wheel torque NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 6 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL R20 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

IPlace disassembled parts in order for easier and proper assembly.

IAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

IGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

IIt is very important to perform functional tests whenever they are indicated.

IThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

IExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

PREPARATION AND PRECAUTIONS

AT- 4

Page 205 of 1767

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

ITo clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

INever use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

IUse flare nut wrench when removing and installing brake

tubes.

IAlways torque brake lines when installing.

IBurnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

IClean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

IAvoid prolonged and repeated skin contact with brake

fluid.

IWear protective clothing, including impervious gloves.

IWhere there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

Page 206 of 1767

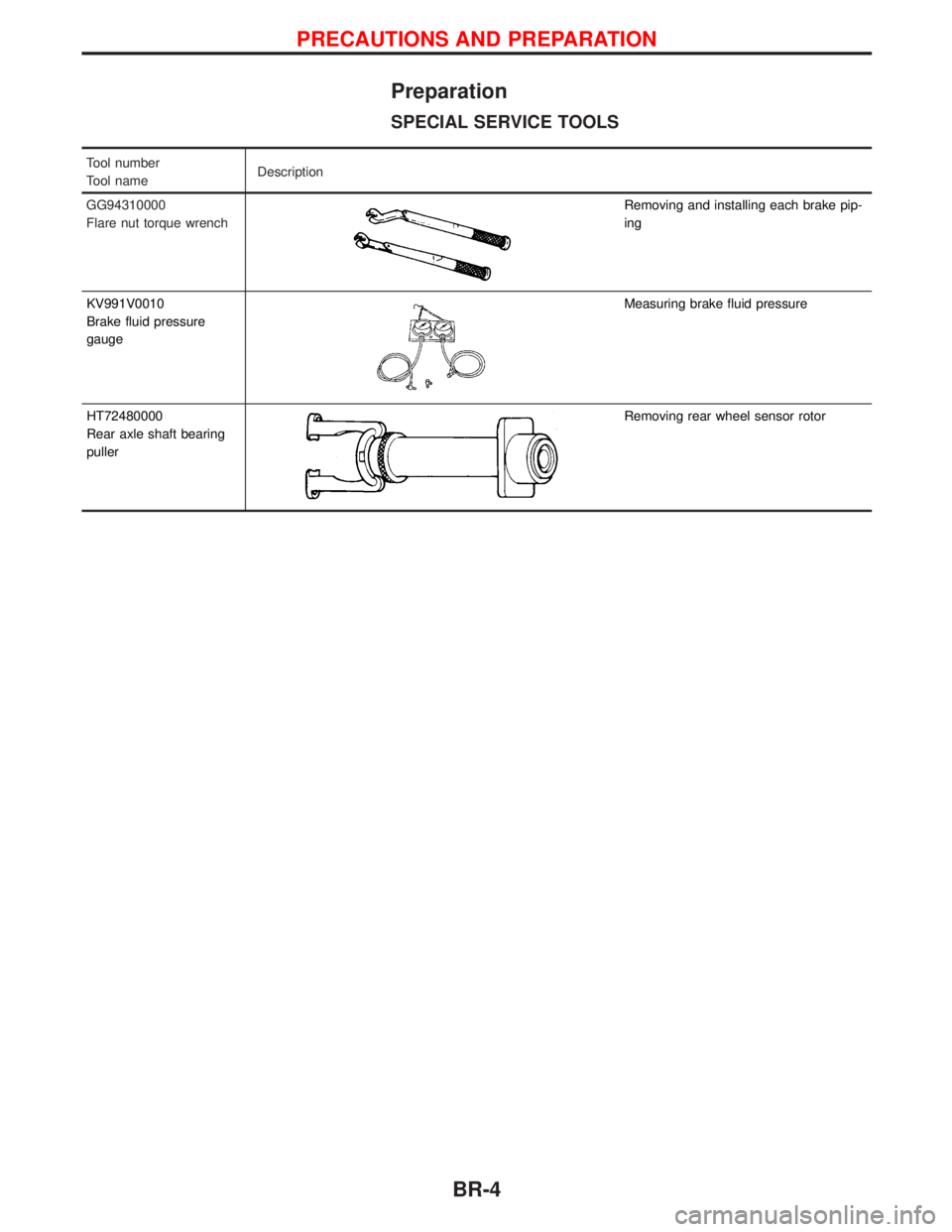

Preparation

SPECIAL SERVICE TOOLS

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

Removing and installing each brake pip-

ing

KV991V0010

Brake fluid pressure

gauge

Measuring brake fluid pressure

HT72480000

Rear axle shaft bearing

puller

Removing rear wheel sensor rotor

PRECAUTIONS AND PREPARATION

BR-4

Page 229 of 1767

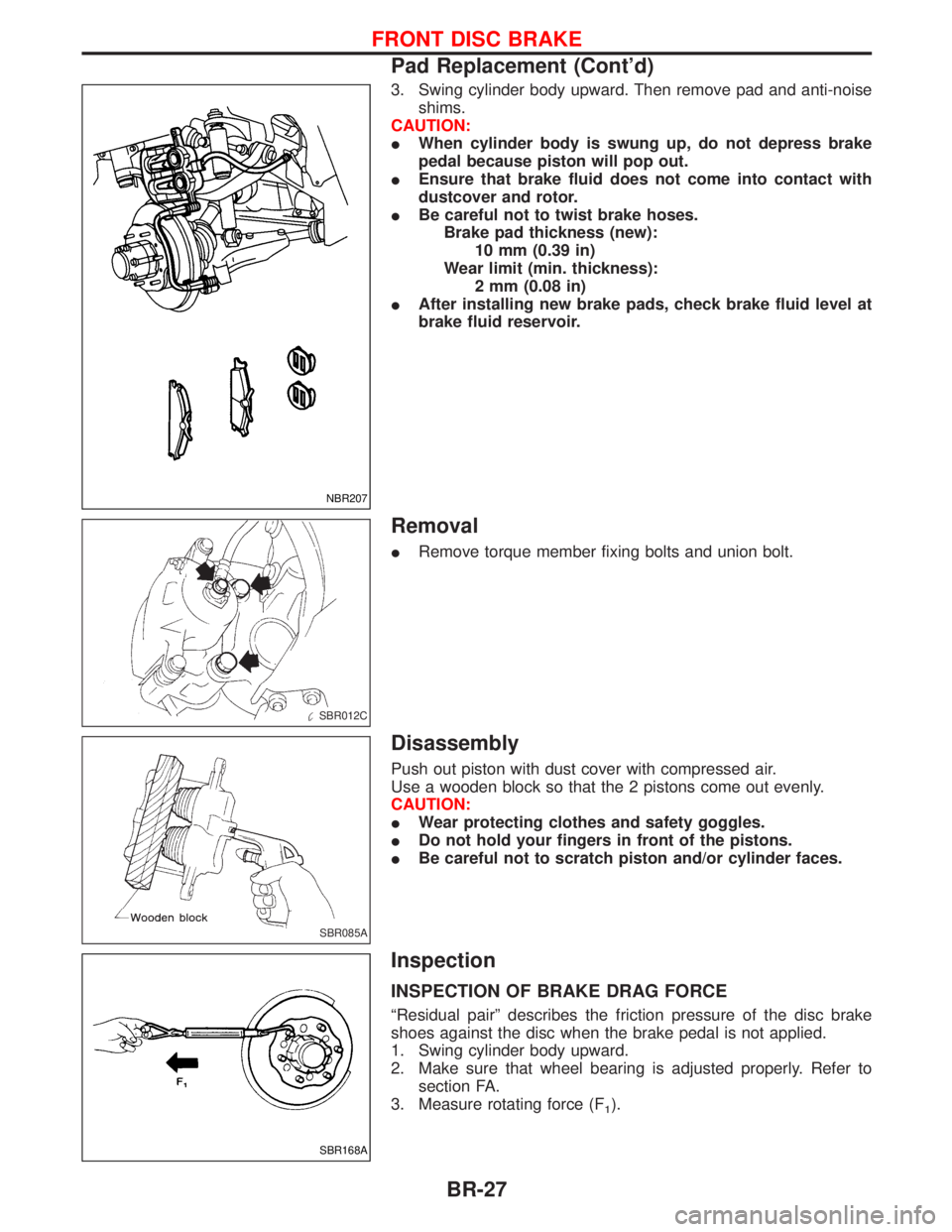

3. Swing cylinder body upward. Then remove pad and anti-noise

shims.

CAUTION:

IWhen cylinder body is swung up, do not depress brake

pedal because piston will pop out.

IEnsure that brake fluid does not come into contact with

dustcover and rotor.

IBe careful not to twist brake hoses.

Brake pad thickness (new):

10 mm (0.39 in)

Wear limit (min. thickness):

2 mm (0.08 in)

IAfter installing new brake pads, check brake fluid level at

brake fluid reservoir.

