engine oil capacity NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 58 of 1833

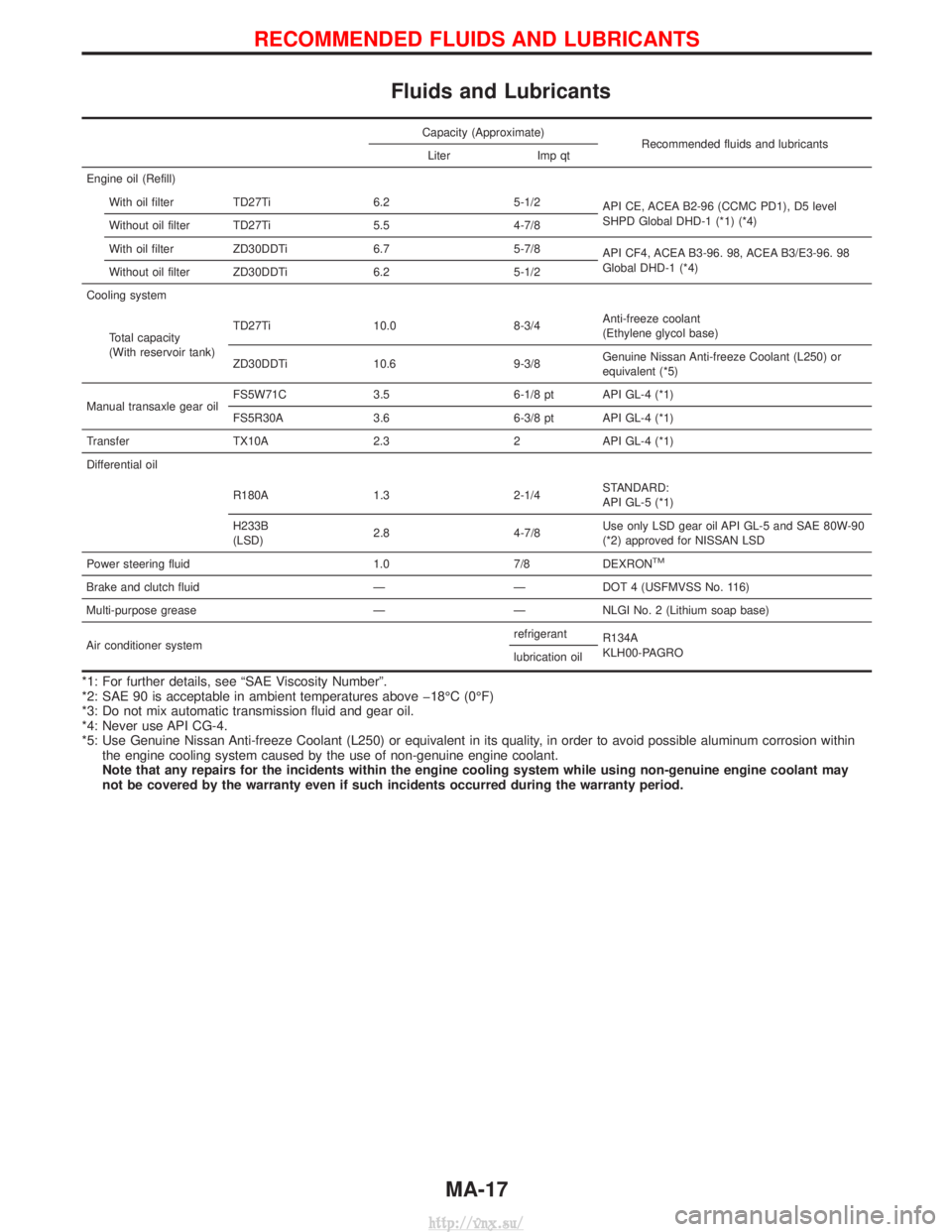

Fluids and Lubricants

Capacity (Approximate)Recommended fluids and lubricants

Liter Imp qt

Engine oil (Refill) With oil filter TD27Ti 6.2 5-1/2 API CE, ACEA B2-96 (CCMC PD1), D5 level

SHPD Global DHD-1 (*1) (*4)

Without oil filter TD27Ti 5.5 4-7/8

With oil filter ZD30DDTi 6.7 5-7/8 API CF4, ACEA B3-96. 98, ACEA B3/E3-96. 98

Global DHD-1 (*4)

Without oil filter ZD30DDTi 6.2 5-1/2

Cooling system

Total capacity

(With reservoir tank) TD27Ti 10.0 8-3/4

Anti-freeze coolant

(Ethylene glycol base)

ZD30DDTi 10.6 9-3/8 Genuine Nissan Anti-freeze Coolant (L250) or

equivalent (*5)

Manual transaxle gear oil FS5W71C 3.5 6-1/8 pt API GL-4 (*1)

FS5R30A 3.6 6-3/8 pt API GL-4 (*1)

Transfer TX10A 2.3 2 API GL-4 (*1)

Differential oil

R180A 1.3 2-1/4 STANDARD:

API GL-5 (*1)

H233B

(LSD) 2.8 4-7/8 Use only LSD gear oil API GL-5 and SAE 80W-90

(*2) approved for NISSAN LSD

Power steering fluid 1.0 7/8 DEXRON

TM

Brake and clutch fluid ÐÐDOT 4 (USFMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioner system refrigerant

R134A

KLH00-PAGRO

lubrication oil

*1: For further details, see ªSAE Viscosity Numberº.

*2: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF)

*3: Do not mix automatic transmission fluid and gear oil.

*4: Never use API CG-4.

