charging NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1 of 1767

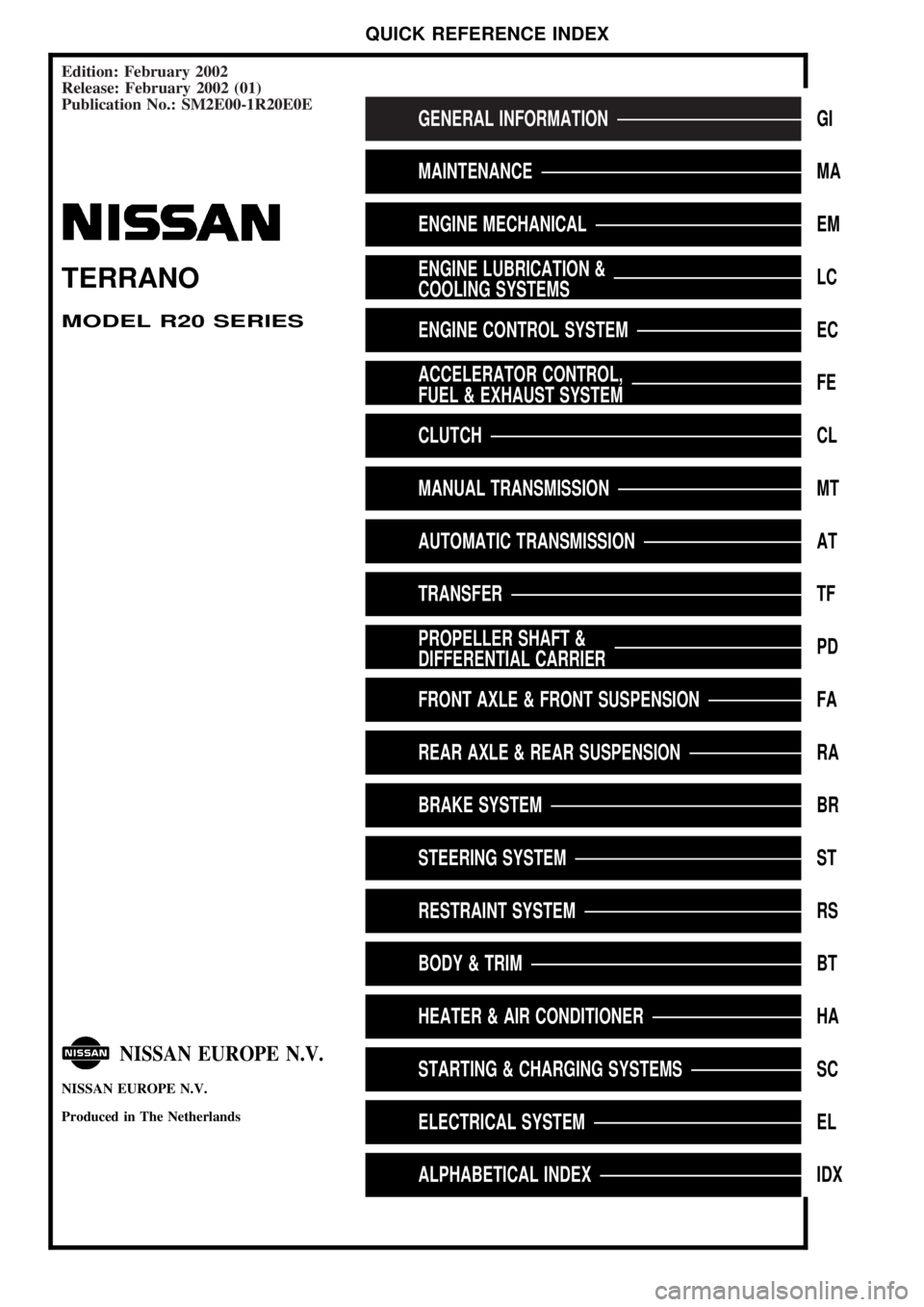

Edition: February 2002

Release: February 2002 (01)

Publication No.: SM2E00-1R20E0E

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE N.V.

NISSAN EUROPE N.V.

