unit NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 6 of 1767

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL R20 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions

IBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

IPlace disassembled parts in order for easier and proper assembly.

IAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

IGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

IIt is very important to perform functional tests whenever they are indicated.

IThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place removed parts in a parts rack in order to replace them in correct positions and sequences. Care will

also prevent springs and small parts from becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

IBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

IExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under ªChanging A/T Fluidº in the MA section when changing A/T fluid.

PREPARATION AND PRECAUTIONS

AT- 4

Page 16 of 1767

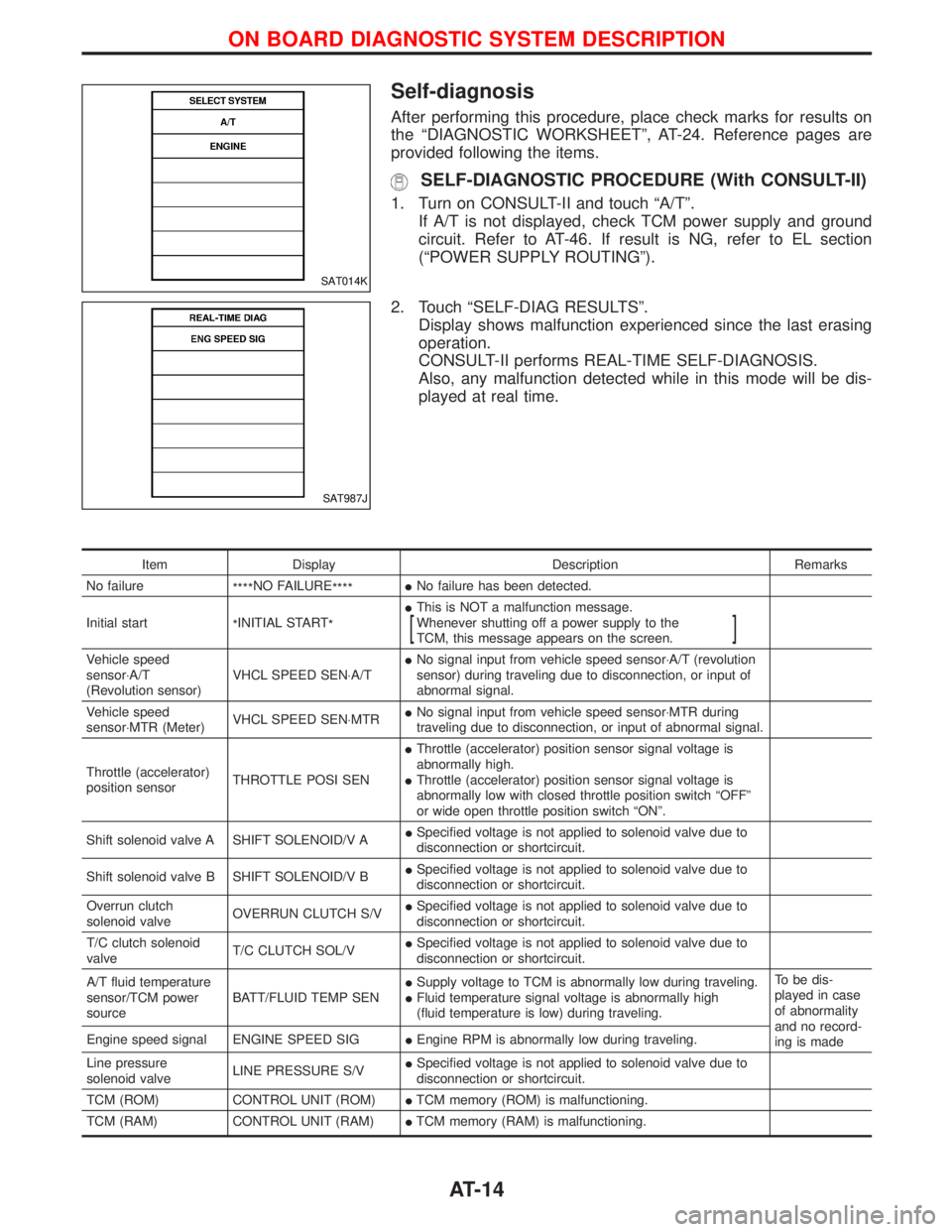

Self-diagnosis

After performing this procedure, place check marks for results on

the ªDIAGNOSTIC WORKSHEETº, AT-24. Reference pages are

provided following the items.

SELF-DIAGNOSTIC PROCEDURE (With CONSULT-II)

1. Turn on CONSULT-II and touch ªA/Tº.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-46. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last erasing

operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be dis-

played at real time.

Item Display Description Remarks

No failure

****NO FAILURE

****INo failure has been detected.

Initial start

*INITIAL START

*IThis is NOT a malfunction message.

Whenever shutting off a power supply to the

TCM, this message appears on the screen.

[]

Vehicle speed

sensor×A/T

(Revolution sensor)VHCL SPEED SEN×A/TINo signal input from vehicle speed sensor×A/T (revolution

sensor) during traveling due to disconnection, or input of

abnormal signal.

Vehicle speed

sensor×MTR (Meter)VHCL SPEED SEN×MTRINo signal input from vehicle speed sensor×MTR during

traveling due to disconnection, or input of abnormal signal.