*5: Use Genuine Nissan Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may

not be covered by the warranty even if such incidents occurred during the warranty period.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

http://vnx.su/

Page 62 of 1833

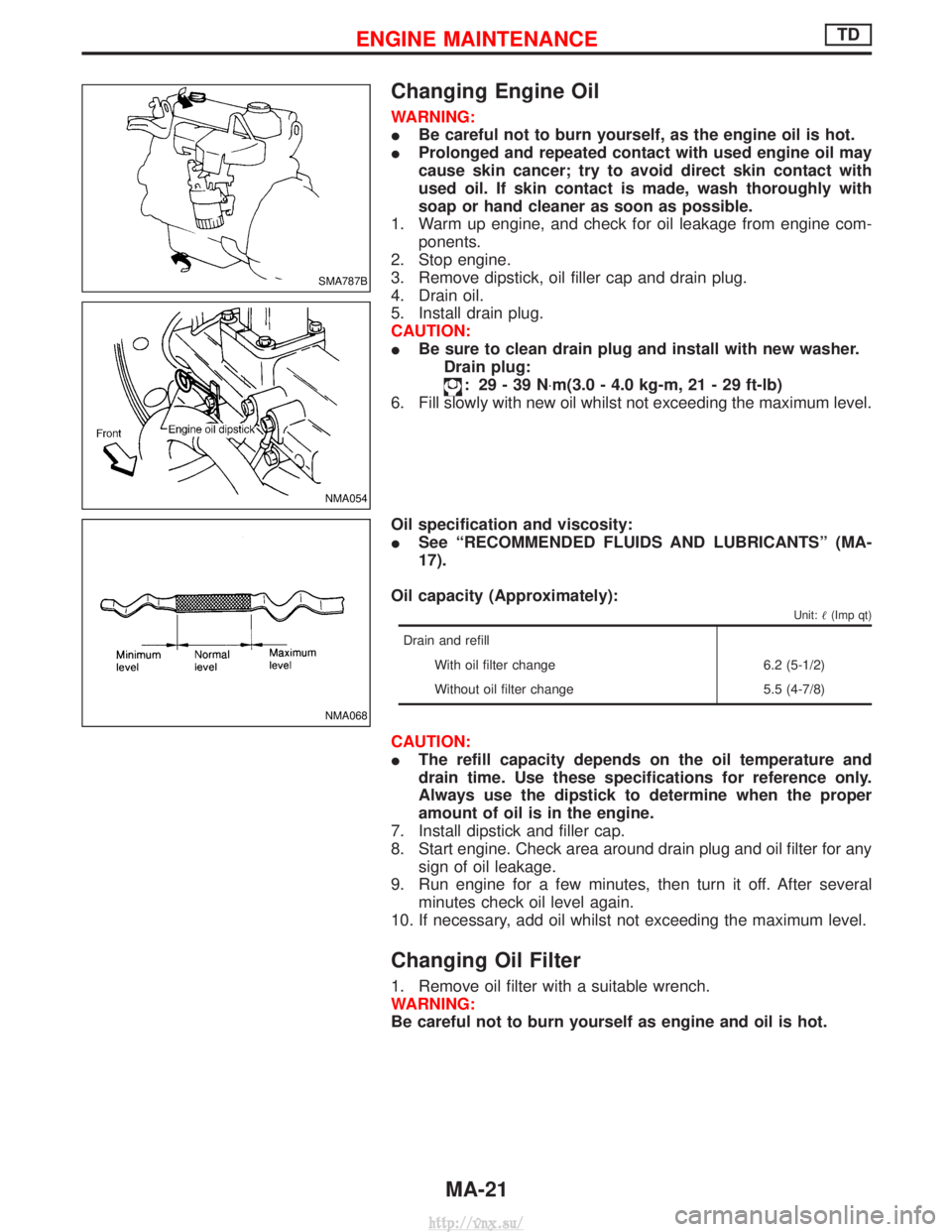

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com- ponents.

2. Stop engine.

3. Remove dipstick, oil filler cap and drain plug.

4. Drain oil.

5. Install drain plug.

CAUTION:

I Be sure to clean drain plug and install with new washer.

Drain plug:

: 29-39N ×m(3.0 - 4.0 kg-m, 21 - 29 ft-lb)

6. Fill slowly with new oil whilst not exceeding the maximum level.

Oil specification and viscosity:

I See ªRECOMMENDED FLUIDS AND LUBRICANTSº (MA-

17).

Oil capacity (Approximately):

Unit: (Imp qt)

Drain and refill

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

CAUTION:

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

7. Install dipstick and filler cap.

8. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

9. Run engine for a few minutes, then turn it off. After several minutes check oil level again.

10. If necessary, add oil whilst not exceeding the maximum level.

Changing Oil Filter

1. Remove oil filter with a suitable wrench.

WARNING:

Be careful not to burn yourself as engine and oil is hot.

