open hood NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 45 of 1833

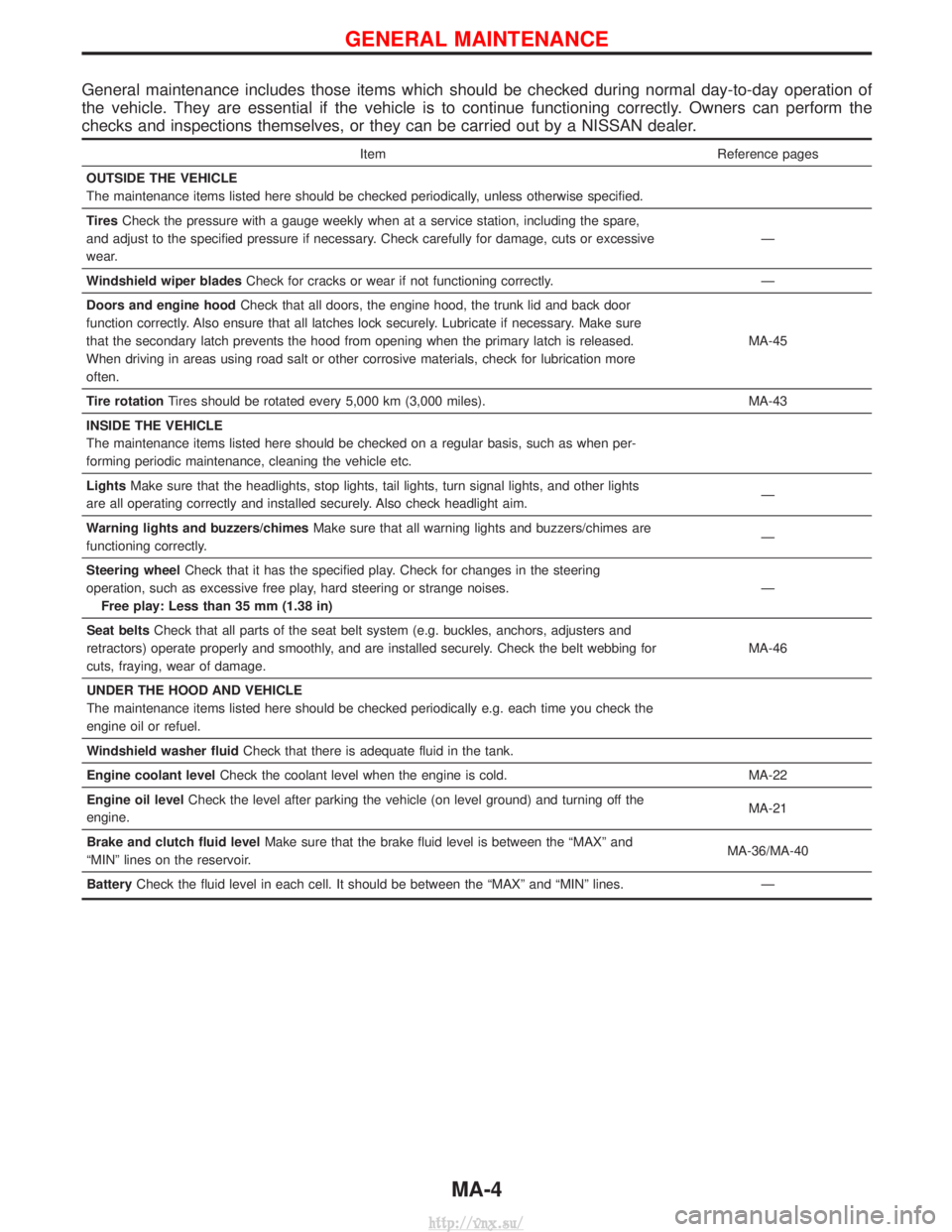

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 88 of 1833

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Back door lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel,

etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

http://vnx.su/

Page 325 of 1833

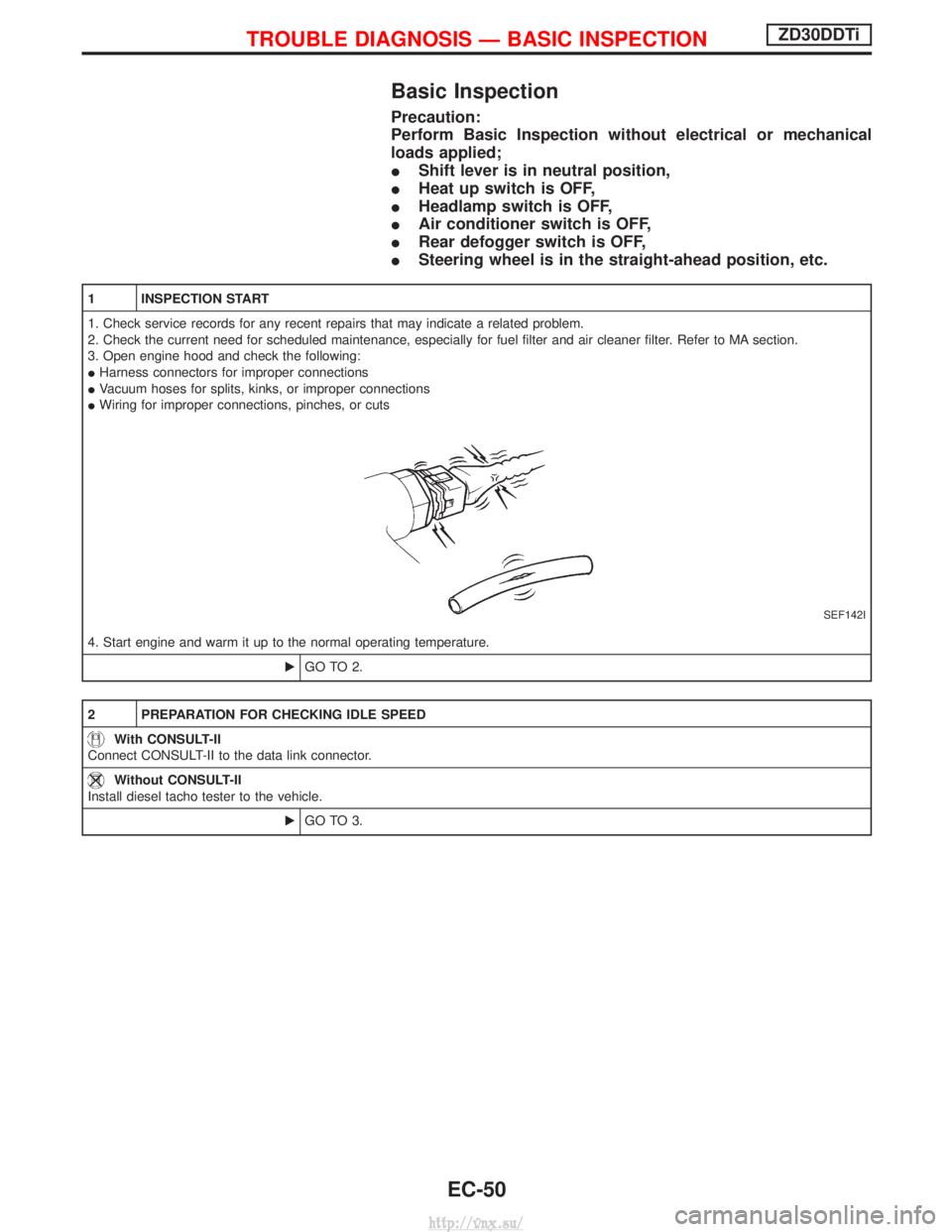

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IShift lever is in neutral position,

I Heat up switch is OFF,

I Headlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to MA section.

3. Open engine hood and check the following:

IHarness connectors for improper connections

I Vacuum hoses for splits, kinks, or improper connections

I Wiring for improper connections, pinches, or cuts

SEF142I

4. Start engine and warm it up to the normal operating temperature.

EGO TO 2.