Removal

IRemove torque member fixing bolts and union bolt.

Disassembly

Push out piston with dust cover with compressed air.

Use a wooden block so that the 2 pistons come out evenly.

CAUTION:

IWear protecting clothes and safety goggles.

IDo not hold your fingers in front of the pistons.

IBe careful not to scratch piston and/or cylinder faces.

Inspection

INSPECTION OF BRAKE DRAG FORCE

ªResidual pairº describes the friction pressure of the disc brake

shoes against the disc when the brake pedal is not applied.

1. Swing cylinder body upward.

2. Make sure that wheel bearing is adjusted properly. Refer to

section FA.

3. Measure rotating force (F

1).

NBR207

SBR012C

SBR085A

SBR168A

FRONT DISC BRAKE

Pad Replacement (Cont'd)

BR-27

Page 1261 of 1767

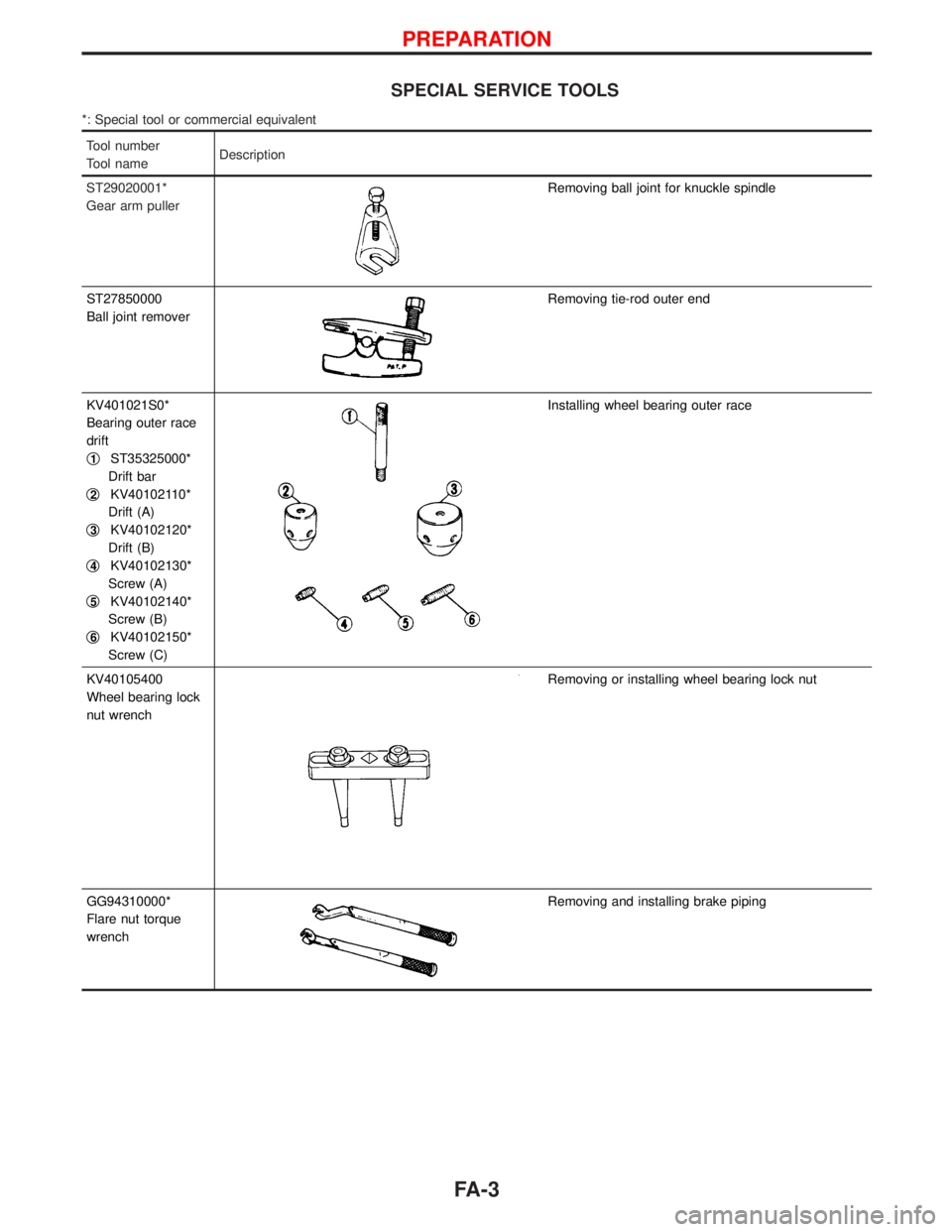

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST29020001*

Gear arm puller

Removing ball joint for knuckle spindle

ST27850000

Ball joint remover

Removing tie-rod outer end

KV401021S0*

Bearing outer race

drift

q

1ST35325000*

Drift bar

q

2KV40102110*

Drift (A)