SMA787B

NMA054

NMA068

ENGINE MAINTENANCETD

MA-21

http://vnx.su/

Page 63 of 1833

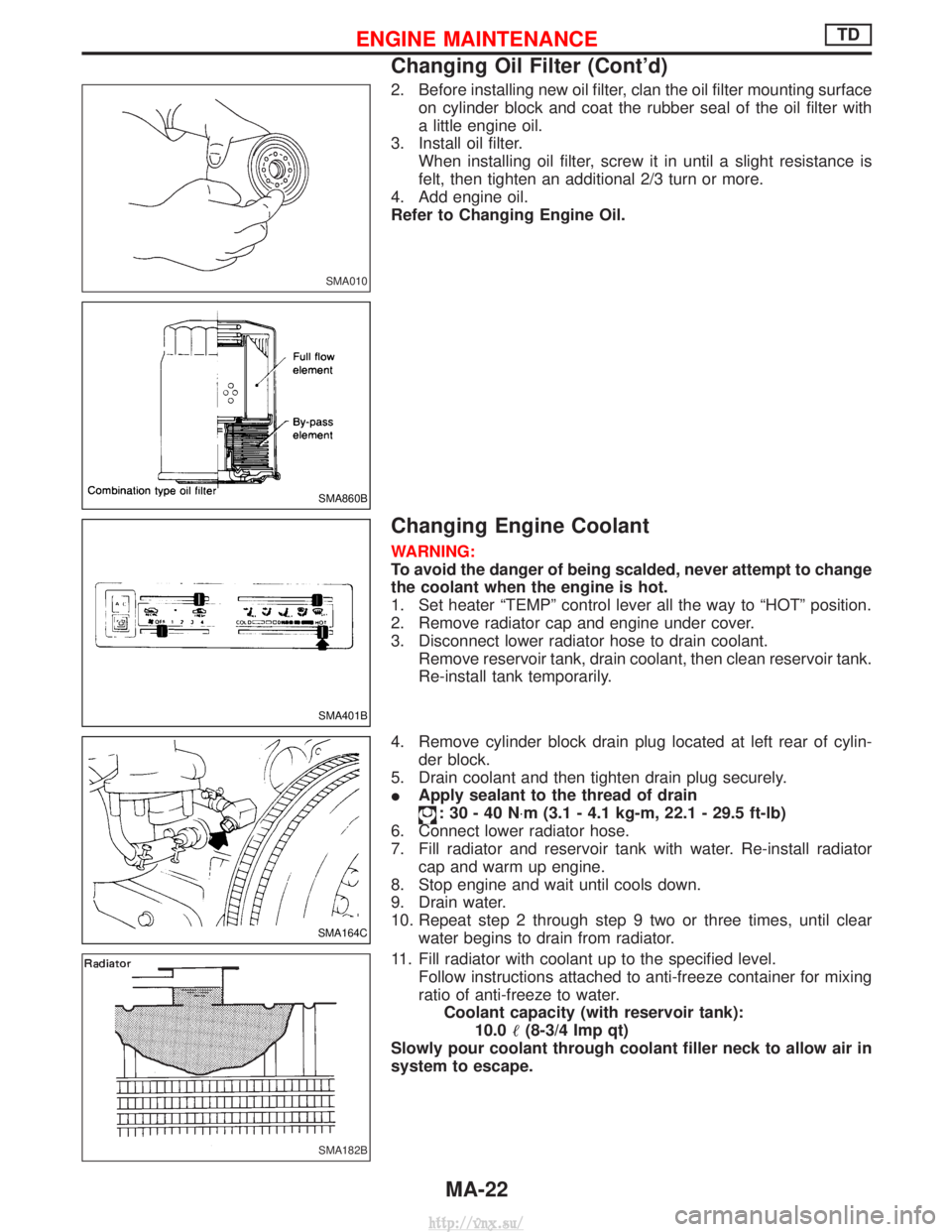

2. Before installing new oil filter, clan the oil filter mounting surfaceon cylinder block and coat the rubber seal of the oil filter with

a little engine oil.

3. Install oil filter. When installing oil filter, screw it in until a slight resistance is

felt, then tighten an additional 2/3 turn or more.

4. Add engine oil.

Refer to Changing Engine Oil.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never attempt to change

the coolant when the engine is hot.

1. Set heater ªTEMPº control lever all the way to ªHOTº position.

2. Remove radiator cap and engine under cover.

3. Disconnect lower radiator hose to drain coolant. Remove reservoir tank, drain coolant, then clean reservoir tank.

Re-install tank temporarily.

4. Remove cylinder block drain plug located at left rear of cylin- der block.

5. Drain coolant and then tighten drain plug securely.

I Apply sealant to the thread of drain

:30-40N ×m (3.1 - 4.1 kg-m, 22.1 - 29.5 ft-lb)

6. Connect lower radiator hose.

7. Fill radiator and reservoir tank with water. Re-install radiator cap and warm up engine.

8. Stop engine and wait until cools down.

9. Drain water.

10. Repeat step 2 through step 9 two or three times, until clear water begins to drain from radiator.

11. Fill radiator with coolant up to the specified level. Follow instructions attached to anti-freeze container for mixing

ratio of anti-freeze to water.Coolant capacity (with reservoir tank): 10.0 (8-3/4 Imp qt)

Slowly pour coolant through coolant filler neck to allow air in

system to escape.

SMA010

SMA860B

SMA401B

SMA164C

SMA182B

ENGINE MAINTENANCETD

Changing Oil Filter (Cont'd)