Produced in The Netherlands

QUICK REFERENCE INDEX

Page 47 of 1767

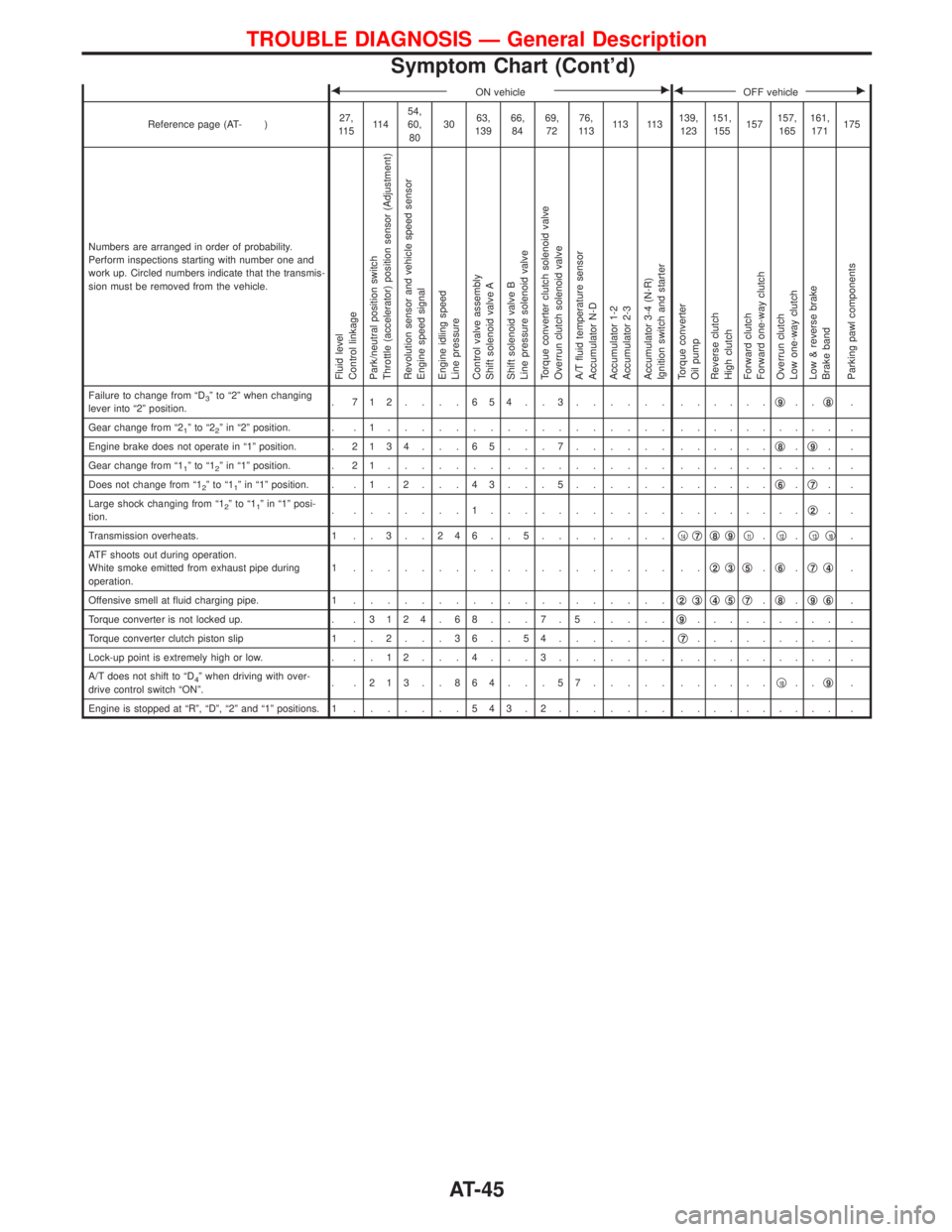

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 3139,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Failure to change from ªD3º to ª2º when changing

lever into ª2º position.. 712....654..3...... ......q9..q8.

Gear change from ª2

1ºtoª22º in ª2º position. . . 1................. .......... .

Engine brake does not operate in ª1º position. .2134 . . . 65 . . . 7...... ......q

8.q9..

Gear change from ª1

1ºtoª12º in ª1º position. . 2 1................. .......... .

Does not change from ª1

2ºtoª11º in ª1º position. . . 1 . 2 . . . 4 3 . . . 5...... ......q6.q7..

Large shock changing from ª1

2ºtoª11º in ª1º posi-

tion.. .......1........... ........q2..

Transmission overheats. 1 . . 3 . . 2 4 6 . . 5........q

14q7q8q9q11.q12.q13q10.

ATF shoots out during operation.

White smoke emitted from exhaust pipe during

operation.1 ................... ..q

2q3q5.q6.q7q4.

Offensive smell at fluid charging pipe. 1...................q

2q3q4q5q7.q8.q9q6.

Torque converter is not locked up. . .3124 . 68 . . . 7 . 5.....q

9......... .

Torque converter clutch piston slip 1 . . 2 . . . 3 6 . . 5 4.......q

7......... .

Lock-up point is extremely high or low. . . . 1 2 . . . 4 . . . 3....... .......... .

A/T does not shift to ªD

4º when driving with over-

drive control switch ªONº.. .213..864...57..... ......q10..q9.

Engine is stopped at ªRº, ªDº, ª2º and ª1º positions. 1.......543.2....... .......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-45

