bulb NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 267 of 1767

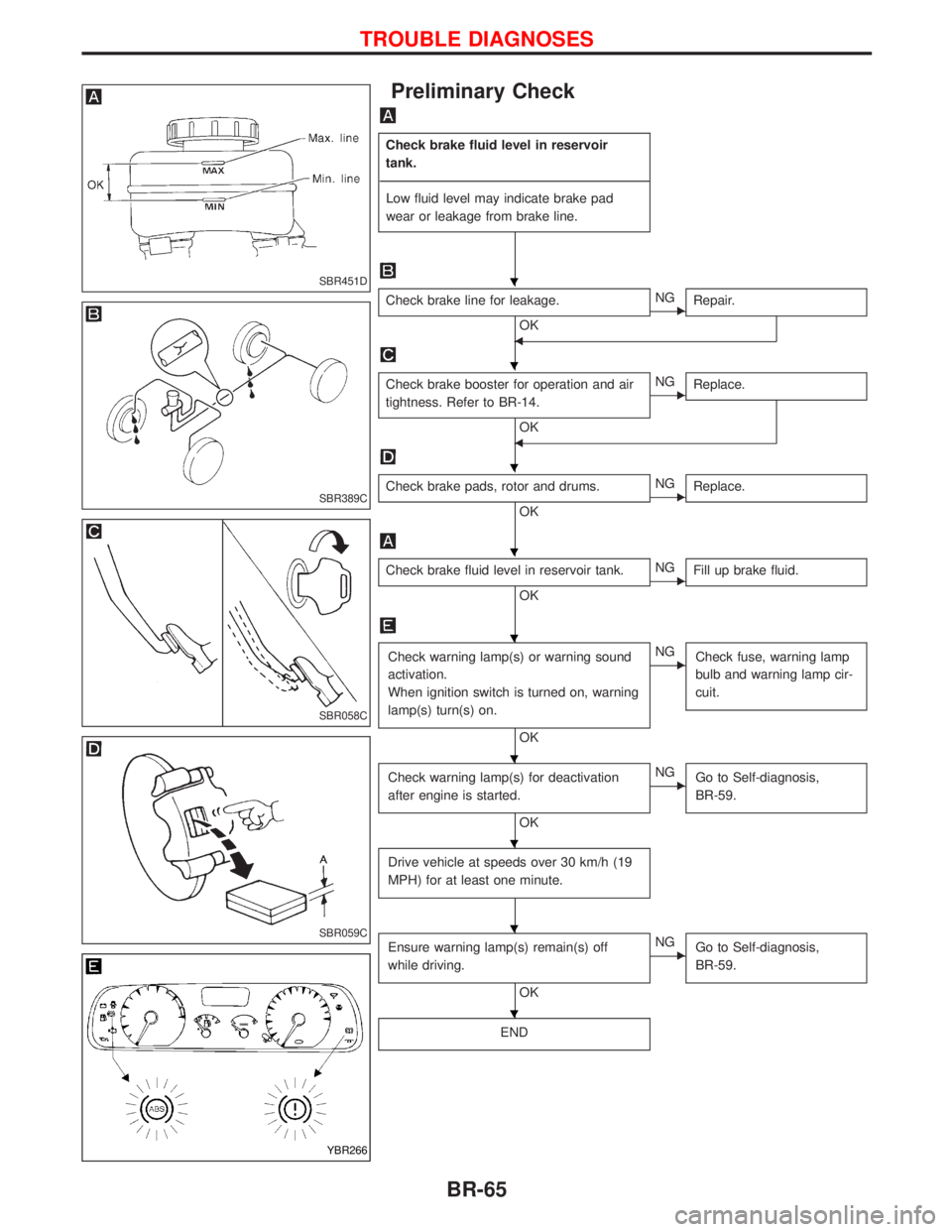

Preliminary Check

Check brake fluid level in reservoir

tank.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low fluid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKENG

Repair.

F

Check brake booster for operation and air

tightness. Refer to BR-14.

OK

ENG

Replace.

F

Check brake pads, rotor and drums.

OKENG

Replace.

Check brake fluid level in reservoir tank.

OKENG

Fill up brake fluid.

Check warning lamp(s) or warning sound

activation.

When ignition switch is turned on, warning

lamp(s) turn(s) on.

OK

ENG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp(s) for deactivation

after engine is started.

OK

ENG

Go to Self-diagnosis,

BR-59.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least one minute.

Ensure warning lamp(s) remain(s) off

while driving.

OK

ENG

Go to Self-diagnosis,

BR-59.

