low oil pressure NISSAN TERRANO 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 579 of 1833

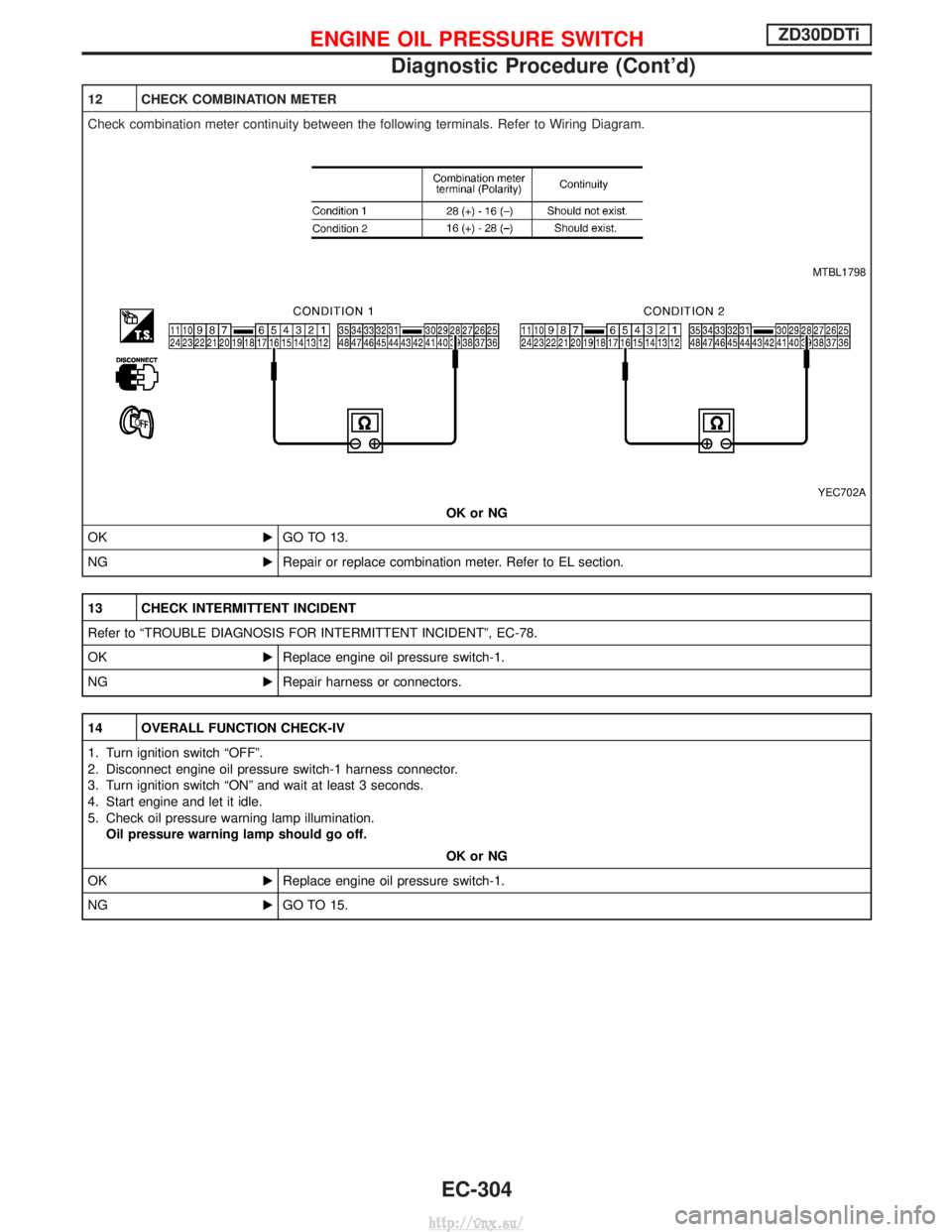

12 CHECK COMBINATION METER

Check combination meter continuity between the following terminals. Refer to Wiring Diagram.

MTBL1798

YEC702A

OK or NG

OK EGO TO 13.

NG ERepair or replace combination meter. Refer to EL section.

