seat adjustment NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 203 of 1767

BRAKE SYSTEM

SECTION

BR

CONTENTS

PRECAUTIONS AND PREPARATION............................3

Supplement Restraint System (SRS)²AIR BAG²

and²SEAT BELT PRE-TENSIONER².........................3

Precautions ..................................................................3

Preparation ..................................................................4

CHECK AND ADJUSTMENT..........................................5

Checking Brake Fluid Level.........................................5

Checking Brake Line ...................................................5

Changing Brake Fluid ..................................................5

Brake Burnishing Procedure........................................5

BRAKE HYDRAULIC LINE.............................................6

Bleeding Brake System ...............................................8

Removal .......................................................................9

Inspection.....................................................................9

Installation ....................................................................9

LOAD SENSING VALVE...............................................10

Removal and Installation ...........................................10

Removal ..................................................................... 11

Installation .................................................................. 11

Inspection and Adjustment ........................................12

BRAKE PEDAL AND BRACKET..................................14

Removal and Installation ...........................................14

Inspection...................................................................15

Adjustment .................................................................15

MASTER CYLINDER.....................................................16

Removal .....................................................................16

Installation ..................................................................16

BRAKE BOOSTER........................................................17

Removal and Installation ...........................................17

Inspection...................................................................17

Installation ..................................................................18

VACUUM HOSE.............................................................19

Removal and Installation ...........................................19

Inspection...................................................................21

VACUUM PUMP (TD27Ti engine model)....................23

Removal and Installation ...........................................23

Inspection...................................................................23VACUUM PUMP (ZD30DDTi engine model)...............25

Removal and Installation ...........................................25

FRONT DISC BRAKE...................................................26

Pad Replacement ......................................................26

Removal .....................................................................27

Disassembly...............................................................27

Inspection...................................................................27

Assembly ...................................................................28

Inspection...................................................................28

Installation ..................................................................30

REAR DRUM BRAKE...................................................31

Removal .....................................................................32

Shoe Replacement ....................................................33

Inspection...................................................................33

Installation ..................................................................33

PARKING BRAKE CONTROL......................................35

Removal and Installation ...........................................35

Inspection...................................................................35

Adjustment .................................................................35

ANTI-LOCK BRAKE SYSTEM......................................37

Purpose......................................................................37

Operation ...................................................................37

ABS Hydraulic Circuit ................................................37

System Description ....................................................38

Removal and Installation ...........................................42

TROUBLE DIAGNOSES...............................................47

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................47

Component Parts and Harness Connector

Location .....................................................................48

Circuit Diagram for Quick Pinpoint Check.................49

Wiring Diagram - ABS - .............................................50

CONSULT-II ...............................................................58

CONSULT-II Inspection Procedure............................59

Preliminary Check......................................................65

Ground Circuit Check ................................................66

Diagnostic Procedure 1 (Not self-diagnostic item) ....67

Page 205 of 1767

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

ITo clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

INever use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

IUse flare nut wrench when removing and installing brake

tubes.

IAlways torque brake lines when installing.

IBurnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

IClean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

IAvoid prolonged and repeated skin contact with brake

fluid.

IWear protective clothing, including impervious gloves.