END

SBR451D

SBR389C

SBR058C

SBR059C

YBR266

H

H

H

H

H

H

H

H

H

TROUBLE DIAGNOSES

BR-65

Page 269 of 1767

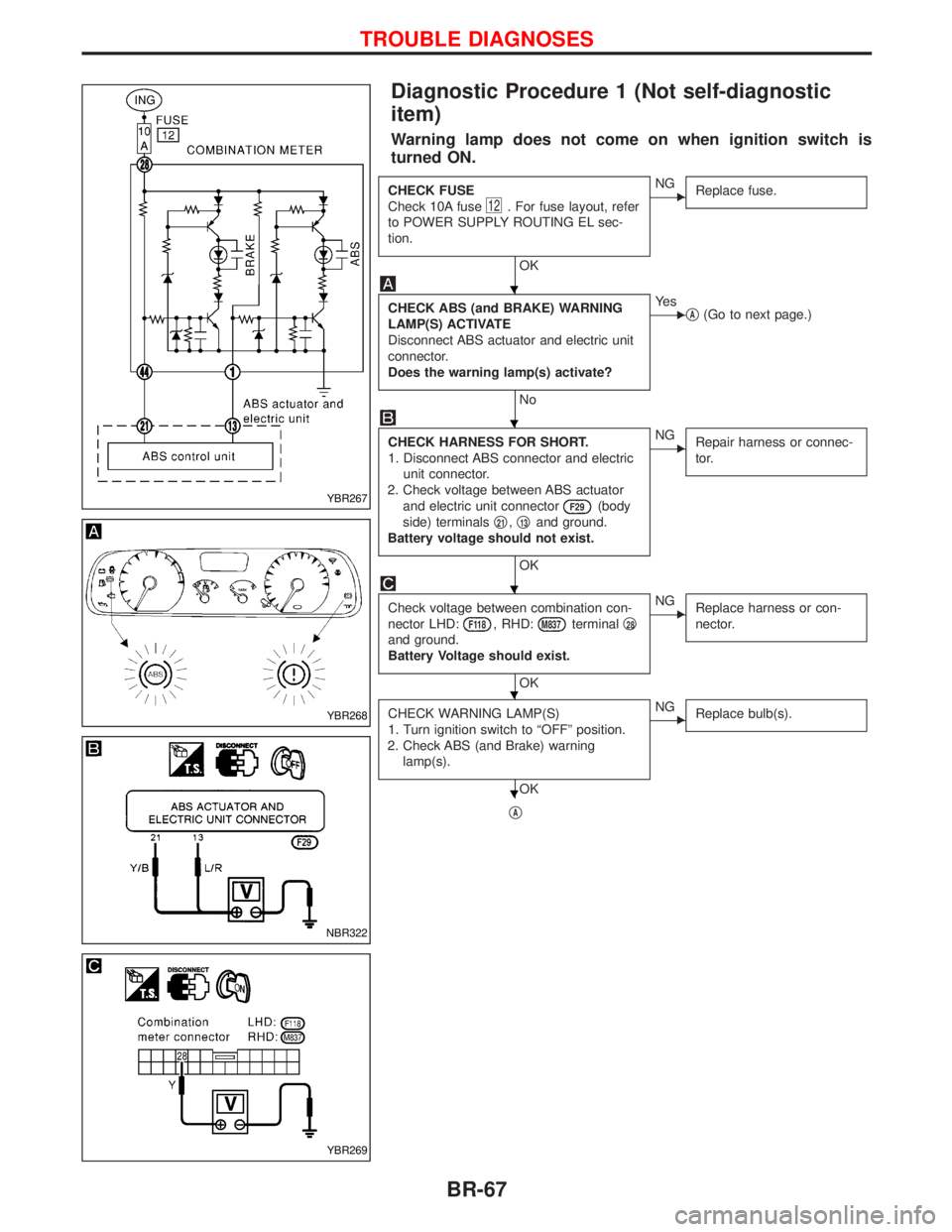

Diagnostic Procedure 1 (Not self-diagnostic

item)

Warning lamp does not come on when ignition switch is

turned ON.

CHECK FUSE

Check 10A fuse

12. For fuse layout, refer

to POWER SUPPLY ROUTING EL sec-

tion.

OK

ENG

Replace fuse.

CHECK ABS (and BRAKE) WARNING

LAMP(S) ACTIVATE

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp(s) activate?

No

EYe s

qA(Go to next page.)

CHECK HARNESS FOR SHORT.

1. Disconnect ABS connector and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

F29(body

side) terminalsq

21,q13and ground.

Battery voltage should not exist.

OK

ENG

Repair harness or connec-

tor.

Check voltage between combination con-

nector LHD:

F118, RHD:M837terminalq28

and ground.

Battery Voltage should exist.

OK

ENG

Replace harness or con-

nector.

CHECK WARNING LAMP(S)

1. Turn ignition switch to ªOFFº position.

2. Check ABS (and Brake) warning

lamp(s).

