suspension NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1 of 1767

Edition: February 2002

Release: February 2002 (01)

Publication No.: SM2E00-1R20E0E

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE N.V.

NISSAN EUROPE N.V.

Produced in The Netherlands

QUICK REFERENCE INDEX

Page 232 of 1767

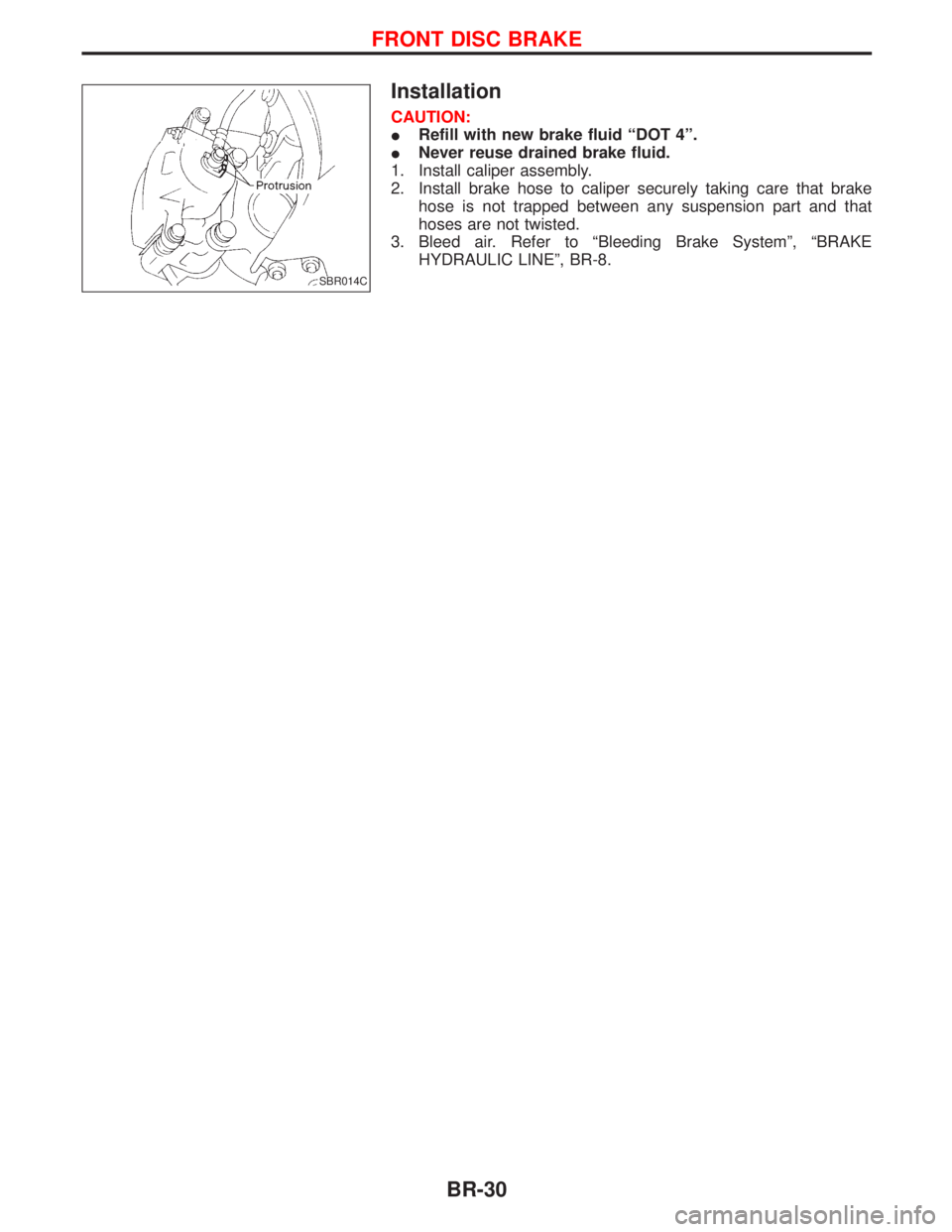

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Install caliper assembly.

