Rocker NISSAN TERRANO 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 238 of 1833

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

StandardLimit

Camshaft journal to

bushing clearance 0.020 - 0.109

(0.0008 - 0.0043) Less than 0.15

(0.0059)

Camshaft journal

diameter

Front 50.721 - 50.740

(1.9969 - 1.9976) Ð

2nd 50.521 - 50.540

(1.9890 - 1.9898) Ð

3rd 50.321 - 50.340

(1.9811 - 1.9819) Ð

4th 50.121 - 50.140

(1.9733 - 1.9740) Ð

Rear 49.921 - 49.940

(1.9654 - 1.9661) Ð

Camshaft bend (Total

indicator reading) Less than 0.02

(0.0008) Less than 0.06

(0.0024)

Camshaft end play 0.08 - 0.28

(0.0031 - 0.0110) Less than 0.50

(0.0197)

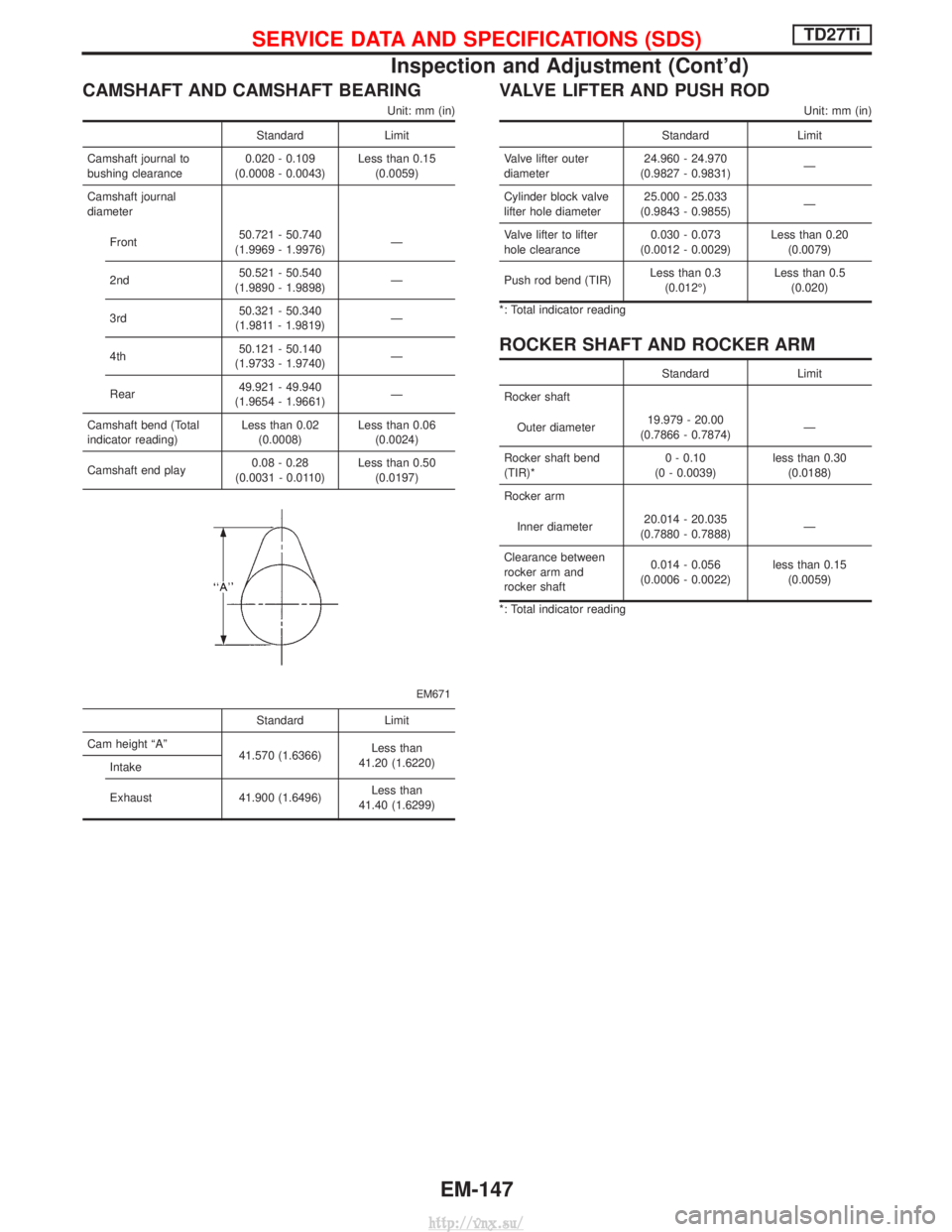

EM671

Standard Limit

Cam height ªAº 41.570 (1.6366)Less than

41.20 (1.6220)