Page 118 of 1767

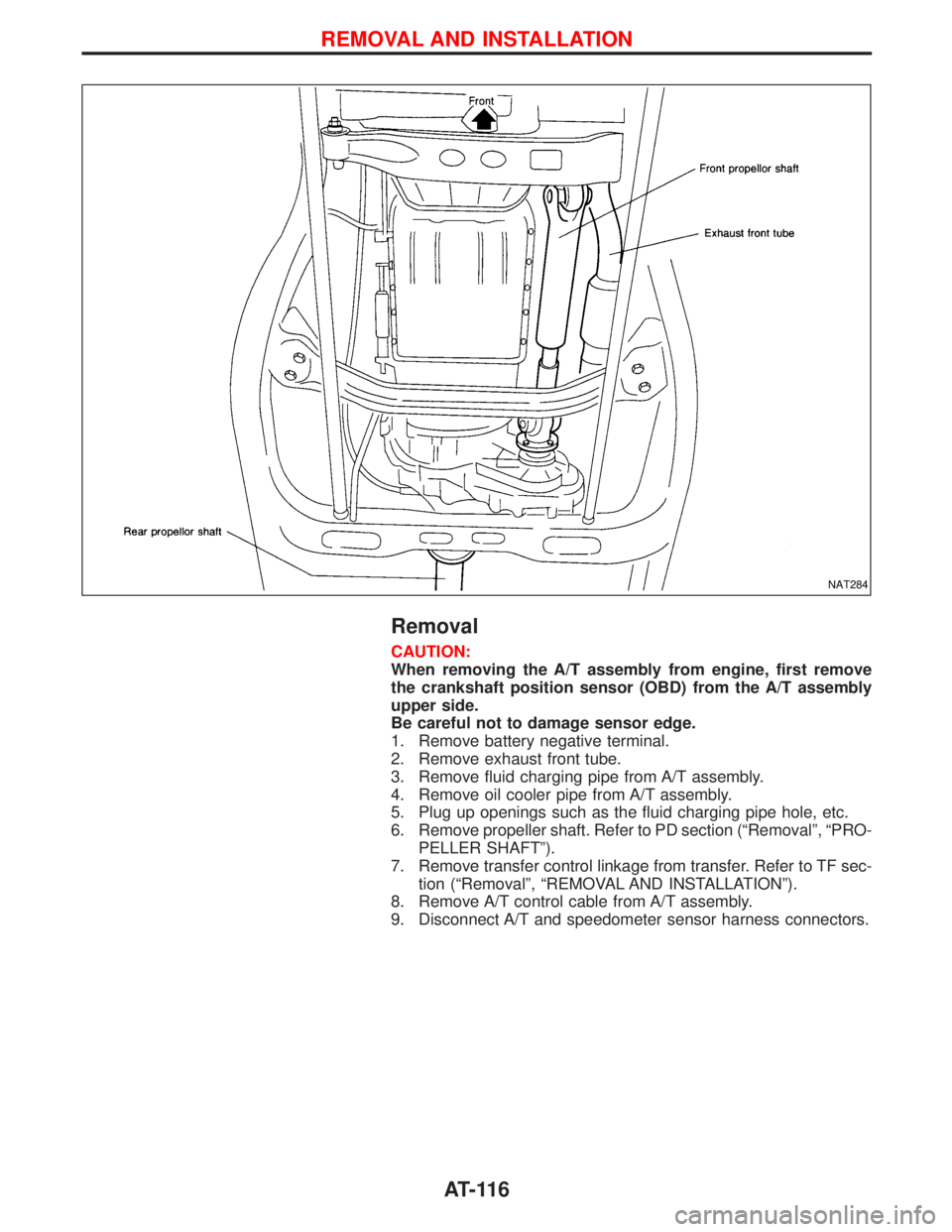

Removal

CAUTION:

When removing the A/T assembly from engine, first remove

the crankshaft position sensor (OBD) from the A/T assembly

upper side.

Be careful not to damage sensor edge.

1. Remove battery negative terminal.

2. Remove exhaust front tube.

3. Remove fluid charging pipe from A/T assembly.

4. Remove oil cooler pipe from A/T assembly.

5. Plug up openings such as the fluid charging pipe hole, etc.

6. Remove propeller shaft. Refer to PD section (ªRemovalº, ªPRO-

PELLER SHAFTº).

7. Remove transfer control linkage from transfer. Refer to TF sec-

tion (ªRemovalº, ªREMOVAL AND INSTALLATIONº).

8. Remove A/T control cable from A/T assembly.

9. Disconnect A/T and speedometer sensor harness connectors.

NAT284

REMOVAL AND INSTALLATION

AT-116

Page 515 of 1767

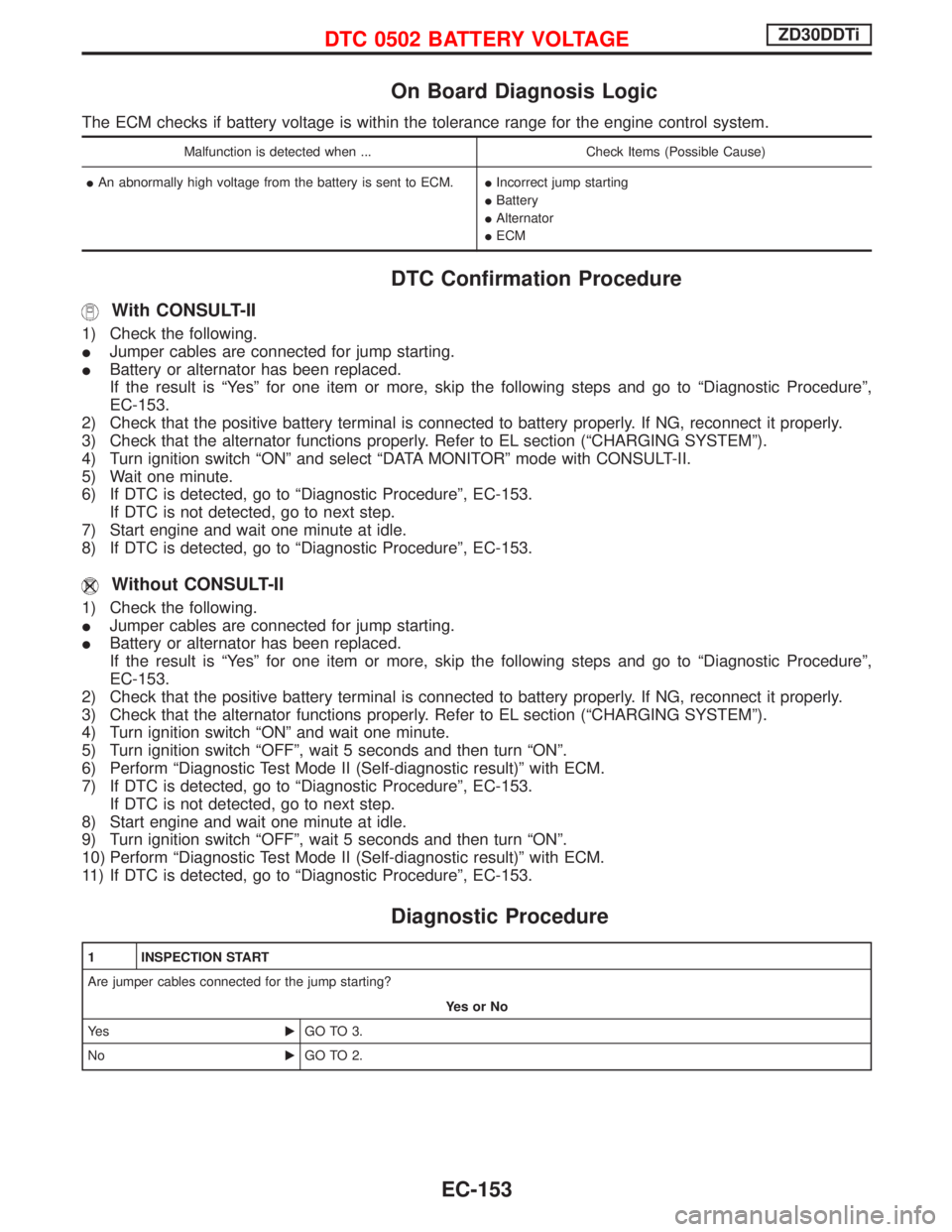

On Board Diagnosis Logic

The ECM checks if battery voltage is within the tolerance range for the engine control system.