2. Install brake hose to caliper securely taking care that brake

hose is not trapped between any suspension part and that

hoses are not twisted.

3. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

SBR014C

FRONT DISC BRAKE

BR-30

Page 1259 of 1767

FRONT AXLE & FRONT SUSPENSION

SECTION

FA

CONTENTS

PRECAUTIONS...............................................................2

PREPARATION................................................................3

FRONT AXLE AND FRONT SUSPENSION...................4

CHECK AND ADJUSTMENT..........................................5

Front Axle and Front Suspension Parts ......................5

Front Wheel Bearing....................................................6

Front Wheel Alignment ................................................8

Drive Shaft .................................................................12

FRONT AXLE................................................................13

FRONT AXLE - Auto-lock Free-running Hub.............14

Removal and Installation ...........................................14

Inspection...................................................................14

Trouble-shooting ........................................................15

FRONT AXLE - Wheel Hub and Rotor Disc...............18

Removal and Installation ...........................................18

Disassembly...............................................................18

Inspection...................................................................19

Assembly ...................................................................19

FRONT AXLE - Knuckle Spindle.................................20

Removal .....................................................................20Inspection...................................................................21

Installation ..................................................................21

FRONT AXLE - Drive Shaft..........................................22

Removal and Installation ...........................................22

Removal .....................................................................22

Disassembly...............................................................24

Inspection...................................................................25

Assembly ...................................................................25

Installation ..................................................................28