OK

ENG

Replace bulb(s).

qA

YBR267

YBR268

NBR322

YBR269

H

H

H

H

H

TROUBLE DIAGNOSES

BR-67

Page 396 of 1767

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

IConfirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

IWhen replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

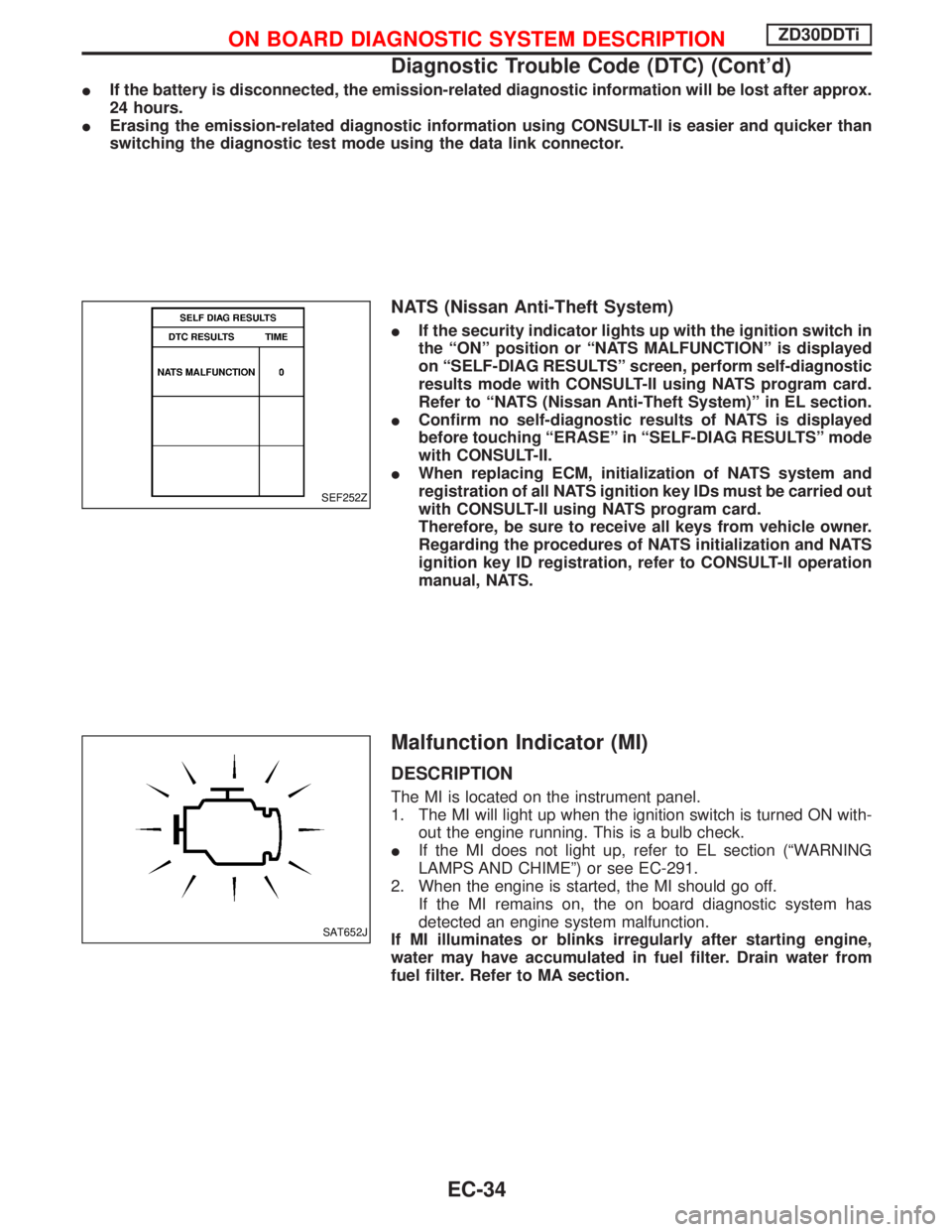

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

IIf the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-291.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

