oil dipstick NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 896 of 1767

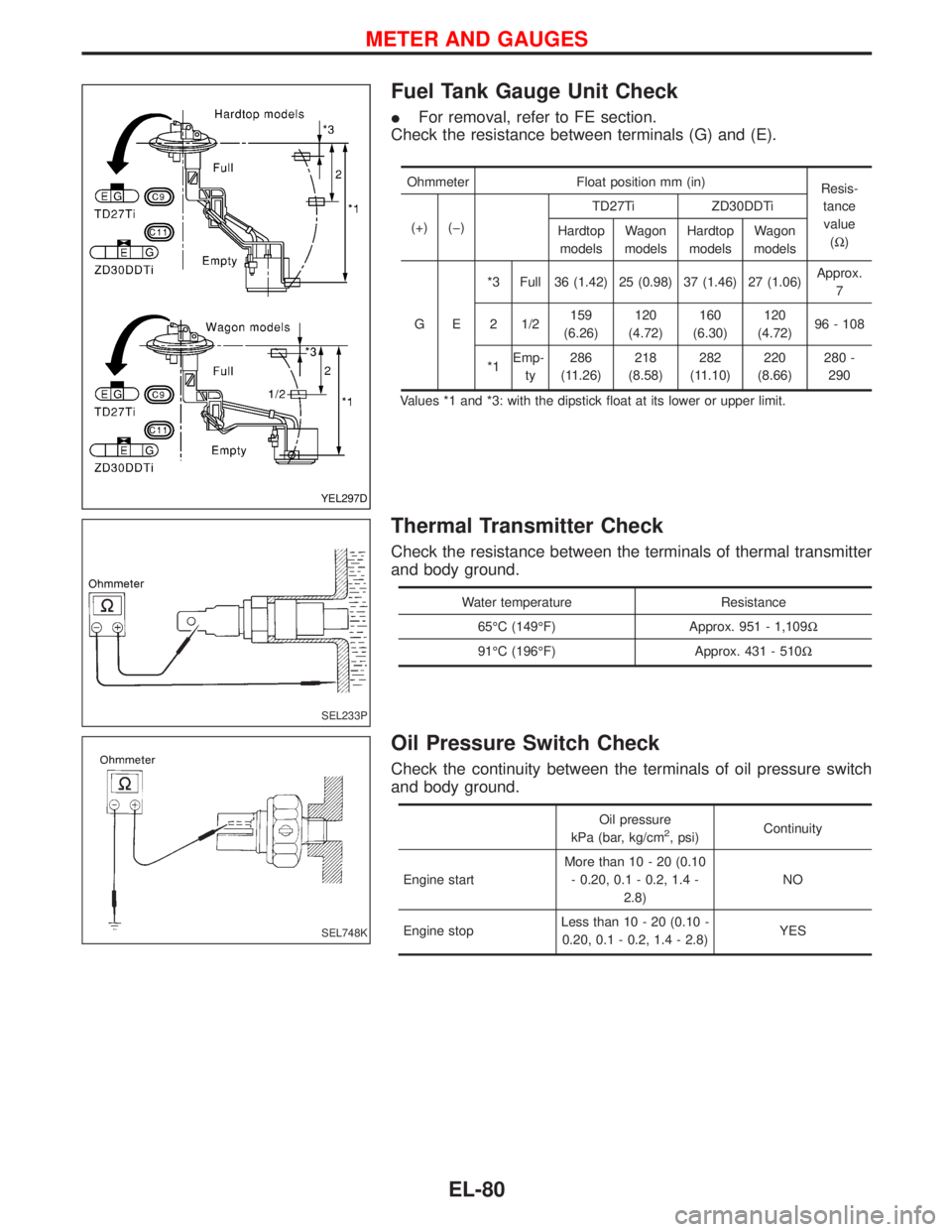

Fuel Tank Gauge Unit Check

IFor removal, refer to FE section.

Check the resistance between terminals (G) and (E).

Ohmmeter Float position mm (in)

Resis-

tance

value

(W) (+) (þ)TD27Ti ZD30DDTi

Hardtop

modelsWagon

modelsHardtop

modelsWagon

models

GE*3 Full 36 (1.42) 25 (0.98) 37 (1.46) 27 (1.06)Approx.

