check engine NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 3 of 1767

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

PREPARATION AND PRECAUTIONS............................3

Special Service Tools ..................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............4

Precautions ..................................................................4

Service Notice or Precautions .....................................5

OVERALL SYSTEM........................................................6

A/T Electrical Parts Location .......................................6

Wiring Diagram - A/T -.................................................7

Cross-sectional View ...................................................8

Hydraulic Control Circuits ............................................9

Shift Mechanism ........................................................10

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................14

Self-diagnosis ............................................................14

Diagnosis by CONSULT-II .........................................20

TROUBLE DIAGNOSIS - Introduction........................22

Introduction ................................................................22

Diagnostic Worksheet ................................................23

Work Flow ..................................................................26

TROUBLE DIAGNOSIS - Basic Inspection................27

A/T Fluid Check .........................................................27

Stall Test ....................................................................27

Line Pressure Test .....................................................30

Road Test...................................................................32

TROUBLE DIAGNOSIS - General Description...........43

Symptom Chart ..........................................................43

TCM Terminals and Reference Value........................46

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×A/T.........................................................................49

Wiring Diagram - AT - VSSA/T ..................................49

Vehicle Speed Sensor×A/T (Revolution sensor) ........50

TROUBLE DIAGNOSIS FOR VHCL SPEED

SEN×MTR.......................................................................52

Wiring Diagram - AT - VSSMTR ................................52

Vehicle Speed Sensor×MTR ......................................54TROUBLE DIAGNOSIS FOR THROTTLE POSI