Malfunction is detected when ... Check Items (Possible Cause)

IAn abnormally high voltage from the battery is sent to ECM.IIncorrect jump starting

IBattery

IAlternator

IECM

DTC Confirmation Procedure

With CONSULT-II

1) Check the following.

IJumper cables are connected for jump starting.

IBattery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-153.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and select ªDATA MONITORº mode with CONSULT-II.

5) Wait one minute.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-153.

If DTC is not detected, go to next step.

7) Start engine and wait one minute at idle.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-153.

Without CONSULT-II

1) Check the following.

IJumper cables are connected for jump starting.

IBattery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-153.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and wait one minute.

5) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-153.

If DTC is not detected, go to next step.

8) Start engine and wait one minute at idle.

9) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

10) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

11) If DTC is detected, go to ªDiagnostic Procedureº, EC-153.

Diagnostic Procedure

1 INSPECTION START

Are jumper cables connected for the jump starting?

YesorNo

Ye sEGO TO 3.

NoEGO TO 2.

DTC 0502 BATTERY VOLTAGEZD30DDTi

EC-153

Page 516 of 1767

2 CHECK BATTERY AND ALTERNATOR

Check that the proper type of battery and alternator is installed.

Refer to EL section (ªBATTERYº and ªCHARGING SYSTEMº).

OK or NG

OKEGO TO 5.

NGEReplace with a proper one.

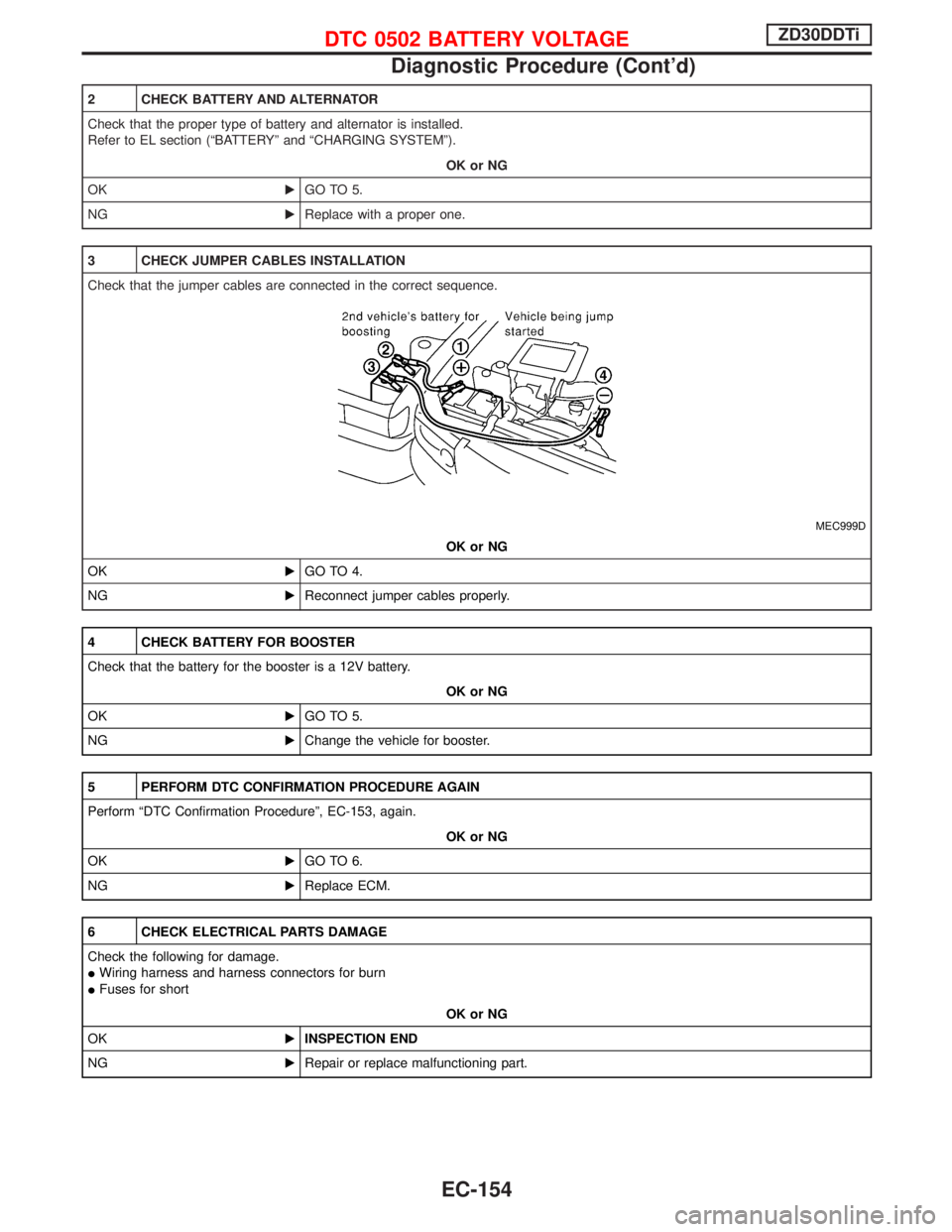

3 CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

MEC999D

OK or NG

OKEGO TO 4.

NGEReconnect jumper cables properly.

4 CHECK BATTERY FOR BOOSTER

Check that the battery for the booster is a 12V battery.

OK or NG

OKEGO TO 5.

NGEChange the vehicle for booster.

5 PERFORM DTC CONFIRMATION PROCEDURE AGAIN

Perform ªDTC Confirmation Procedureº, EC-153, again.

OK or NG

OKEGO TO 6.

NGEReplace ECM.

6 CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

IWiring harness and harness connectors for burn

IFuses for short

OK or NG

OKEINSPECTION END

NGERepair or replace malfunctioning part.