Page 397 of 1767

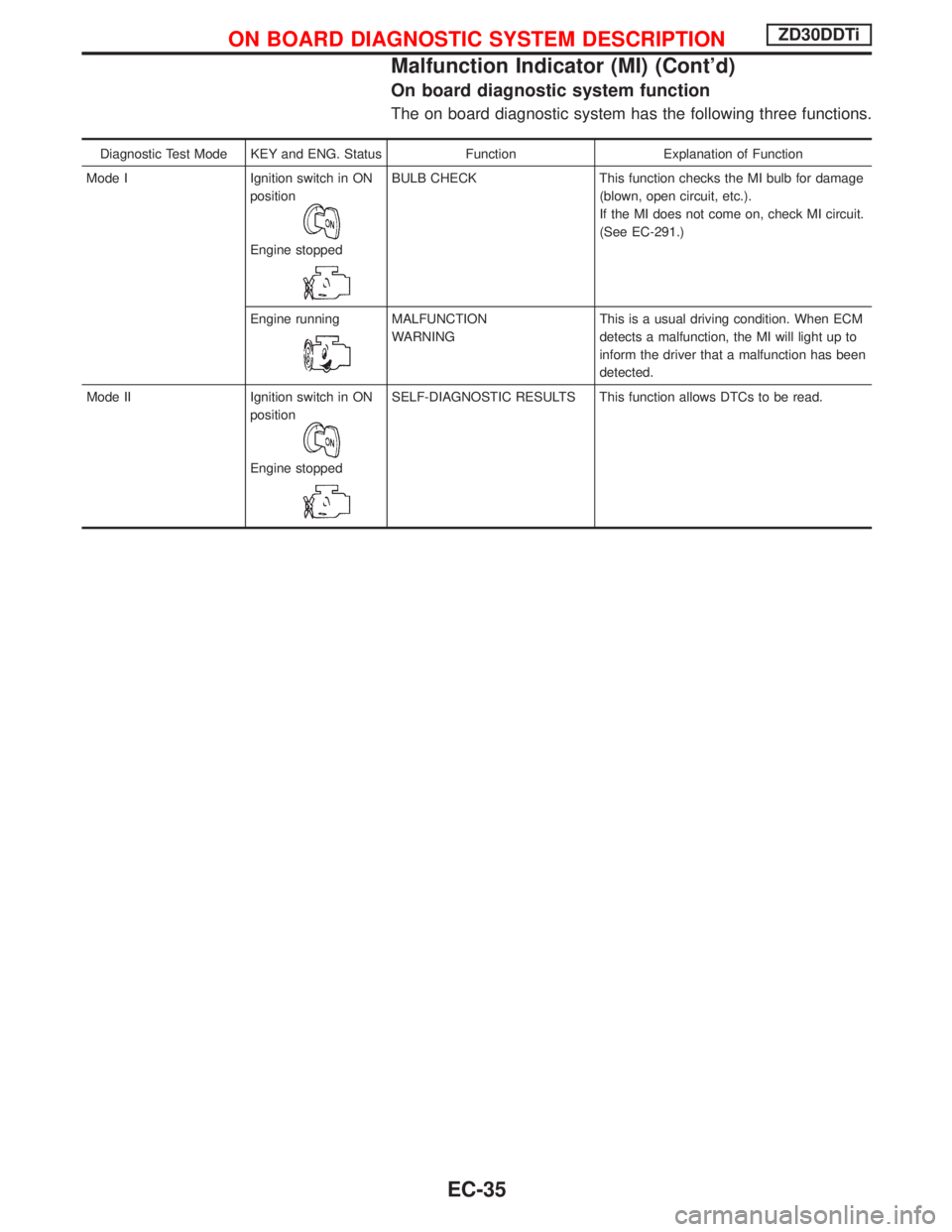

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-291.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

Page 399 of 1767

Diagnostic test mode I Ð Bulb check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to EL

section, ªWARNING LAMPS AND CHIMEº or see EC-291.