MA-22

http://vnx.su/

Page 71 of 1833

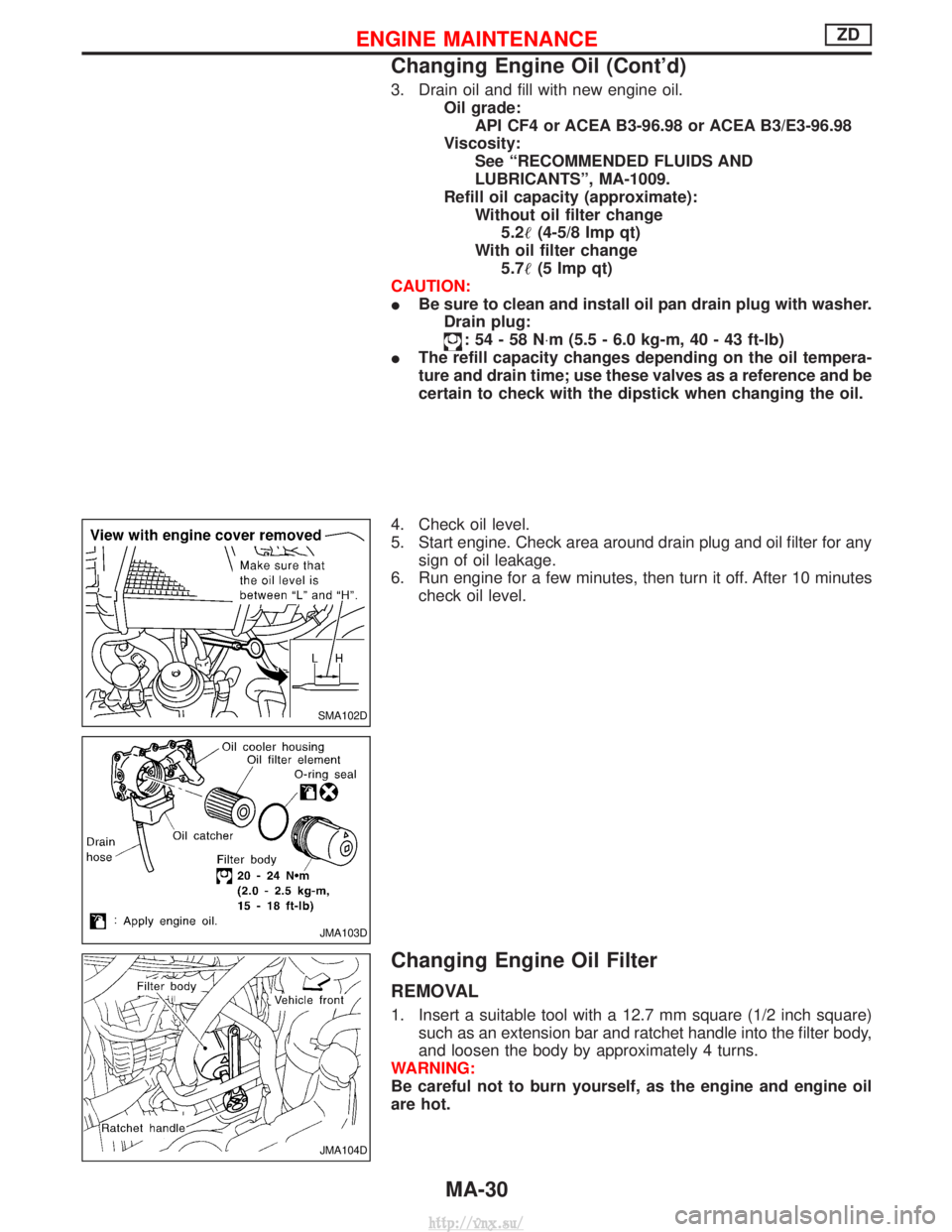

3. Drain oil and fill with new engine oil.Oil grade:API CF4 or ACEA B3-96.98 or ACEA B3/E3-96.98

Viscosity: See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate): Without oil filter change5.2 (4-5/8 Imp qt)

With oil filter change 5.7 (5 Imp qt)

CAUTION:

I Be sure to clean and install oil pan drain plug with washer.

Drain plug:

:54-58N ×m (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

I The refill capacity changes depending on the oil tempera-

ture and drain time; use these valves as a reference and be

certain to check with the dipstick when changing the oil.

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 minutes check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)such as an extension bar and ratchet handle into the filter body,