FRONT SUSPENSION..................................................29

Shock Absorber .........................................................30

Torsion Bar.................................................................30

Stabilizer Bar .............................................................33

Upper Link .................................................................33

Compression Rod ......................................................35

Lower Link .................................................................35

Upper Ball Joint and Lower Ball Joint .......................36

SERVICE DATA AND SPECIFICATIONS (SDS)..........38

General Specifications ...............................................38

Inspection and Adjustment ........................................39

Page 1260 of 1767

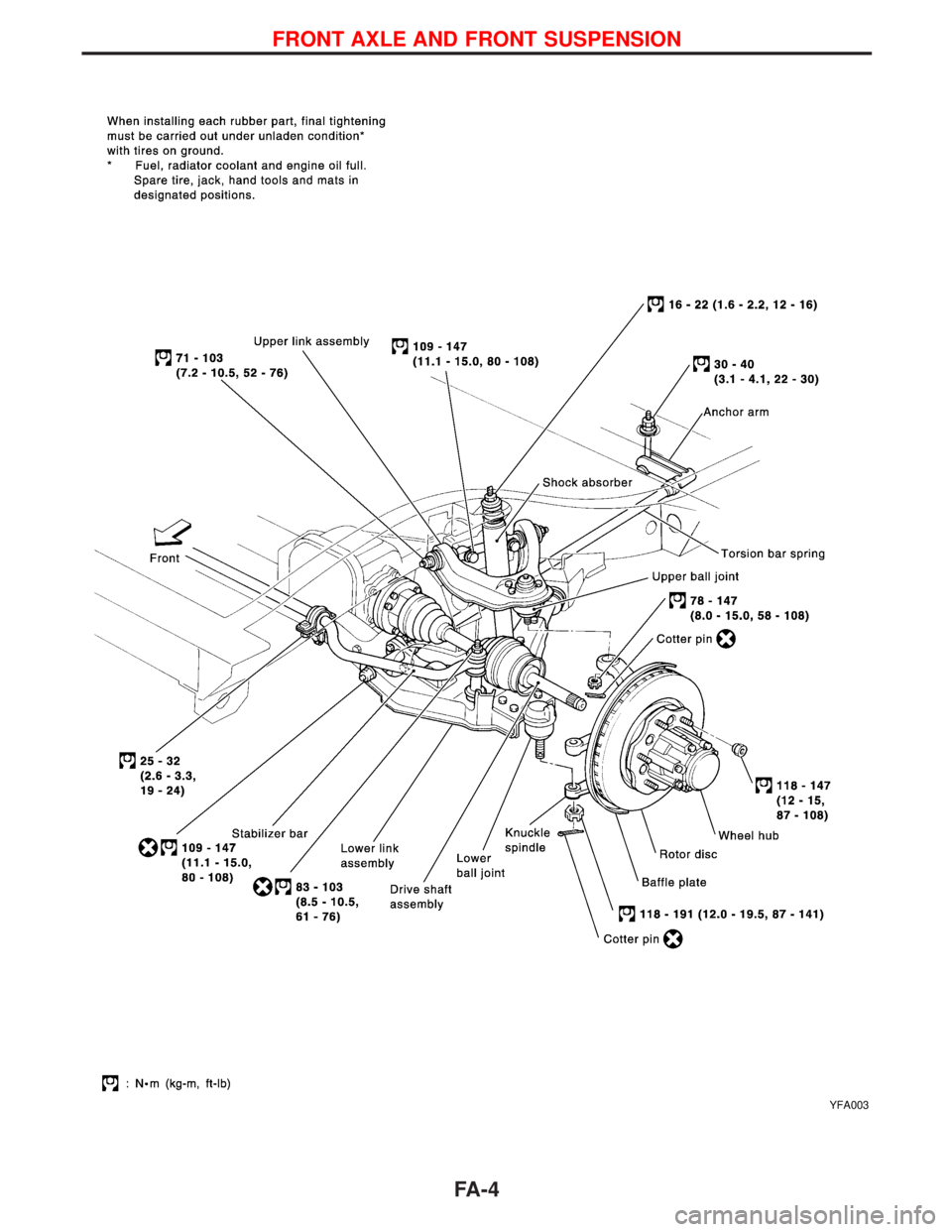

(1) When installing each rubber part, final tightening must be car-

ried out under unladen condition * with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

(2) When removing each suspension part, check wheel alignment

and adjust if necessary.

(3) Use Tool when removing or installing brake tubes.

