gas type NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1321 of 1767

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine.

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

IAbove þ7ÉC (20ÉF) ... Summer type diesel fuel.

IBelow þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

IDo not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

IDo not use summer fuel at temperature below þ7ÉC (20ÉF).

The cold temperature will cause wax to form in the fuel. As

a result, it may prevent the engine from running smoothly.

IDo not add gasoline or other alternate fuels to diesel fuel.

Precautions for Engine Oils

Prolonged and repeated contact with mineral oil will result in the

removal of natural fats from the skin, leading to dryness, irritation

and dermatitis. In addition, used engine oil contains potentially

harmful contaminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must be provided.

HEALTH PROTECTION PRECAUTIONS

1. Avoid prolonged and repeated contact with oils, particularly

used engine oils.

2. Wear protective clothing, including impervious gloves where

practicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly underwear, with oil.

5. Heavily soiled clothing and oil-impregnated footwear should not

be worn. Overalls must be cleaned regularly.

6. First Aid treatment should be obtained immediately for open

cuts and wounds.

7. Use barrier creams, applying them before each work period, to

help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

9. Do not use petrol, kerosine, diesel fuel, gas oil, thinners or sol-

vents for cleaning skin.

10. If skin disorders develop, obtain medical advice without delay.

11. Where practicable, degrease components prior to handling.

12. Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addition

an eye wash facility should be provided.

(For the United Kingdom, see also HSE Cautionary Notice SHW

397 ªEffects of Mineral Oil on the Skinº.)

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt check with the

appropriate local authority and/or manufacturer of the approved

appliance.

PRECAUTIONS

GI-6

Page 1356 of 1767

Precautions for Working with HFC-134a

(R-134a)

WARNING:

ICFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant must never be mixed, even in the

smallest amounts, as they are incompatible with each other. If the refrigerants are mixed, com-

pressor failure is likely to occur.

IUse only specified lubrication oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a)

components. If lubrication oil other than that specified is used, compressor failure is likely to

occur.

IThe specified HFC-134a (R-134a) lubrication oil absorbs moisture from the atmosphere at a rapid

rate, therefore the following handling precautions must be observed:

a: When removing refrigerant components from a vehicle, immediately cap (seal) the component

to minimize the entry of moisture from the atmosphere.

b: When installing refrigerant components to a vehicle, do not remove the caps (unseal) until

just before connecting the components. Also, complete the connection of all refrigerant loop

components as quickly as possible to minimize the entry of moisture into the system.

c: Use the specified lubrication oil from a sealed container only. Containers must be re-sealed

immediately after dispensing the lubrication oil. Lubrication oil in containers which are not

properly sealed will become moisture saturated, and such lubrication oil is no longer suitable

for use and should be properly disposed of.

d: Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a)

system. If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

e: Do not allow lubrication oil (Nissan A/C System Oil Type S or Type R) to come in contact with

styrofoam parts. Damage may result.

General Refrigerant Precautions

WARNING:

IDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

IAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

IDo not store or heat refrigerant containers above 52ÉC (125ÉF).

IDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

IDo not drop, puncture, or incinerate refrigerant containers.

IKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

IRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

IDo not introduce compressed air to any refrigerant container or refrigerant component.

PRECAUTIONS

HA-3

Page 1357 of 1767

Precautions for Refrigerant Connection

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system

is less than atmospheric. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IDo not leave compressor on its side or upside down for more than 10 minutes, as compressor oil

will enter low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, plug all openings immediately to prevent entrance of dirt and moisture.

IWhen installing an air conditioner in the vehicle, the pipes must be connected at the final stage of

the operation. The seal caps of the pipes and other components must not be removed until their

removal is required for connection.

ITo prevent the condensation of moisture inside A/C components, components stored in cool areas

should be allowed to warm to the working area temperature before removing the seal caps.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