IWhere there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

Page 215 of 1767

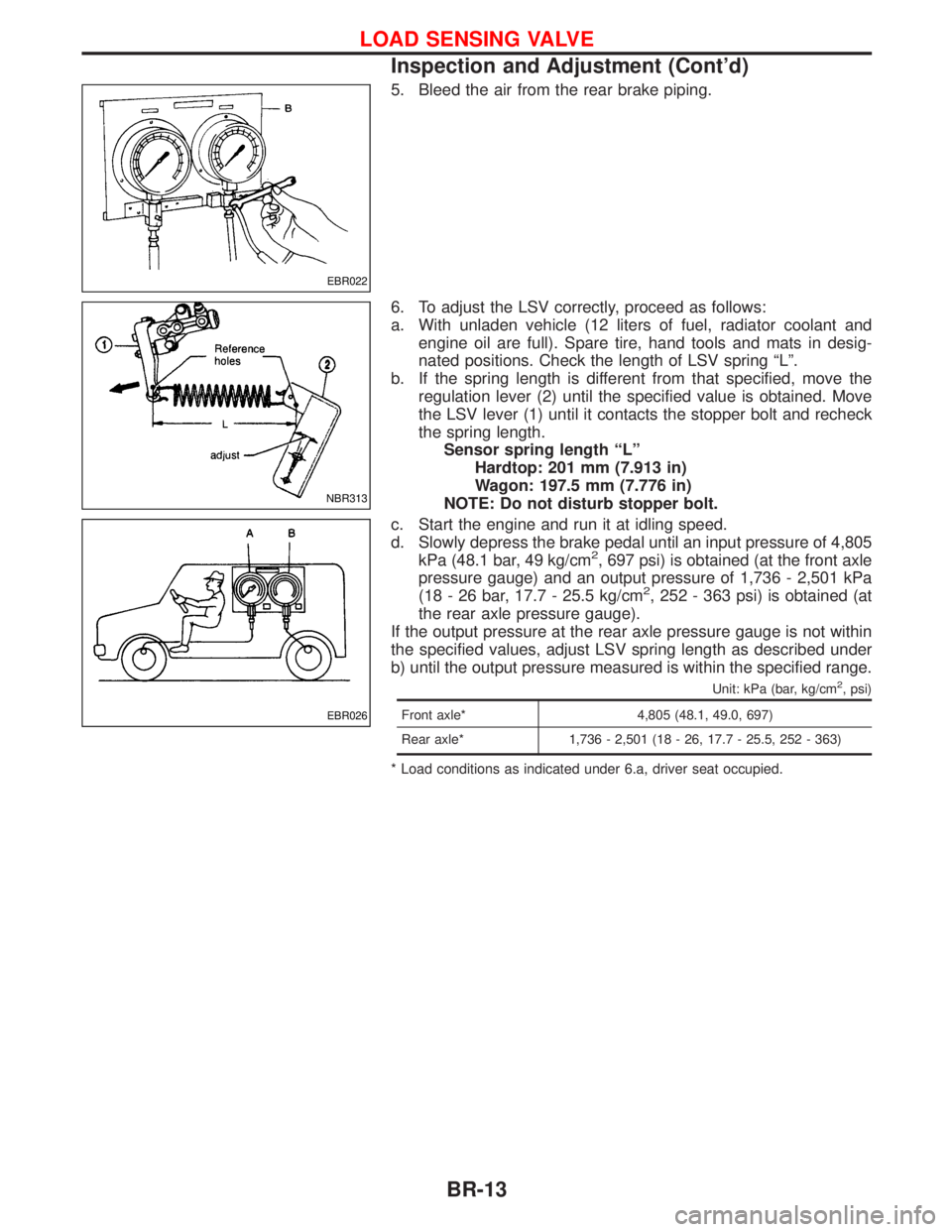

5. Bleed the air from the rear brake piping.

6. To adjust the LSV correctly, proceed as follows:

a. With unladen vehicle (12 liters of fuel, radiator coolant and

engine oil are full). Spare tire, hand tools and mats in desig-

nated positions. Check the length of LSV spring ªLº.

b. If the spring length is different from that specified, move the

regulation lever (2) until the specified value is obtained. Move

the LSV lever (1) until it contacts the stopper bolt and recheck

the spring length.

Sensor spring length ªLº

Hardtop: 201 mm (7.913 in)

Wagon: 197.5 mm (7.776 in)

NOTE: Do not disturb stopper bolt.

c. Start the engine and run it at idling speed.

d. Slowly depress the brake pedal until an input pressure of 4,805

kPa (48.1 bar, 49 kg/cm

2, 697 psi) is obtained (at the front axle

pressure gauge) and an output pressure of 1,736 - 2,501 kPa

(18 - 26 bar, 17.7 - 25.5 kg/cm

2, 252 - 363 psi) is obtained (at

the rear axle pressure gauge).

If the output pressure at the rear axle pressure gauge is not within

the specified values, adjust LSV spring length as described under

b) until the output pressure measured is within the specified range.

Unit: kPa (bar, kg/cm2, psi)

Front axle* 4,805 (48.1, 49.0, 697)

Rear axle* 1,736 - 2,501 (18 - 26, 17.7 - 25.5, 252 - 363)

* Load conditions as indicated under 6.a, driver seat occupied.

EBR022

NBR313

EBR026

LOAD SENSING VALVE

Inspection and Adjustment (Cont'd)

BR-13

Page 1109 of 1767

ENGINE MECHANICAL

SECTION

EM

CONTENTS

ZD

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE....10

INTERCOOLER............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER...........................................22

Removal and Installation ...........................................22

VACUUM PUMP............................................................24

Removal and Installation ...........................................24

TIMING CHAIN..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT..........................................50

CYLINDER HEAD..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL.......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK.......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS)..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ..........................................................................84