DTC 0502 BATTERY VOLTAGEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-154

Page 1107 of 1767

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST. SIGNAL

2NDSIG AT A/T 2ND. SIGNAL

3RDSIG AT A/T 3RD. SIGNAL

4THSIG AT A/T 4TH. SIGNAL

A/C, M HA MANUAL AIR CONDITIONER

A/CCUT EC AIR CONDITIONER CUT CONTROL

ABS BR ANTI-LOCK BRAKE SYSTEM

ACC/SW EC ACCELERATOR SWITCH (FC)

ACL/SW ECACCELERATOR POSITION

SWITCH

APS AT, ECACCELERATOR POSITION SEN-

SOR

AT/C EC A/T CONTROL

AUDIO EL AUDIO

BA/FTS ATA/T FLUID TEMPERATURE SEN-

SOR AND TCM POWER SUPPLY

BACK/L EL BACK-UP LAMP

BOOST ECTURBOCHARGER BOOST SEN-

SOR

BRK/SW EC BRAKE SWITCH

CHARGE SC CHARGING SYSTEM

CHIME EL WARNING CHIME

CIGAR EL CIGARETTE LIGHTER

CKPS ECCRANK SHAFT POSITION SEN-

SOR (OBD)

CLOCK EL CLOCK

COOL/F EC COOLING FAN CONTROL

D/LOCK EL POWER DOOR LOCK

DEF EL REAR WINDOW DEFOGGER

DTRL ELHEADLAMP Ð WITH DAYTIME

LIGHT SYSTEM

ECMRLY EC ECM RELAY

ECTS ECENGINE COOLANT TEMPERA-

TURE SENSOR

EGRC/V ECEGR VALVE AND EVAP CANISTER

PURGE CONTROL SOLENOID

VA LV E

EGVC/V EC EGR VOLUME CONTROL VALVE

ENGSS AT ENGINE SPEED SIGNAL

F/FOG EL FRONT FOG LAMP

Code Section Wiring Diagram Name

FTS ATA/T FLUID TEMPERATURE SEN-

SOR

GLOW EC QUICK GLOW SYSTEM

H/AIM ELHEADLAMP AIMING CONTROL

SYSTEM

H/LAMP EL HEADLAMP

HEATER HA HEATER SYSTEM

HEATUP EC HEAT UP SWITCH

HLC EL HEADLAMP CLEANER

HORN EL HORN

HSEAT EL HEATED SEAT

ILL EL ILLUMINATION

INJPMP ECELECTRONIC CONTROL FUEL

INJECTION PUMP

INT/L EL INTERIOR AND MAP LAMPS

INT/V ECINTAKE AIR CONTROL VALVE

CONTROL SOLENOID VALVE

LPSV ATLINE PRESSURE SOLENOID

VA LV E

MAFS EC MASS AIR FLOW SENSOR

MAIN ATMAIN POWER SUPPLY AND

GROUND CIRCUIT

MAIN ECMAIN POWER SUPPLY AND

GROUND CIRCUIT

METER ELSPEEDOMETER, TACHOMETER,

TEMP. AND FUEL GAUGES

MIL/DL ECMIL AND DATA LINK CONNEC-

TORS

MIRROR EL DOOR MIRROR

MULTI ELREMOTE KEYLESS ENTRY SYS-

TEM

NATS EL NISSAN ANTI-THEFT SYSTEM

NLS EC NEEDLE LIFT SENSOR

NONDTC AT NON-DETECTABLE ITEMS

OILPSW EC OIL PRESSURE SWITCH

OVRCSV ATOVER RUN CLUTCH SOLENOID

VA LV E

PNP/SW ATPARK/NEUTRAL POSITION

SWITCH

PNP/SW EC NEUTRAL POSITION SWITCH

R/FOG EL REAR FOG LAMP

REMOTE ELAUDIO (REMOTE CONTROL

SWITCH)

S/LOCK ELPOWER DOOR LOCK-SUPER

LOCK

S/SIG EC START SIGNAL

WIRING DIAGRAM CODES (CELL CODES)