13 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

OK EReplace engine oil pressure switch-1.

NG ERepair harness or connectors.

14 OVERALL FUNCTION CHECK-IV

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-1 harness connector.

3. Turn ignition switch ªONº and wait at least 3 seconds.

4. Start engine and let it idle.

5. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should go off.

OK or NG

OK EReplace engine oil pressure switch-1.

NG EGO TO 15.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-304

http://vnx.su/

Page 580 of 1833

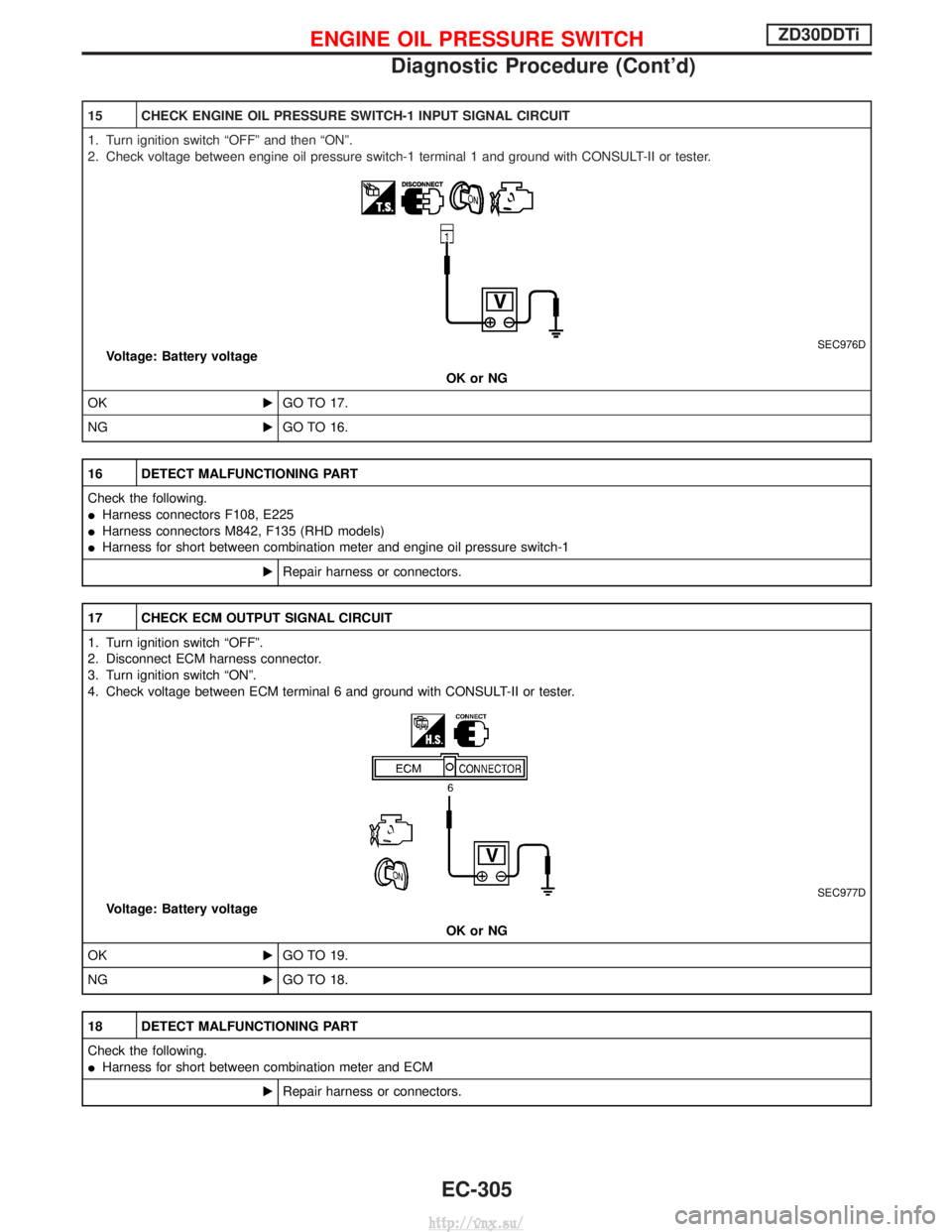

15 CHECK ENGINE OIL PRESSURE SWITCH-1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between engine oil pressure switch-1 terminal 1 and ground with CONSULT-II or tester.