7

2 1/2159

(6.26)120

(4.72)160

(6.30)120

(4.72)96 - 108

*1Emp-

ty286

(11.26)218

(8.58)282

(11.10)220

(8.66)280 -

290

Values *1 and *3: with the dipstick float at its lower or upper limit.

Thermal Transmitter Check

Check the resistance between the terminals of thermal transmitter

and body ground.

Water temperature Resistance

65ÉC (149ÉF) Approx. 951 - 1,109W

91ÉC (196ÉF) Approx. 431 - 510W

Oil Pressure Switch Check

Check the continuity between the terminals of oil pressure switch

and body ground.

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20 (0.10

- 0.20, 0.1 - 0.2, 1.4 -

2.8)NO

Engine stopLess than 10 - 20 (0.10 -

0.20, 0.1 - 0.2, 1.4 - 2.8)YES

YEL297D

SEL233P

SEL748K

METER AND GAUGES

EL-80

Page 1125 of 1767

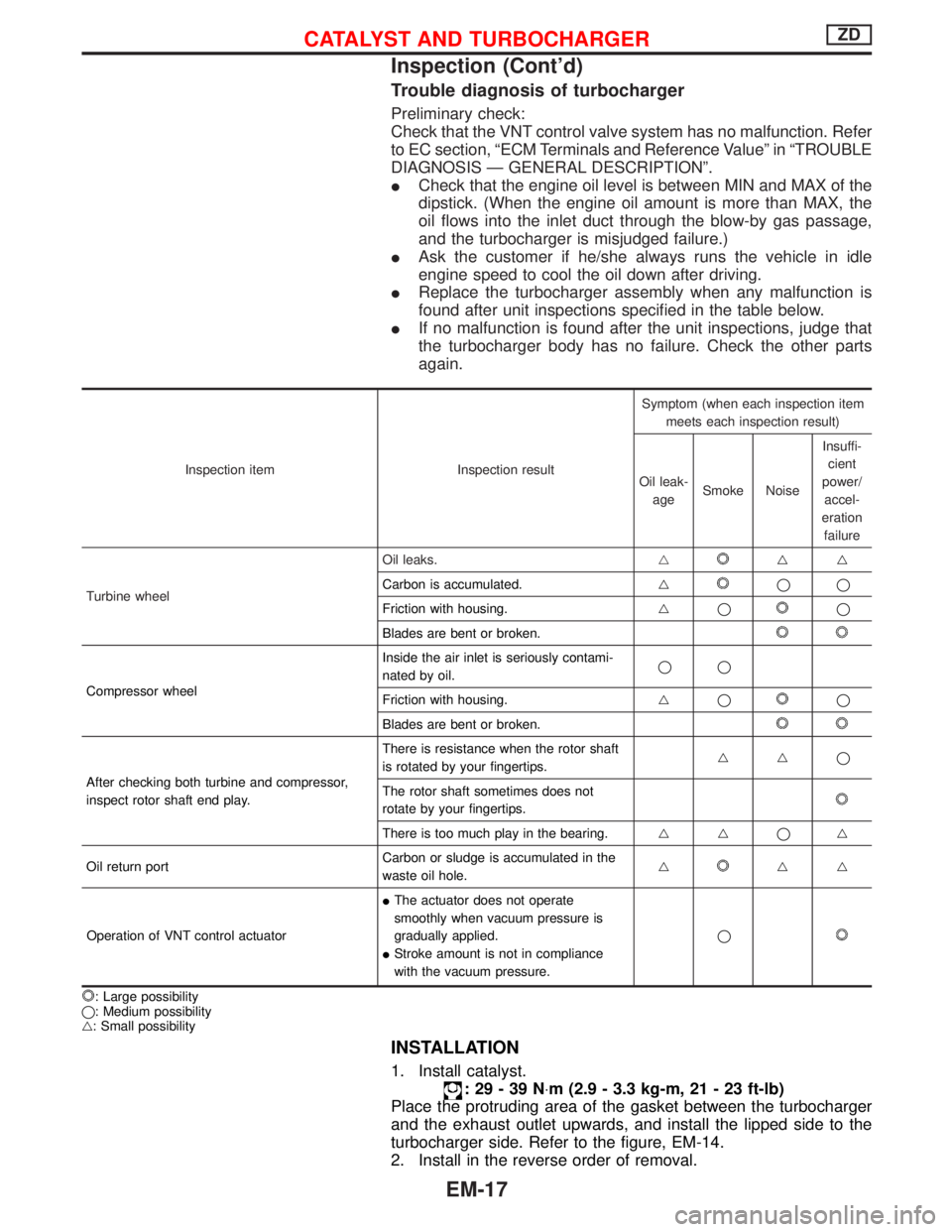

Trouble diagnosis of turbocharger

Preliminary check:

Check that the VNT control valve system has no malfunction. Refer

to EC section, ªECM Terminals and Reference Valueº in ªTROUBLE

DIAGNOSIS Ð GENERAL DESCRIPTIONº.

ICheck that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

IAsk the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

IReplace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

IIf no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item

meets each inspection result)

Oil leak-

ageSmoke NoiseInsuffi-

cient

power/

accel-

eration

failure

Turbine wheelOil leaks.g

gg

Carbon is accumulated.g

qq

Friction with housing.gq

q

Blades are bent or broken.

Compressor wheelInside the air inlet is seriously contami-

nated by oil.qq

Friction with housing.gqq

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play.There is resistance when the rotor shaft

is rotated by your fingertips.ggq

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing.ggqg

Oil return portCarbon or sludge is accumulated in the

waste oil hole.g

gg

Operation of VNT control actuatorIThe actuator does not operate

smoothly when vacuum pressure is

gradually applied.

IStroke amount is not in compliance

with the vacuum pressure.q

: Large possibility

q: Medium possibility

g: Small possibility

INSTALLATION

1. Install catalyst.

:29-39N×m (2.9 - 3.3 kg-m, 21 - 23 ft-lb)

Place the protruding area of the gasket between the turbocharger

and the exhaust outlet upwards, and install the lipped side to the

turbocharger side. Refer to the figure, EM-14.