EL-291

Page 1357 of 1767

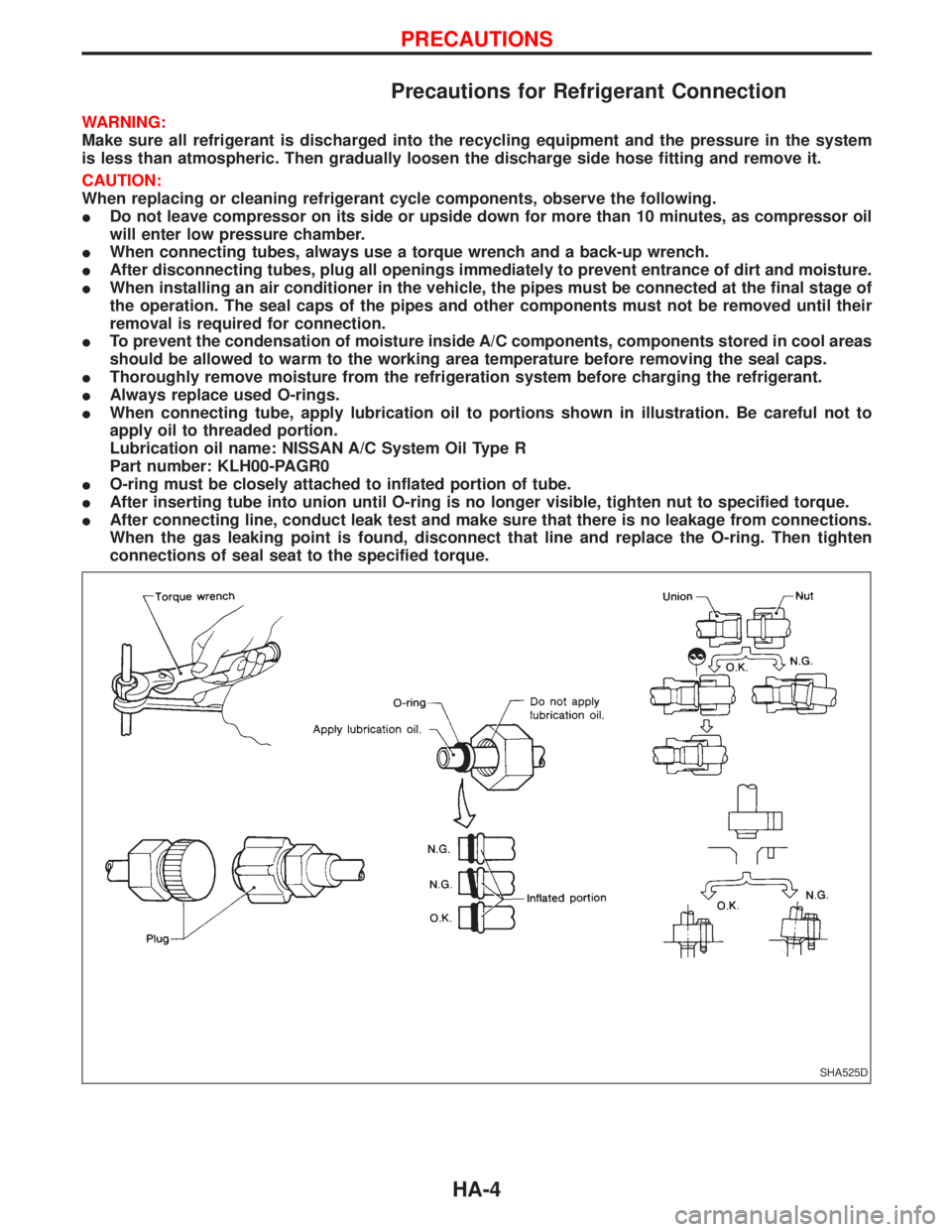

Precautions for Refrigerant Connection

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system

is less than atmospheric. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IDo not leave compressor on its side or upside down for more than 10 minutes, as compressor oil

will enter low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, plug all openings immediately to prevent entrance of dirt and moisture.

IWhen installing an air conditioner in the vehicle, the pipes must be connected at the final stage of

the operation. The seal caps of the pipes and other components must not be removed until their

removal is required for connection.

ITo prevent the condensation of moisture inside A/C components, components stored in cool areas

should be allowed to warm to the working area temperature before removing the seal caps.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

IAlways replace used O-rings.

IWhen connecting tube, apply lubrication oil to portions shown in illustration. Be careful not to

apply oil to threaded portion.

Lubrication oil name: NISSAN A/C System Oil Type R

Part number: KLH00-PAGR0

IO-ring must be closely attached to inflated portion of tube.

IAfter inserting tube into union until O-ring is no longer visible, tighten nut to specified torque.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

SHA525D

PRECAUTIONS

HA-4

Page 1364 of 1767

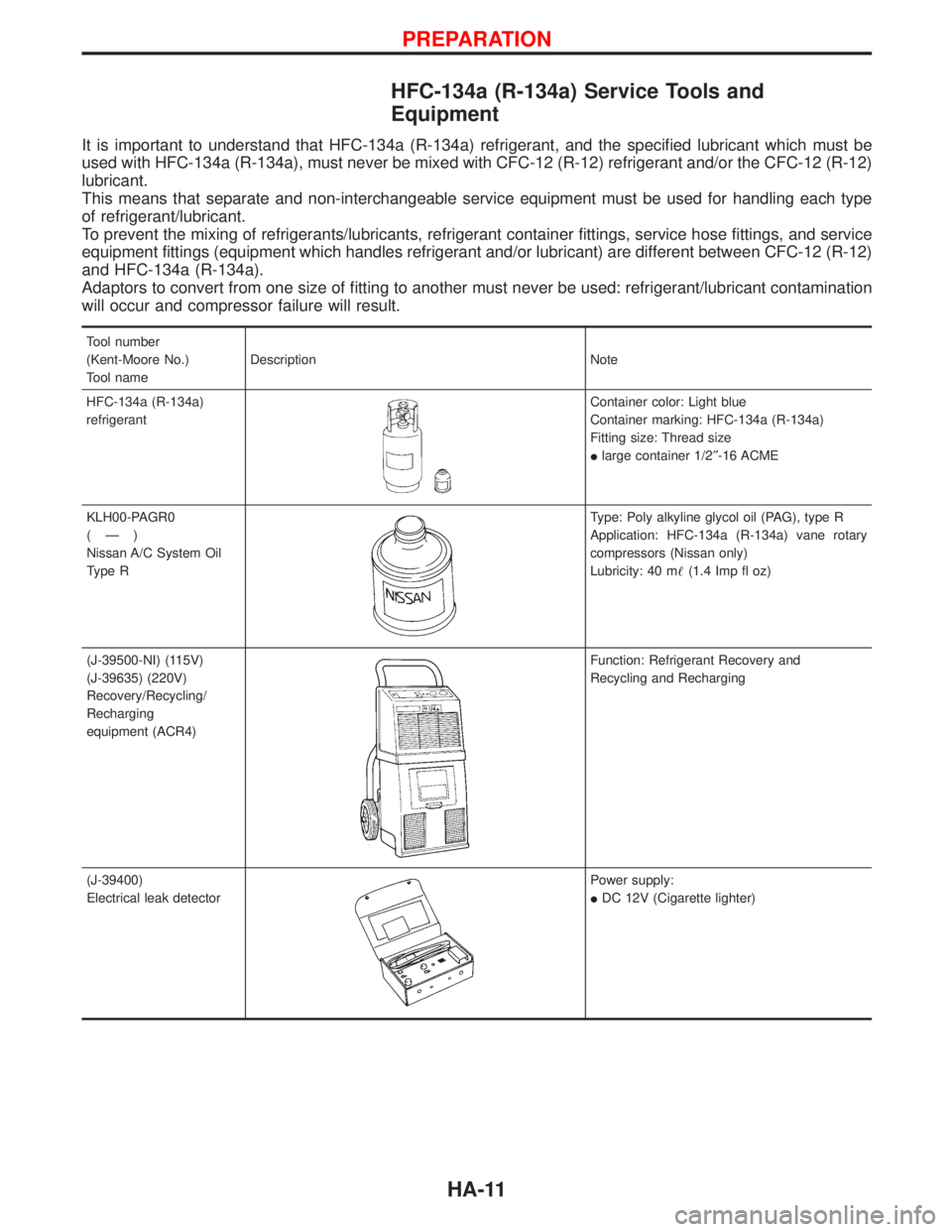

HFC-134a (R-134a) Service Tools and

Equipment

It is important to understand that HFC-134a (R-134a) refrigerant, and the specified lubricant which must be

used with HFC-134a (R-134a), must never be mixed with CFC-12 (R-12) refrigerant and/or the CFC-12 (R-12)

lubricant.