SBR820B

PRECAUTIONS

FA-2

Page 1262 of 1767

YFA003

FRONT AXLE AND FRONT SUSPENSION

FA-4

Page 1263 of 1767

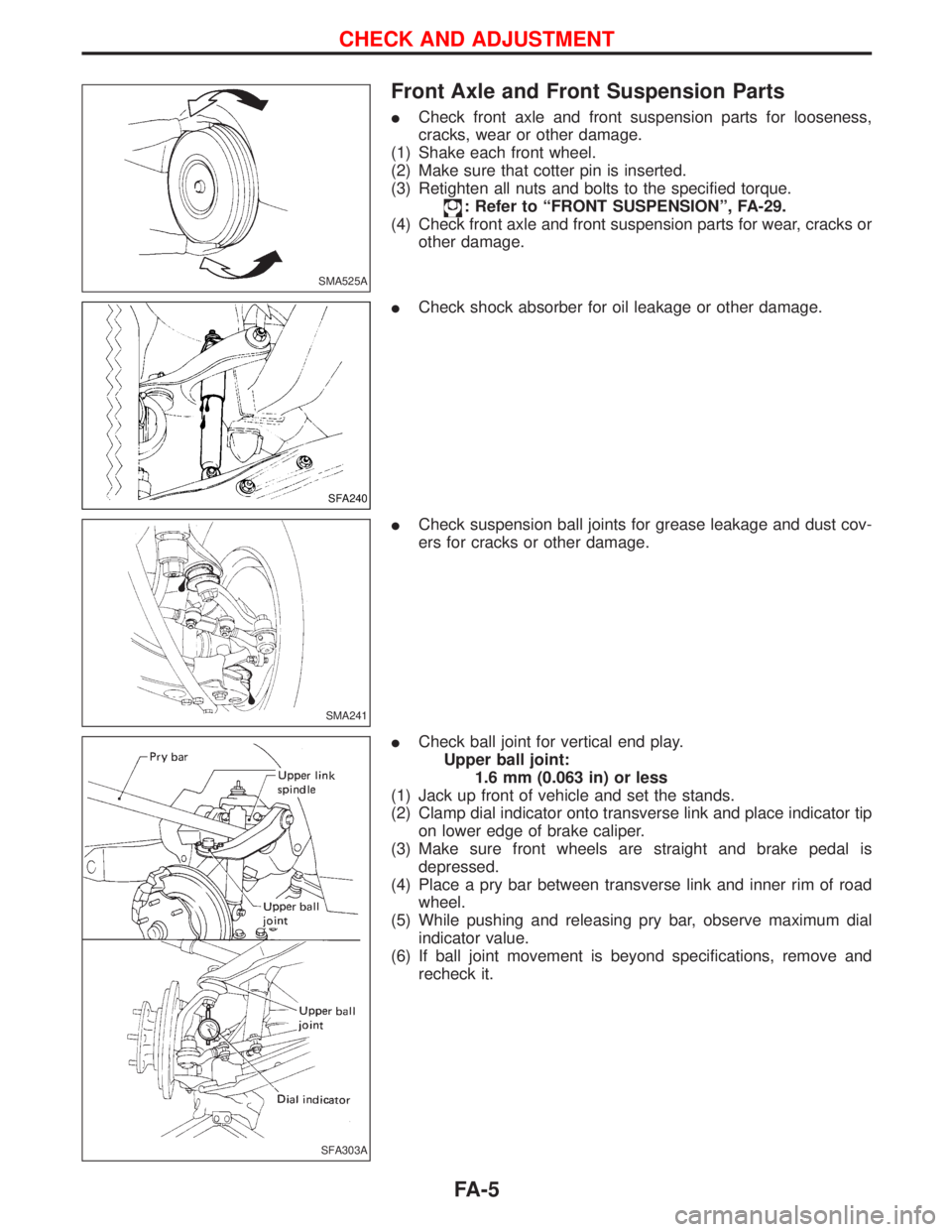

Front Axle and Front Suspension Parts

ICheck front axle and front suspension parts for looseness,

cracks, wear or other damage.

(1) Shake each front wheel.

(2) Make sure that cotter pin is inserted.

(3) Retighten all nuts and bolts to the specified torque.

: Refer to ªFRONT SUSPENSIONº, FA-29.

(4) Check front axle and front suspension parts for wear, cracks or

other damage.

ICheck shock absorber for oil leakage or other damage.

ICheck suspension ball joints for grease leakage and dust cov-

ers for cracks or other damage.

ICheck ball joint for vertical end play.

Upper ball joint:

1.6 mm (0.063 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

(3) Make sure front wheels are straight and brake pedal is

depressed.

(4) Place a pry bar between transverse link and inner rim of road

wheel.

(5) While pushing and releasing pry bar, observe maximum dial

indicator value.

(6) If ball joint movement is beyond specifications, remove and

recheck it.