Throttle (accelerator)

position sensorTHROTTLE POSI SENIThrottle (accelerator) position sensor signal voltage is

abnormally high.

IThrottle (accelerator) position sensor signal voltage is

abnormally low with closed throttle position switch ªOFFº

or wide open throttle position switch ªONº.

Shift solenoid valve A SHIFT SOLENOID/V AISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Shift solenoid valve B SHIFT SOLENOID/V BISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

Overrun clutch

solenoid valveOVERRUN CLUTCH S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

T/C clutch solenoid

valveT/C CLUTCH SOL/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

A/T fluid temperature

sensor/TCM power

sourceBATT/FLUID TEMP SENISupply voltage to TCM is abnormally low during traveling.

IFluid temperature signal voltage is abnormally high

(fluid temperature is low) during traveling.To be dis-

played in case

of abnormality

and no record-

ing is made Engine speed signal ENGINE SPEED SIGIEngine RPM is abnormally low during traveling.

Line pressure

solenoid valveLINE PRESSURE S/VISpecified voltage is not applied to solenoid valve due to

disconnection or shortcircuit.

TCM (ROM) CONTROL UNIT (ROM)ITCM memory (ROM) is malfunctioning.

TCM (RAM) CONTROL UNIT (RAM)ITCM memory (RAM) is malfunctioning.

SAT014K

SAT987J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-14

Page 22 of 1767

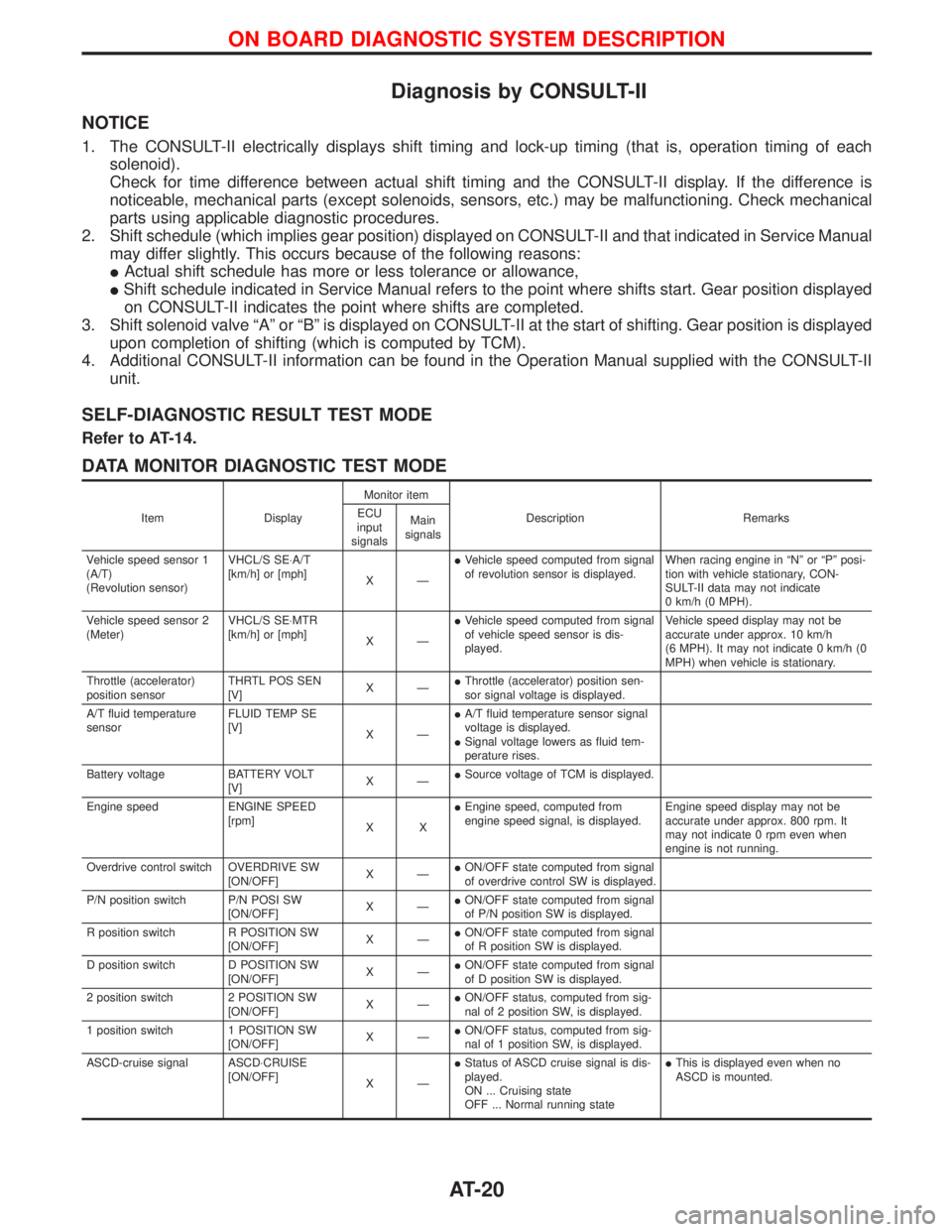

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

IShift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed

upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks ECU

input

signalsMain

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor)VHCL/S SE×A/T

[km/h] or [mph]

XÐIVehicle speed computed from signal

of revolution sensor is displayed.When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SE×MTR

[km/h] or [mph]

XÐIVehicle speed computed from signal

of vehicle speed sensor is dis-

played.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensorTHRTL POS SEN

[V]XÐIThrottle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensorFLUID TEMP SE

[V]

XÐIA/T fluid temperature sensor signal

voltage is displayed.