Diagnostic test mode I Ð Malfunction warning

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

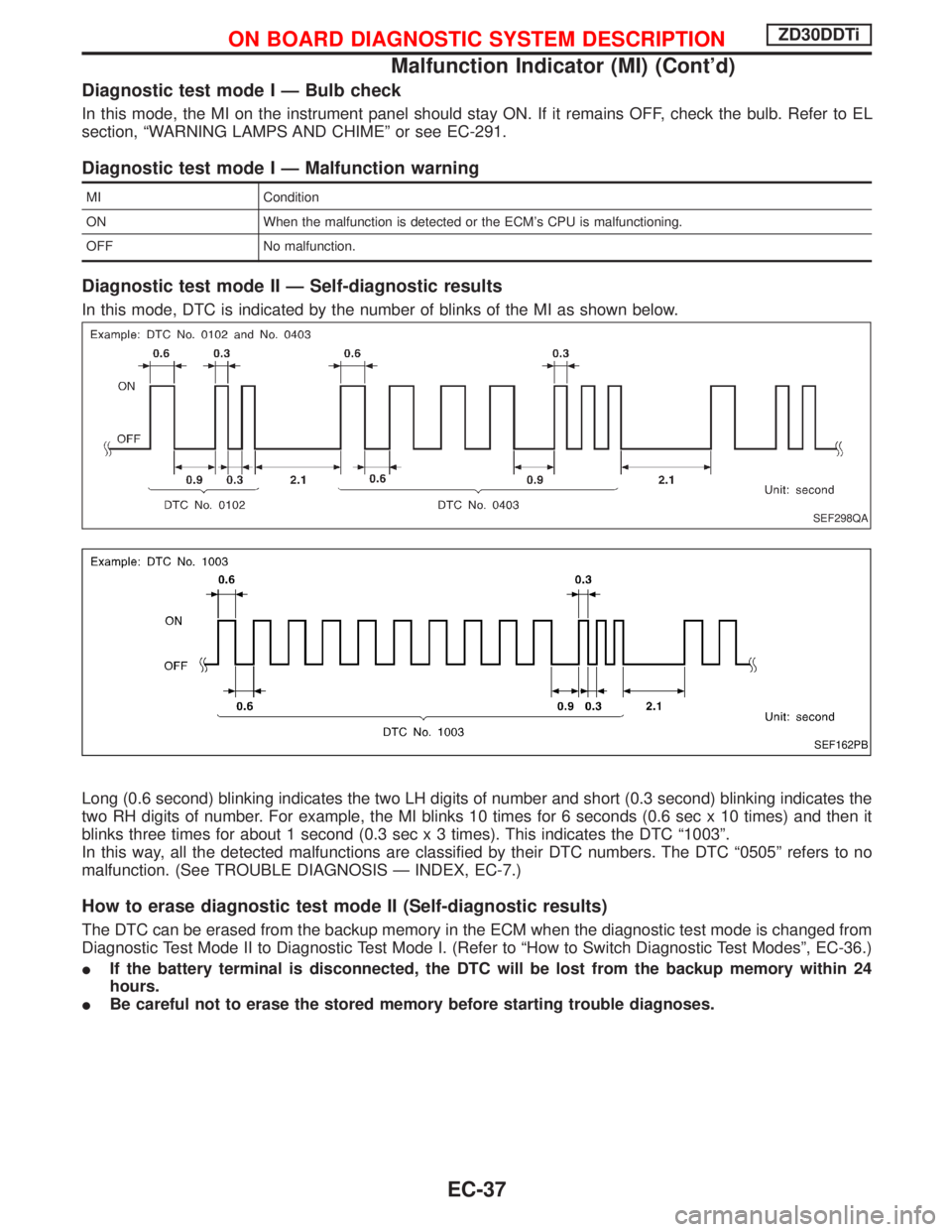

Diagnostic test mode II Ð Self-diagnostic results

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates the

two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and then it

blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-7.)

How to erase diagnostic test mode II (Self-diagnostic results)

The DTC can be erased from the backup memory in the ECM when the diagnostic test mode is changed from

Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ªHow to Switch Diagnostic Test Modesº, EC-36.)

IIf the battery terminal is disconnected, the DTC will be lost from the backup memory within 24

hours.

IBe careful not to erase the stored memory before starting trouble diagnoses.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-37

Page 684 of 1767

How to Erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-323.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

Malfunction Indicator (MI)

1. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is a bulb check.

IIf the malfunction indicator does not light up, refer to EL sec-

tion (ªWARNING LAMPS/WIRING DIAGRAMº) or see MI &

DATA LINK CONNECTORS.

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or flashes irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

Diagnostic

Test ModeKEY and ENG.

StatusFunction Explanation of Function

Mode IIgnition switch in

ON position

Engine stoppedBULB CHECKThis function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (See EC-452.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM detects a

malfunction, the MI will light up to inform the driver that a mal-

function has been detected.

Mode IIIgnition switch in

ON position

Engine stopped

SELF-DIAGNOSTIC

RESULTSThis function allows DTCs to be read.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Diagnostic Trouble Code (DTC) (Cont'd)

EC-322

Page 686 of 1767

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR on the instrument panel should stay ON. If it remains OFF,

check the bulb. Refer to EL section (ªWARNING LAMPS/WIRING DIAGRAMº) or see EC-452.

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MI Condition

ON When a malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

IThese Diagnostic Trouble Code Numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