Valve Seat..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

Page 1223 of 1767

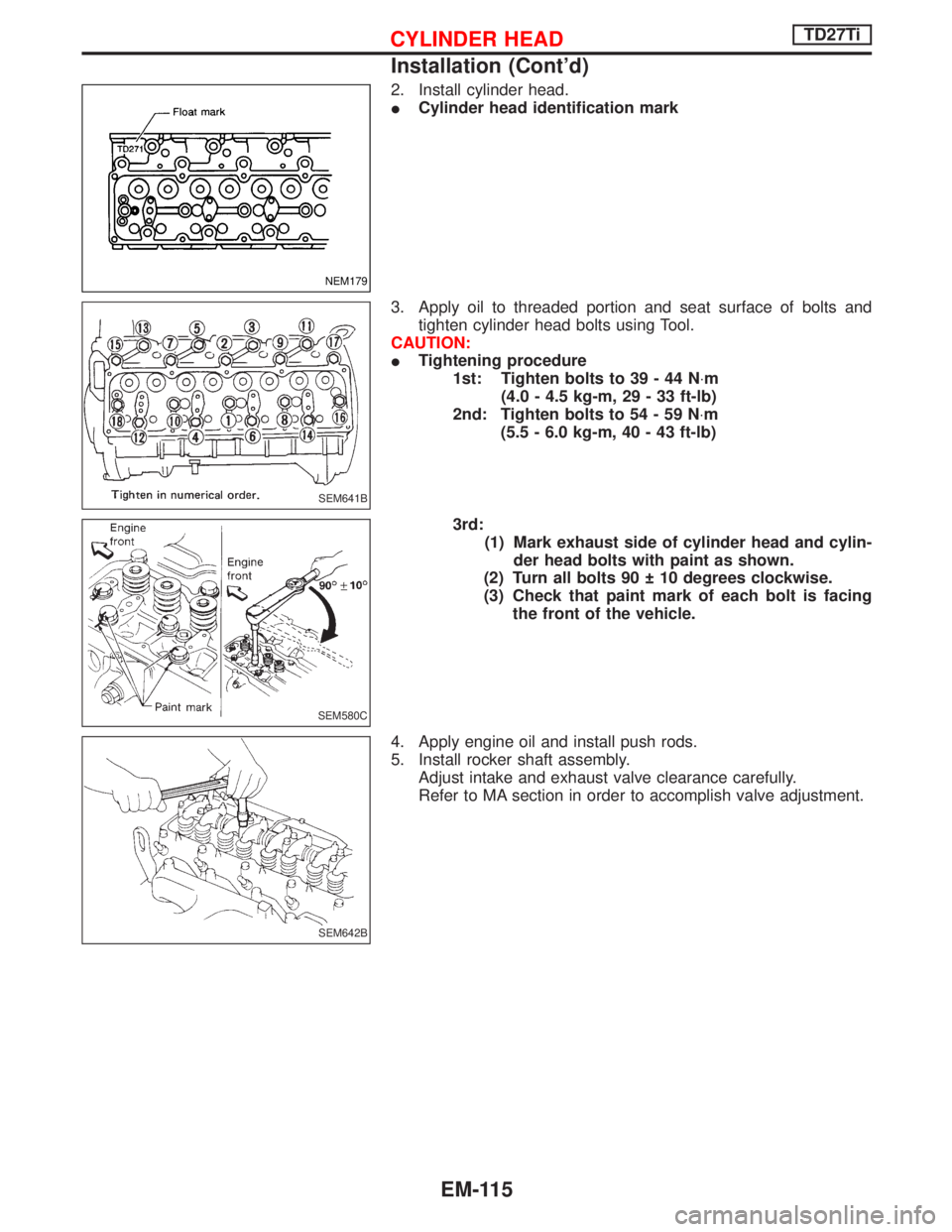

2. Install cylinder head.

ICylinder head identification mark

3. Apply oil to threaded portion and seat surface of bolts and

tighten cylinder head bolts using Tool.

CAUTION:

ITightening procedure

1st: Tighten bolts to 39 - 44 N×m

(4.0 - 4.5 kg-m, 29 - 33 ft-lb)

2nd: Tighten bolts to 54 - 59 N×m

(5.5 - 6.0 kg-m, 40 - 43 ft-lb)

3rd:

(1) Mark exhaust side of cylinder head and cylin-

der head bolts with paint as shown.

(2) Turn all bolts 90 10 degrees clockwise.

(3) Check that paint mark of each bolt is facing

the front of the vehicle.

4. Apply engine oil and install push rods.

5. Install rocker shaft assembly.

Adjust intake and exhaust valve clearance carefully.

Refer to MA section in order to accomplish valve adjustment.

NEM179

SEM641B

SEM580C

SEM642B

CYLINDER HEADTD27Ti

Installation (Cont'd)