ISignal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT

[V]XÐISource voltage of TCM is displayed.

Engine speed ENGINE SPEED

[rpm]

XXIEngine speed, computed from

engine speed signal, is displayed.Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF]XÐION/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW

[ON/OFF]XÐION/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW

[ON/OFF]XÐION/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW

[ON/OFF]XÐION/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE

[ON/OFF]

XÐIStatus of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running stateIThis is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

Page 125 of 1767

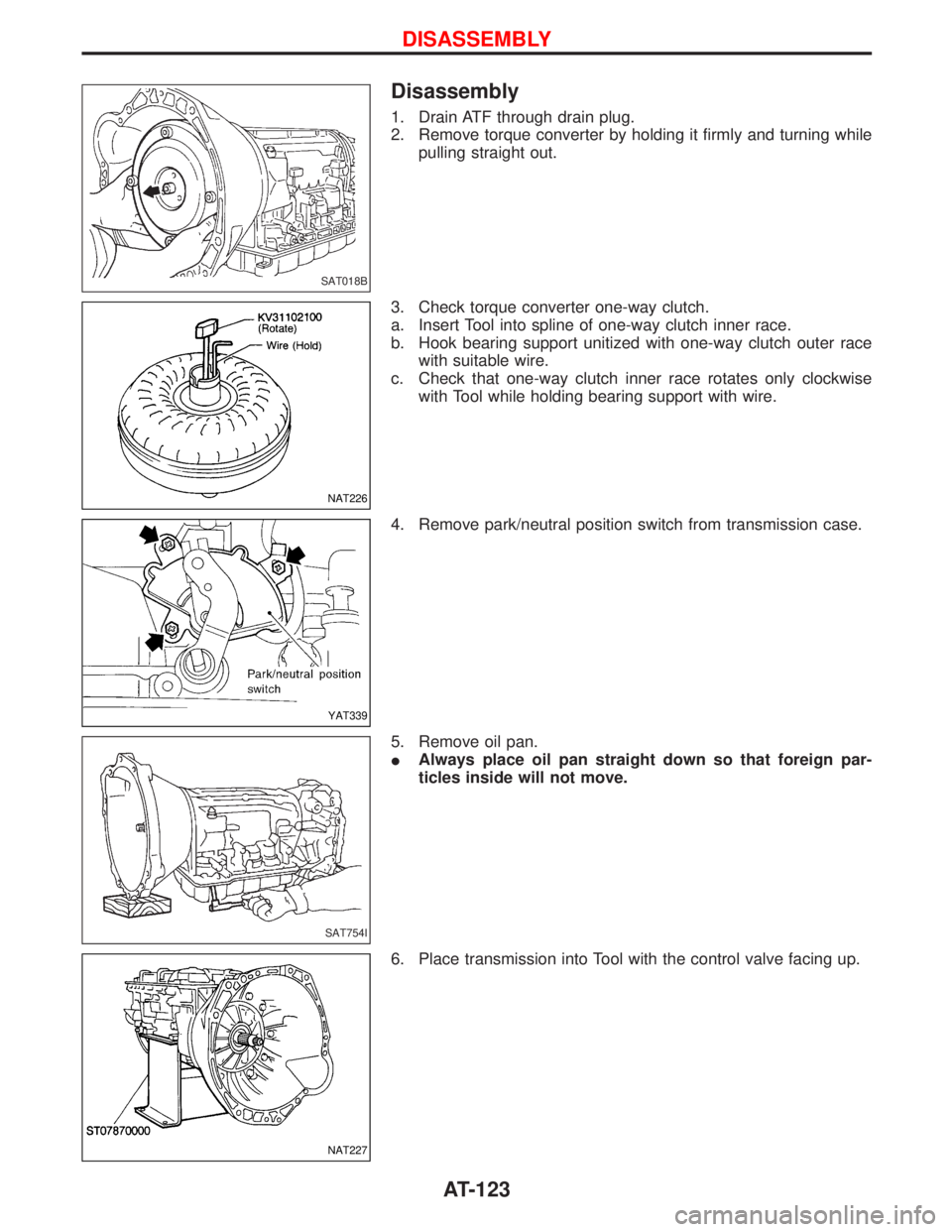

Disassembly

1. Drain ATF through drain plug.

2. Remove torque converter by holding it firmly and turning while

pulling straight out.

3. Check torque converter one-way clutch.

a. Insert Tool into spline of one-way clutch inner race.

b. Hook bearing support unitized with one-way clutch outer race

with suitable wire.

c. Check that one-way clutch inner race rotates only clockwise

with Tool while holding bearing support with wire.

4. Remove park/neutral position switch from transmission case.

5. Remove oil pan.

IAlways place oil pan straight down so that foreign par-

ticles inside will not move.