2. Install in the reverse order of removal.

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-17

Page 1210 of 1767

q1Cylinder block

q

2Oil pump

q

3Camshaft bushing

q

4Front plate

q

5Camshaft gear

q

6Snap ring

q

7Piston pin

q

8Connecting rod bearing

q

9Oil jet

q

10Crank pulleyq

11Main bearing

q

12Oil pan

q

13Thrust washer

q

14Crankshaft

q

15Pilot bushing

q

16Flywheel

q

17Connecting rod

q

18Piston

q

19Piston ringq

20Camshaft

q

21Rear oil seal retainer

q

22Rear oil seal

q

23Rear plate

q

24Vacuum pump

q

25Dipstick

q

26Drain plug

q

27Timing gear case

q

28Idler gear

YEM036

ENGINE COMPONENTS Ð Internal PartsTD27Ti

EM-102

Page 1480 of 1767

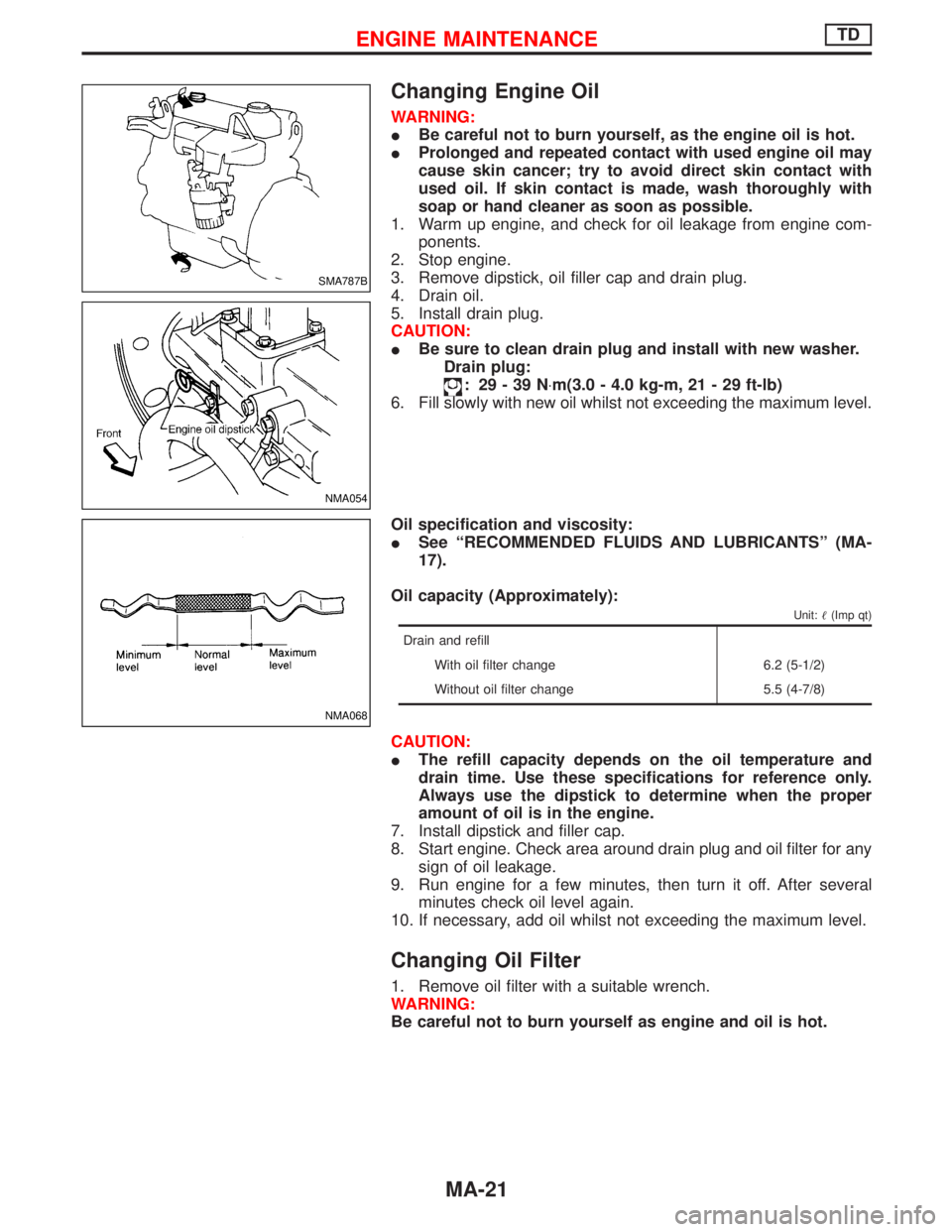

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine.

3. Remove dipstick, oil filler cap and drain plug.

4. Drain oil.

5. Install drain plug.

CAUTION:

IBe sure to clean drain plug and install with new washer.

Drain plug:

: 29-39N×m(3.0 - 4.0 kg-m, 21 - 29 ft-lb)

6. Fill slowly with new oil whilst not exceeding the maximum level.

Oil specification and viscosity:

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº (MA-

17).

Oil capacity (Approximately):

Unit:(Imp qt)

Drain and refill

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

CAUTION:

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

7. Install dipstick and filler cap.

8. Start engine. Check area around drain plug and oil filter for any

sign of oil leakage.

9. Run engine for a few minutes, then turn it off. After several

minutes check oil level again.

10. If necessary, add oil whilst not exceeding the maximum level.

Changing Oil Filter

1. Remove oil filter with a suitable wrench.

WARNING:

Be careful not to burn yourself as engine and oil is hot.