and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-30

http://vnx.su/

Page 78 of 1833

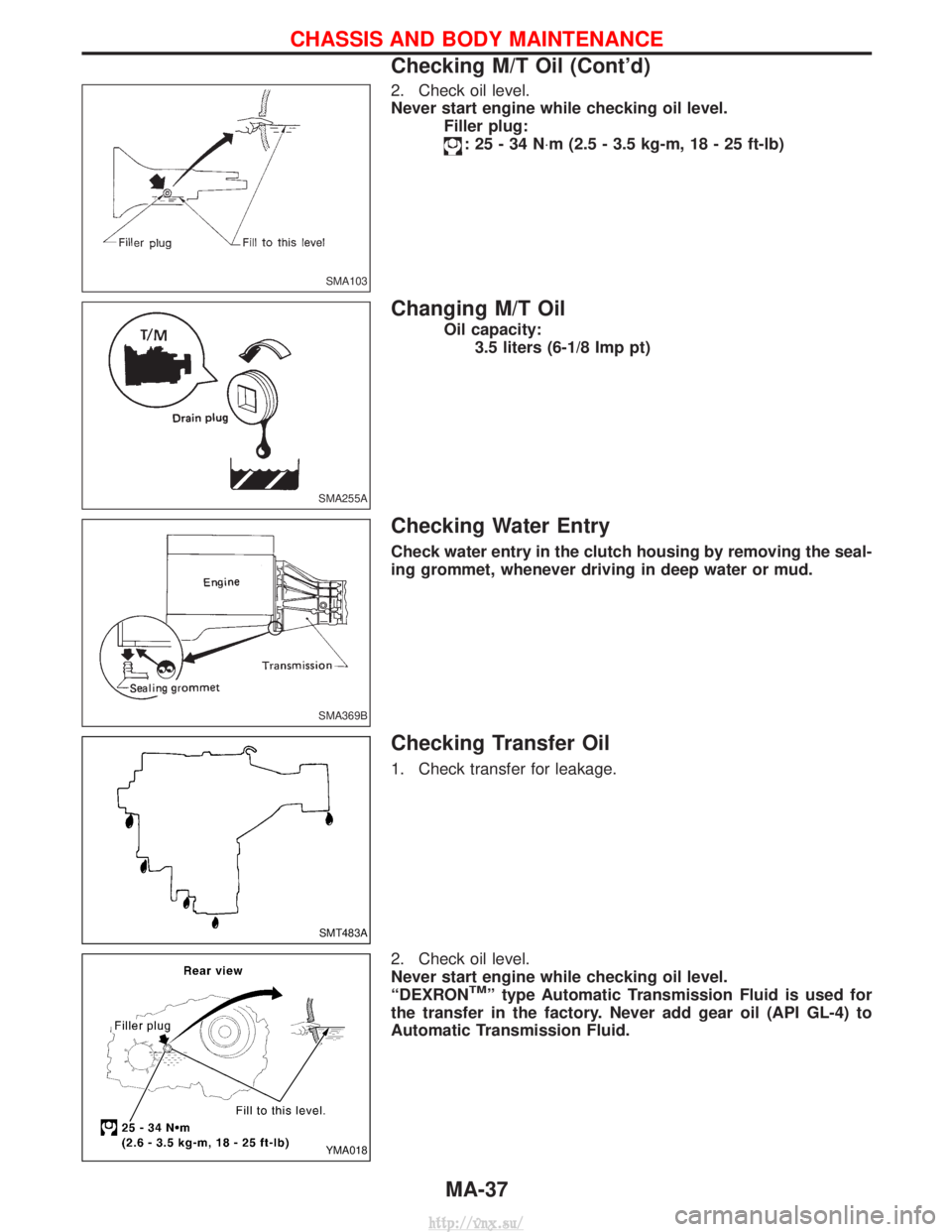

2. Check oil level.

Never start engine while checking oil level.Filler plug:

:25-34N ×m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil capacity:

3.5 liters (6-1/8 Imp pt)

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Oil

1. Check transfer for leakage.

2. Check oil level.

Never start engine while checking oil level.

ªDEXRON

TMº type Automatic Transmission Fluid is used for

the transfer in the factory. Never add gear oil (API GL-4) to

Automatic Transmission Fluid.

SMA103

SMA255A

SMA369B

SMT483A

YMA018

CHASSIS AND BODY MAINTENANCE

Checking M/T Oil (Cont'd)