q

3KV40102120*

Drift (B)

q

4KV40102130*

Screw (A)

q

5KV40102140*

Screw (B)

q

6KV40102150*

Screw (C)

Installing wheel bearing outer race

KV40105400

Wheel bearing lock

nut wrench

Removing or installing wheel bearing lock nut

GG94310000*

Flare nut torque

wrench

Removing and installing brake piping

PREPARATION

FA-3

Page 1263 of 1767

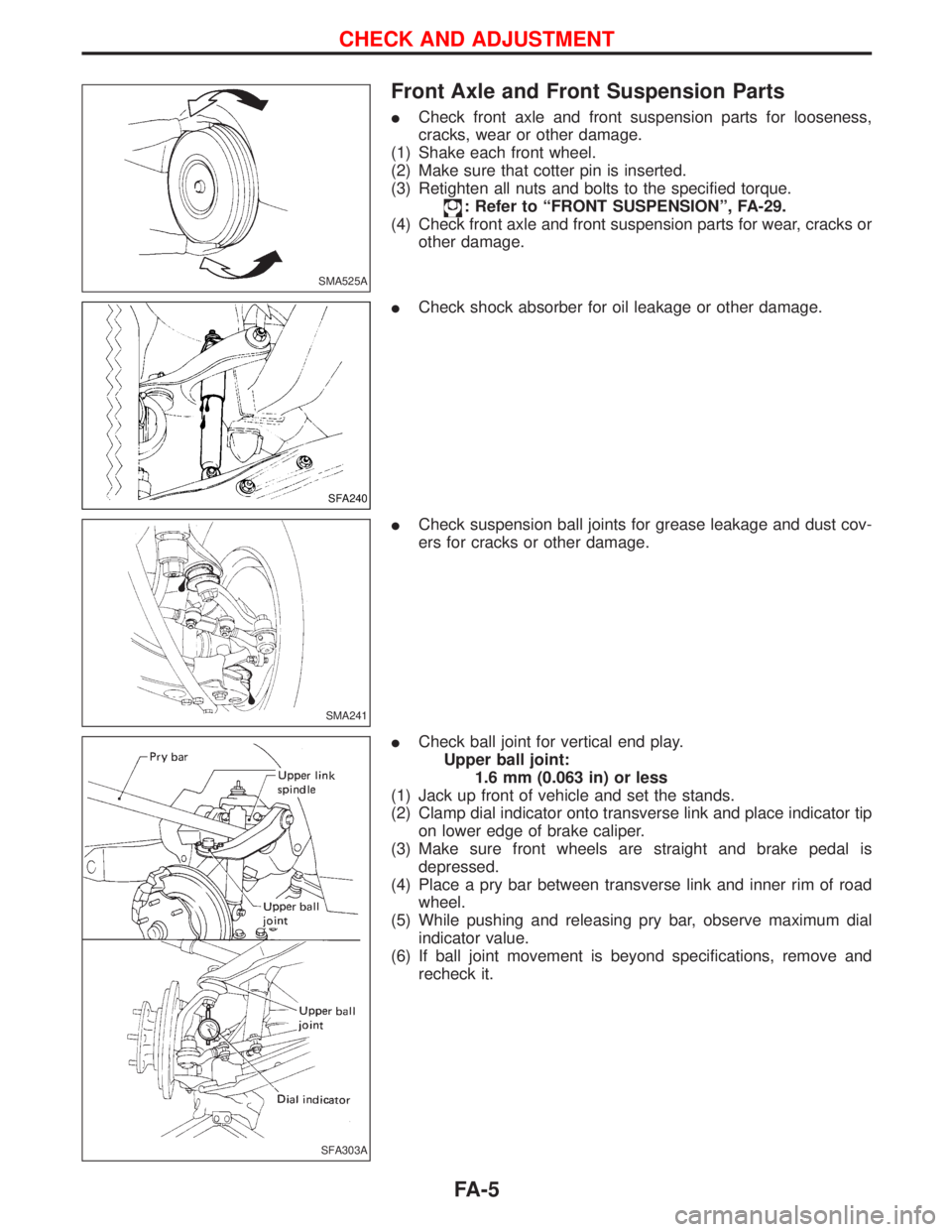

Front Axle and Front Suspension Parts

ICheck front axle and front suspension parts for looseness,

cracks, wear or other damage.