SMA787B

NMA054

NMA068

ENGINE MAINTENANCETD

MA-21

Page 1489 of 1767

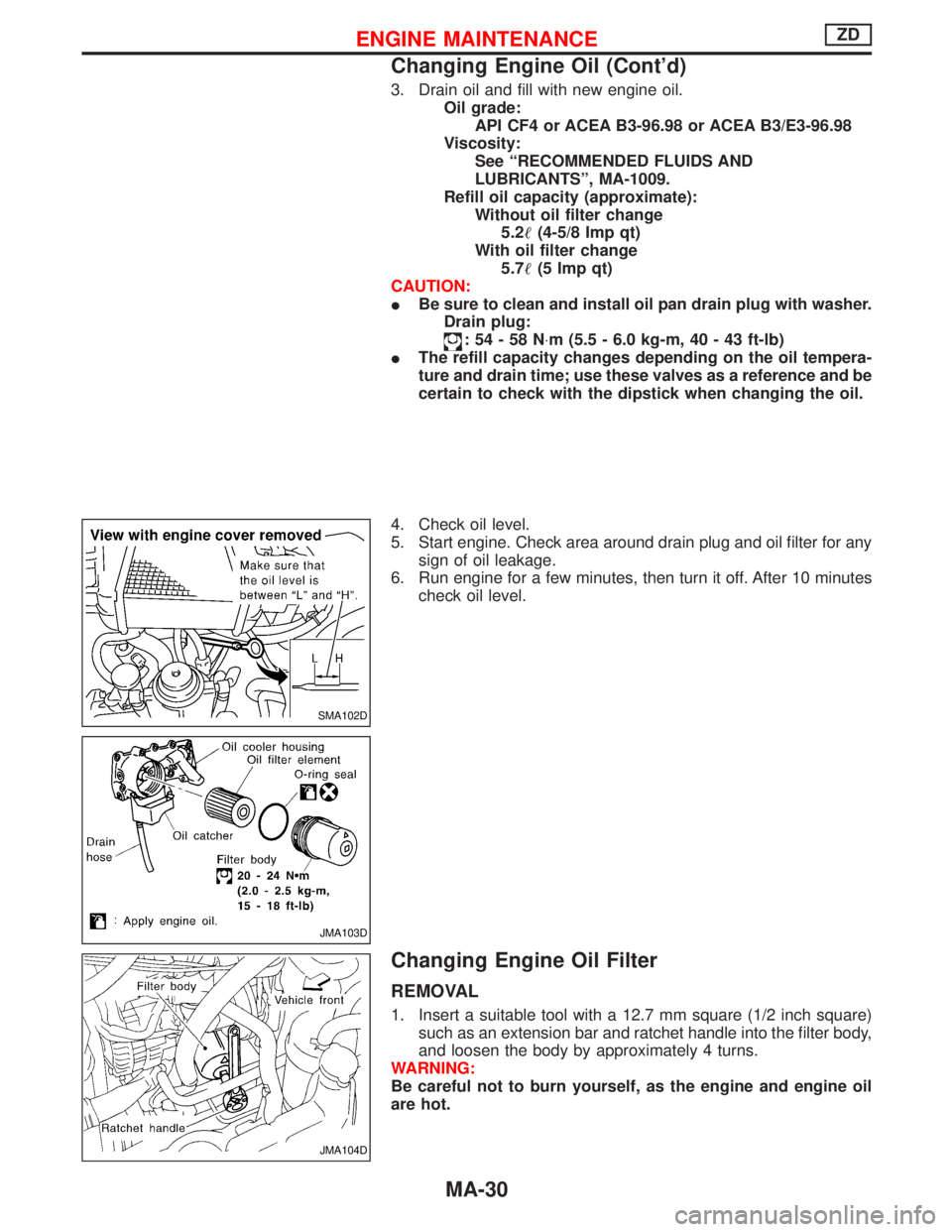

3. Drain oil and fill with new engine oil.

Oil grade:

API CF4 or ACEA B3-96.98 or ACEA B3/E3-96.98

Viscosity:

See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate):

Without oil filter change

5.2(4-5/8 Imp qt)

With oil filter change

5.7(5 Imp qt)

CAUTION:

IBe sure to clean and install oil pan drain plug with washer.

Drain plug:

:54-58N×m (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

IThe refill capacity changes depending on the oil tempera-

ture and drain time; use these valves as a reference and be

certain to check with the dipstick when changing the oil.

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for any

sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 minutes

check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)

such as an extension bar and ratchet handle into the filter body,

and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-30