This means that separate and non-interchangeable service equipment must be used for handling each type

of refrigerant/lubricant.

To prevent the mixing of refrigerants/lubricants, refrigerant container fittings, service hose fittings, and service

equipment fittings (equipment which handles refrigerant and/or lubricant) are different between CFC-12 (R-12)

and HFC-134a (R-134a).

Adaptors to convert from one size of fitting to another must never be used: refrigerant/lubricant contamination

will occur and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool nameDescription Note

HFC-134a (R-134a)

refrigerant

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

Ilarge container 1/2²-16 ACME

KLH00-PAGR0

(Ð)

Nissan A/C System Oil

Type R

Type: Poly alkyline glycol oil (PAG), type R

Application: HFC-134a (R-134a) vane rotary

compressors (Nissan only)

Lubricity: 40 m(1.4 Imp fl oz)

(J-39500-NI) (115V)

(J-39635) (220V)

Recovery/Recycling/

Recharging

equipment (ACR4)

Function: Refrigerant Recovery and

Recycling and Recharging

(J-39400)

Electrical leak detector

Power supply:

IDC 12V (Cigarette lighter)

PREPARATION

HA-11

Page 1366 of 1767

Precautions for Service Equipment

RECOVERY/RECYCLING/RECHARGING EQUIPMENT

Be certain to follow the manufacturers instructions for machine

operation and machine maintenance. Never introduce any refriger-

ant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufactures instructions for tester opera-

tion and tester maintenance.

VACUUM PUMP

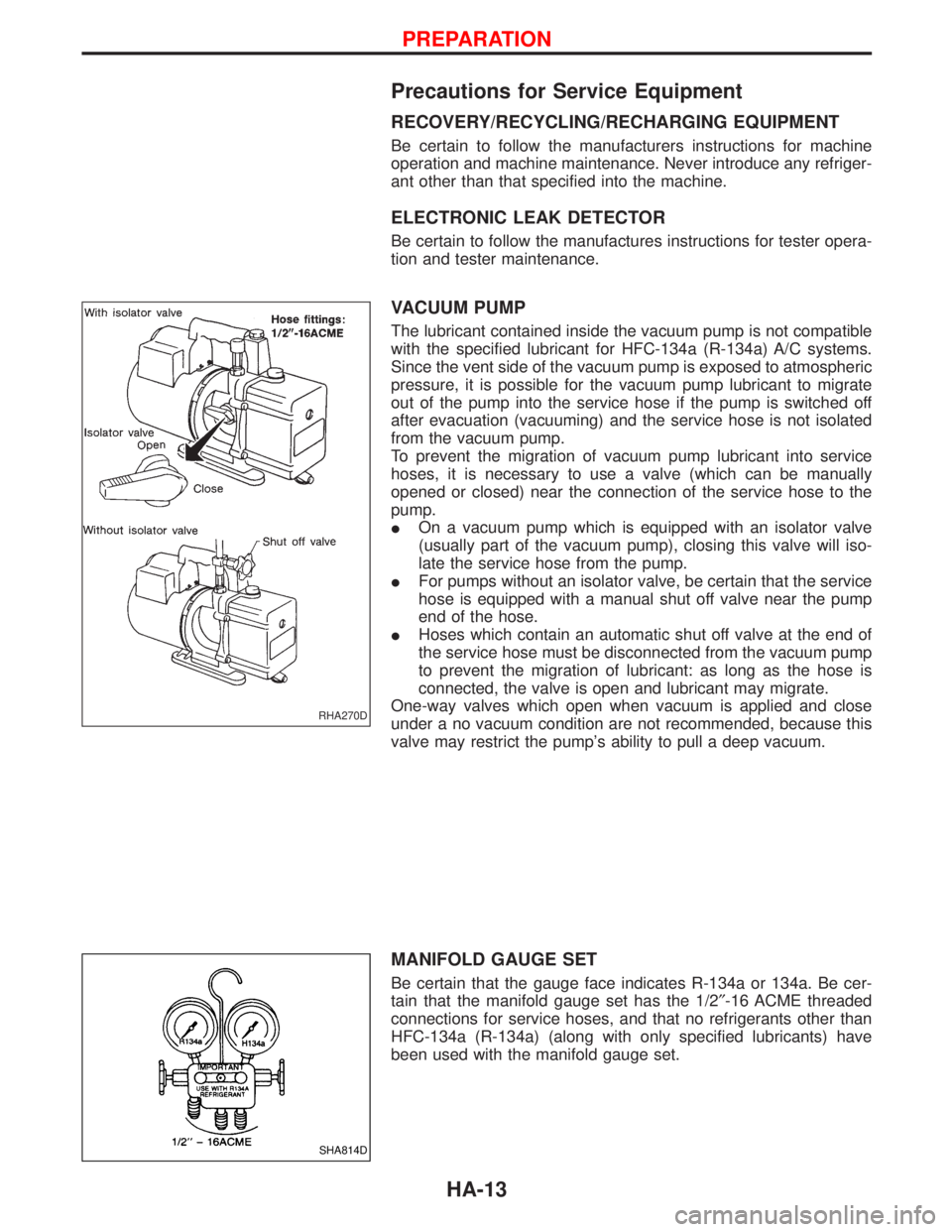

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

Since the vent side of the vacuum pump is exposed to atmospheric

pressure, it is possible for the vacuum pump lubricant to migrate

out of the pump into the service hose if the pump is switched off

after evacuation (vacuuming) and the service hose is not isolated

from the vacuum pump.

