEFINITE FAIL-

URES

(PRE-TENSIONER)Driver's and front passenger seat belt pre-tensioners are out of

order.1. Visually check wiring harness con-

nections.

2. Replace diagnosis sensor unit.

3. Replace spiral cable and air bag

modules.

4. Replace air bag and pre-tensioner

harness.

5. Replace main harness.

CONTROL UNITILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE 3

(RS-40) after charging battery.

IDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace diagnosis sensor unit.

4. Replace the related harness.

* Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is eliminated using the

air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, proceed to the next step. When mal-

function is eliminated, further repair work is not required.

DIAGNOSTIC PROCEDURE 3

Final checking after repairing SRS by using CONSULT-II Ð

Diagnosis mode

1. After repairing SRS, connect both battery cables.

2. Connect CONSULT-II to data link connector.

3. Turn ignition switch from ªOFFº to ªONº.

NRS122

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-40