MA-37

http://vnx.su/

Page 89 of 1833

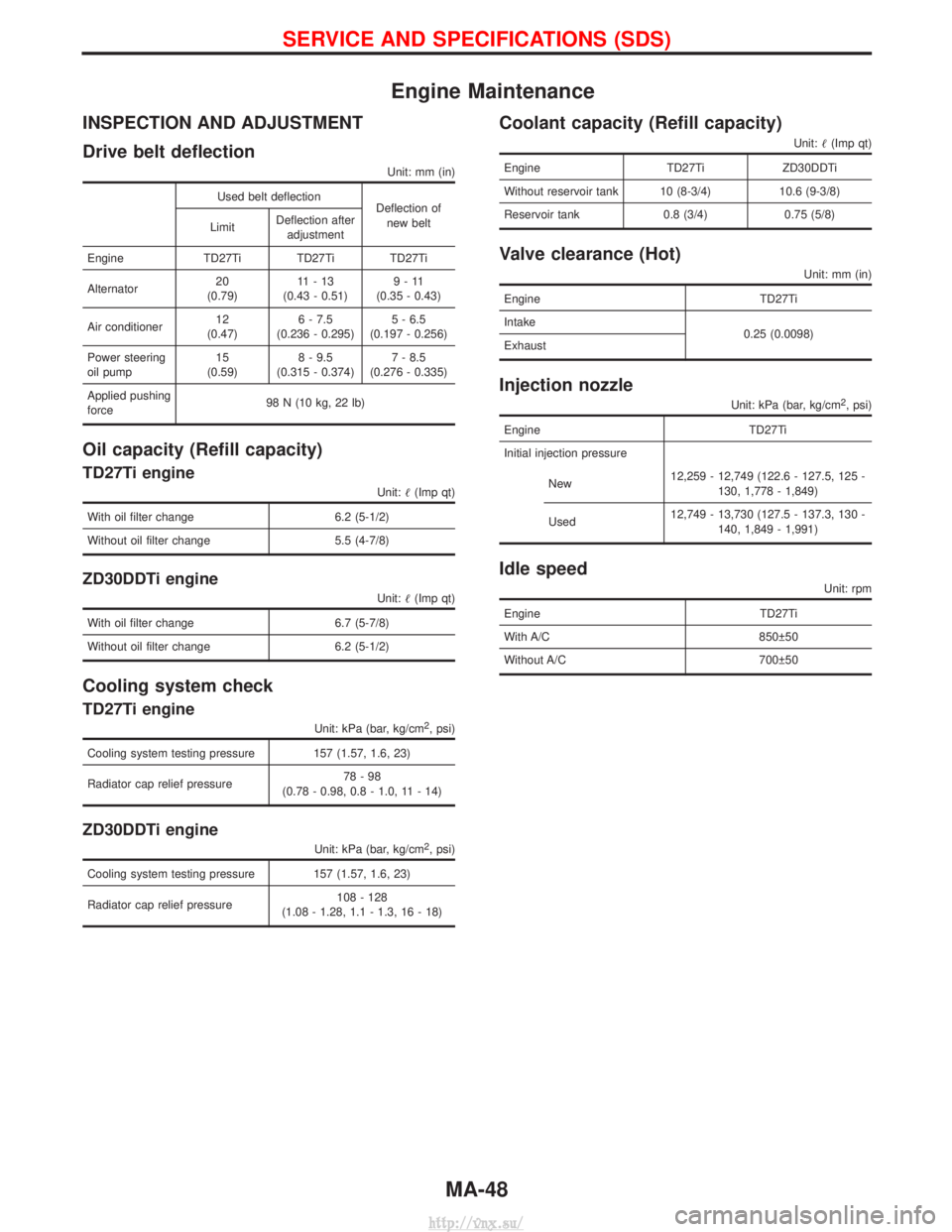

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 811 of 1833

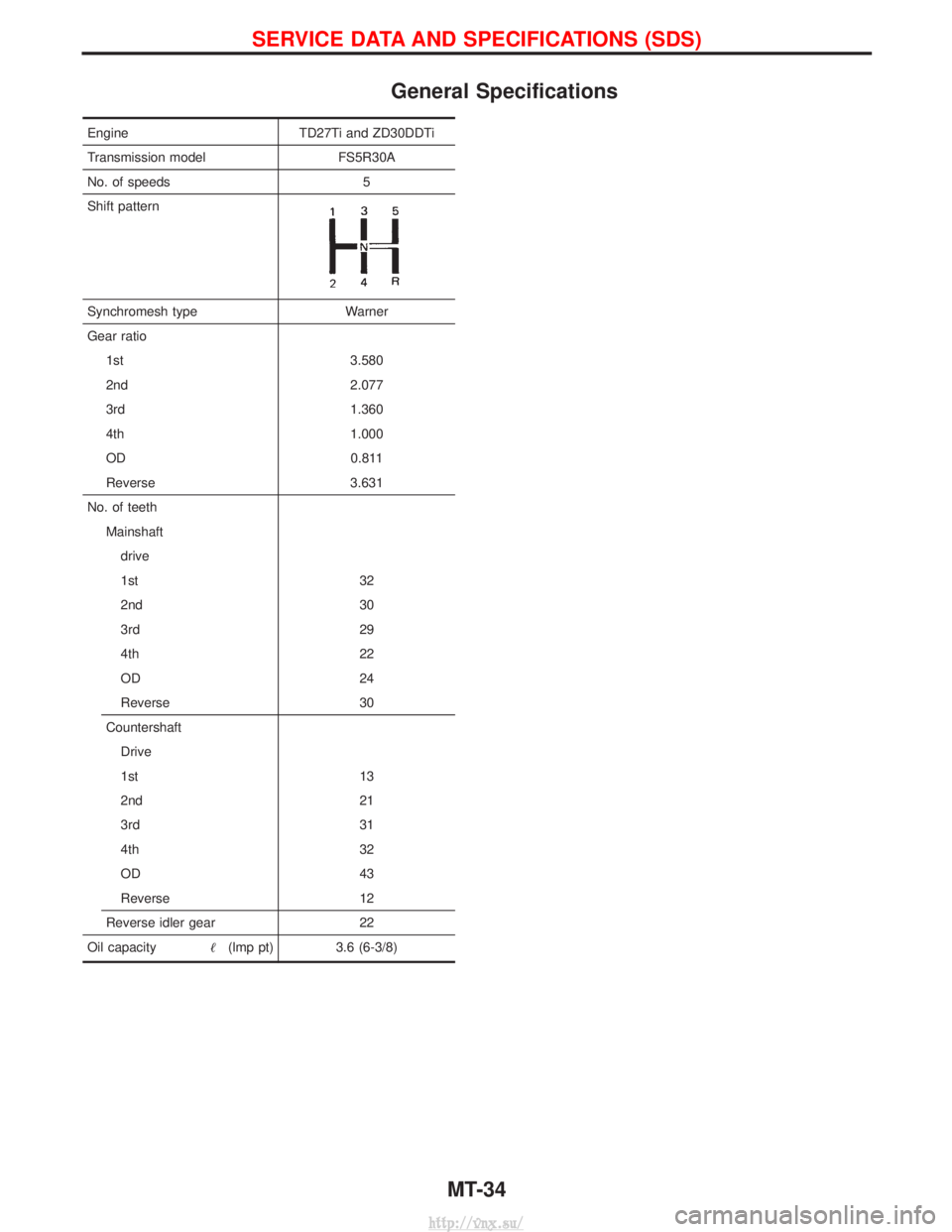

General Specifications

EngineTD27Ti and ZD30DDTi

Transmission model FS5R30A

No. of speeds 5

Shift pattern

Synchromesh type Warner

Gear ratio 1st 3.580

2nd 2.077

3rd 1.360

4th 1.000

OD 0.811

Reverse 3.631

No. of teeth Mainshaftdrive

1st 32

2nd 30

3rd 29

4th 22

OD 24

Reverse 30

Countershaft Drive

1st 13

2nd 21

3rd 31

4th 32

OD 43

Reverse 12

Reverse idler gear 22

Oil capacity (lmp pt) 3.6 (6-3/8)