To prevent the migration of vacuum pump lubricant into service

hoses, it is necessary to use a valve (which can be manually

opened or closed) near the connection of the service hose to the

pump.

IOn a vacuum pump which is equipped with an isolator valve

(usually part of the vacuum pump), closing this valve will iso-

late the service hose from the pump.

IFor pumps without an isolator valve, be certain that the service

hose is equipped with a manual shut off valve near the pump

end of the hose.

IHoses which contain an automatic shut off valve at the end of

the service hose must be disconnected from the vacuum pump

to prevent the migration of lubricant: as long as the hose is

connected, the valve is open and lubricant may migrate.

One-way valves which open when vacuum is applied and close

under a no vacuum condition are not recommended, because this

valve may restrict the pump's ability to pull a deep vacuum.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Be cer-

tain that the manifold gauge set has the 1/2²-16 ACME threaded

connections for service hoses, and that no refrigerants other than

HFC-134a (R-134a) (along with only specified lubricants) have

been used with the manifold gauge set.

RHA270D

SHA814D

PREPARATION

HA-13

Page 1367 of 1767

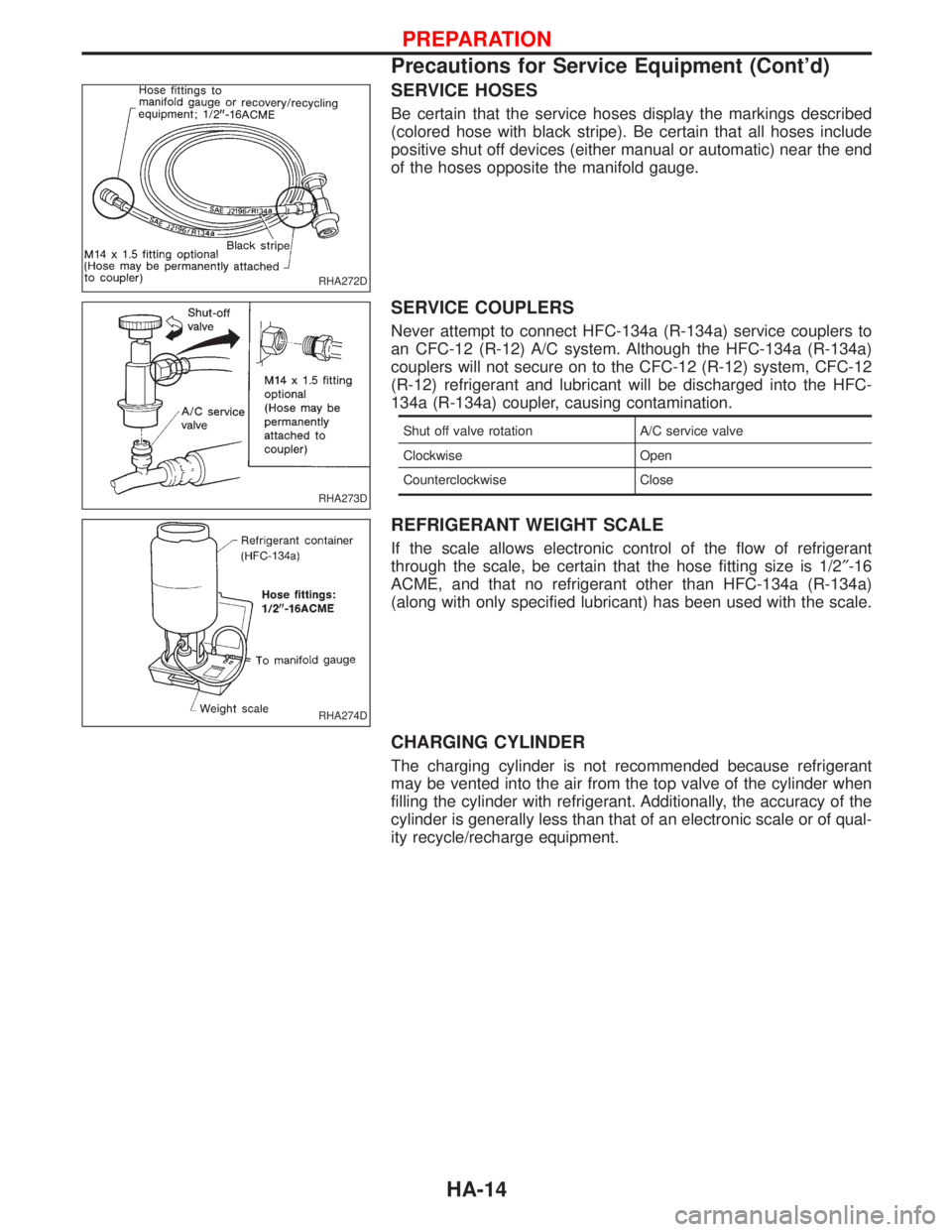

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). Be certain that all hoses include

positive shut off devices (either manual or automatic) near the end

of the hoses opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to

an CFC-12 (R-12) A/C system. Although the HFC-134a (R-134a)

couplers will not secure on to the CFC-12 (R-12) system, CFC-12

(R-12) refrigerant and lubricant will be discharged into the HFC-

134a (R-134a) coupler, causing contamination.

Shut off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

If the scale allows electronic control of the flow of refrigerant

through the scale, be certain that the hose fitting size is 1/2²-16

ACME, and that no refrigerant other than HFC-134a (R-134a)

(along with only specified lubricant) has been used with the scale.

CHARGING CYLINDER

The charging cylinder is not recommended because refrigerant

may be vented into the air from the top valve of the cylinder when

filling the cylinder with refrigerant. Additionally, the accuracy of the

cylinder is generally less than that of an electronic scale or of qual-

ity recycle/recharge equipment.

RHA272D

RHA273D

RHA274D

PREPARATION

Precautions for Service Equipment (Cont'd)

HA-14