SEC976DVoltage: Battery voltageOK or NG

OK EGO TO 17.

NG EGO TO 16.

16 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F108, E225

I Harness connectors M842, F135 (RHD models)

I Harness for short between combination meter and engine oil pressure switch-1

ERepair harness or connectors.

17 CHECK ECM OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 6 and ground with CONSULT-II or tester.

SEC977D

Voltage: Battery voltage

OK or NG

OK EGO TO 19.

NG EGO TO 18.

18 DETECT MALFUNCTIONING PART

Check the following.

IHarness for short between combination meter and ECM

ERepair harness or connectors.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-305

http://vnx.su/

Page 581 of 1833

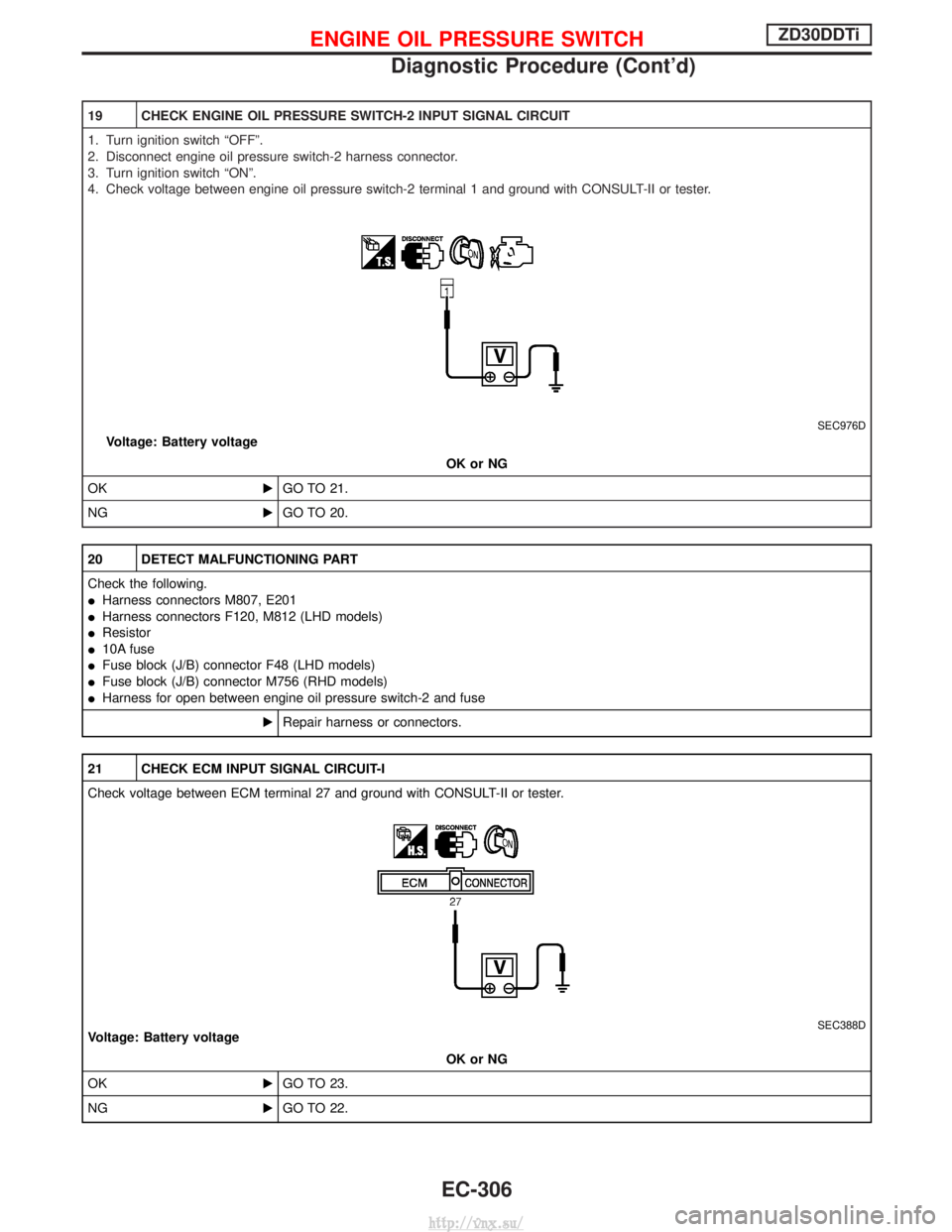

19 CHECK ENGINE OIL PRESSURE SWITCH-2 INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-2 harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between engine oil pressure switch-2 terminal 1 and ground with CONSULT-II or tester.

SEC976D

Voltage: Battery voltageOK or NG

OK EGO TO 21.

NG EGO TO 20.

20 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M807, E201

I Harness connectors F120, M812 (LHD models)

I Resistor

I 10A fuse

I Fuse block (J/B) connector F48 (LHD models)

I Fuse block (J/B) connector M756 (RHD models)

I Harness for open between engine oil pressure switch-2 and fuse

ERepair harness or connectors.