6. Place transmission into Tool with the control valve facing up.

SAT018B

NAT226

YAT339

SAT754I

NAT227

DISASSEMBLY

AT-123

Page 131 of 1767

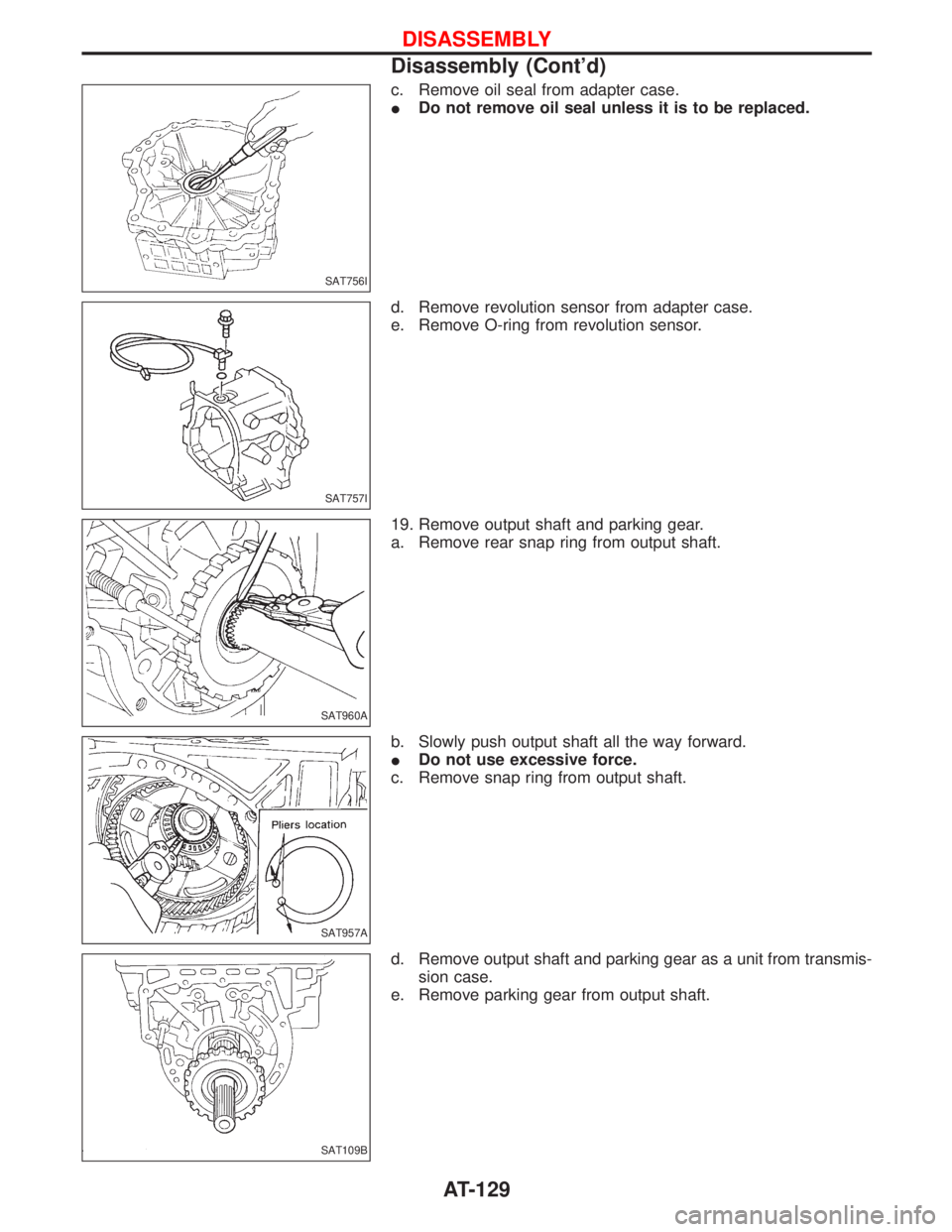

c. Remove oil seal from adapter case.

IDo not remove oil seal unless it is to be replaced.

d. Remove revolution sensor from adapter case.

e. Remove O-ring from revolution sensor.

19. Remove output shaft and parking gear.

a. Remove rear snap ring from output shaft.

b. Slowly push output shaft all the way forward.

IDo not use excessive force.

c. Remove snap ring from output shaft.

d. Remove output shaft and parking gear as a unit from transmis-

sion case.

e. Remove parking gear from output shaft.

SAT756I

SAT757I

SAT960A

SAT957A

SAT109B

DISASSEMBLY

Disassembly (Cont'd)