(1) Shake each front wheel.

(2) Make sure that cotter pin is inserted.

(3) Retighten all nuts and bolts to the specified torque.

: Refer to ªFRONT SUSPENSIONº, FA-29.

(4) Check front axle and front suspension parts for wear, cracks or

other damage.

ICheck shock absorber for oil leakage or other damage.

ICheck suspension ball joints for grease leakage and dust cov-

ers for cracks or other damage.

ICheck ball joint for vertical end play.

Upper ball joint:

1.6 mm (0.063 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

(3) Make sure front wheels are straight and brake pedal is

depressed.

(4) Place a pry bar between transverse link and inner rim of road

wheel.

(5) While pushing and releasing pry bar, observe maximum dial

indicator value.

(6) If ball joint movement is beyond specifications, remove and

recheck it.

SMA525A

SFA240

SMA241

SFA303A

CHECK AND ADJUSTMENT

FA-5

Page 1265 of 1767

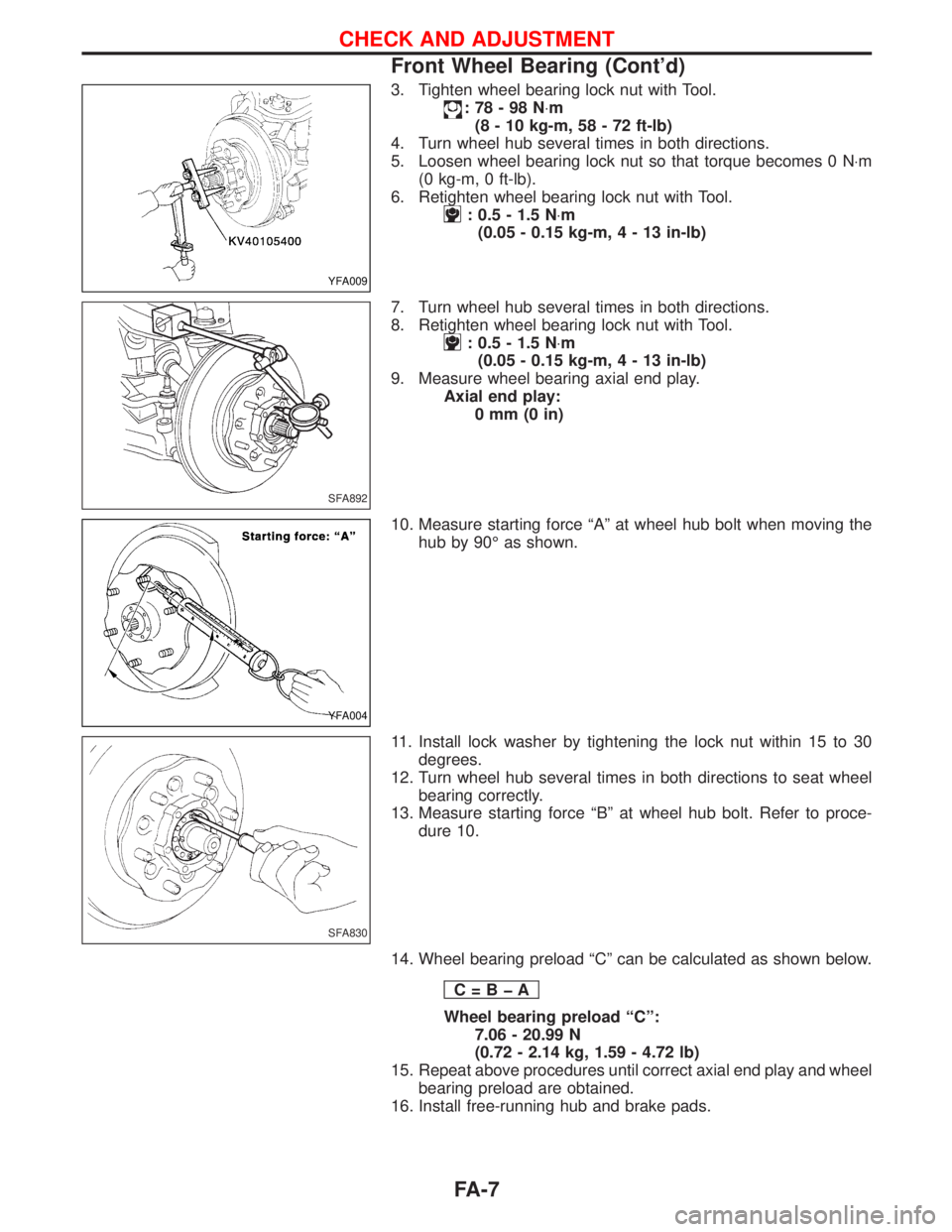

3. Tighten wheel bearing lock nut with Tool.

:78-98N×m

(8 - 10 kg-m, 58 - 72 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes 0 N×m

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

9. Measure wheel bearing axial end play.

Axial end play:

0mm(0in)

10. Measure starting force ªAº at wheel hub bolt when moving the

hub by 90É as shown.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N

(0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat above procedures until correct axial end play and wheel

bearing preload are obtained.

16. Install free-running hub and brake pads.

YFA009

SFA892

YFA004

SFA830

CHECK AND ADJUSTMENT

Front Wheel Bearing (Cont'd)