SEN................................................................................56

Wiring Diagram - AT - TPS ........................................56

Throttle (Accelerator) Position Sensor ......................60

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

A.....................................................................................62

Wiring Diagram - AT - SSV/A ....................................62

Shift Solenoid Valve A ...............................................63

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V

B.....................................................................................65

Wiring Diagram - AT - SSV/B ....................................65

Shift Solenoid Valve B ...............................................66

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH

S/V..................................................................................68

Wiring Diagram - AT - OVRCSV................................68

Overrun Clutch Solenoid Valve .................................69

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V.....71

Wiring Diagram - AT - TCV........................................71

Torque Converter Clutch Solenoid Valve ..................72

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP

SEN................................................................................75

Wiring Diagram - AT - BA/FTS ..................................75

A/T Fluid Temperature Sensor and TCM Power

Source........................................................................76

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG....79

Wiring Diagram - AT - ENGSS ..................................79

Engine Speed Signal .................................................80

TROUBLE DIAGNOSIS FOR LINE PRESSURE

S/V..................................................................................82

Wiring Diagram - AT - LPSV......................................82

Line Pressure Solenoid Valve ...................................84

TROUBLE DIAGNOSIS FOR NON-DETECTABLE

ITEMS.............................................................................87

Wiring Diagram - AT - PNP/SW.................................87

Park/neutral Position, Overdrive Control or

Throttle (Accelerator) Position Switches ...................88

DIAGNOSTIC PROCEDURES FOR SYMPTOMS........94

Page 16 of 1767

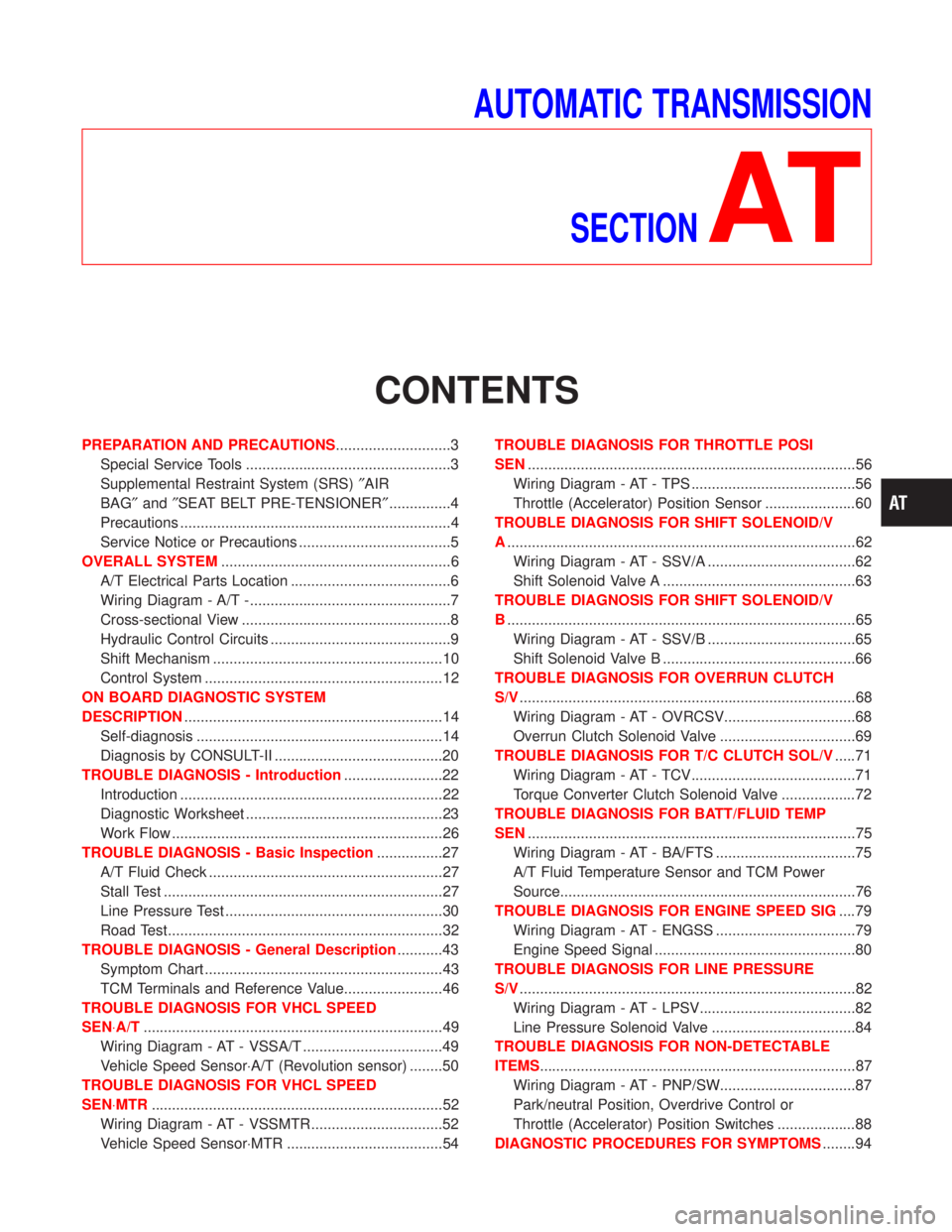

Self-diagnosis

After performing this procedure, place check marks for results on

the ªDIAGNOSTIC WORKSHEETº, AT-24. Reference pages are

provided following the items.

SELF-DIAGNOSTIC PROCEDURE (With CONSULT-II)

1. Turn on CONSULT-II and touch ªA/Tº.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-46. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last erasing

operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be dis-

played at real time.

Item Display Description Remarks

No failure

****NO FAILURE

****INo failure has been detected.

Initial start

*INITIAL START

*IThis is NOT a malfunction message.

Whenever shutting off a power supply to the

TCM, this message appears on the screen.

[]

Vehicle speed

sensor×A/T

(Revolution sensor)VHCL SPEED SEN×A/TINo signal input from vehicle speed sensor×A/T (revolution

sensor) during traveling due to disconnection, or input of

abnormal signal.

Vehicle speed

sensor×MTR (Meter)VHCL SPEED SEN×MTRINo signal input from vehicle speed sensor×MTR during

traveling due to disconnection, or input of abnormal signal.

Throttle (accelerator)

position sensorTHROTTLE POSI SENIThrottle (accelerator) position sensor signal voltage is

abnormally high.