2 PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

EGO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONZD30DDTi

EC-50

http://vnx.su/

Page 636 of 1833

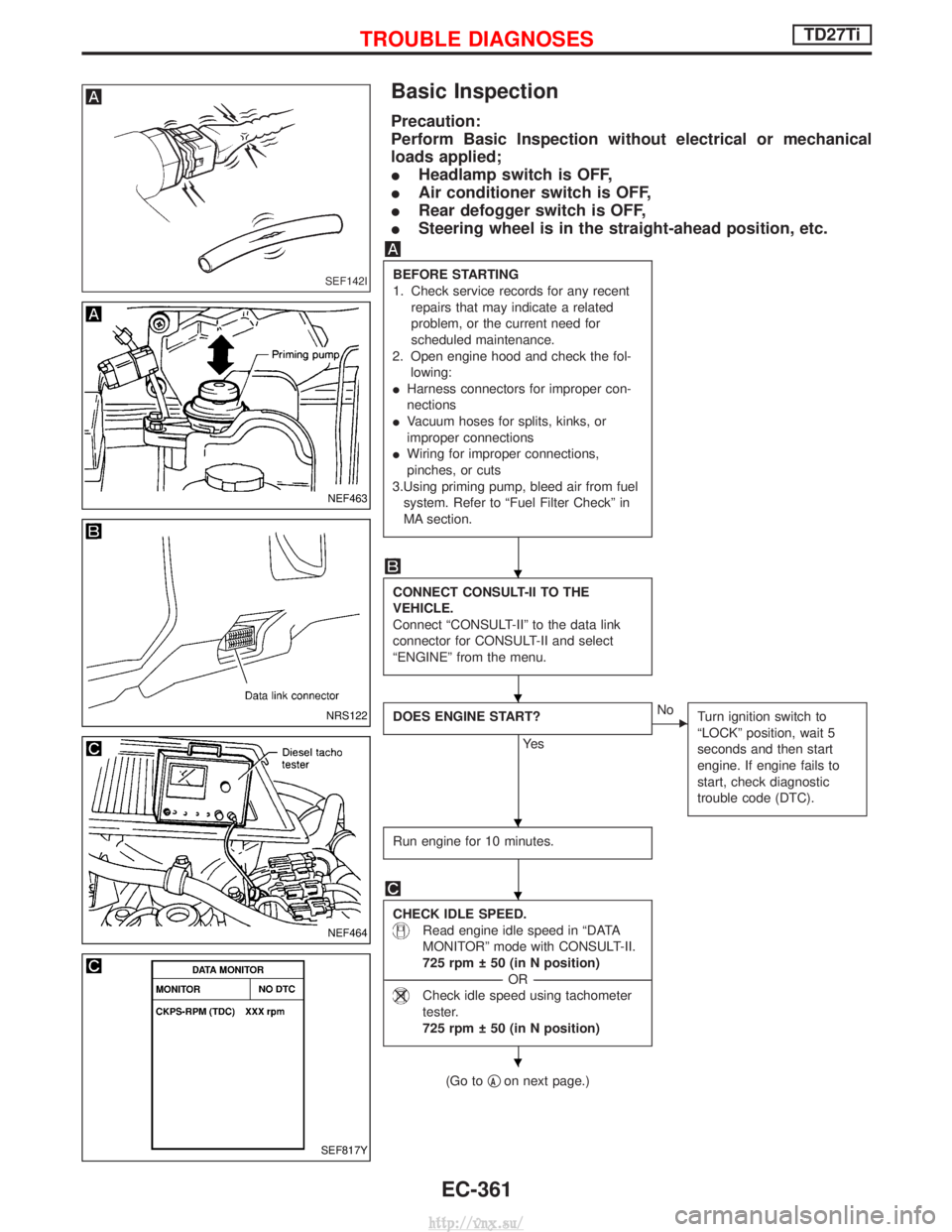

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

2. Open engine hood and check the fol- lowing:

I Harness connectors for improper con-

nections

I Vacuum hoses for splits, kinks, or

improper connections

I Wiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

----------------------------------------------------------------------------------------------------------------------------------- -OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go to qAon next page.)