FA-7

Page 1269 of 1767

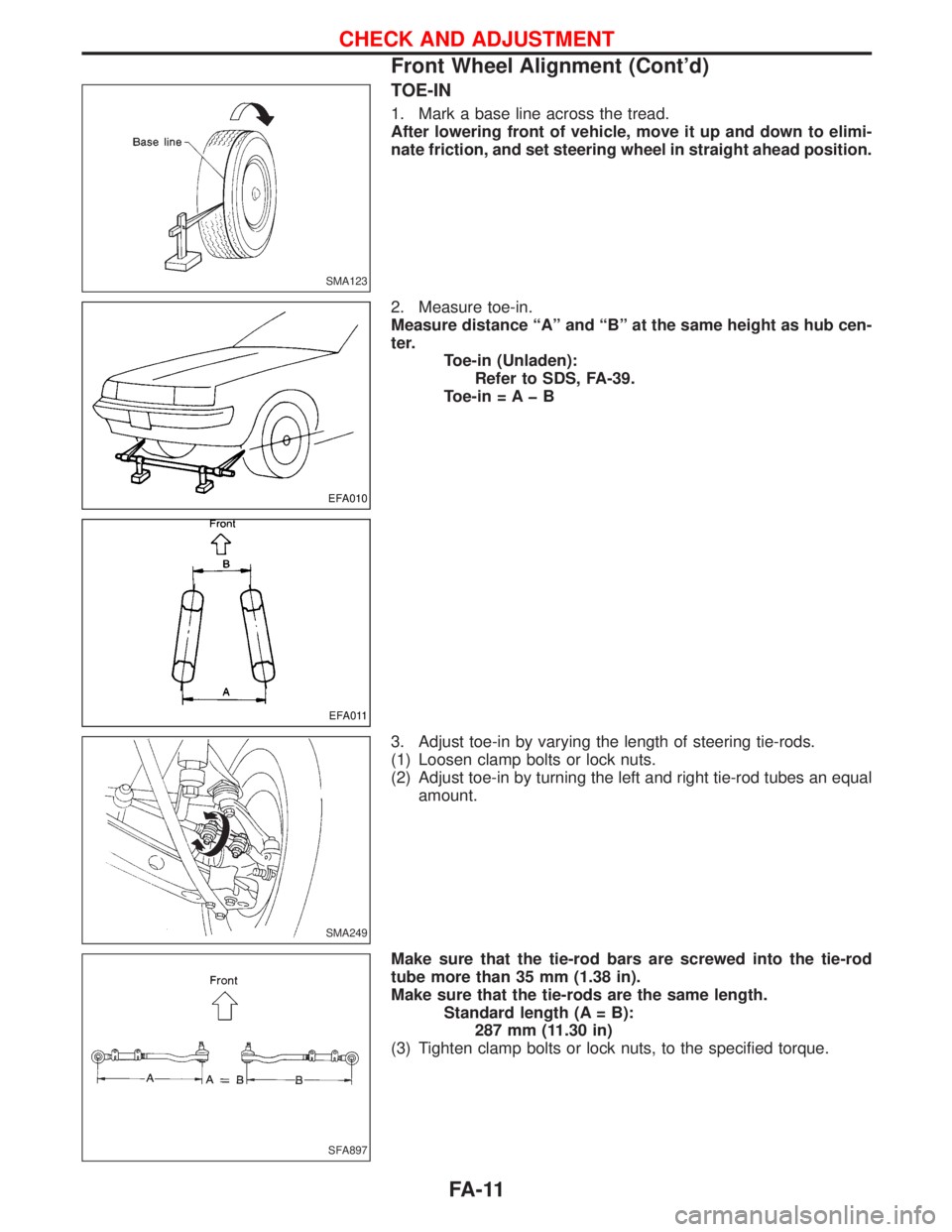

TOE-IN

1. Mark a base line across the tread.

After lowering front of vehicle, move it up and down to elimi-

nate friction, and set steering wheel in straight ahead position.

2. Measure toe-in.

Measure distance ªAº and ªBº at the same height as hub cen-

ter.

Toe-in (Unladen):

Refer to SDS, FA-39.

Toe-in = A þ B

3. Adjust toe-in by varying the length of steering tie-rods.

(1) Loosen clamp bolts or lock nuts.

(2) Adjust toe-in by turning the left and right tie-rod tubes an equal

amount.

Make sure that the tie-rod bars are screwed into the tie-rod

tube more than 35 mm (1.38 in).

Make sure that the tie-rods are the same length.

Standard length (A = B):

287 mm (11.30 in)

(3) Tighten clamp bolts or lock nuts, to the specified torque.