EM-115

Page 1253 of 1767

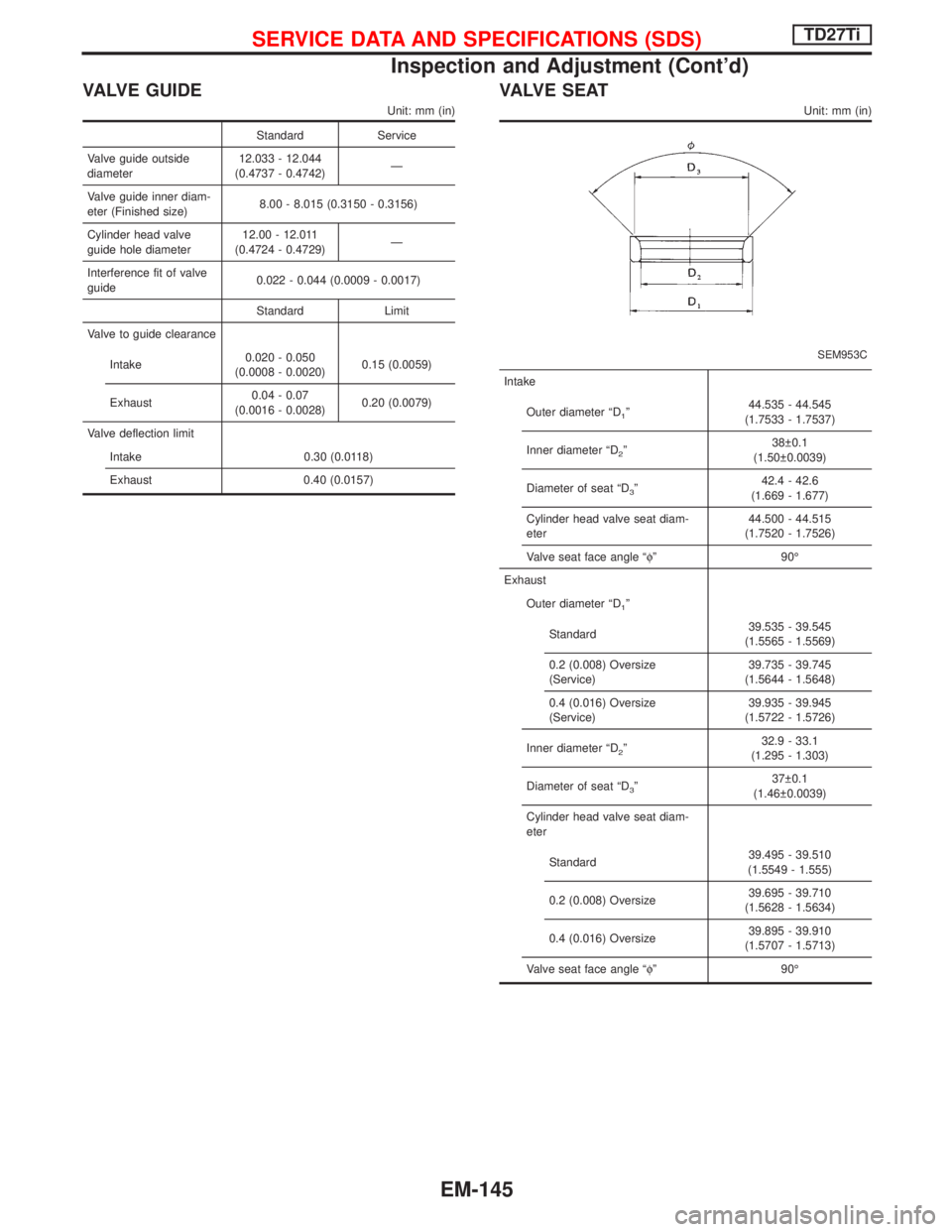

VALVE GUIDE

Unit: mm (in)

Standard Service

Valve guide outside

diameter12.033 - 12.044

(0.4737 - 0.4742)Ð

Valve guide inner diam-

eter (Finished size)8.00 - 8.015 (0.3150 - 0.3156)

Cylinder head valve

guide hole diameter12.00 - 12.011

(0.4724 - 0.4729)Ð

Interference fit of valve

guide0.022 - 0.044 (0.0009 - 0.0017)

Standard Limit

Valve to guide clearance

Intake0.020 - 0.050

(0.0008 - 0.0020)0.15 (0.0059)

Exhaust0.04 - 0.07

(0.0016 - 0.0028)0.20 (0.0079)

Valve deflection limit

Intake 0.30 (0.0118)

Exhaust 0.40 (0.0157)

VA LV E S E AT

Unit: mm (in)

SEM953C

Intake

Outer diameter ªD

1º44.535 - 44.545

(1.7533 - 1.7537)

Inner diameter ªD

2º38 0.1

(1.50 0.0039)

Diameter of seat ªD

3º42.4 - 42.6

(1.669 - 1.677)

Cylinder head valve seat diam-

eter44.500 - 44.515

(1.7520 - 1.7526)

Valve seat face angle ªfº 90É

Exhaust

Outer diameter ªD

1º

Standard39.535 - 39.545

(1.5565 - 1.5569)

0.2 (0.008) Oversize

(Service)39.735 - 39.745

(1.5644 - 1.5648)

0.4 (0.016) Oversize

(Service)39.935 - 39.945

(1.5722 - 1.5726)

Inner diameter ªD

2º32.9 - 33.1

(1.295 - 1.303)

Diameter of seat ªD

3º37 0.1

(1.46 0.0039)

Cylinder head valve seat diam-

eter

Standard39.495 - 39.510

(1.5549 - 1.555)

0.2 (0.008) Oversize39.695 - 39.710

(1.5628 - 1.5634)

0.4 (0.016) Oversize39.895 - 39.910

(1.5707 - 1.5713)