SEF142I

NEF463

NRS122

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-361

http://vnx.su/

Page 1342 of 1833

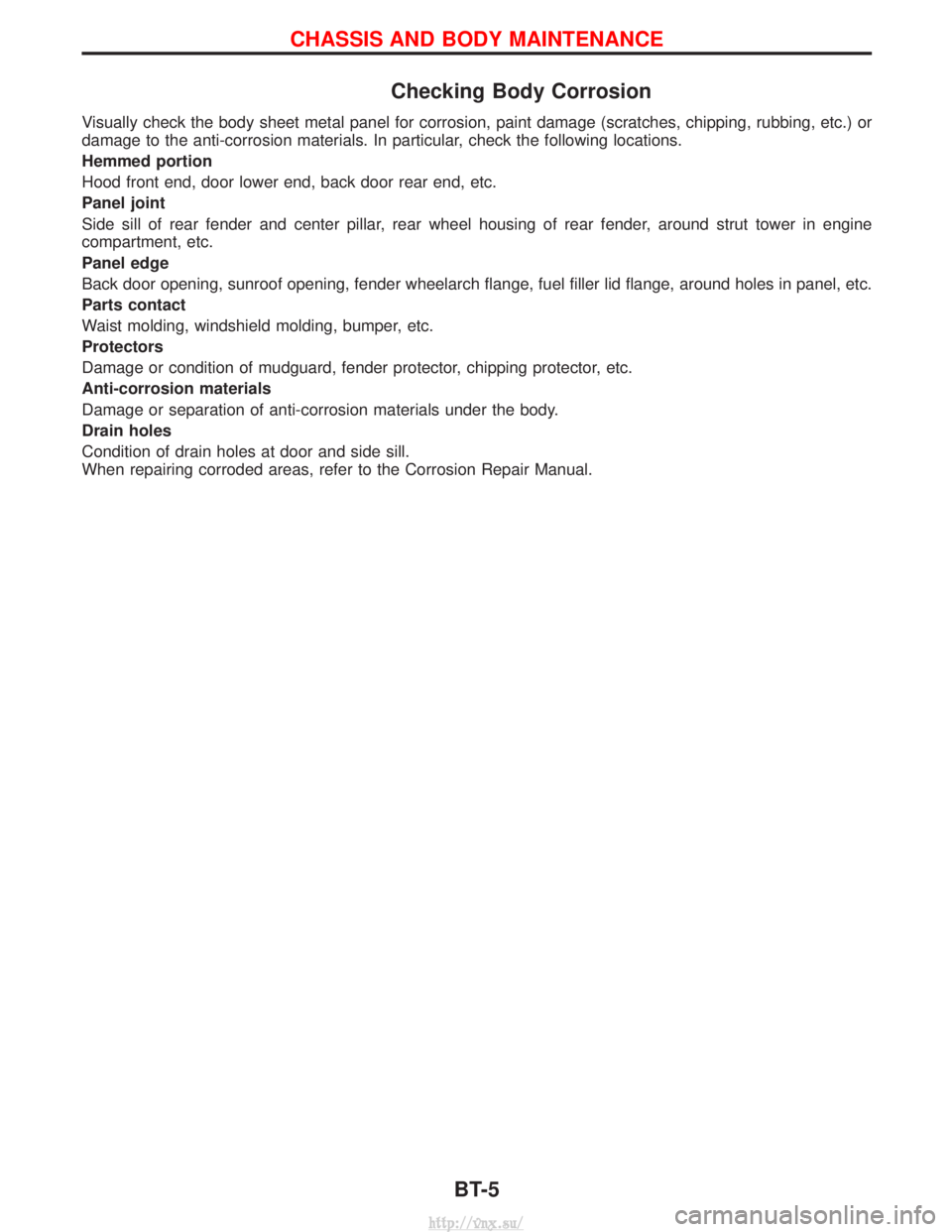

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, back door rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Back door opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

BT-5

http://vnx.su/

Page 1343 of 1833

Removal and Installation

IWhen removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body from

being scratched.

I Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

I Hood adjustment: Adjust at hinge portion.

I Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

I Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

BODY FRONT END

BT-6

http://vnx.su/

Page 1428 of 1833

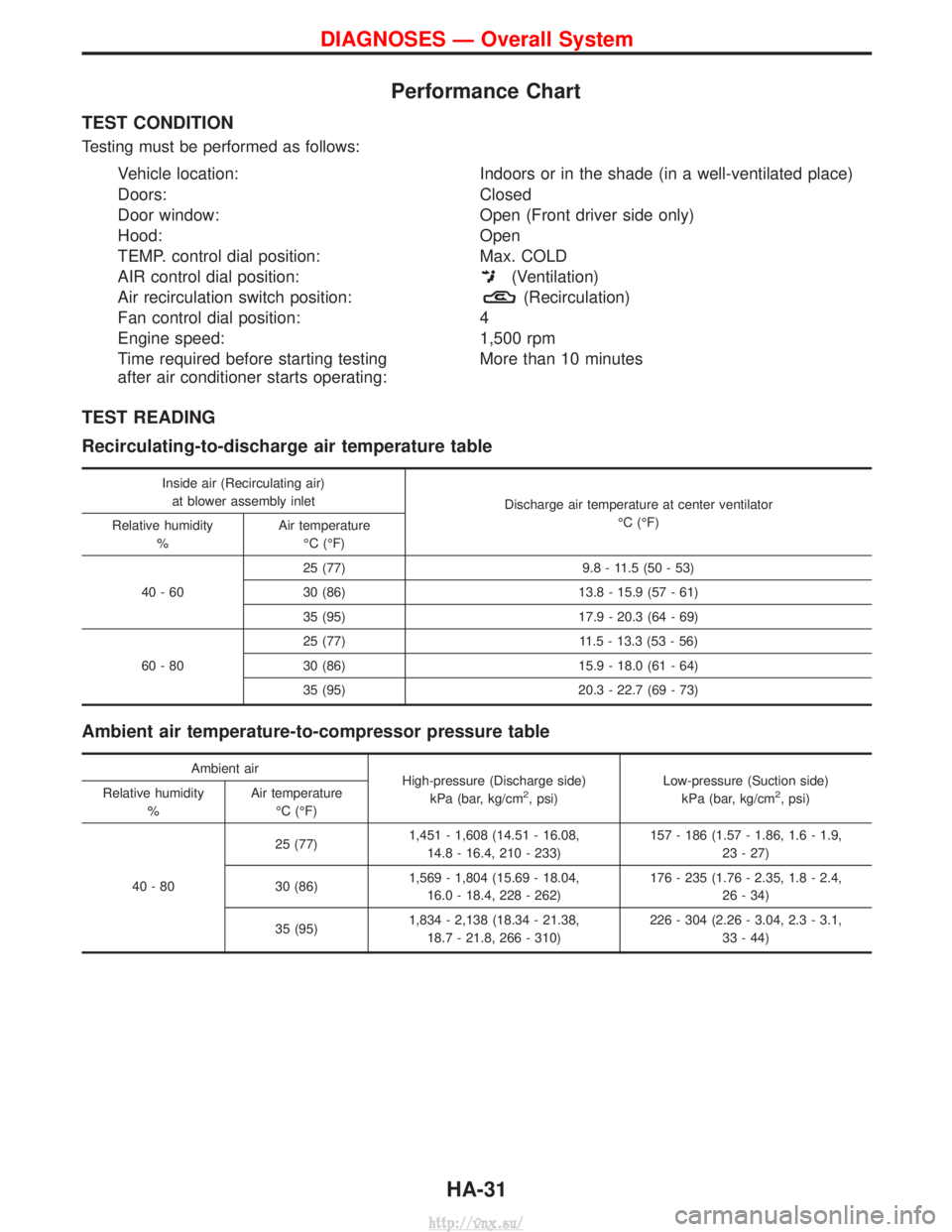

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location:Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control dial position: Max. COLD

AIR control dial position:

(Ventilation)

Air recirculation switch position:

(Recirculation)

Fan control dial position: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating: More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

% Air temperature

ÉC (ÉF)

40-60 25 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-80 25 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi) Low-pressure (Suction side)

kPa (bar, kg/cm2, psi)

Relative humidity

% Air temperature

ÉC (ÉF)

40-80 25 (77)

1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233) 157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86) 1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262) 176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95) 1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310) 226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-31