AT-129

Page 141 of 1767

DISASSEMBLY

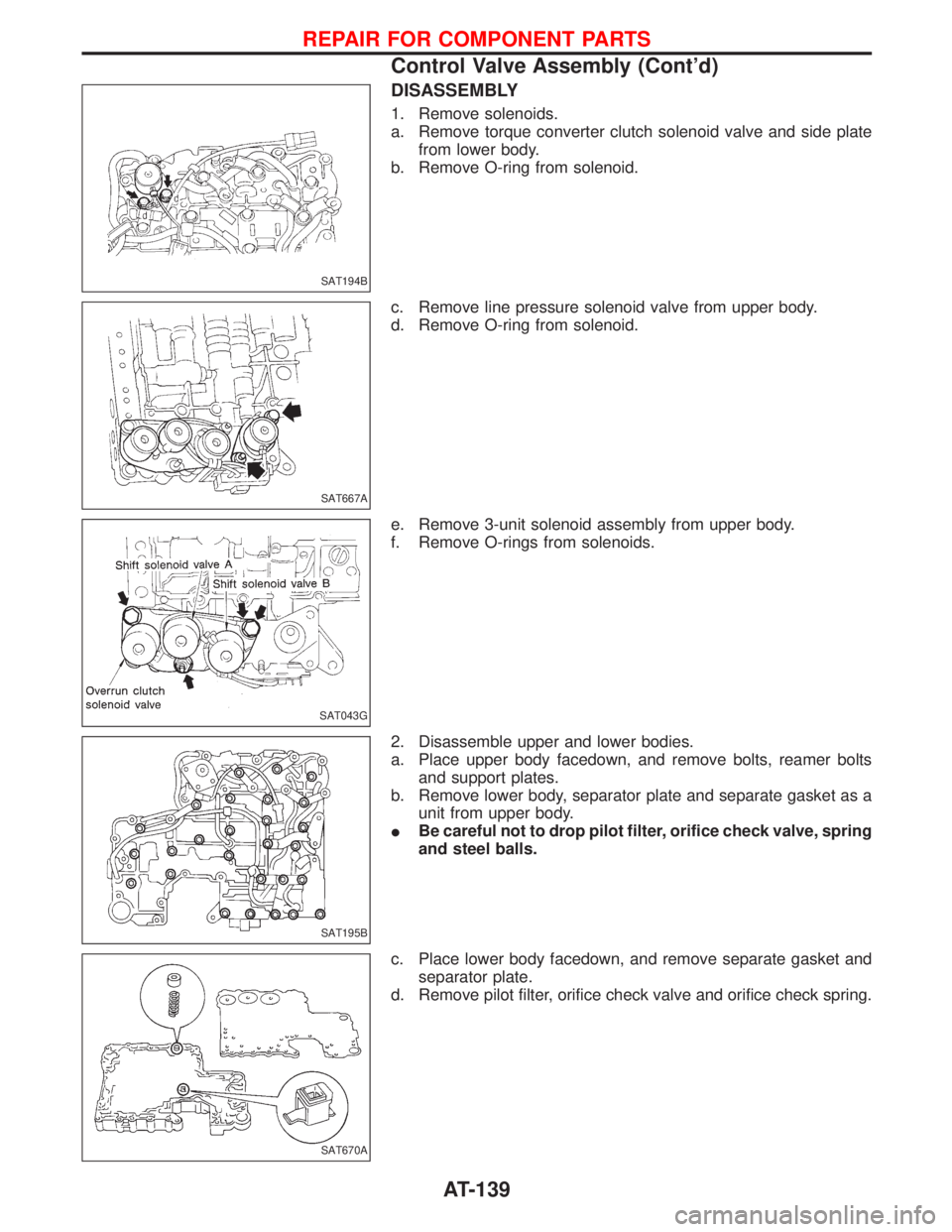

1. Remove solenoids.

a. Remove torque converter clutch solenoid valve and side plate

from lower body.

b. Remove O-ring from solenoid.

c. Remove line pressure solenoid valve from upper body.

d. Remove O-ring from solenoid.

e. Remove 3-unit solenoid assembly from upper body.

f. Remove O-rings from solenoids.

2. Disassemble upper and lower bodies.

a. Place upper body facedown, and remove bolts, reamer bolts

and support plates.

b. Remove lower body, separator plate and separate gasket as a

unit from upper body.

IBe careful not to drop pilot filter, orifice check valve, spring

and steel balls.

c. Place lower body facedown, and remove separate gasket and

separator plate.

d. Remove pilot filter, orifice check valve and orifice check spring.