SMA525A

SFA240

SMA241

SFA303A

CHECK AND ADJUSTMENT

FA-5

Page 1264 of 1767

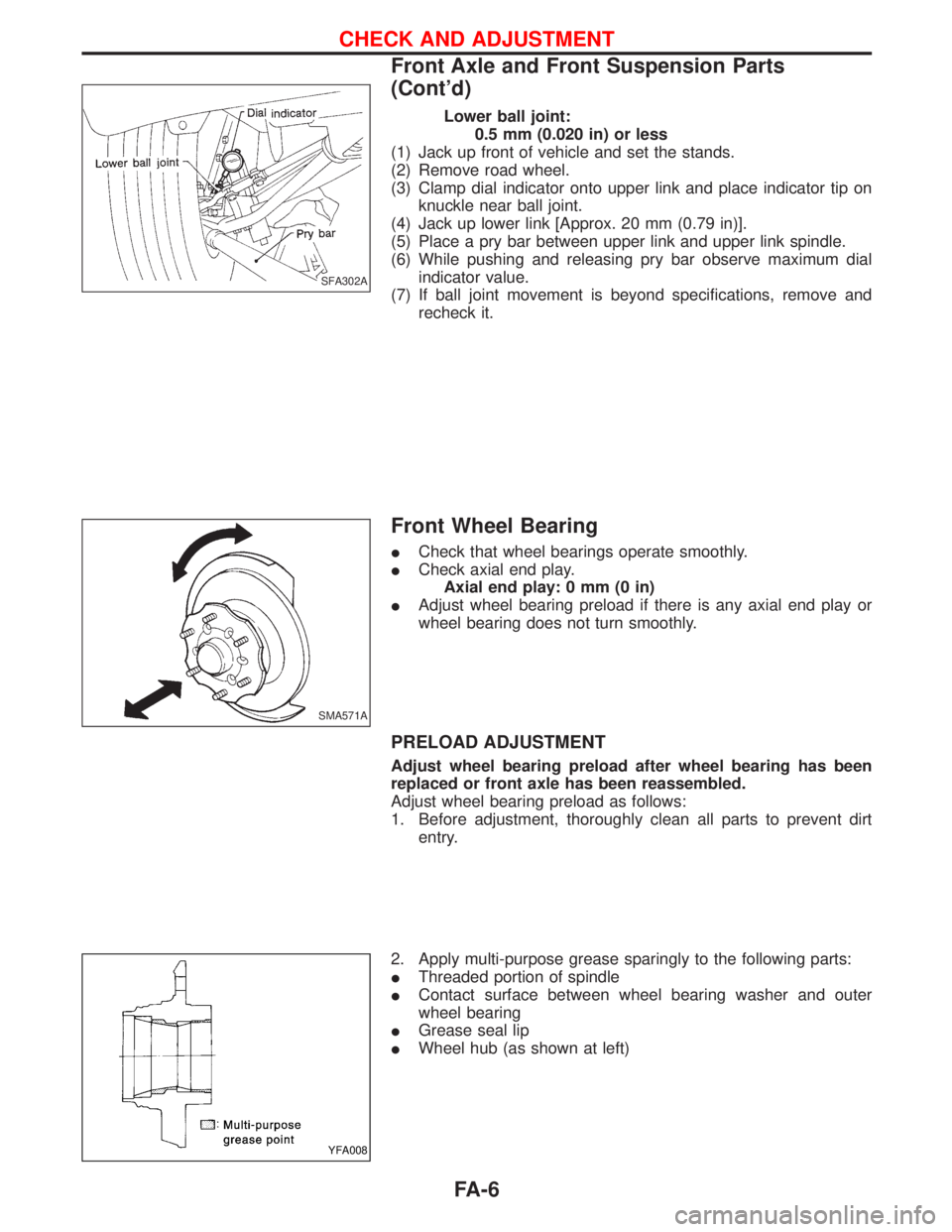

Lower ball joint:

0.5 mm (0.020 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Remove road wheel.

(3) Clamp dial indicator onto upper link and place indicator tip on

knuckle near ball joint.

(4) Jack up lower link [Approx. 20 mm (0.79 in)].

(5) Place a pry bar between upper link and upper link spindle.

(6) While pushing and releasing pry bar observe maximum dial

indicator value.

(7) If ball joint movement is beyond specifications, remove and

recheck it.

Front Wheel Bearing

ICheck that wheel bearings operate smoothly.

ICheck axial end play.

Axial end play: 0 mm (0 in)

IAdjust wheel bearing preload if there is any axial end play or

wheel bearing does not turn smoothly.

PRELOAD ADJUSTMENT

Adjust wheel bearing preload after wheel bearing has been

replaced or front axle has been reassembled.

Adjust wheel bearing preload as follows:

1. Before adjustment, thoroughly clean all parts to prevent dirt

entry.

2. Apply multi-purpose grease sparingly to the following parts:

IThreaded portion of spindle

IContact surface between wheel bearing washer and outer

wheel bearing

IGrease seal lip

IWheel hub (as shown at left)

SFA302A

SMA571A

YFA008

CHECK AND ADJUSTMENT

Front Axle and Front Suspension Parts

(Cont'd)