Intake

Exhaust 41.900 (1.6496) Less than

41.40 (1.6299)

VALVE LIFTER AND PUSH ROD

Unit: mm (in)

Standard Limit

Valve lifter outer

diameter 24.960 - 24.970

(0.9827 - 0.9831) Ð

Cylinder block valve

lifter hole diameter 25.000 - 25.033

(0.9843 - 0.9855) Ð

Valve lifter to lifter

hole clearance 0.030 - 0.073

(0.0012 - 0.0029) Less than 0.20

(0.0079)

Push rod bend (TIR) Less than 0.3

(0.012É) Less than 0.5

(0.020)

*: Total indicator reading

ROCKER SHAFT AND ROCKER ARM

Standard Limit

Rocker shaft

Outer diameter 19.979 - 20.00

(0.7866 - 0.7874) Ð

Rocker shaft bend

(TIR)* 0 - 0.10

(0 - 0.0039) less than 0.30

(0.0188)

Rocker arm

Inner diameter 20.014 - 20.035

(0.7880 - 0.7888) Ð

Clearance between

rocker arm and

rocker shaft 0.014 - 0.056

(0.0006 - 0.0022) less than 0.15

(0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-147

http://vnx.su/

Page 298 of 1833

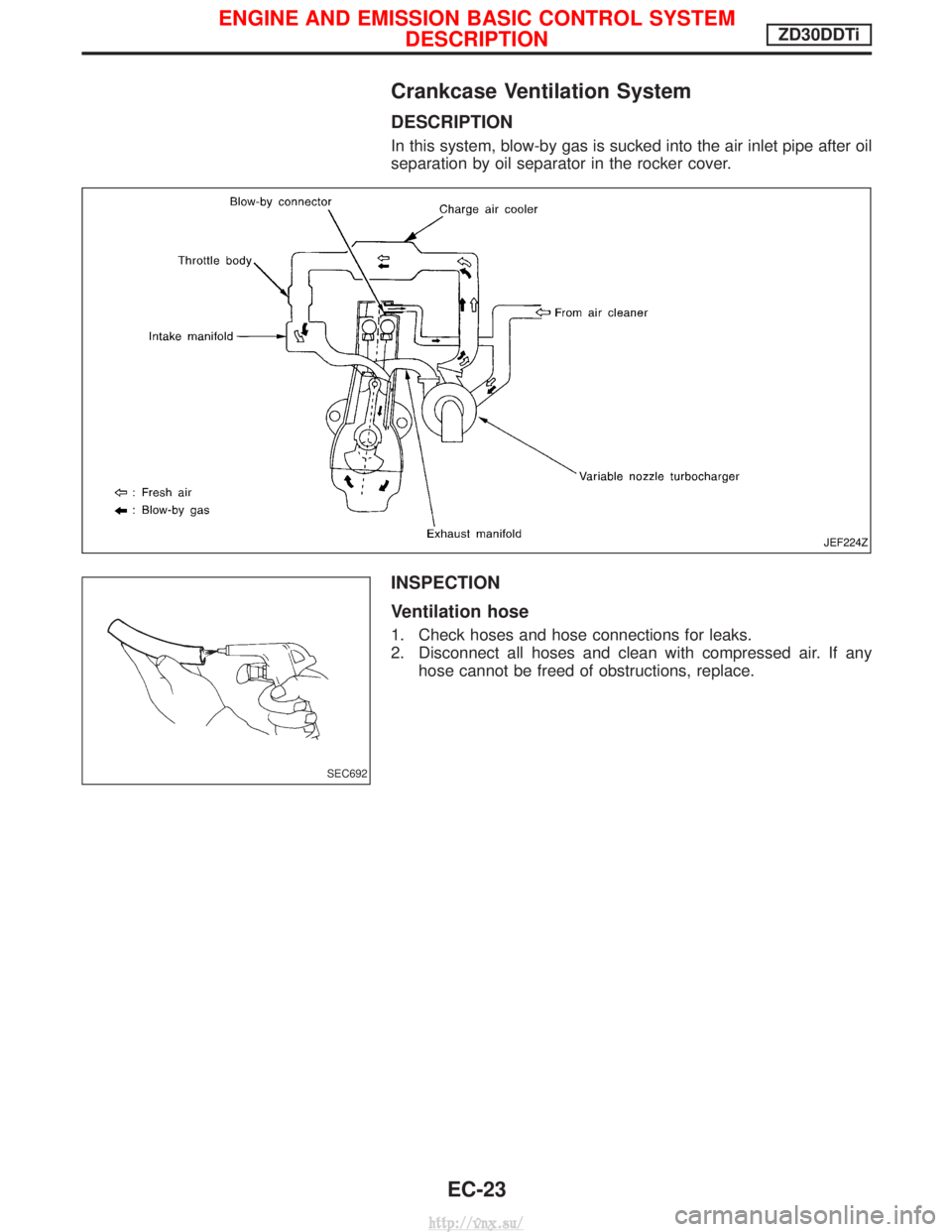

Crankcase Ventilation System

DESCRIPTION

In this system, blow-by gas is sucked into the air inlet pipe after oil

separation by oil separator in the rocker cover.

INSPECTION

Ventilation hose

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If anyhose cannot be freed of obstructions, replace.