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-34

http://vnx.su/

Page 1462 of 1833

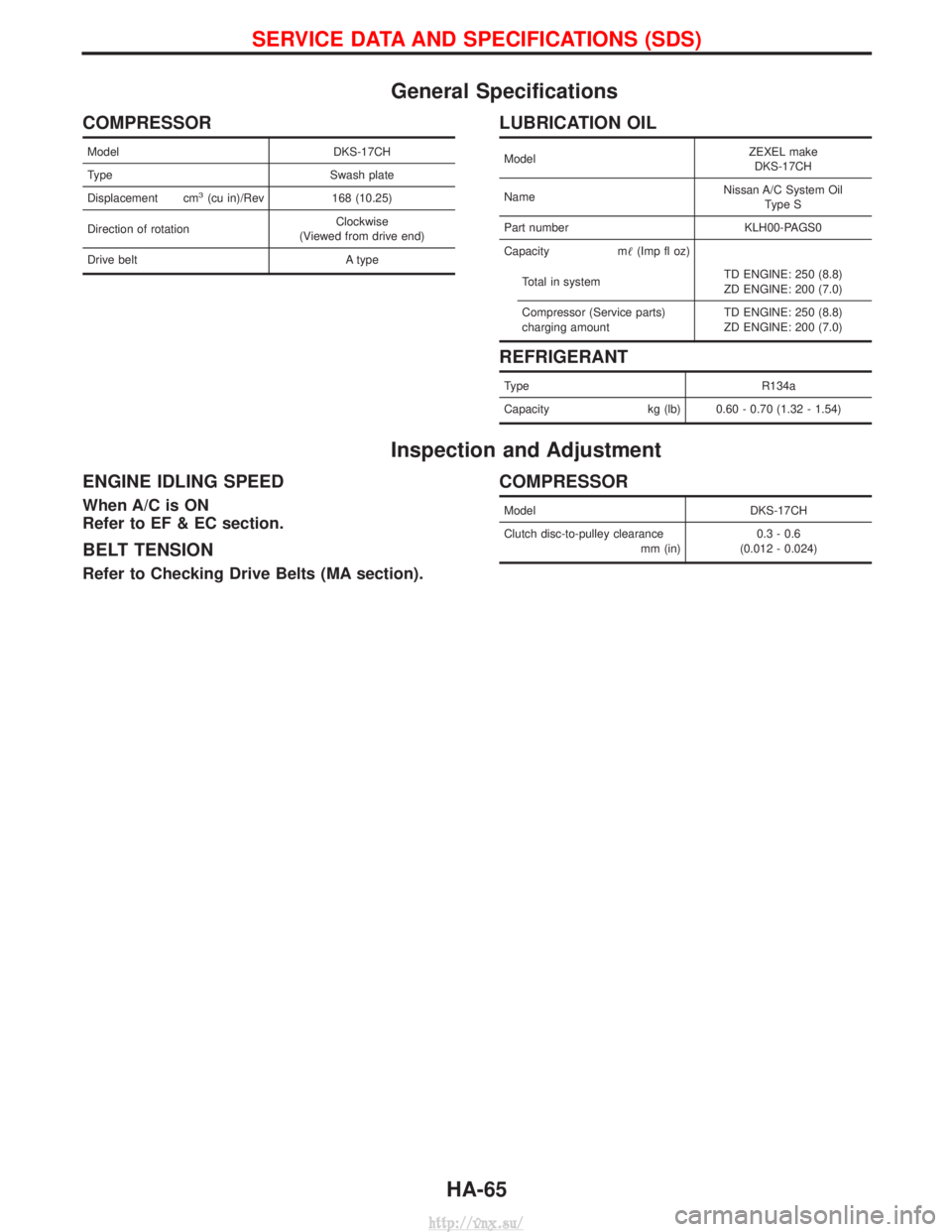

General Specifications

COMPRESSOR

ModelDKS-17CH

Type Swash plate

Displacement cm

3(cu in)/Rev 168 (10.25)

Direction of rotation Clockwise

(Viewed from drive end)

Drive belt A type

LUBRICATION OIL

ModelZEXEL make

DKS-17CH

Name Nissan A/C System Oil

Type S

Part number KLH00-PAGS0

Capacity m (Imp fl oz)

Total in system TD ENGINE: 250 (8.8)

ZD ENGINE: 200 (7.0)

Compressor (Service parts)

charging amount TD ENGINE: 250 (8.8)

ZD ENGINE: 200 (7.0)

REFRIGERANT

Type

R134a

Capacity kg (lb) 0.60 - 0.70 (1.32 - 1.54)

Inspection and Adjustment

ENGINE IDLING SPEED

When A/C is ON

Refer to EF & EC section.

BELT TENSION

Refer to Checking Drive Belts (MA section).

COMPRESSOR

Model DKS-17CH

Clutch disc-to-pulley clearance mm (in)0.3 - 0.6

(0.012 - 0.024)

SERVICE DATA AND SPECIFICATIONS (SDS)