SMA123

EFA010

EFA011

SMA249

SFA897

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-11

Page 1297 of 1767

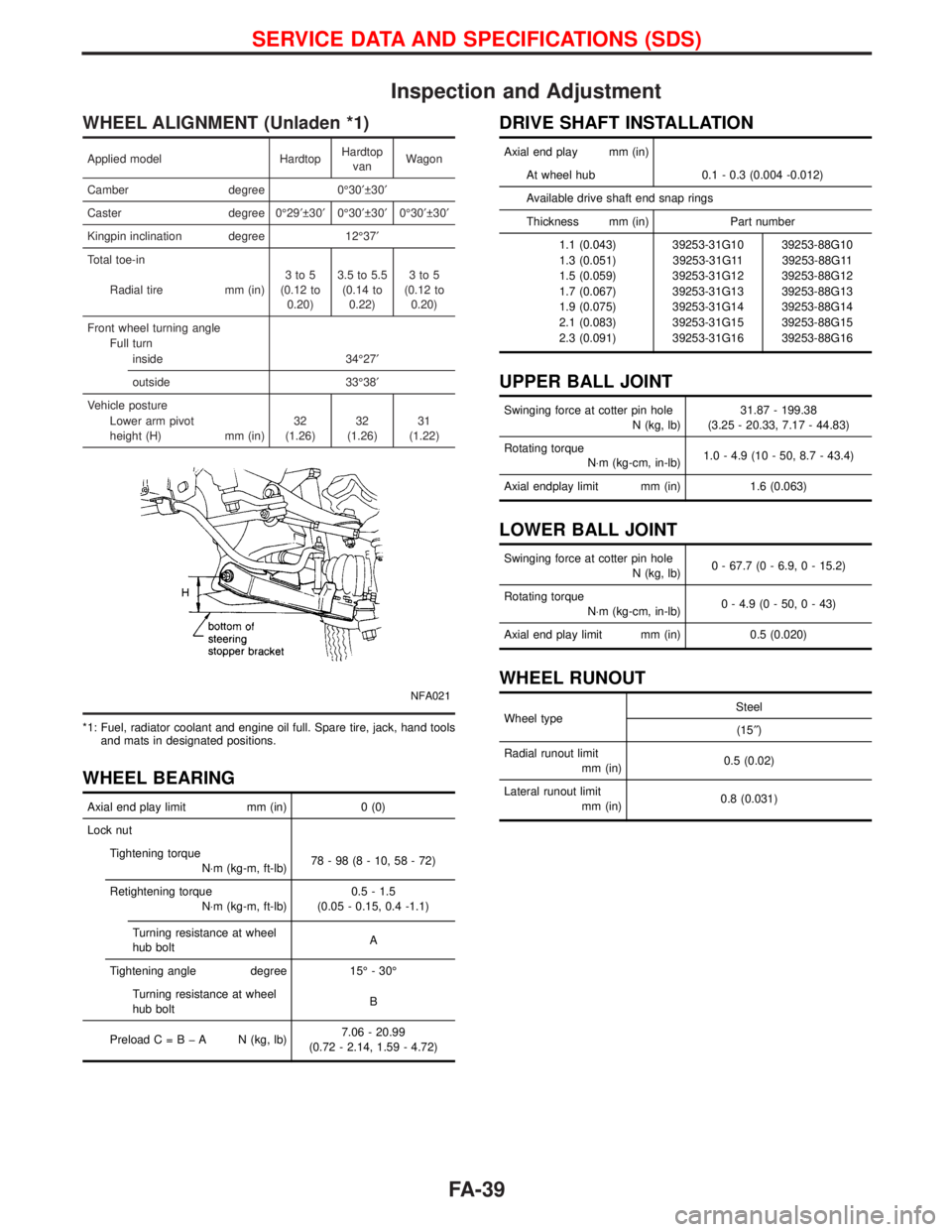

Inspection and Adjustment

WHEEL ALIGNMENT (Unladen *1)

Applied model HardtopHardtop

vanWagon

Camber degree 0É30¢ 30¢

Caster degree 0É29¢ 30¢0É30¢ 30¢0É30¢ 30¢

Kingpin inclination degree 12É37¢

Total toe-in

Radial tire mm (in)3to5

(0.12 to

0.20)3.5 to 5.5

(0.14 to

0.22)3to5

(0.12 to

0.20)

Front wheel turning angle

Full turn

inside 34É27¢

outside 33É38¢

Vehicle posture

Lower arm pivot

height (H) mm (in)32

(1.26)32

(1.26)31

(1.22)

NFA021

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools

and mats in designated positions.

WHEEL BEARING

Axial end play limit mm (in) 0 (0)

Lock nut

Tightening torque

N×m (kg-m, ft-lb)78-98(8-10,58-72)

Retightening torque

N×m (kg-m, ft-lb)0.5 - 1.5

(0.05 - 0.15, 0.4 -1.1)

Turning resistance at wheel

hub boltA

Tightening angle degree 15É - 30É

Turning resistance at wheel

hub boltB

PreloadC=BþA N(kg, lb)7.06 - 20.99

(0.72 - 2.14, 1.59 - 4.72)

DRIVE SHAFT INSTALLATION

Axial end play mm (in)

At wheel hub 0.1 - 0.3 (0.004 -0.012)

Available drive shaft end snap rings

Thickness mm (in) Part number

1.1 (0.043) 39253-31G10 39253-88G10

1.3 (0.051) 39253-31G11 39253-88G11

1.5 (0.059) 39253-31G12 39253-88G12

1.7 (0.067) 39253-31G13 39253-88G13

1.9 (0.075) 39253-31G14 39253-88G14

2.1 (0.083) 39253-31G15 39253-88G15

2.3 (0.091) 39253-31G16 39253-88G16

UPPER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)31.87 - 199.38

(3.25 - 20.33, 7.17 - 44.83)

Rotating torque

N×m (kg-cm, in-lb)1.0 - 4.9 (10 - 50, 8.7 - 43.4)

Axial endplay limit mm (in) 1.6 (0.063)

LOWER BALL JOINT

Swinging force at cotter pin hole

N (kg, lb)0 - 67.7 (0 - 6.9, 0 - 15.2)

Rotating torque

N×m (kg-cm, in-lb)0 - 4.9 (0 - 50, 0 - 43)

Axial end play limit mm (in) 0.5 (0.020)

WHEEL RUNOUT

Wheel typeSteel

(15²)

Radial runout limit

mm (in)0.5 (0.02)

Lateral runout limit

mm (in)0.8 (0.031)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-39

Page 1316 of 1767

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL........................................8

HOW TO READ WIRING DIAGRAMS..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL.......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT........................................22Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES..................................................................25

CONSULT-II CHECKING SYSTEM...............................26

General ......................................................................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............27

Checking Equipment..................................................27

IDENTIFICATION INFORMATION.................................28

Model Variation ..........................................................28

Identification Number .................................................29

Dimensions ................................................................31

Wheels and Tires .......................................................31

LIFTING POINTS AND TOW TRUCK TOWING...........32

Garage Jack and Safety Stand .................................32

Screw Jack ................................................................32

4-pole Lift ...................................................................33

Tow Truck Towing ......................................................33

ISO 15031-2 TERMINOLOGY LIST..............................35

ISO 15031-2 Terminology List ...................................35

TIGHTENING TORQUE OF STANDARD BOLTS........38