Valve seat face angle ªfº 90É

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-145

Page 1254 of 1767

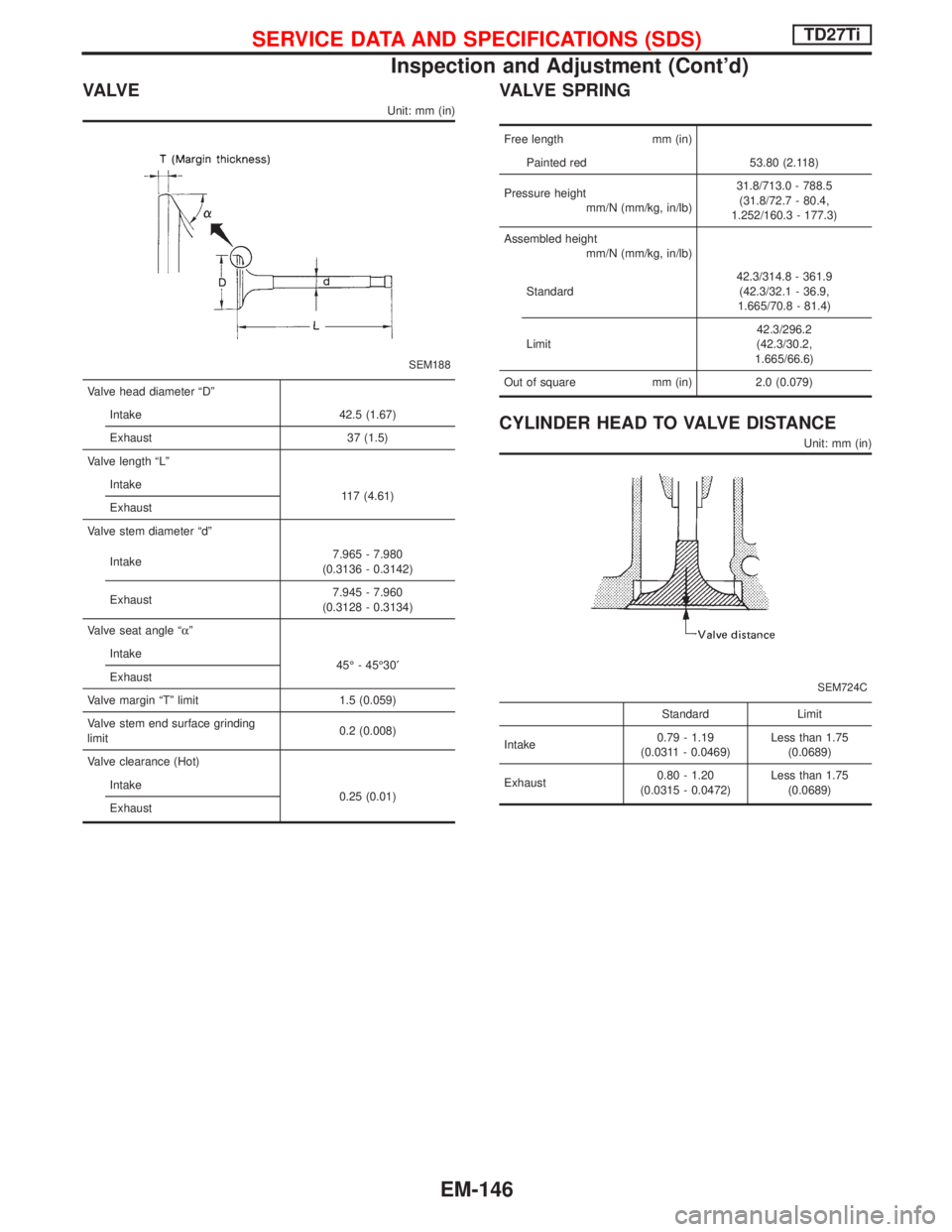

VA LV E

Unit: mm (in)

SEM188

Valve head diameter ªDº

Intake 42.5 (1.67)

Exhaust 37 (1.5)

Valve length ªLº

Intake

117 (4.61)

Exhaust

Valve stem diameter ªdº

Intake7.965 - 7.980

(0.3136 - 0.3142)

Exhaust7.945 - 7.960

(0.3128 - 0.3134)

Valve seat angle ªaº

Intake

45É - 45É30¢

Exhaust

Valve margin ªTº limit 1.5 (0.059)

Valve stem end surface grinding

limit0.2 (0.008)

Valve clearance (Hot)

Intake

0.25 (0.01)

Exhaust

VALVE SPRING

Free length mm (in)

Painted red 53.80 (2.118)

Pressure height

mm/N (mm/kg, in/lb)31.8/713.0 - 788.5

(31.8/72.7 - 80.4,

1.252/160.3 - 177.3)

Assembled height

mm/N (mm/kg, in/lb)

Standard42.3/314.8 - 361.9

(42.3/32.1 - 36.9,

1.665/70.8 - 81.4)

Limit42.3/296.2

(42.3/30.2,

1.665/66.6)