SAT194B

SAT667A

SAT043G

SAT195B

SAT670A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-139

Page 143 of 1767

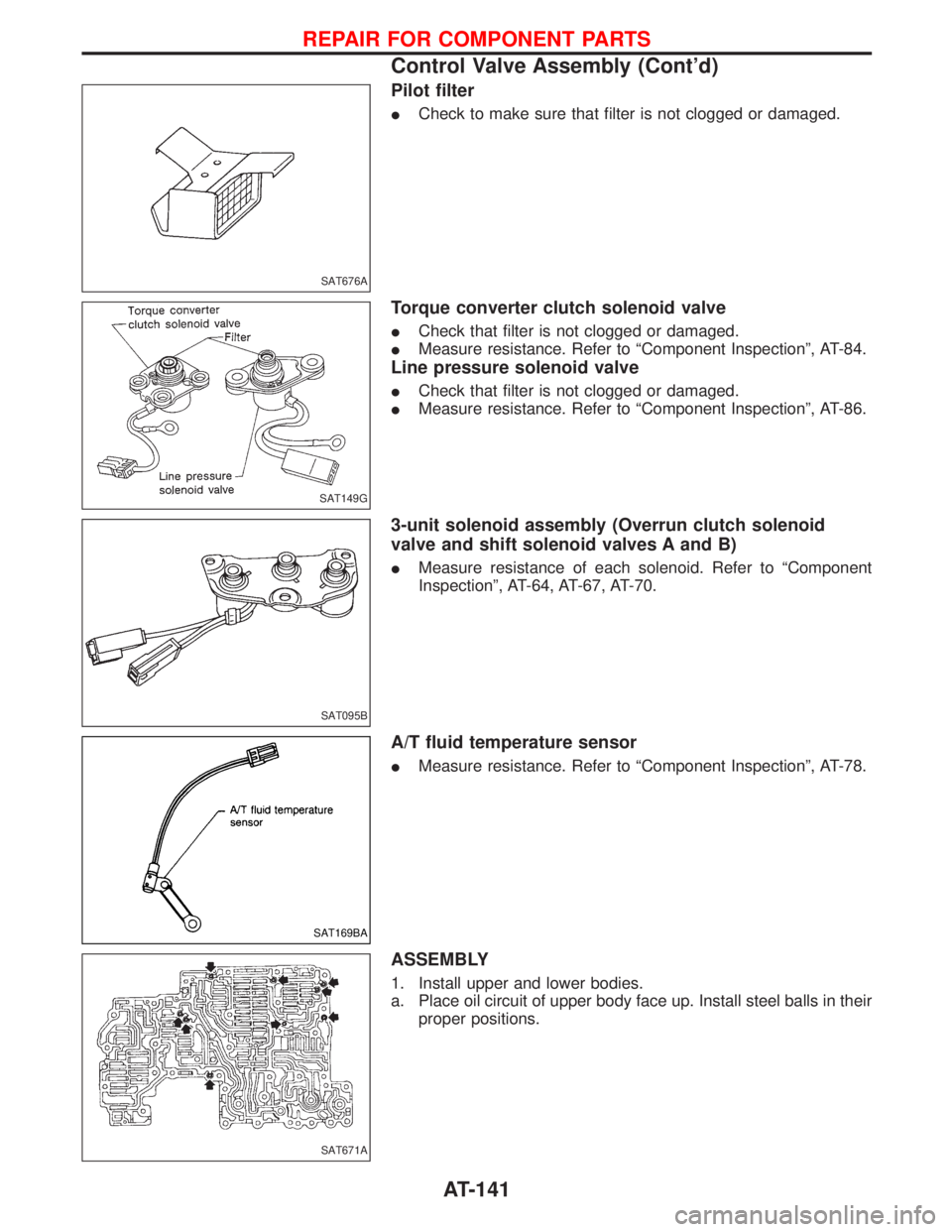

Pilot filter

ICheck to make sure that filter is not clogged or damaged.

Torque converter clutch solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-84.

Line pressure solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-86.

3-unit solenoid assembly (Overrun clutch solenoid

valve and shift solenoid valves A and B)

IMeasure resistance of each solenoid. Refer to ªComponent

Inspectionº, AT-64, AT-67, AT-70.

A/T fluid temperature sensor

IMeasure resistance. Refer to ªComponent Inspectionº, AT-78.