IThrottle (accelerator) position sensor signal voltage is

abnormally low with closed throttle position switch ªOFFº

or wide open throttle position switch ªONº.

Shift solenoid valve A SHIFT SOLENOID/V AISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Shift solenoid valve B SHIFT SOLENOID/V BISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Overrun clutch

solenoid valveOVERRUN CLUTCH S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

T/C clutch solenoid

valveT/C CLUTCH SOL/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

A/T fluid temperature

sensor/TCM power

sourceBATT/FLUID TEMP SENISupply voltage to TCM is abnormally low during traveling.

IFluid temperature signal voltage is abnormally high

(fluid temperature is low) during traveling.To be dis-

played in case

of abnormality

and no record-

ing is made Engine speed signal ENGINE SPEED SIGIEngine RPM is abnormally low during traveling.

Line pressure

solenoid valveLINE PRESSURE S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

TCM (ROM) CONTROL UNIT (ROM)ITCM memory (ROM) is malfunctioning.

TCM (RAM) CONTROL UNIT (RAM)ITCM memory (RAM) is malfunctioning.

SAT014K

SAT987J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-14

Page 18 of 1767

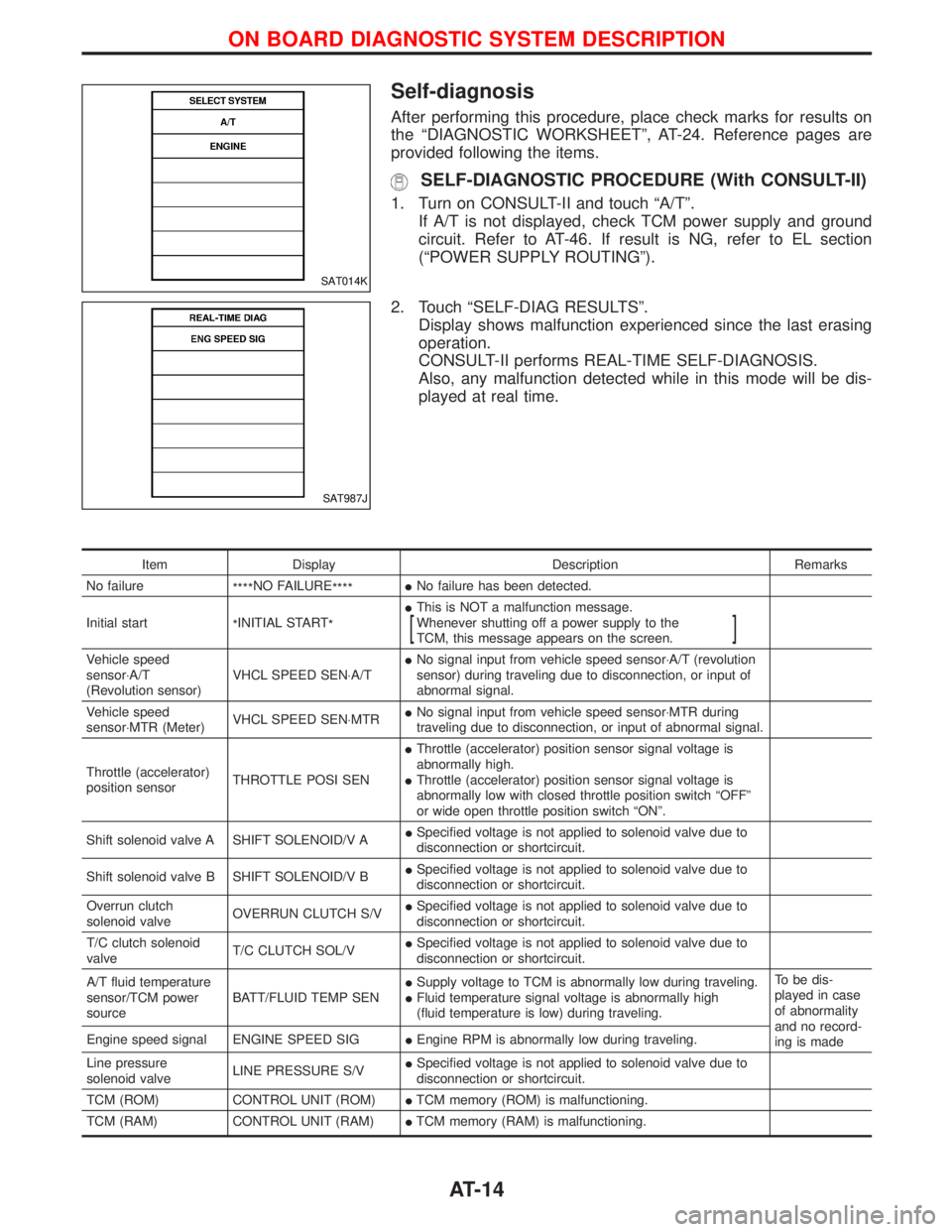

qA

1. Set overdrive control switch in ªOFFº

position.

2. Depress accelerator pedal fully and

release it.

3. Turn ignition switch ªONº.

(Do not start engine.)

1. Move selector lever to ª2º position.

2. Set overdrive control switch in ªONº

position.

1. Move selector lever to ª1º position.

2. Set overdrive control switch in ªOFFº

position.

Depress accelerator pedal fully and

release it.

Check SPORT indicator lamp.

Refer to JUDGEMENT OF SELF-

DIAGNOSIS CODE, AT-17.

DIAGNOSIS END

SAT881E

FAT245I

SAT246I

SAT981F

NAT309

H

H

H

H

H

H

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Self-diagnosis (Cont'd)