http://vnx.su/

Page 1710 of 1833

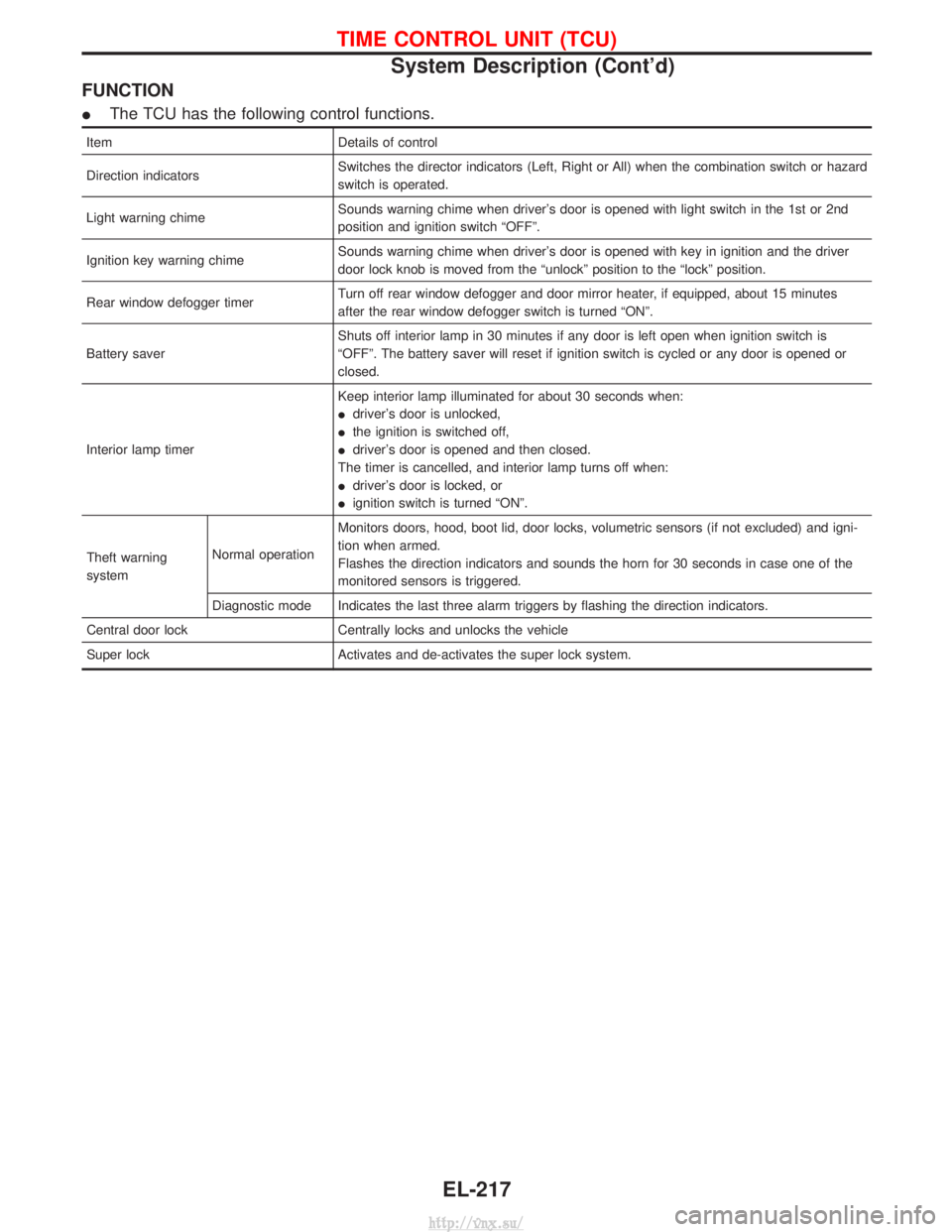

FUNCTION

IThe TCU has the following control functions.

Item Details of control

Direction indicators Switches the director indicators (Left, Right or All) when the combination switch or hazard

switch is operated.

Light warning chime Sounds warning chime when driver's door is opened with light switch in the 1st or 2nd

position and ignition switch ªOFFº.

Ignition key warning chime Sounds warning chime when driver's door is opened with key in ignition and the driver

door lock knob is moved from the ªunlockº position to the ªlockº position.

Rear window defogger timer Turn off rear window defogger and door mirror heater, if equipped, about 15 minutes

after the rear window defogger switch is turned ªONº.

Battery saver Shuts off interior lamp in 30 minutes if any door is left open when ignition switch is

ªOFFº. The battery saver will reset if ignition switch is cycled or any door is opened or

closed.

Interior lamp timer Keep interior lamp illuminated for about 30 seconds when:

I

driver's door is unlocked,

I the ignition is switched off,

I driver's door is opened and then closed.

The timer is cancelled, and interior lamp turns off when:

I driver's door is locked, or

I ignition switch is turned ªONº.

Theft warning

system Normal operationMonitors doors, hood, boot lid, door locks, volumetric sensors (if not excluded) and igni-

tion when armed.