ASSEMBLY

1. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

SAT676A

SAT149G

SAT095B

SAT169BA

SAT671A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-141

Page 145 of 1767

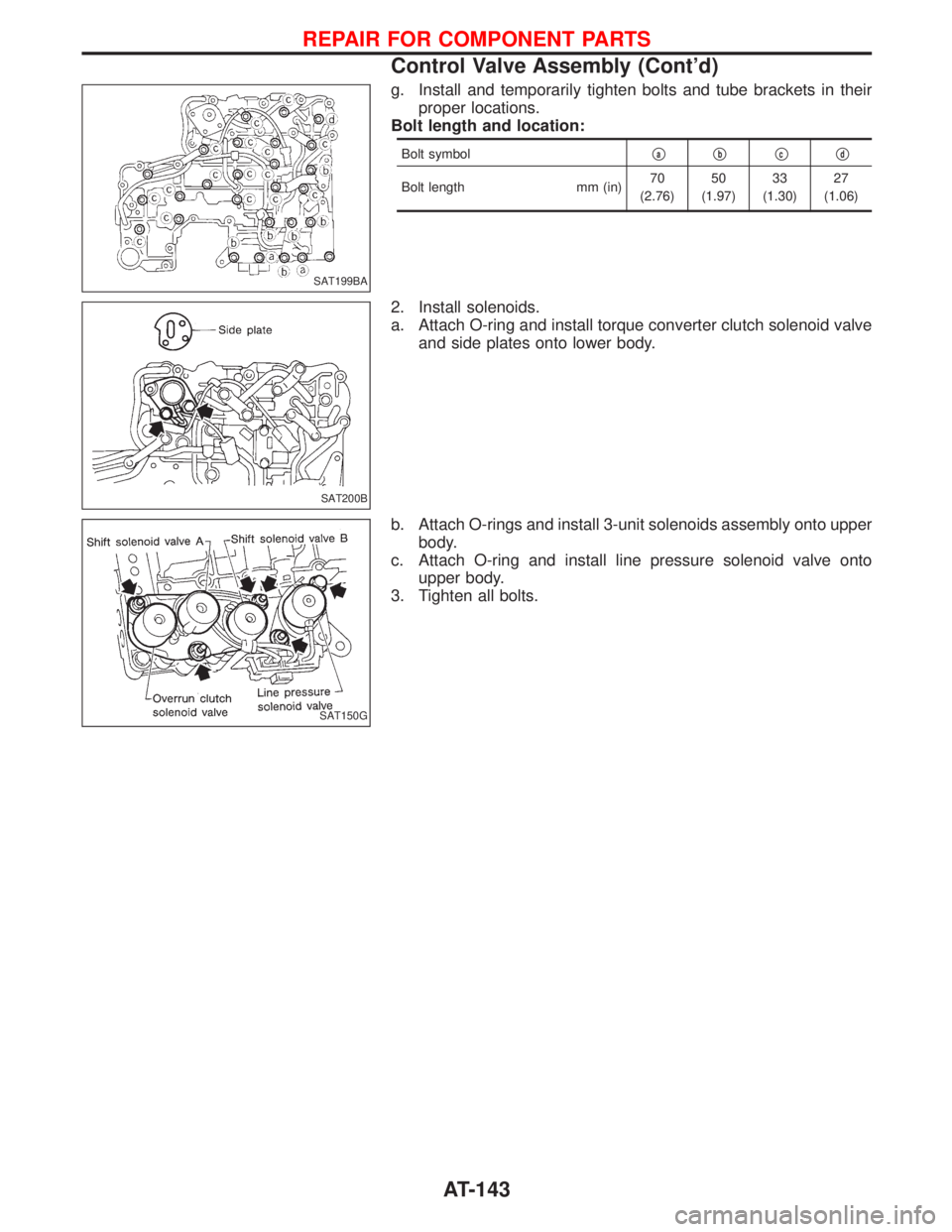

g. Install and temporarily tighten bolts and tube brackets in their

proper locations.

Bolt length and location:

Bolt symbolqaqbqcqd

Bolt length mm (in)70

(2.76)50

(1.97)33

(1.30)27

(1.06)

2. Install solenoids.

a. Attach O-ring and install torque converter clutch solenoid valve

and side plates onto lower body.

b. Attach O-rings and install 3-unit solenoids assembly onto upper

body.

c. Attach O-ring and install line pressure solenoid valve onto

upper body.

3. Tighten all bolts.

SAT199BA

SAT200B

SAT150G

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-143

Page 171 of 1767

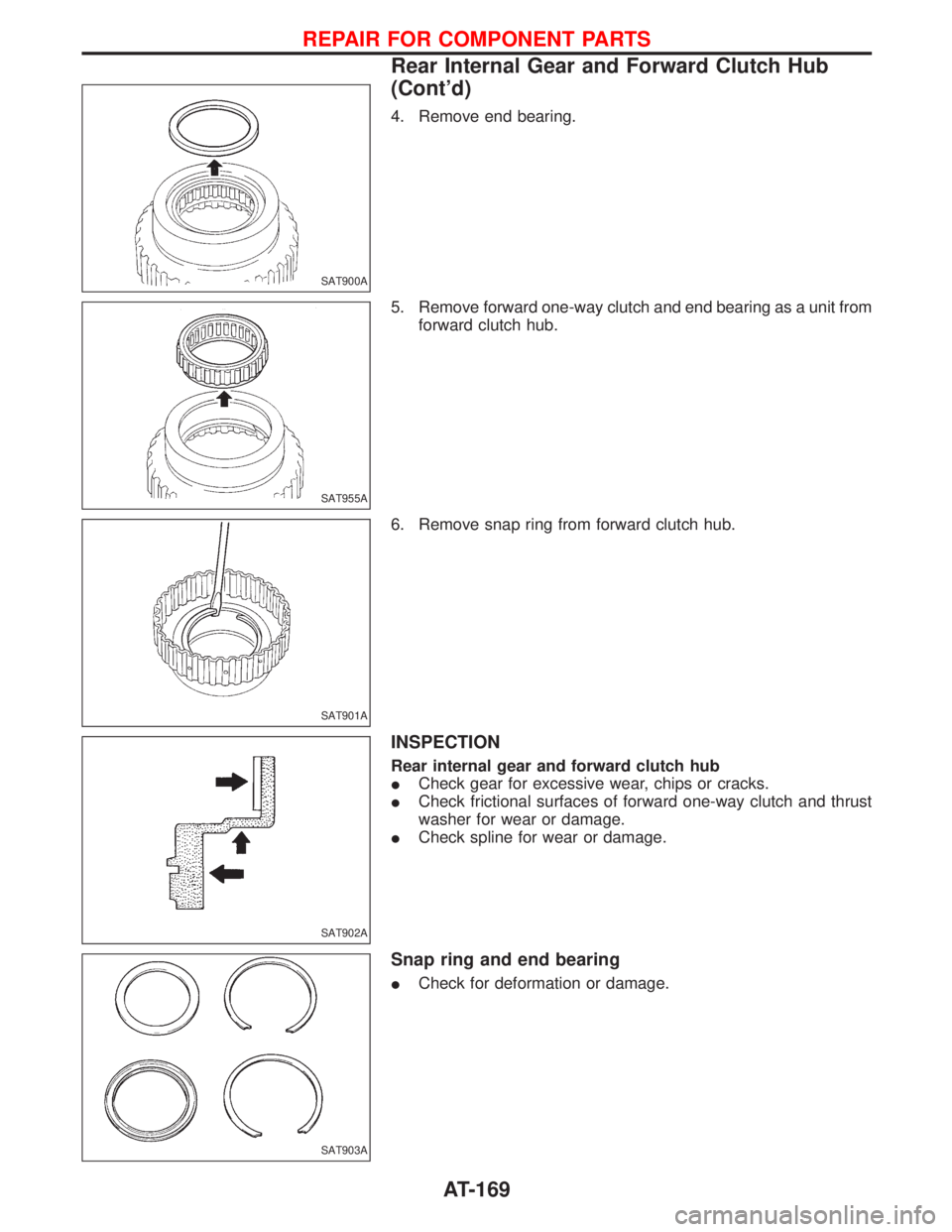

4. Remove end bearing.

5. Remove forward one-way clutch and end bearing as a unit from

forward clutch hub.