FA-6

Page 1266 of 1767

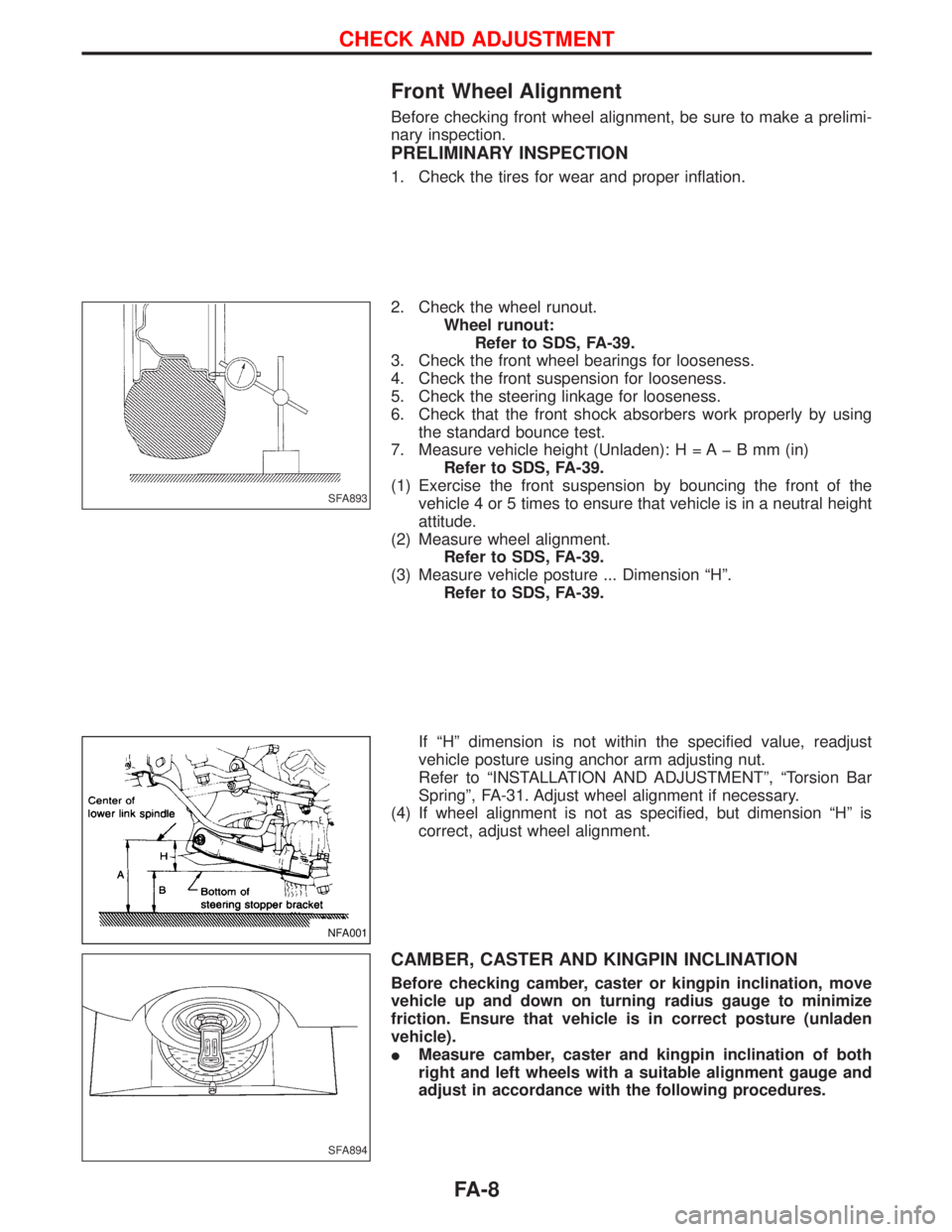

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

2. Check the wheel runout.

Wheel runout:

Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using

the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in)

Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment.

Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº.

Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is

correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8

Page 1287 of 1767

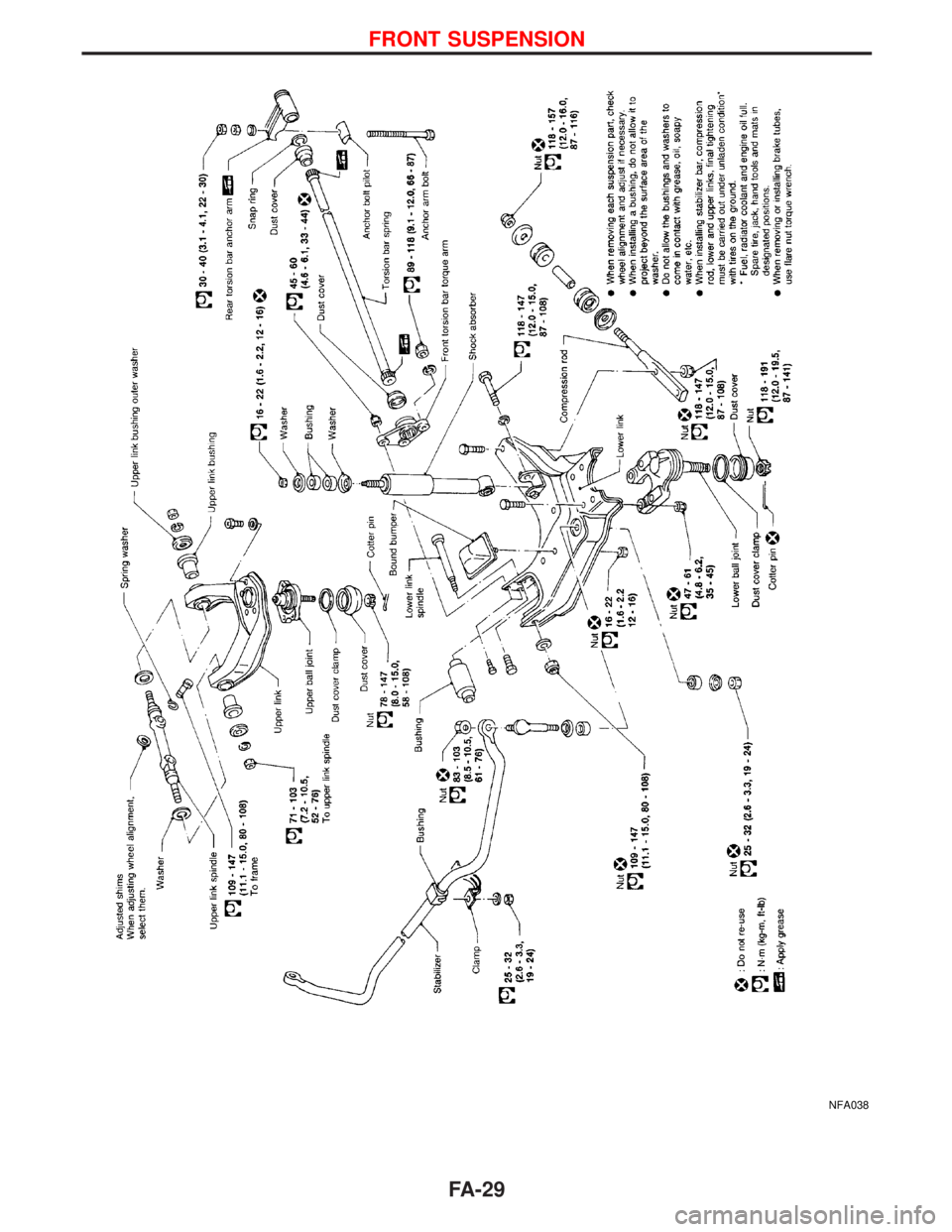

NFA038

FRONT SUSPENSION

FA-29

Page 1288 of 1767

Shock Absorber

REMOVAL AND INSTALLATION

When removing and installing shock absorber, do not allow oil or

grease to come into contact with rubber parts.

INSPECTION

Wash all parts, except for nonmetallic parts, with suitable solvent

and dry with compressed air.

Blow dirt and dust off of nonmetallic parts with compressed air.

ICheck for oil leakage and cracks. Replace if necessary.

ICheck piston rod for smooth operation. Replace if necessary.

ICheck rubber parts for wear, cracks, damage or deformation.

Replace if necessary.