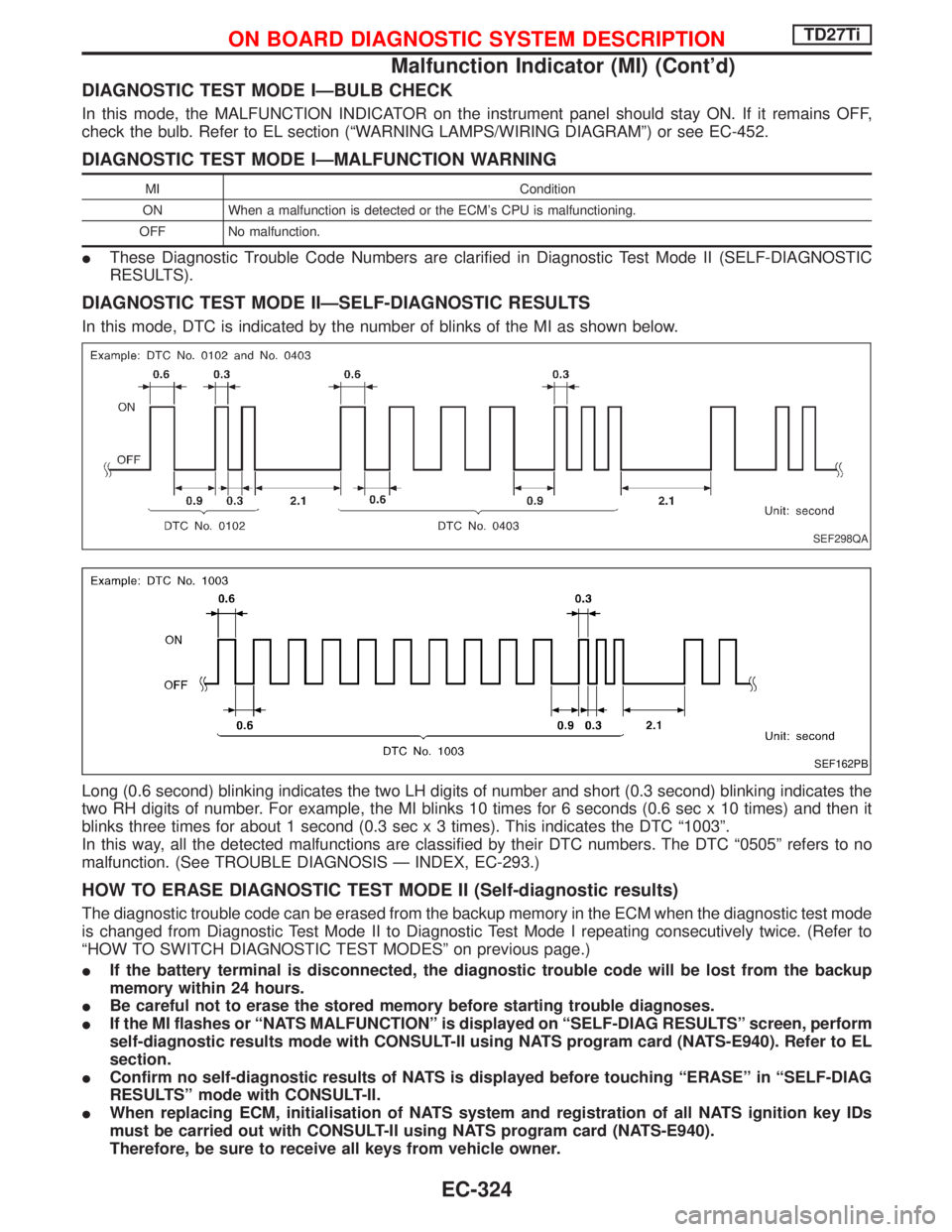

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates the

two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and then it

blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-293.)

HOW TO ERASE DIAGNOSTIC TEST MODE II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test mode

is changed from Diagnostic Test Mode II to Diagnostic Test Mode I repeating consecutively twice. (Refer to

ªHOW TO SWITCH DIAGNOSTIC TEST MODESº on previous page.)

IIf the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

IBe careful not to erase the stored memory before starting trouble diagnoses.

IIf the MI flashes or ªNATS MALFUNCTIONº is displayed on ªSELF-DIAG RESULTSº screen, perform

self-diagnostic results mode with CONSULT-II using NATS program card (NATS-E940). Refer to EL

section.

IConfirm no self-diagnostic results of NATS is displayed before touching ªERASEº in ªSELF-DIAG

RESULTSº mode with CONSULT-II.

IWhen replacing ECM, initialisation of NATS system and registration of all NATS ignition key IDs

must be carried out with CONSULT-II using NATS program card (NATS-E940).

Therefore, be sure to receive all keys from vehicle owner.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Malfunction Indicator (MI) (Cont'd)