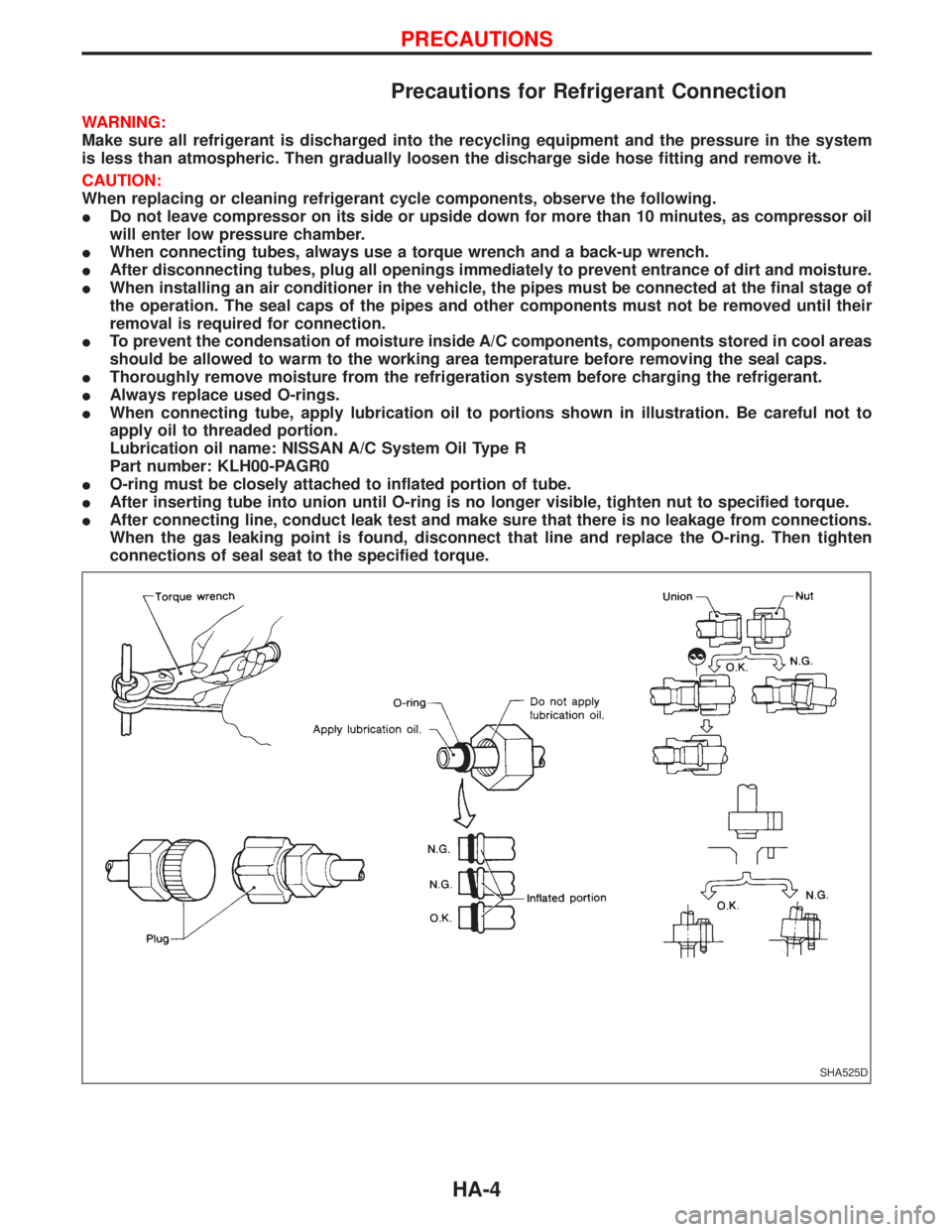

IAlways replace used O-rings.

IWhen connecting tube, apply lubrication oil to portions shown in illustration. Be careful not to

apply oil to threaded portion.

Lubrication oil name: NISSAN A/C System Oil Type R

Part number: KLH00-PAGR0

IO-ring must be closely attached to inflated portion of tube.

IAfter inserting tube into union until O-ring is no longer visible, tighten nut to specified torque.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

SHA525D

PRECAUTIONS

HA-4

Page 1375 of 1767

Lubrication Oil

Name: Nissan A/C System Oil Type R

Part number: KLH00-PAGR0

Maintenance of Oil Quantity in Compressor

The oil used to lubricate the compressor circulates through the

system with the refrigerant. Whenever any component of the sys-

tem is replaced or a large amount of gas leakage occurs, add oil

to the compressor to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions

may result:

ILack of oil: May lead to a seized compressor

IExcessive oil: Inadequate cooling (thermal exchange impeded)