Out of square mm (in) 2.0 (0.079)

CYLINDER HEAD TO VALVE DISTANCE

Unit: mm (in)

SEM724C

Standard Limit

Intake0.79 - 1.19

(0.0311 - 0.0469)Less than 1.75

(0.0689)

Exhaust0.80 - 1.20

(0.0315 - 0.0472)Less than 1.75

(0.0689)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-146

Page 1265 of 1767

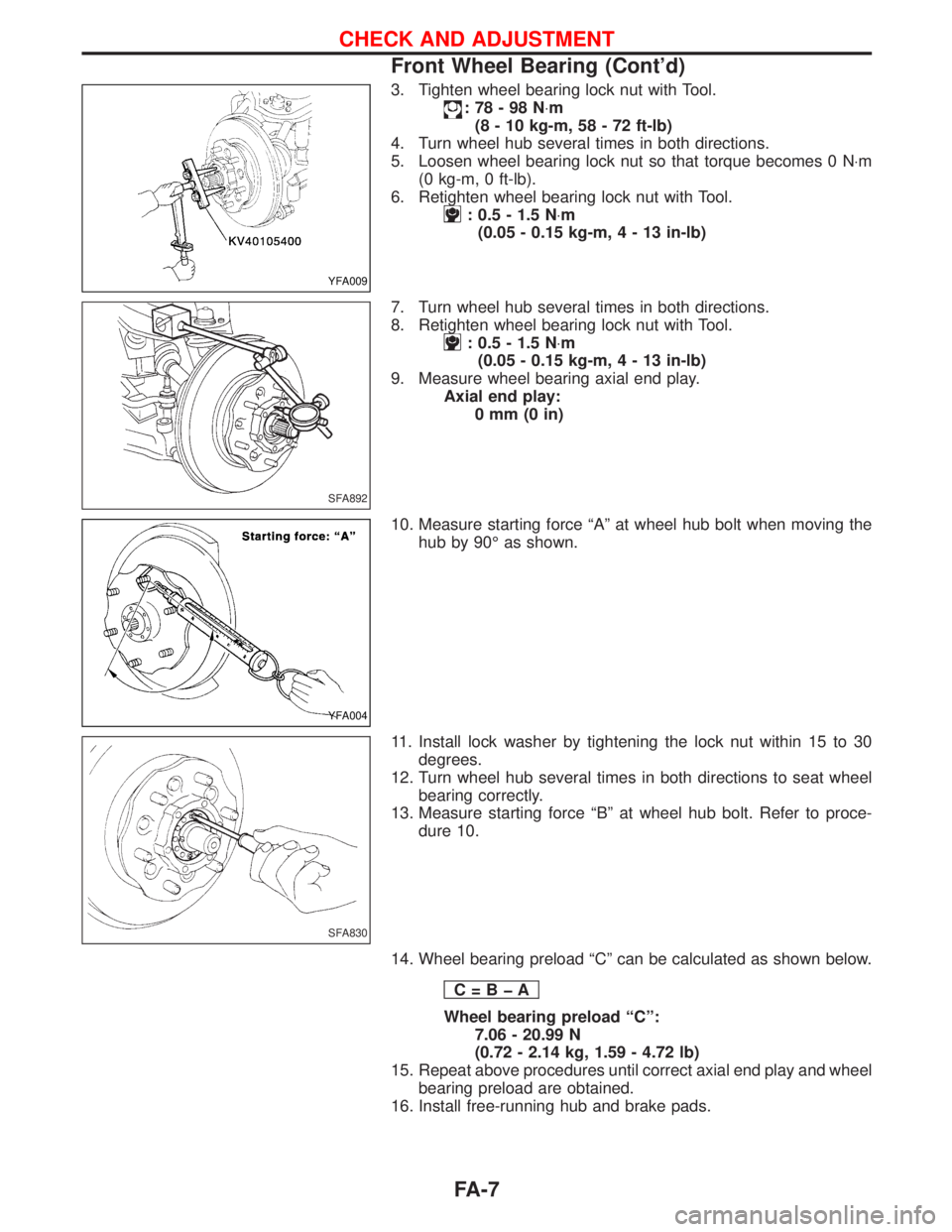

3. Tighten wheel bearing lock nut with Tool.

:78-98N×m

(8 - 10 kg-m, 58 - 72 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes 0 N×m

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

9. Measure wheel bearing axial end play.

Axial end play:

0mm(0in)

10. Measure starting force ªAº at wheel hub bolt when moving the

hub by 90É as shown.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N

(0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat above procedures until correct axial end play and wheel

bearing preload are obtained.