JEF224Z

SEC692

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONZD30DDTi

EC-23

http://vnx.su/

Page 301 of 1833

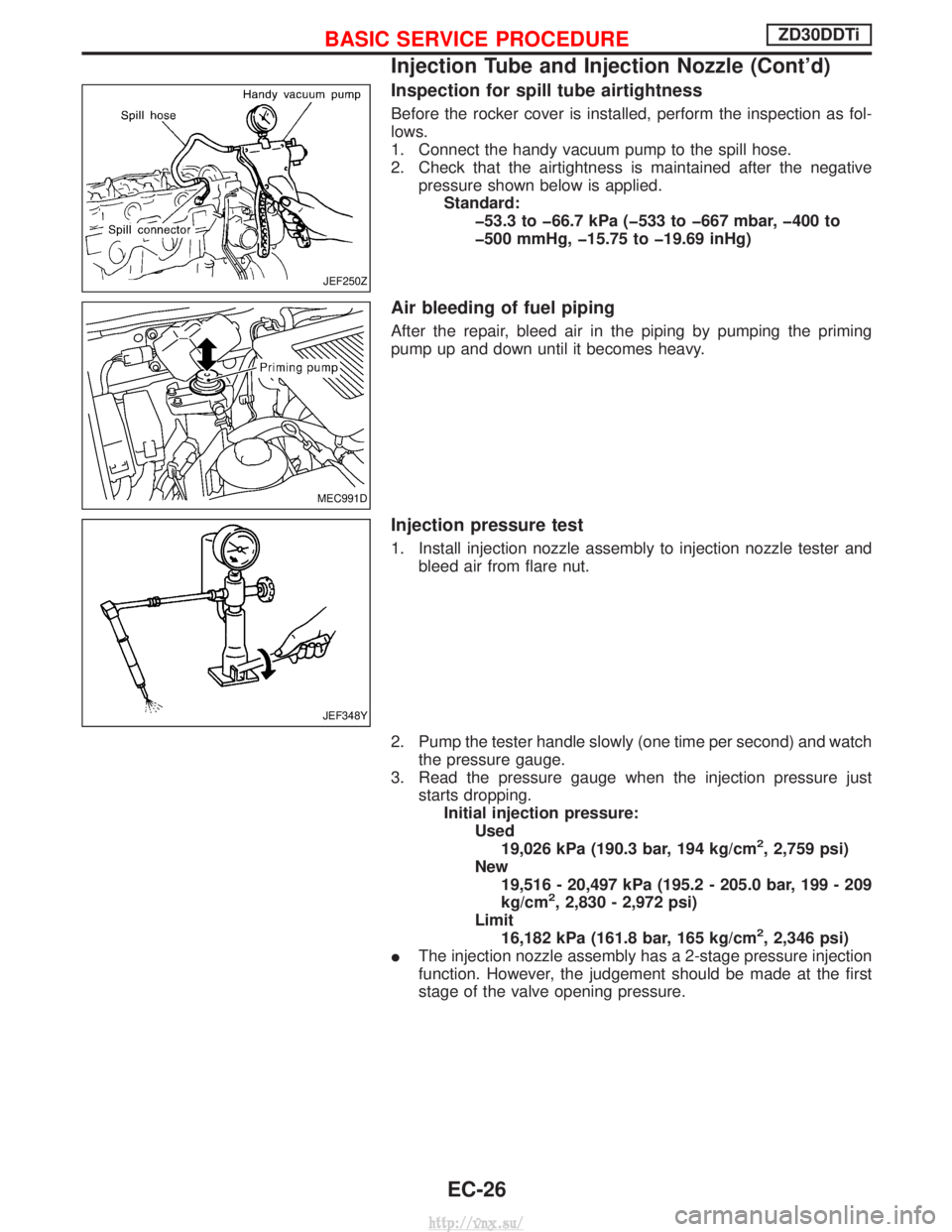

Inspection for spill tube airtightness

Before the rocker cover is installed, perform the inspection as fol-

lows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negativepressure shown below is applied.Standard: þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air bleeding of fuel piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy.

Injection pressure test

1. Install injection nozzle assembly to injection nozzle tester andbleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and watch the pressure gauge.

3. Read the pressure gauge when the injection pressure just starts dropping.Initial injection pressure: Used19,026 kPa (190.3 bar, 194 kg/cm

2, 2,759 psi)

New 19,516 - 20,497 kPa (195.2 - 205.0 bar, 199 - 209

kg/cm

2, 2,830 - 2,972 psi)

Limit 16,182 kPa (161.8 bar, 165 kg/cm

2, 2,346 psi)

I The injection nozzle assembly has a 2-stage pressure injection

function. However, the judgement should be made at the first

stage of the valve opening pressure.