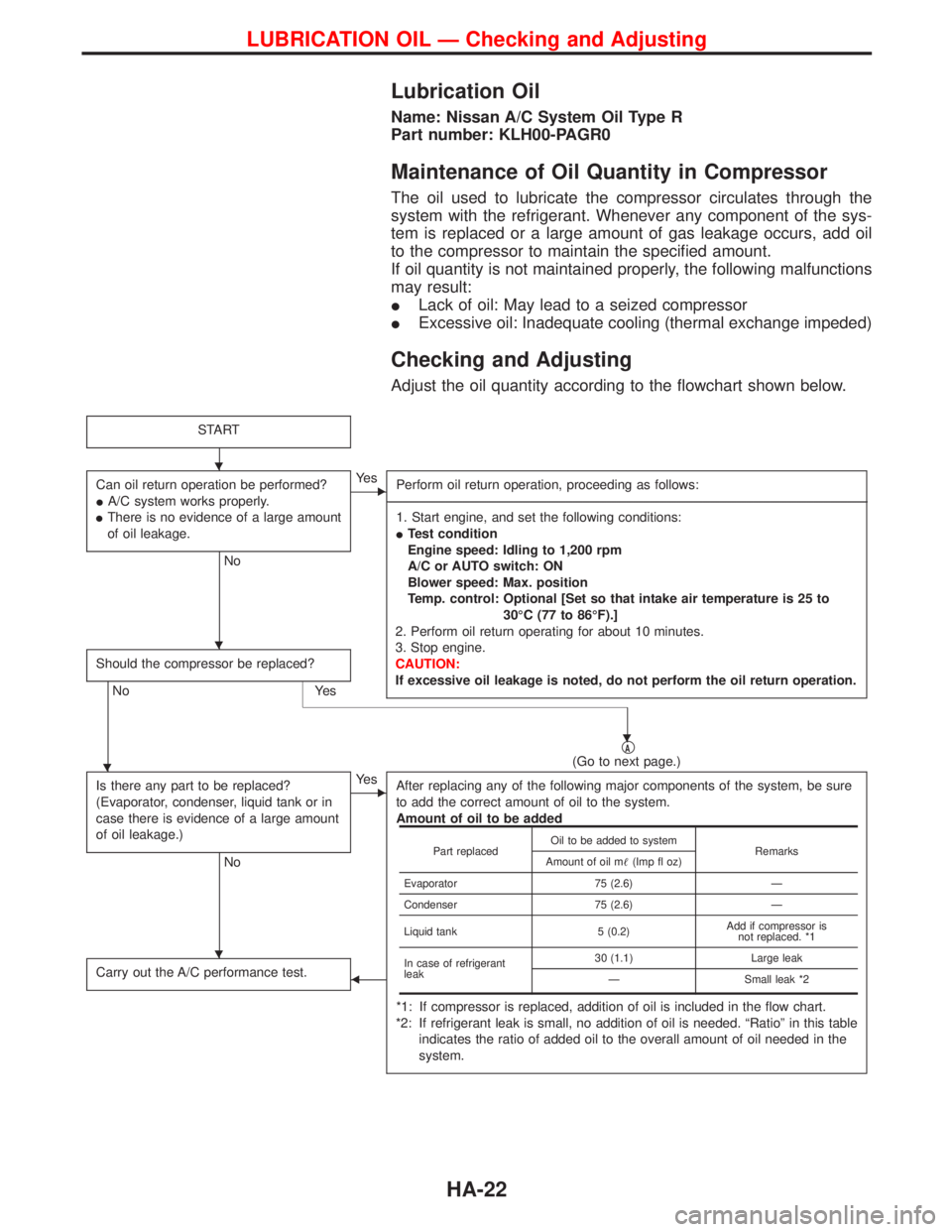

Checking and Adjusting

Adjust the oil quantity according to the flowchart shown below.

START

Can oil return operation be performed?

IA/C system works properly.

IThere is no evidence of a large amount

of oil leakage.

No

EYe s

Perform oil return operation, proceeding as follows:

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

ITest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to

30ÉC (77 to 86ÉF).]

2. Perform oil return operating for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Should the compressor be replaced?

No Yes

qA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount

of oil leakage.)

No

EYe s

After replacing any of the following major components of the system, be sure

to add the correct amount of oil to the system.

Amount of oil to be added

*1: If compressor is replaced, addition of oil is included in the flow chart.

*2: If refrigerant leak is small, no addition of oil is needed. ªRatioº in this table

indicates the ratio of added oil to the overall amount of oil needed in the

system.

Carry out the A/C performance test.F

Part replacedOil to be added to system

Remarks

Amount of oil m(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is

not replaced. *1

In case of refrigerant

leak30 (1.1) Large leak

Ð Small leak *2

H

H

H

H

H

LUBRICATION OIL Ð Checking and Adjusting

HA-22