21 CHECK ECM INPUT SIGNAL CIRCUIT-I

Check voltage between ECM terminal 27 and ground with CONSULT-II or tester.

SEC388DVoltage: Battery voltage

OK or NG

OK EGO TO 23.

NG EGO TO 22.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-306

http://vnx.su/

Page 582 of 1833

22 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F120, M812 (LHD models)

I Fuse block (J/B) connector F48 (LHD models)

I Fuse block (J/B) connector M756 (RHD models)

I 10A fuse

I Resistor

I Harness for open or short between ECM and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

23 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº EC-78.

OK or NG

OK EReplace engine oil pressure switch-2.

NG ERepair harness or connectors.

24 OVERALL FUNCTION CHECK-V

1. Turn ignition switch ªOFFº.

2. Disconnect engine oil pressure switch-2 harness connector.

3. Start engine and warm it up to normal operating temperature.

4. Keep engine speed between 3,600 to 4,200 rpm at least 30 seconds.

5. Check oil pressure warning lamp illumination.

Oil pressure warning lamp should not illuminate.

OK or NG

OK EGO TO 25.

NG EReplace oil pressure switch-2.

25 DETECT MALFUNCTIONING PART

Check the following.

IHarness for short to ground between ECM and engine oil pressure switch-2

I Harness for short to ground between ECM and fuse block

ERepair short to ground in harness or connectors.