AT-16

Page 22 of 1767

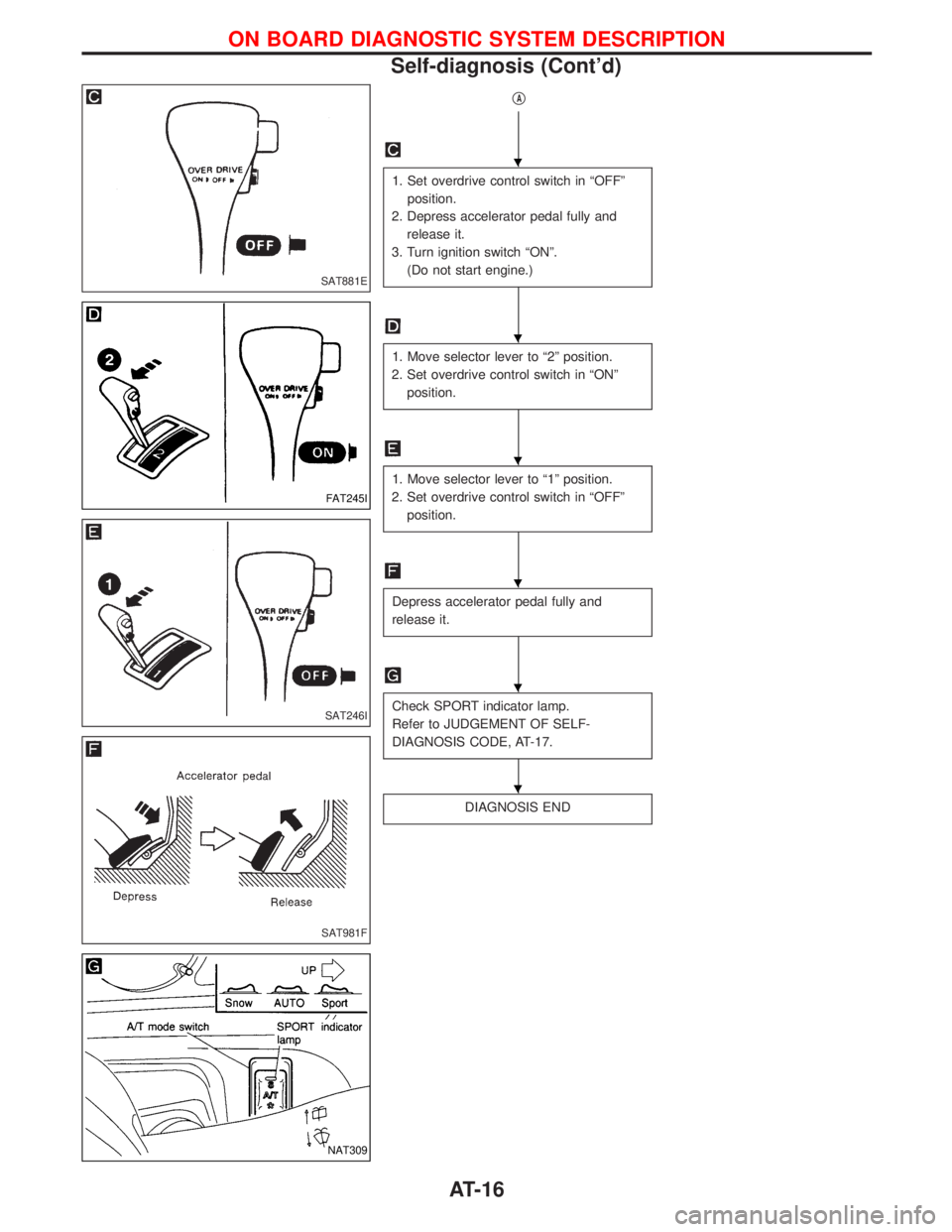

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed

upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor)VHCL/S SE×A/T

[km/h] or [mph]

XÐIVehicle speed computed from signal

of revolution sensor is displayed.When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SE×MTR

[km/h] or [mph]

XÐIVehicle speed computed from signal

of vehicle speed sensor is dis-

played.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensorTHRTL POS SEN

[V]XÐIThrottle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensorFLUID TEMP SE

[V]

XÐIA/T fluid temperature sensor signal

voltage is displayed.

ISignal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT

[V]XÐISource voltage of TCM is displayed.

Engine speed ENGINE SPEED

[rpm]

XXIEngine speed, computed from

engine speed signal, is displayed.Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF]XÐION/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW

[ON/OFF]XÐION/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE

[ON/OFF]

XÐIStatus of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running stateIThis is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

Page 24 of 1767

Introduction

The TCM receives a signal from the vehicle-speed sensor, throttle

(accelerator) position sensor or park/neutral position switch and

provides shift control or lock-up control via solenoid valves.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº. Refer to AT-26.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-24) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

SAT631IA

SAT632I

SEF234G

TROUBLE DIAGNOSIS Ð Introduction

AT-22

Page 26 of 1767

DIAGNOSTIC WORKSHEET

1.lRead the Fail-safe and listen to customer complaints. AT-5

2.lA/T FLUID CHECK AT-27

lLeakage (Follow specified procedure)

lFluid condition

lFluid level

3.lPerform STALL TEST and LINE PRESSURE TEST. AT-27,

AT-30

lStall test Ð Mark possible damaged components/others.

lTorque converter one-way clutch

lReverse clutch

lForward clutch

lOverrun clutch

lForward one-way clutchlLow & reverse brake

lLow one-way clutch

lEngine

lLine pressure is low

lClutches and brakes except high

clutch and brake band are OK

lLine pressure test Ð Suspected parts:

4.lPerform all ROAD TEST and mark required procedures. AT-32

4-1. Check before engine is started. AT-33

lSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

lVehicle speed sensor×A/T (Revolution sensor), AT-50.

lVehicle speed sensor×MTR, AT-54.

lThrottle (accelerator) position sensor, AT-60.

lShift solenoid valve A, AT-63.

lShift solenoid valve B, AT-66.

lOverrun clutch solenoid valve, AT-69.

lTorque converter clutch solenoid valve, AT-88.

lA/T fluid temperature sensor and TCM power source, AT-76.

lEngine speed signal, AT-80.

lLine pressure solenoid valve, AT-84.