Flashes the direction indicators and sounds the horn for 30 seconds in case one of the

monitored sensors is triggered.

Diagnostic mode Indicates the last three alarm triggers by flashing the direction indicators.

Central door lock Centrally locks and unlocks the vehicle

Super lock Activates and de-activates the super lock system.

TIME CONTROL UNIT (TCU)

System Description (Cont'd)

EL-217

http://vnx.su/

Page 1712 of 1833

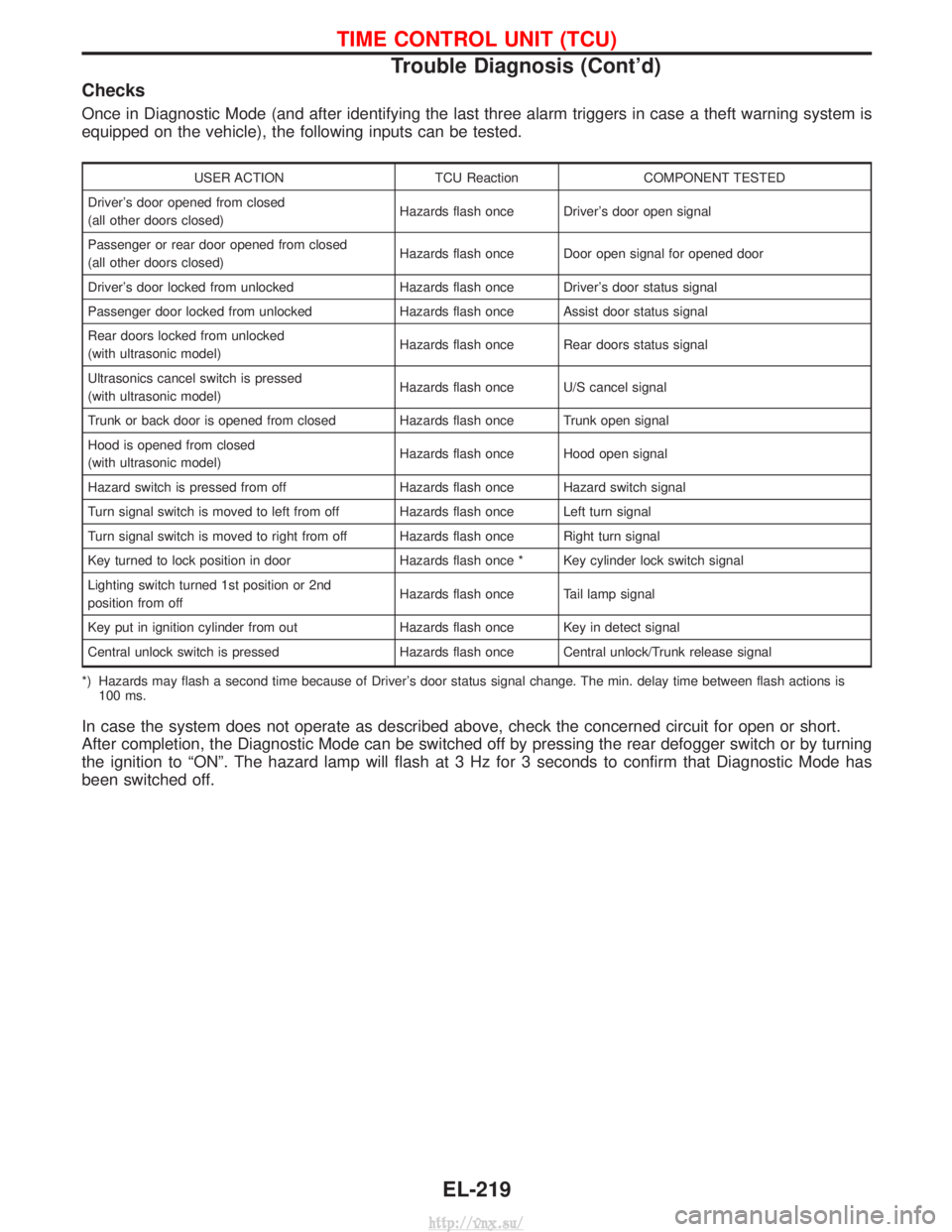

Checks

Once in Diagnostic Mode (and after identifying the last three alarm triggers in case a theft warning system is

equipped on the vehicle), the following inputs can be tested.