16. Install free-running hub and brake pads.

YFA009

SFA892

YFA004

SFA830

CHECK AND ADJUSTMENT

Front Wheel Bearing (Cont'd)

FA-7

Page 1424 of 1767

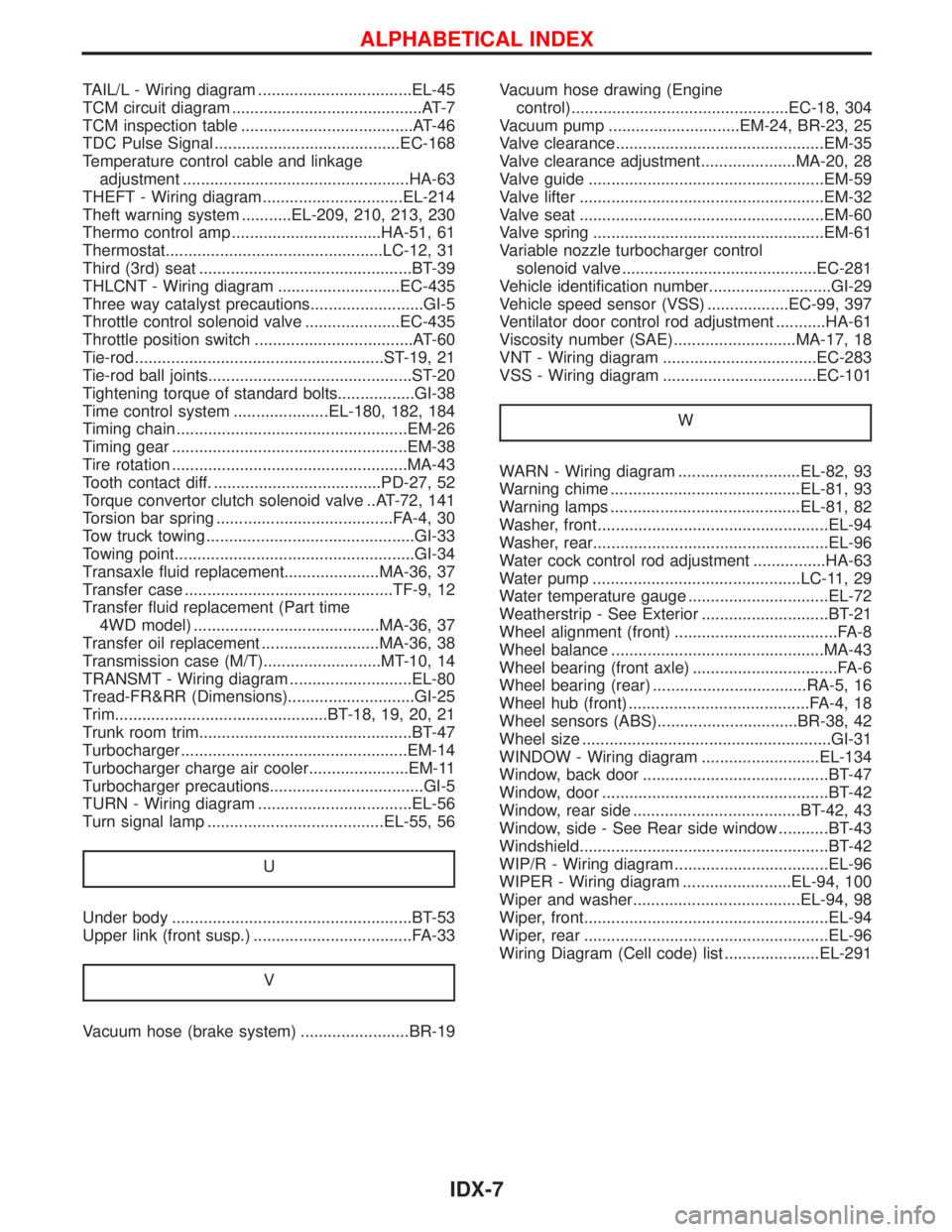

TAIL/L - Wiring diagram ..................................EL-45

TCM circuit diagram ..........................................AT-7

TCM inspection table ......................................AT-46

TDC Pulse Signal .........................................EC-168

Temperature control cable and linkage

adjustment ..................................................HA-63

THEFT - Wiring diagram...............................EL-214

Theft warning system ...........EL-209, 210, 213, 230

Thermo control amp .................................HA-51, 61

Thermostat................................................LC-12, 31

Third (3rd) seat ...............................................BT-39

THLCNT - Wiring diagram ...........................EC-435

Three way catalyst precautions.........................GI-5

Throttle control solenoid valve .....................EC-435

Throttle position switch ...................................AT-60

Tie-rod .......................................................ST-19, 21

Tie-rod ball joints.............................................ST-20

Tightening torque of standard bolts.................GI-38

Time control system .....................EL-180, 182, 184

Timing chain ...................................................EM-26

Timing gear ....................................................EM-38

Tire rotation ....................................................MA-43

Tooth contact diff. .....................................PD-27, 52

Torque convertor clutch solenoid valve ..AT-72, 141

Torsion bar spring .......................................FA-4, 30

Tow truck towing ..............................................GI-33

Towing point.....................................................GI-34

Transaxle fluid replacement.....................MA-36, 37

Transfer case ..............................................TF-9, 12

Transfer fluid replacement (Part time

4WD model) .........................................MA-36, 37

Transfer oil replacement ..........................MA-36, 38

Transmission case (M/T)..........................MT-10, 14

TRANSMT - Wiring diagram ...........................EL-80

Tread-FR&RR (Dimensions)............................GI-25

Trim...............................................BT-18, 19, 20, 21

Trunk room trim...............................................BT-47

Turbocharger ..................................................EM-14

Turbocharger charge air cooler......................EM-11

Turbocharger precautions..................................GI-5

TURN - Wiring diagram ..................................EL-56

Turn signal lamp .......................................EL-55, 56

U

Under body .....................................................BT-53

Upper link (front susp.) ...................................FA-33

V

Vacuum hose (brake system) ........................BR-19Vacuum hose drawing (Engine

control)................................................EC-18, 304

Vacuum pump .............................EM-24, BR-23, 25

Valve clearance..............................................EM-35

Valve clearance adjustment.....................MA-20, 28

Valve guide ....................................................EM-59

Valve lifter ......................................................EM-32

Valve seat ......................................................EM-60

Valve spring ...................................................EM-61

Variable nozzle turbocharger control

solenoid valve ...........................................EC-281

Vehicle identification number...........................GI-29

Vehicle speed sensor (VSS) ..................EC-99, 397

Ventilator door control rod adjustment ...........HA-61