lPark/neutral position, overdrive control, A/T check and throttle

(accelerator) position switches, AT-88.

lBattery

lOthers

4-2. Check at idle AT-35

l1. SPORT Indicator Lamp Does Not Come On, AT-92.

l2. SPORT or SNOW Indicator Lamp Does Not Come On, AT-95.

l3. O/D OFF Indicator Lamp Does Not Come On, AT-95.

l4. SPORT Indicator Lamp Does Not Come On, AT-96.

l5. Engine Cannot Be Started In ªPº And ªNº Position, AT-97.

l6. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed, AT-97.

l7. In ªNº Position, Vehicle Moves, AT-98.

l8. Large Shock. ªNº,ªRº Position, AT-99.

l9. Vehicle Does Not Creep Backward In ªRº Position, AT-100.

l10. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-101.

4-3. Cruise testAT-36,

AT-39

Part-1

l11. Vehicle Cannot Be Started From D

1, AT-102.

l12. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-103.

l13. A/T Does Not Shift: D

2,D3, AT-104.

l14. A/T Does Not Shift: D

3,D4, AT-105.

l15. A/T Does Not Perform Lock-up, AT-106.

l16. A/T Does Not Hold Lock-up Condition, AT-107.

l17. Lock-up Is Not Released, AT-107.

l18. Engine Speed Does Not Return To Idle (Light Braking D

4,D3), AT-108.

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-24

Page 27 of 1767

4. Part-2

l19. Vehicle Does Not Start From D

1, AT-109.

l12. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-103.

l13. A/T Does Not Shift: D

2,D3, AT-104.

l14. A/T Does Not Shift: D

3,D4, AT-105.AT-41

Part-3

l20. A/T Does Not Shift: D

2,D1When Depressing Accelerator Pedal, AT-5.

l21. A/T Does Not Shift: D

4,D3When Overdrive Control Switch ªONº,

ªOFFº, AT-111.

l18. Engine Speed Does Not Return To Idle (Engine Brake In D

3), AT-108.

l22. A/T Does Not Shift: D

3,22, When Selector Lever ªDº,ª2º Position,

AT- 111 .

l18. Engine Speed Does Not Return To Idle (Engine Brake In 2

2), AT-108.

l23. A/T Does Not Shift: 2

2,11, When Selector Lever ª2º,ª1º Position,

AT-5.

l24. Vehicle Does Not Decelerate By Engine Brake, AT-112.

lSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.AT-42

lVehicle speed sensor×A/T (Revolution sensor), AT-50.

lVehicle speed sensor×MTR, AT-54.

lThrottle (accelerator) position sensor, AT-60.

lShift solenoid valve A, AT-63.

lShift solenoid valve B, AT-66.

lOverrun clutch solenoid valve, AT-69.

lTorque converter clutch solenoid valve, AT-69.

lA/T fluid temperature sensor and TCM power source, AT-76.

lEngine speed signal, AT-80.

lLine pressure solenoid valve, AT-84.

lPark/neutral position, overdrive control, A/T check and throttle

(accelerator) position switches, AT-88.

lBattery

lOthers

5.lFor self-diagnosis NG items, inspect each component. Repair or replace the

damaged parts.AT-14

6.lPerform all ROAD TEST and re-mark required procedures. AT-32

7.lPerform the Diagnostic Procedures for all remaining items marked NG. Repair or

replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also

shows some other possible symptoms and the component inspection orders.)AT-46

AT-43

8.lErase self-diagnosis code from TCM memories. AT-19

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-25

Page 29 of 1767

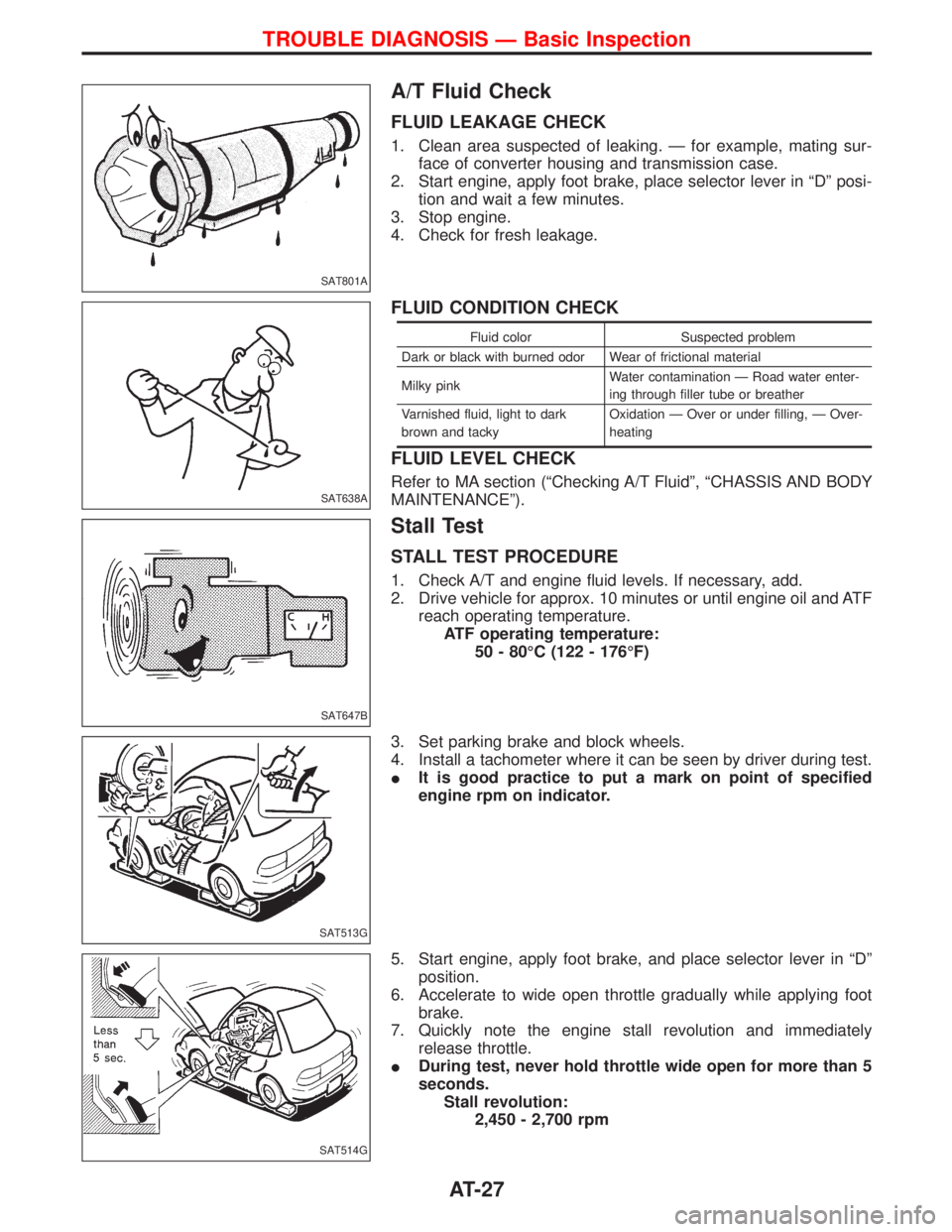

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water enter-

ing through filler tube or breather

Varnished fluid, light to dark

brown and tackyOxidation Ð Over or under filling, Ð Over-

heating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND BODY

MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

IDuring test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

2,450 - 2,700 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-27

Page 32 of 1767

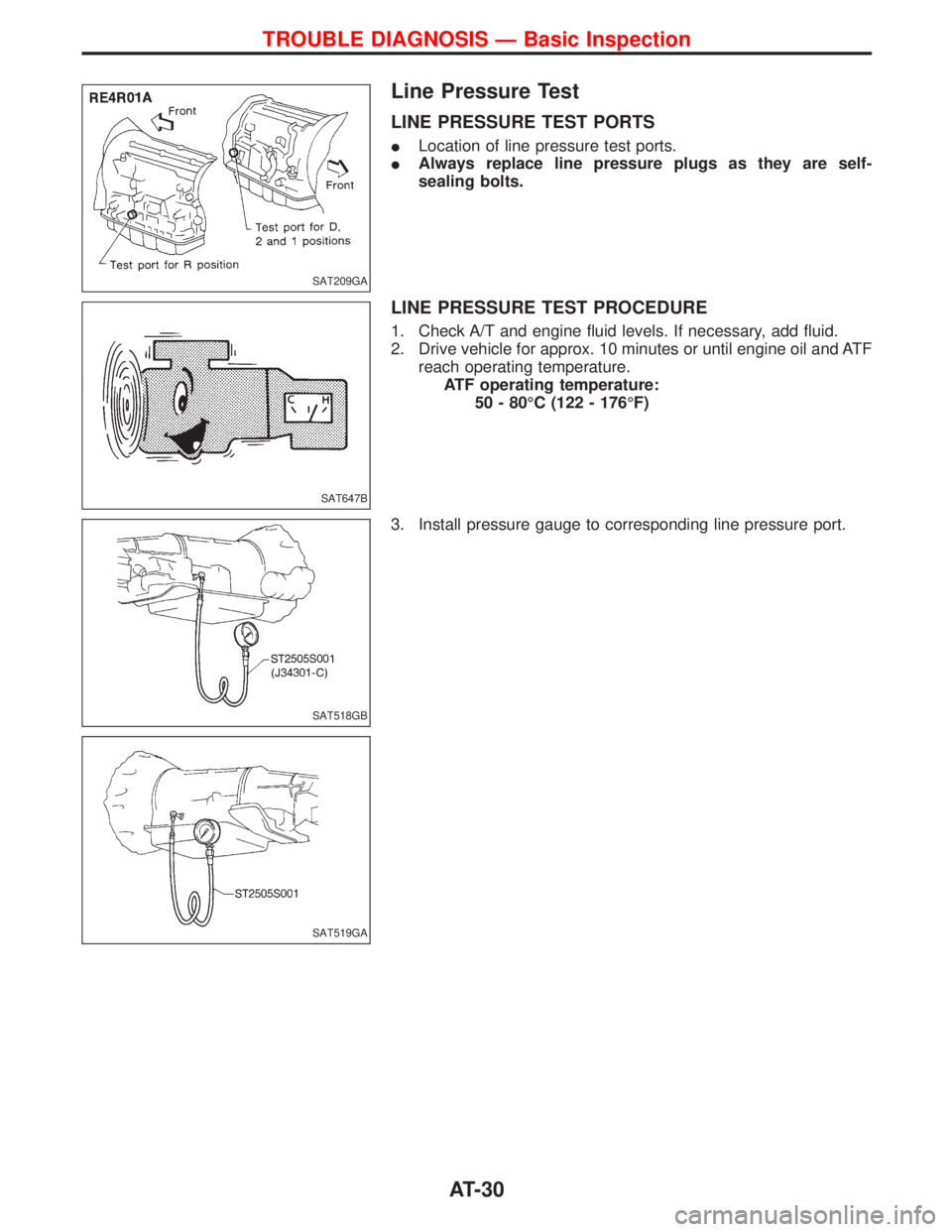

Line Pressure Test

LINE PRESSURE TEST PORTS

ILocation of line pressure test ports.

IAlways replace line pressure plugs as they are self-

sealing bolts.

LINE PRESSURE TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add fluid.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Install pressure gauge to corresponding line pressure port.

SAT209GA

SAT647B

SAT518GB

SAT519GA

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-30

Page 34 of 1767

Road Test

DESCRIPTION

IThe purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

IThe road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

IBefore road test, familiarize yourself with all test procedures

and items to check.

IConduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº

and ªDIAGNOSTIC PROCEDURES FOR SYMPTOMSº, AT-14

- AT-20 and AT-92 - AT-112.

SAT786A

SAT496G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-32