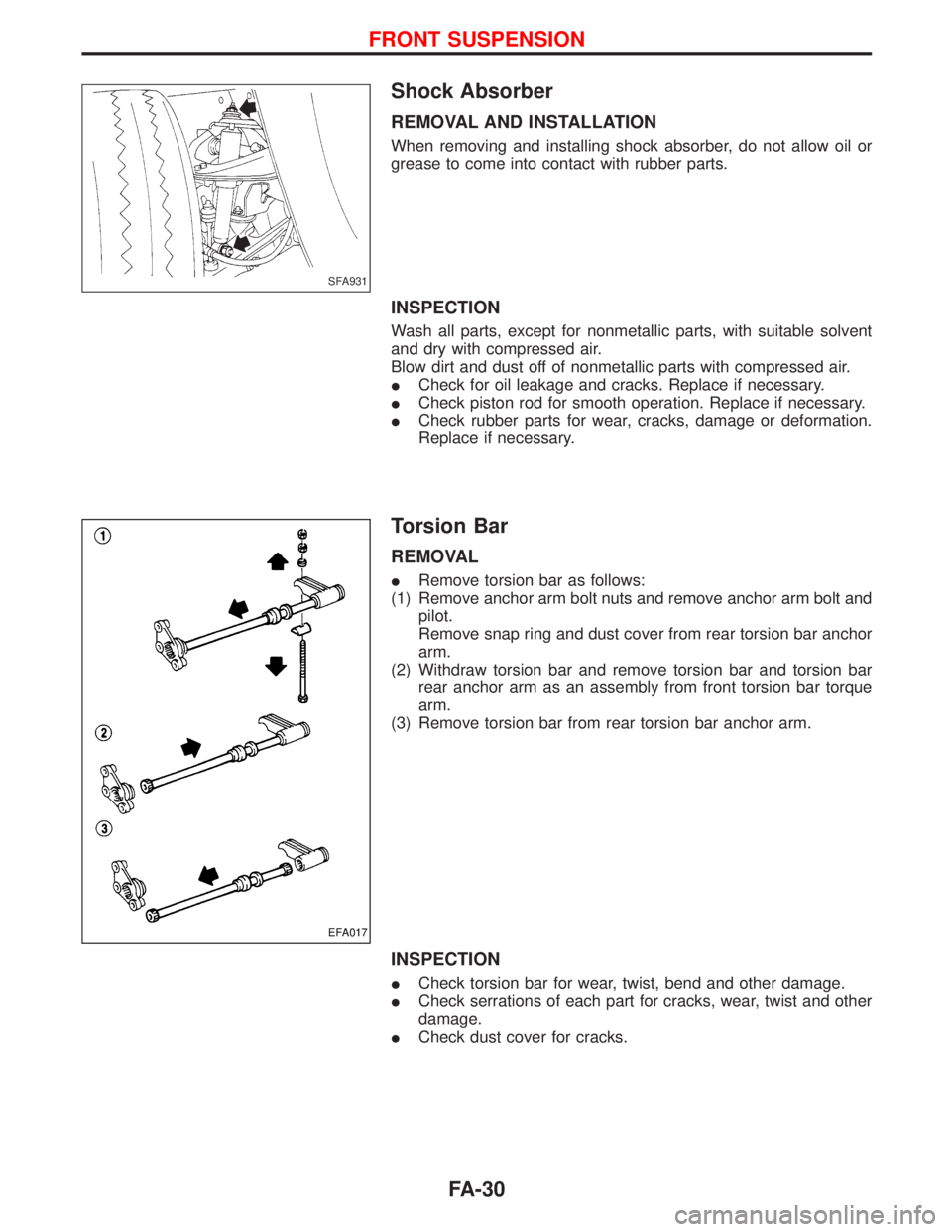

Torsion Bar

REMOVAL

IRemove torsion bar as follows:

(1) Remove anchor arm bolt nuts and remove anchor arm bolt and

pilot.

Remove snap ring and dust cover from rear torsion bar anchor

arm.

(2) Withdraw torsion bar and remove torsion bar and torsion bar

rear anchor arm as an assembly from front torsion bar torque

arm.

(3) Remove torsion bar from rear torsion bar anchor arm.

INSPECTION

ICheck torsion bar for wear, twist, bend and other damage.

ICheck serrations of each part for cracks, wear, twist and other

damage.

ICheck dust cover for cracks.

SFA931

EFA017

FRONT SUSPENSION

FA-30