JEF250Z

MEC991D

JEF348Y

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-26

http://vnx.su/

Page 303 of 1833

REMOVAL

1. Remove the following:

IEngine coolant draining

I Charge air cooler

I Air inlet pipe

I Throttle body

I Rocker cover

I Oil level gauge guide

I EGR cooler

I EGR guide tube

I EGR volume control solenoid valve

I Fuel hose

I Injection tube

I Radiator upper hose

I Radiator shroud

I Cooling fan

I Drive belt

I Vacuum pipe

I Vacuum pump

2. Move the power steering pump.

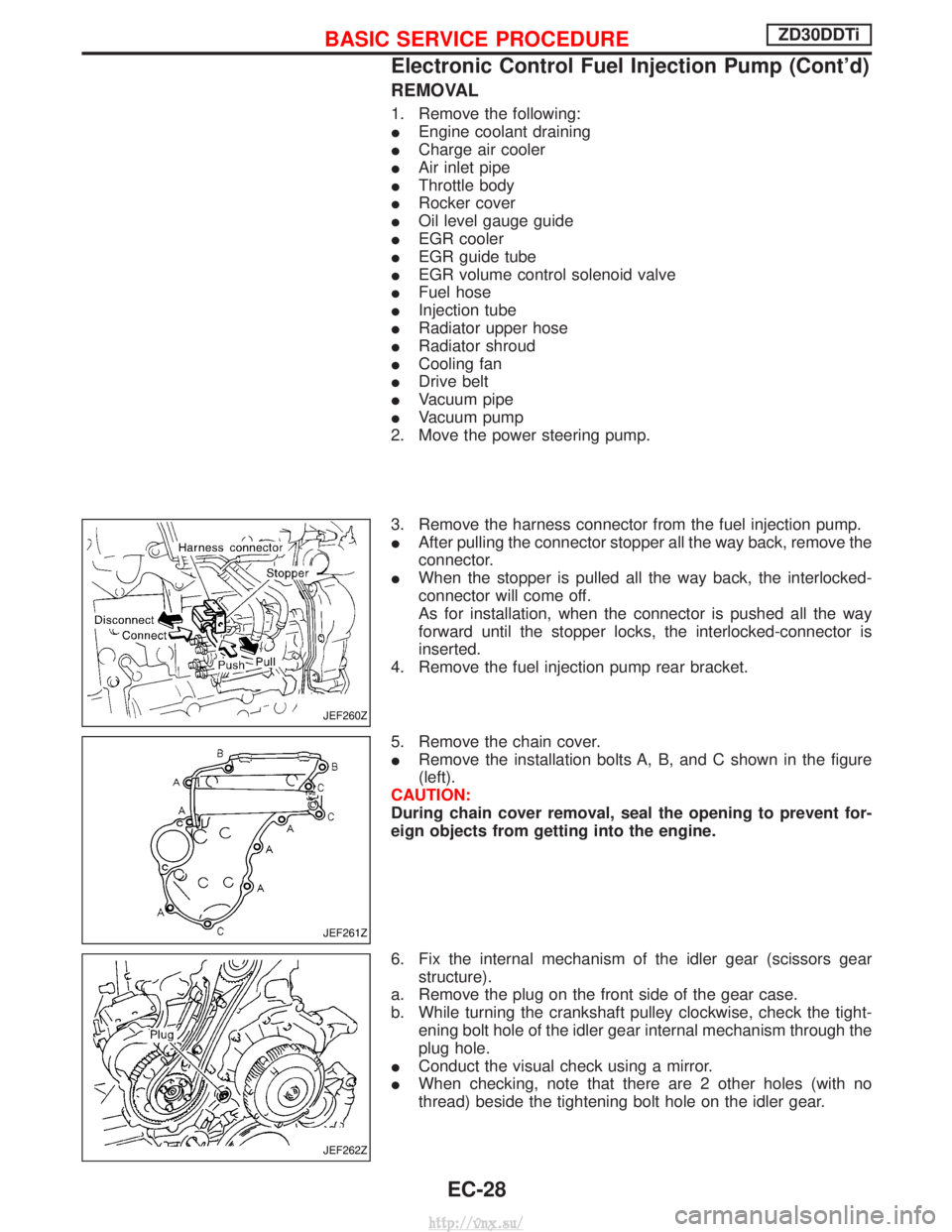

3. Remove the harness connector from the fuel injection pump.

I After pulling the connector stopper all the way back, remove the

connector.

I When the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

I Remove the installation bolts A, B, and C shown in the figure

(left).

CAUTION:

During chain cover removal, seal the opening to prevent for-

eign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the tight- ening bolt hole of the idler gear internal mechanism through the

plug hole.

I Conduct the visual check using a mirror.