6. Remove snap ring from forward clutch hub.

INSPECTION

Rear internal gear and forward clutch hub

ICheck gear for excessive wear, chips or cracks.

ICheck frictional surfaces of forward one-way clutch and thrust

washer for wear or damage.

ICheck spline for wear or damage.

Snap ring and end bearing

ICheck for deformation or damage.

SAT900A

SAT955A

SAT901A

SAT902A

SAT903A

REPAIR FOR COMPONENT PARTS

Rear Internal Gear and Forward Clutch Hub

(Cont'd)

AT-169

Page 179 of 1767

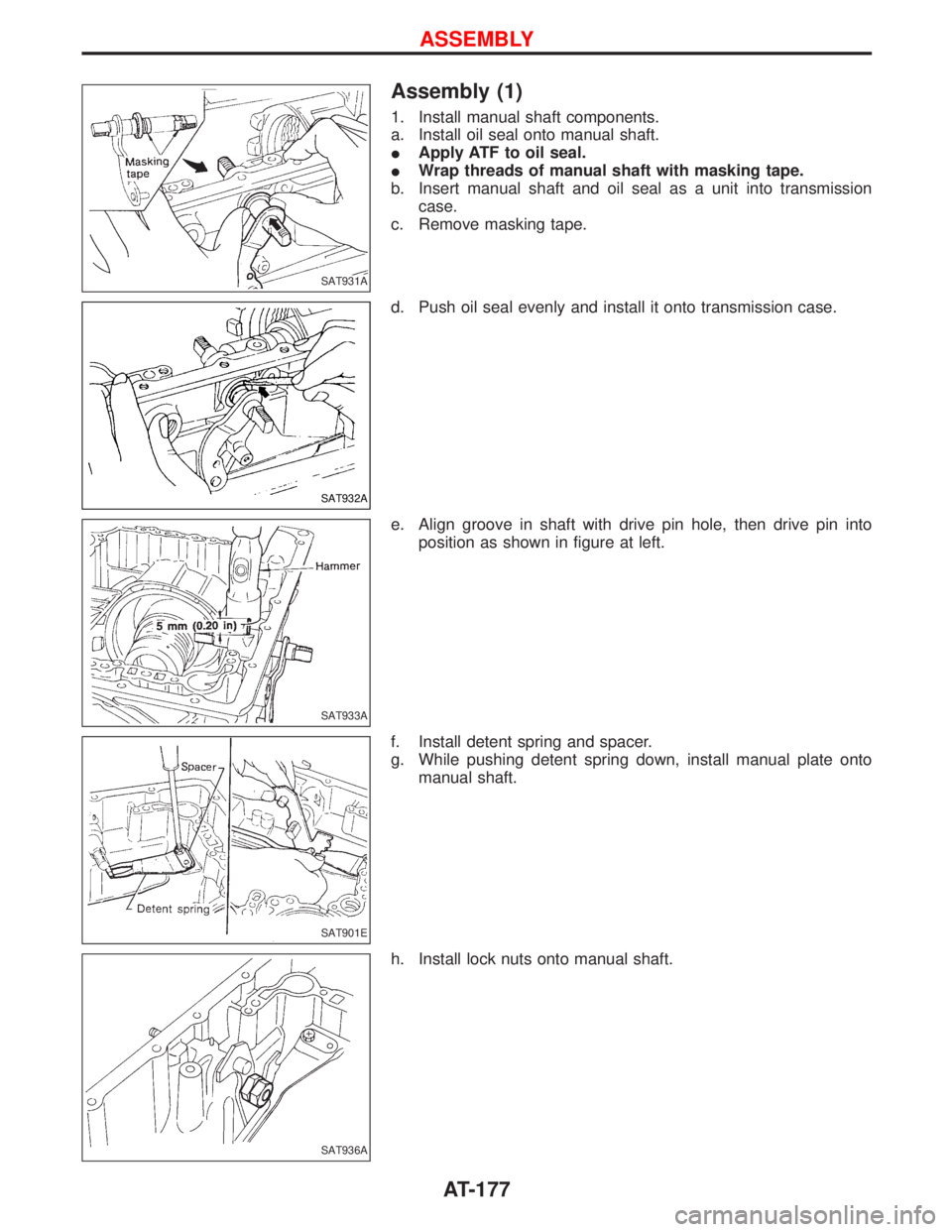

Assembly (1)

1. Install manual shaft components.

a. Install oil seal onto manual shaft.

IApply ATF to oil seal.

IWrap threads of manual shaft with masking tape.

b. Insert manual shaft and oil seal as a unit into transmission

case.

c. Remove masking tape.

d. Push oil seal evenly and install it onto transmission case.

e. Align groove in shaft with drive pin hole, then drive pin into

position as shown in figure at left.

f. Install detent spring and spacer.

g. While pushing detent spring down, install manual plate onto

manual shaft.

h. Install lock nuts onto manual shaft.

SAT931A

SAT932A

SAT933A

SAT901E

SAT936A

ASSEMBLY

AT-177