EC-324

Page 766 of 1767

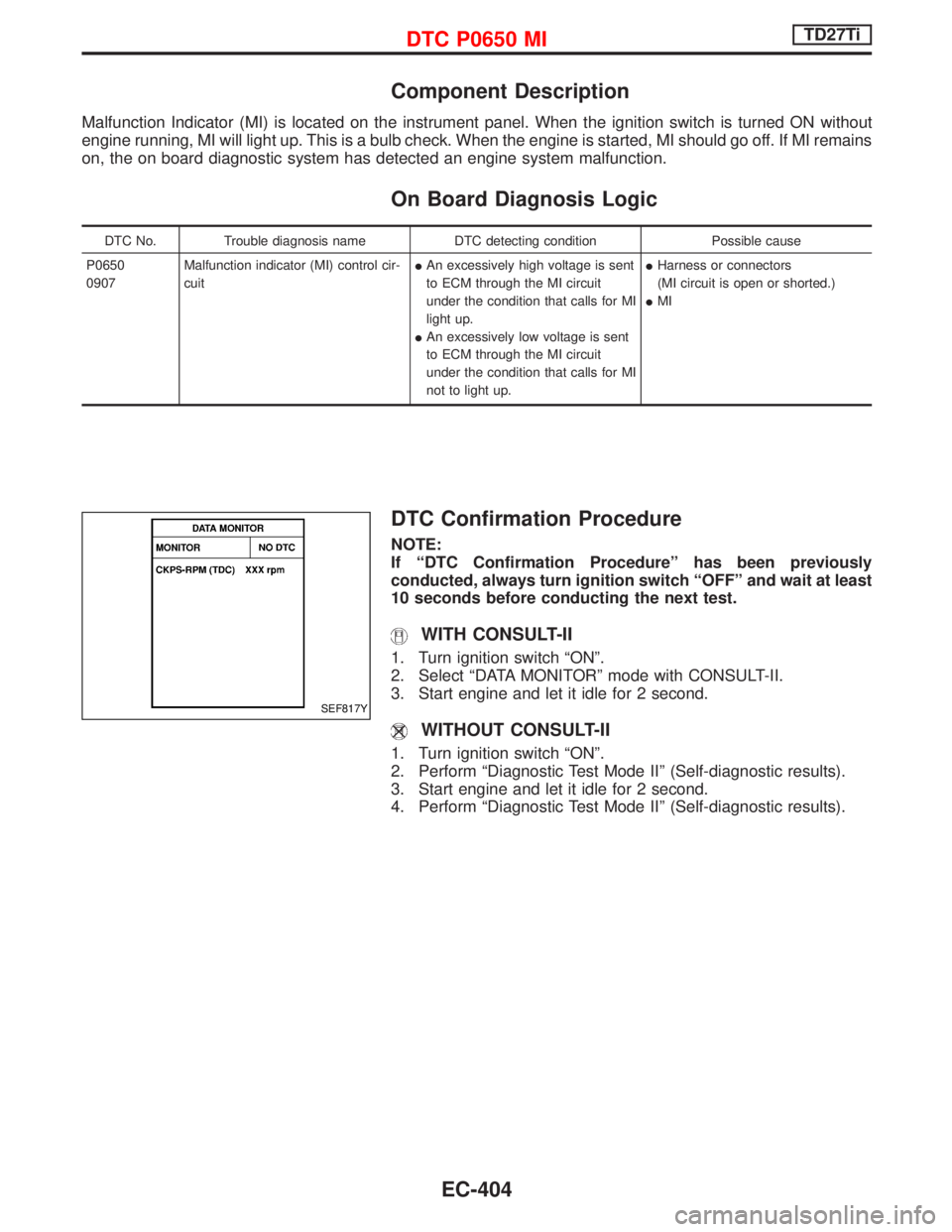

Component Description

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI remains

on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis Logic

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0650

0907Malfunction indicator (MI) control cir-

cuitIAn excessively high voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

light up.

IAn excessively low voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

not to light up.IHarness or connectors

(MI circuit is open or shorted.)

IMI

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Start engine and let it idle for 2 second.

WITHOUT CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

3. Start engine and let it idle for 2 second.

4. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF817Y

DTC P0650 MITD27Ti

EC-404

Page 817 of 1767

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

CONTENTS

HARNESS CONNECTOR................................................3

Description ...................................................................3

STANDARDIZED RELAYS..............................................4

Description ...................................................................4

POWER SUPPLY ROUTING...........................................6

Schematic ....................................................................6

Wiring Diagram - POWER - ........................................8

Fuse ...........................................................................17

Fusible Link................................................................17

Circuit Breaker Inspection .........................................17

GROUND DISTRIBUTION.............................................18

COMBINATION SWITCH...............................................23

Check .........................................................................23

Replacement ..............................................................24

STEERING SWITCH......................................................25

Check .........................................................................25

HEADLAMP - Without Daytime Light System -.........26

Wiring Diagram - H/LAMP -.......................................26

HEADLAMP - Daytime Light System -.......................29

Operation ...................................................................29

Schematic ..................................................................30

Wiring Diagram - DTRL - ...........................................31

HEADLAMP - Headlamp Aiming Control -.................37

Description .................................................................37

Replacing Headlamp Aiming Actuator .......................38

Wiring Diagram - H/AIM - ..........................................39

Trouble Diagnoses.....................................................42

HEADLAMP...................................................................43

Bulb Replacement .....................................................43

Aiming Adjustment .....................................................43

EXTERIOR LAMP..........................................................45

Wiring Diagram - TAIL/L - ..........................................45

Wiring Diagram - STOP/L - .......................................48

Wiring Diagram - BACK/L - .......................................49

Wiring Diagram - F/FOG - .........................................51

Front Fog Lamp Aiming Adjustment ..........................53

Wiring Diagram - R/FOG -.........................................54

Schematic ..................................................................55Wiring Diagram - TURN - ..........................................56

Bulb Specifications ....................................................60

INTERIOR LAMP...........................................................61

Schematic ..................................................................61

Wiring Diagram - ILL - ...............................................62

Wiring Diagram - INT/L - ...........................................66

METER AND GAUGES.................................................70

Combination Meter ....................................................70

Schematic ..................................................................71

Wiring Diagram - METER - .......................................72

Combination Meter Self-Diagnosis ............................76

Components Inspection .............................................78

Trouble Diagnoses.....................................................79

Fuel Tank Gauge Unit Check ....................................80

Thermal Transmitter Check .......................................80

Oil Pressure Switch Check ........................................80

WARNING LAMPS AND CHIME...................................81

Schematic ..................................................................81

Wiring Diagram - WARN - .........................................82

Diode Check ..............................................................92

Wiring Diagram - CHIME - ........................................93

WIPER AND WASHER..................................................94

Wiring Diagram - WIPER - ........................................94

Wiring Diagram - WIP/R -..........................................96

Installation ..................................................................98