USER ACTIONTCU ReactionCOMPONENT TESTED

Driver's door opened from closed

(all other doors closed) Hazards flash once Driver's door open signal

Passenger or rear door opened from closed

(all other doors closed) Hazards flash once Door open signal for opened door

Driver's door locked from unlocked Hazards flash once Driver's door status signal

Passenger door locked from unlocked Hazards flash once Assist door status signal

Rear doors locked from unlocked

(with ultrasonic model) Hazards flash once Rear doors status signal

Ultrasonics cancel switch is pressed

(with ultrasonic model) Hazards flash once U/S cancel signal

Trunk or back door is opened from closed Hazards flash once Trunk open signal

Hood is opened from closed

(with ultrasonic model) Hazards flash once Hood open signal

Hazard switch is pressed from off Hazards flash once Hazard switch signal

Turn signal switch is moved to left from off Hazards flash once Left turn signal

Turn signal switch is moved to right from off Hazards flash once Right turn signal

Key turned to lock position in door Hazards flash once * Key cylinder lock switch signal

Lighting switch turned 1st position or 2nd

position from off Hazards flash once Tail lamp signal

Key put in ignition cylinder from out Hazards flash once Key in detect signal

Central unlock switch is pressed Hazards flash once Central unlock/Trunk release signal

*) Hazards may flash a second time because of Driver's door status signal change. The min. delay time between flash actions is 100 ms.

In case the system does not operate as described above, check the concerned circuit for open or short.

After completion, the Diagnostic Mode can be switched off by pressing the rear defogger switch or by turning

the ignition to ªONº. The hazard lamp will flash at 3 Hz for 3 seconds to confirm that Diagnostic Mode has

been switched off.

TIME CONTROL UNIT (TCU)

Trouble Diagnosis (Cont'd)

EL-219

http://vnx.su/

Page 1738 of 1833

SETTING THE THEFT WARNING SYSTEM

Initial condition

(1) Close all doors.

(2) Close hood.

Pre-armed phase and armed phase

The theft warning system turns into the ªpre-armedº phase when hood and all doors are closed and locked by

key or multi-remote controller. (The security indicator lamp blinks intermittently for 30 seconds.)

After about 30 seconds, the system automatically shifts into the ªarmedº phase (the system is set).

CANCELING THE SET THEFT WARNING SYSTEM

When the following (a) or (b) operation is performed, the armed phase is canceled.

(a) Unlock the doors with the multi-remote controller.

(b) Insert key in ignition key cylinder and turn it to ON. Then NATS IMMU will send a disarm signal to the timecontrol unit.

ACTIVATING THE ALARM OPERATION OF THE THEFT WARNING SYSTEM

Make sure the system is in the armed phase. When the following operation (a) (b) (c) or (d) is performed, the

system sounds the horns and flashes the hazard lamp for about 30 seconds.

(a) Engine hood or any door is opened before unlocking door with the multi-remote controller.

(b) A door is unlocked without using the multi-remote controller.

(c) The ignition is switched ON without using a NATS registered key.

(d) The ultrasonic sensing is triggered.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times.

IThrough 10A fuse [No.

16, located in the fuse block (J/B)]

I to combination meter (security indicator lamp) terminal q

27.

I through 10A fuse [No.

5, located in the fuse block (J/B)]

I to time control unit terminal

U09.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No.

26, located in the fuse block (J/B)]

I to time control unit terminal

U01.

Ground is supplied

I to time control unit terminal

U16

Ithrough body groundsF36andF47(LHD models), orM33andM754(RHD models).

INITIAL CONDITION TO ARM THE SYSTEM

The operation of the theft warning system is controlled by all the doors and hood.

To activate the theft warning system, the time control unit must receive signals indicating all the doors and

hood are closed and the doors are locked.

When a door is open, time control unit terminal

U06orU07receives a ground signal from each door switch.

When a door is unlocked, time control unit terminal

U25,U35orU36receives a ground signal from each door

unlock sensor.

When the hood is open, time control unit terminal

U32receives a ground signal

I from the hood switch

I through body grounds

M33andM754.

THEFT WARNING SYSTEM

System Description (Cont'd)

EL-245

http://vnx.su/