HA-65

http://vnx.su/

Page 1830 of 1833

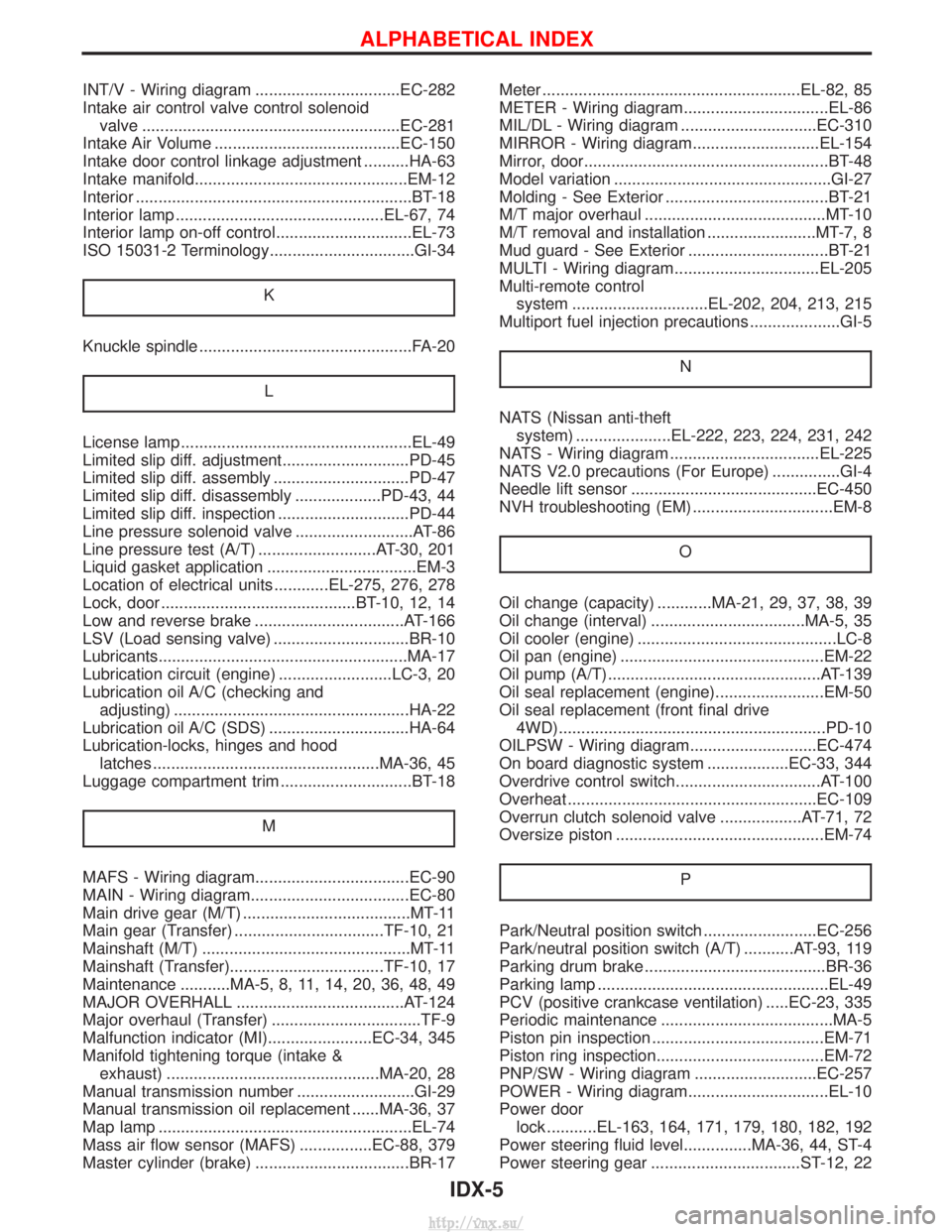

INT/V - Wiring diagram ................................EC-282

Intake air control valve control solenoidvalve .........................................................EC-281

Intake Air Volume .........................................EC-150

Intake door control linkage adjustment ..........HA-63

Intake manifold...............................................EM-12

Interior .............................................................BT-18

Interior lamp ..............................................EL-67, 74

Interior lamp on-off control..............................EL-73

ISO 15031-2 Terminology................................GI-34

K

Knuckle spindle ...............................................FA-20 L

License lamp ...................................................EL-49

Limited slip diff. adjustment............................PD-45

Limited slip diff. assembly ..............................PD-47

Limited slip diff. disassembly ...................PD-43, 44

Limited slip diff. inspection .............................PD-44

Line pressure solenoid valve ..........................AT-86

Line pressure test (A/T) ..........................AT-30, 201

Liquid gasket application .................................EM-3

Location of electrical units ............EL-275, 276, 278

Lock, door ...........................................BT-10, 12, 14

Low and reverse brake .................................AT-166

LSV (Load sensing valve) ..............................BR-10

Lubricants.......................................................MA-17

Lubrication circuit (engine) .........................LC-3, 20

Lubrication oil A/C (checking andadjusting) ....................................................HA-22

Lubrication oil A/C (SDS) ...............................HA-64

Lubrication-locks, hinges and hood latches ..................................................MA-36, 45

Luggage compartment trim .............................BT-18

M

MAFS - Wiring diagram..................................EC-90

MAIN - Wiring diagram...................................EC-80

Main drive gear (M/T) .....................................MT-11

Main gear (Transfer) .................................TF-10, 21

Mainshaft (M/T) ..............................................MT-11

Mainshaft (Transfer)..................................TF-10, 17

Maintenance ...........MA-5, 8, 11, 14, 20, 36, 48, 49

MAJOR OVERHALL .....................................AT-124

Major overhaul (Transfer) .................................TF-9

Malfunction indicator (MI).......................EC-34, 345

Manifold tightening torque (intake &exhaust) ...............................................MA-20, 28

Manual transmission number ..........................GI-29

Manual transmission oil replacement ......MA-36, 37

Map lamp ........................................................EL-74

Mass air flow sensor (MAFS) ................EC-88, 379

Master cylinder (brake) ..................................BR-17 Meter .........................................................EL-82, 85

METER - Wiring diagram................................EL-86

MIL/DL - Wiring diagram ..............................EC-310

MIRROR - Wiring diagram............................EL-154

Mirror, door......................................................BT-48

Model variation ................................................GI-27

Molding - See Exterior ....................................BT-21

M/T major overhaul ........................................MT-10

M/T removal and installation ........................MT-7, 8

Mud guard - See Exterior ...............................BT-21

MULTI - Wiring diagram................................EL-205

Multi-remote control

system ..............................EL-202, 204, 213, 215

Multiport fuel injection precautions ....................GI-5

N

NATS (Nissan anti-theftsystem) .....................EL-222, 223, 224, 231, 242

NATS - Wiring diagram .................................EL-225

NATS V2.0 precautions (For Europe) ...............GI-4

Needle lift sensor .........................................EC-450

NVH troubleshooting (EM) ...............................EM-8

O

Oil change (capacity) ............MA-21, 29, 37, 38, 39

Oil change (interval) ..................................MA-5, 35

Oil cooler (engine) ............................................LC-8

Oil pan (engine) .............................................EM-22

Oil pump (A/T)...............................................AT-139

Oil seal replacement (engine)........................EM-50

Oil seal replacement (front final drive4WD)...........................................................PD-10

OILPSW - Wiring diagram............................EC-474

On board diagnostic system ..................EC-33, 344

Overdrive control switch................................AT-100

Overheat .......................................................EC-109

Overrun clutch solenoid valve ..................AT-71, 72

Oversize piston ..............................................EM-74

P

Park/Neutral position switch .........................EC-256

Park/neutral position switch (A/T) ...........AT-93, 119

Parking drum brake ........................................BR-36

Parking lamp ...................................................EL-49

PCV (positive crankcase ventilation) .....EC-23, 335

Periodic maintenance ......................................MA-5

Piston pin inspection ......................................EM-71

Piston ring inspection.....................................EM-72

PNP/SW - Wiring diagram ...........................EC-257

POWER - Wiring diagram...............................EL-10

Power doorlock ...........EL-163, 164, 171, 179, 180, 182, 192

Power steering fluid level...............MA-36, 44, ST-4

Power steering gear .................................ST-12, 22

ALPHABETICAL INDEX

IDX-5

http://vnx.su/