I When checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-28

http://vnx.su/

Page 1831 of 1833

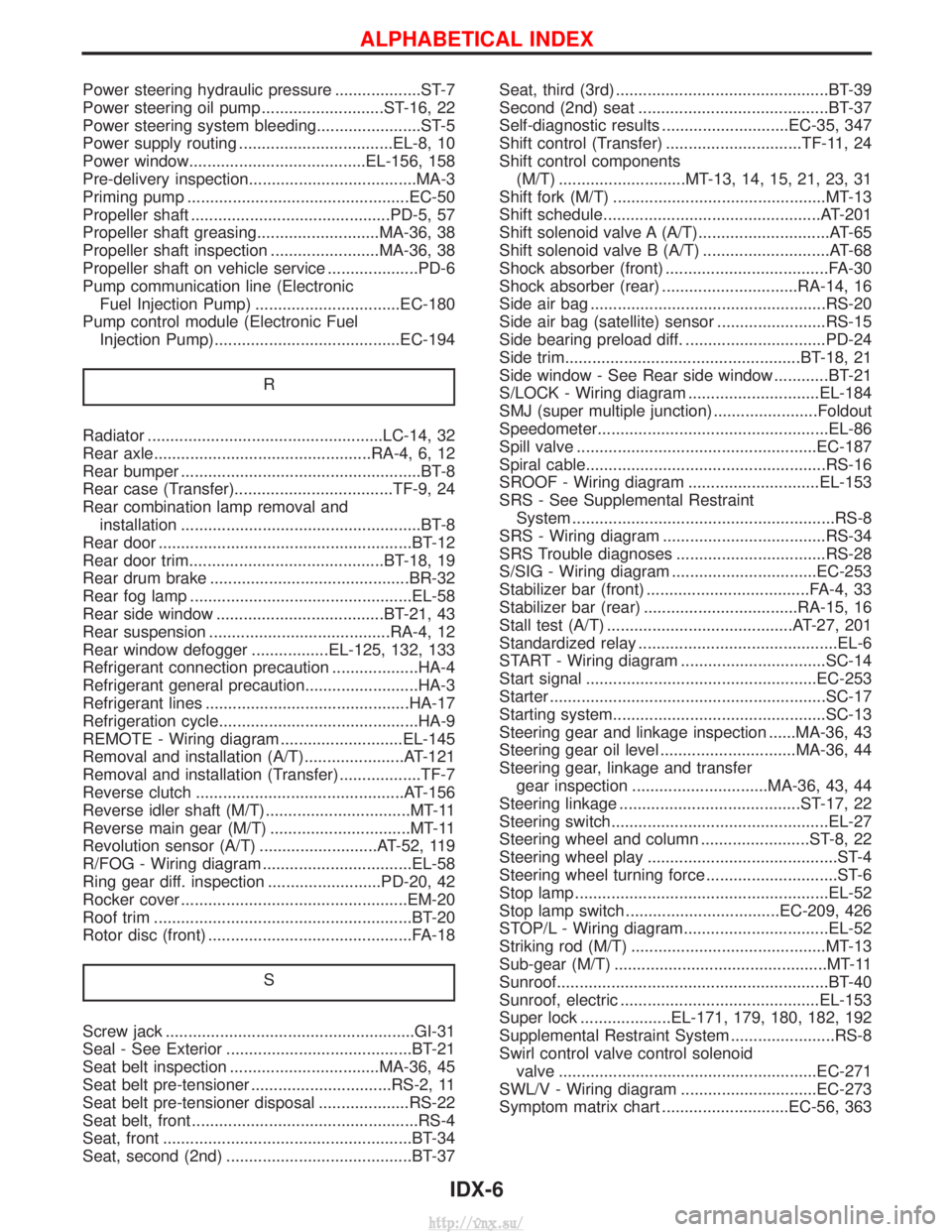

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ..................................EL-8, 10

Power window.......................................EL-156, 158

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (ElectronicFuel Injection Pump) ................................EC-180

Pump control module (Electronic Fuel Injection Pump).........................................EC-194

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal andinstallation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-32

Rear fog lamp .................................................EL-58

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger .................EL-125, 132, 133

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-145

Removal and installation (A/T)......................AT-121

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-156

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-52, 119

R/FOG - Wiring diagram .................................EL-58

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-31

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner ...............................RS-2, 11

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37 Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 347

Shift control (Transfer) ..............................TF-11, 24

Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-201

Shift solenoid valve A (A/T).............................AT-65

Shift solenoid valve B (A/T) ............................AT-68

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-20

Side air bag (satellite) sensor ........................RS-15

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-184

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-86

Spill valve .....................................................EC-187

Spiral cable.....................................................RS-16

SROOF - Wiring diagram .............................EL-153

SRS - See Supplemental Restraint System ..........................................................RS-8

SRS - Wiring diagram ....................................RS-34

SRS Trouble diagnoses .................................RS-28

S/SIG - Wiring diagram ................................EC-253

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 201

Standardized relay ............................................EL-6

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-253

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-27

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-52

Stop lamp switch ..................................EC-209, 426

STOP/L - Wiring diagram................................EL-52

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sunroof............................................................BT-40

Sunroof, electric ............................................EL-153

Super lock ....................EL-171, 179, 180, 182, 192

Supplemental Restraint System .......................RS-8

Swirl control valve control solenoid valve .........................................................EC-271

SWL/V - Wiring diagram ..............................EC-273

Symptom matrix chart ............................EC-56, 363

ALPHABETICAL INDEX

IDX-6

http://vnx.su/