Viscosity number (SAE)...........................MA-17, 18

VNT - Wiring diagram ..................................EC-283

VSS - Wiring diagram ..................................EC-101

W

WARN - Wiring diagram ...........................EL-82, 93

Warning chime ..........................................EL-81, 93

Warning lamps ..........................................EL-81, 82

Washer, front ...................................................EL-94

Washer, rear....................................................EL-96

Water cock control rod adjustment ................HA-63

Water pump ..............................................LC-11, 29

Water temperature gauge ...............................EL-72

Weatherstrip - See Exterior ............................BT-21

Wheel alignment (front) ....................................FA-8

Wheel balance ...............................................MA-43

Wheel bearing (front axle) ................................FA-6

Wheel bearing (rear) ..................................RA-5, 16

Wheel hub (front) ........................................FA-4, 18

Wheel sensors (ABS)...............................BR-38, 42

Wheel size .......................................................GI-31

WINDOW - Wiring diagram ..........................EL-134

Window, back door .........................................BT-47

Window, door ..................................................BT-42

Window, rear side .....................................BT-42, 43

Window, side - See Rear side window ...........BT-43

Windshield.......................................................BT-42

WIP/R - Wiring diagram ..................................EL-96

WIPER - Wiring diagram ........................EL-94, 100

Wiper and washer.....................................EL-94, 98

Wiper, front......................................................EL-94

Wiper, rear ......................................................EL-96

Wiring Diagram (Cell code) list .....................EL-291

ALPHABETICAL INDEX

IDX-7

Page 1570 of 1767

![NISSAN TERRANO 2002 Service Repair Manual 3. Measure how far under the standard thickness [20 mm (0.79

in)] the side bearings are.

It will require tools shown below.

q

1Weight Block (ST32501000)

q

2Master Gauge (KV38101900)

q

3Base Plate

q

4D NISSAN TERRANO 2002 Service Repair Manual 3. Measure how far under the standard thickness [20 mm (0.79

in)] the side bearings are.

It will require tools shown below.

q

1Weight Block (ST32501000)

q

2Master Gauge (KV38101900)

q

3Base Plate

q

4D](/img/5/57393/w960_57393-1569.png)

3. Measure how far under the standard thickness [20 mm (0.79

in)] the side bearings are.

It will require tools shown below.

q

1Weight Block (ST32501000)

q

2Master Gauge (KV38101900)

q

3Base Plate

q

4Dial Indicator

4. Place the outer race of the opposite side bearing to the mea-

sured.

5. Place a weight block on the outer race, and a master gauge on

the block.

Tool number:

q

AST32501000

q

BKV38101900

6. Adjust dial indicator scale to zero.

7. Carefully slide master gauge and weight block out from under

dial indicator.

8. Lubricate side bearing and place the bearing outer race and

inner cone to be measured on the opposite side outer race.

If the bearing assembly is placed on the base plate, the bear-

ing width cannot be accurately determined due to its cage

being in contact with the base plate.

9. Place weight block (ST32501000) on side bearing.

10. Slide dial indicator on weight block.

11. Turn weight block a few times to ensure that bearing is prop-

erly seated.

12. Read dial indicator.

INormal indication:

0.10 - 0.30 mm (0.0039 - 0.0118 in)

IIf the needle fluctuates erratically then bearing is either dirty or

defective and should be cleaned or replaced.

SPD048

SPD150

SPD050

SPD591

SPD051

ADJUSTMENT (R180A)

Side Bearing Preload (Cont'd)

PD-25