Washer Nozzle Adjustment .......................................99

Check Valve ...............................................................99

Wiring Diagram - HLC - ...........................................100

HORN, CIGARETTE LIGHTER AND CLOCK............104

Wiring Diagram - HORN - .......................................104

Wiring Diagram - CIGAR -.......................................105

Wiring Diagram - CLOCK -......................................106

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER.................................................107

Wiring Diagram - DEF - ...........................................107

Filament Check ........................................................109

Filament Repair ....................................................... 110

AUDIO.......................................................................... 111

Page 859 of 1767

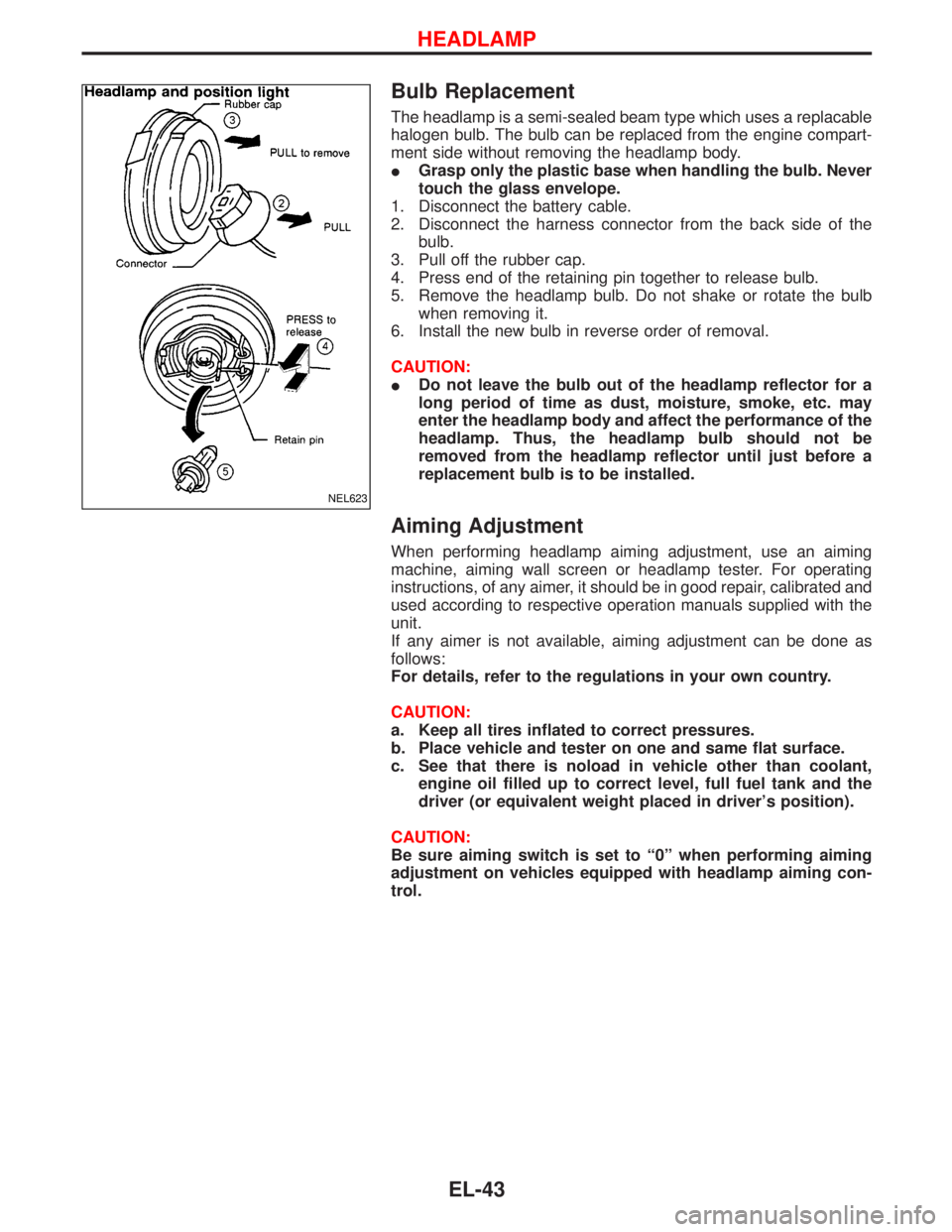

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb

when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

IDo not leave the bulb out of the headlamp reflector for a

long period of time as dust, moisture, smoke, etc. may

enter the headlamp body and affect the performance of the

headlamp. Thus, the headlamp bulb should not be

removed from the headlamp reflector until just before a

replacement bulb is to be installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

CAUTION:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

HEADLAMP

EL-43