ENGINE OIL PRESSURE SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-307

http://vnx.su/

Page 638 of 1833

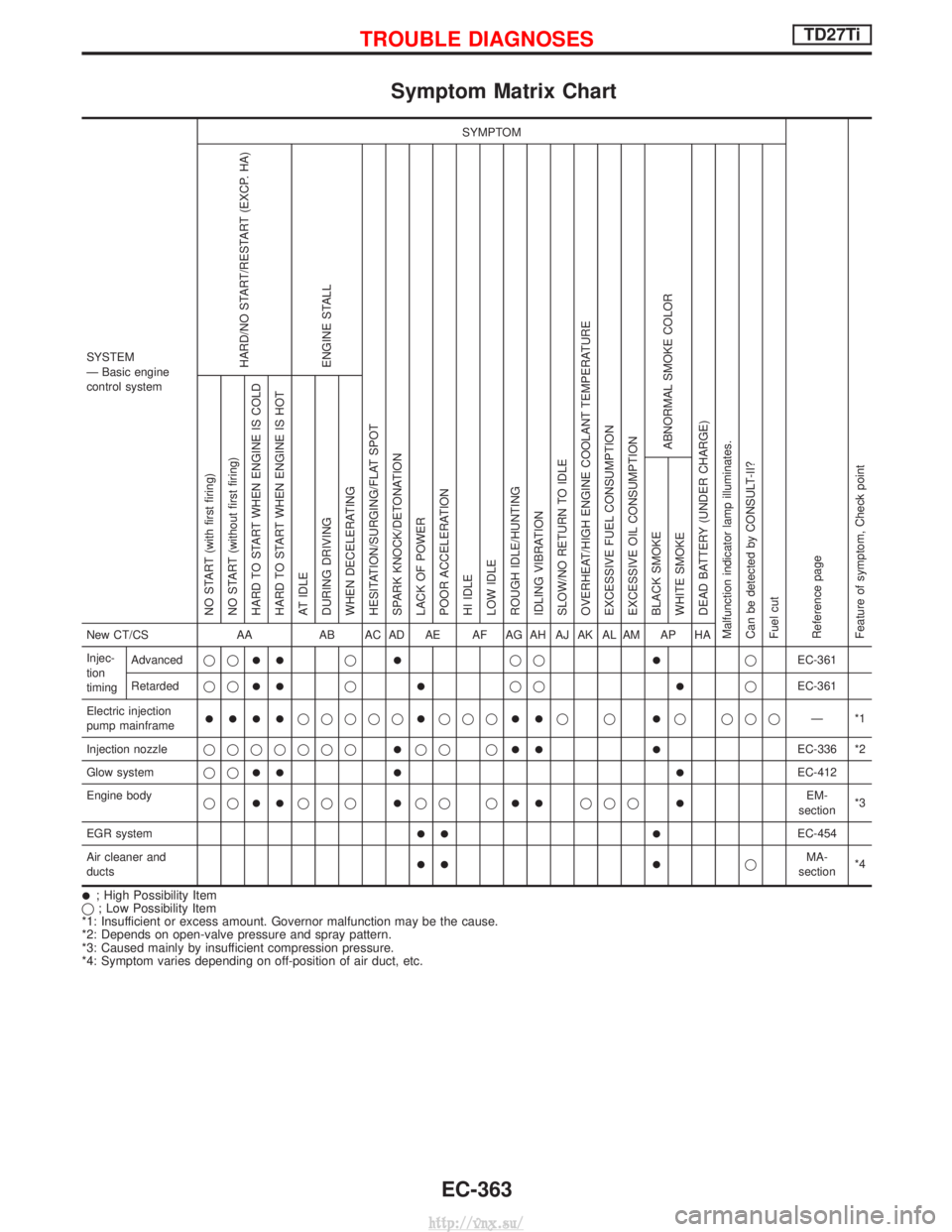

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS

AAAB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timing Advanced

qq

IIqIqqIqEC-361

Retarded qq

IIqIqqIqEC-361

Electric injection

pump mainframe

IIIIqqqqqIqqqIIqqIq qqq Ð*1

Injection nozzle qqqqqqq

Iqq qIIIEC-336 *2

Glow system qq

III IEC-412

Engine body qq

IIqqqIqq qIIqqqIEM-

section *3

EGR system

II IEC-454

Air cleaner and

ducts

II IqMA-

section *4

I; High Possibility Item

q ; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSESTD27Ti

EC-363

http://vnx.su/

Page 645 of 1833

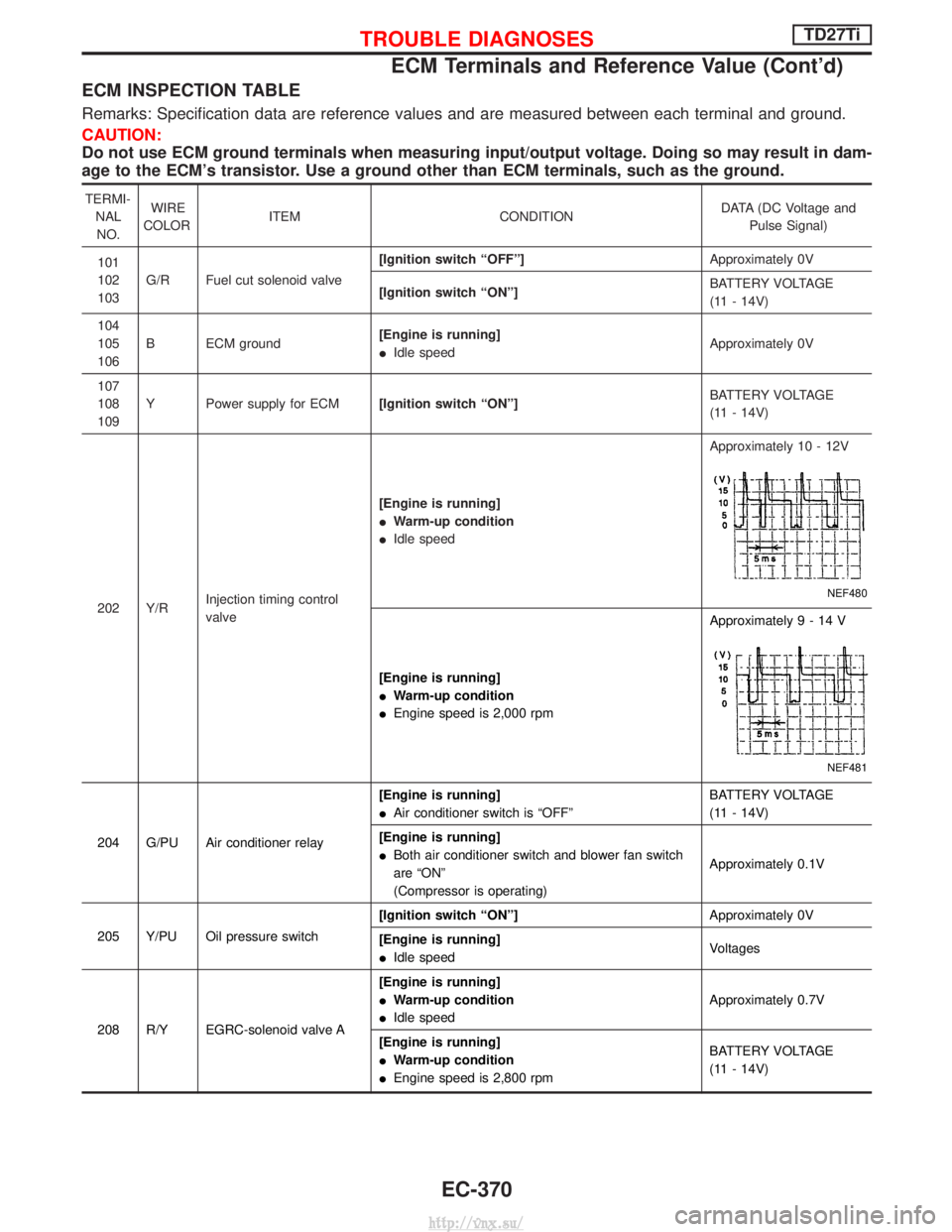

ECM INSPECTION TABLE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-NALNO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

101

102

103 G/R Fuel cut solenoid valve [Ignition switch ªOFFº]

Approximately 0V

[Ignition switch ªONº] BATTERY VOLTAGE

(11 - 14V)

104

105

106 B ECM ground

[Engine is running]

I

Idle speed Approximately 0V

107

108

109 Y Power supply for ECM

[Ignition switch ªONº] BATTERY VOLTAGE

(11 - 14V)

202 Y/R Injection timing control

valve [Engine is running]

I

Warm-up condition

I Idle speed Approximately 10 - 12V

NEF480

[Engine is running]

I

Warm-up condition

I Engine speed is 2,000 rpm Approximately9-14V

NEF481

204 G/PU Air conditioner relay

[Engine is running]

I

Air conditioner switch is ªOFFº BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

I Both air conditioner switch and blower fan switch

are ªONº

(Compressor is operating) Approximately 0.1V

205 Y/PU Oil pressure switch [Ignition switch ªONº]

Approximately 0V

[Engine is running]

I Idle speed Voltages

208 R/Y EGRC-solenoid valve A [Engine is running]

I

Warm-up condition

I Idle speed Approximately 0.7V

[Engine is running]

I Warm-up condition

I Engine speed is 2,800 rpm BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-370

http://vnx.su/

Page 824 of 1833

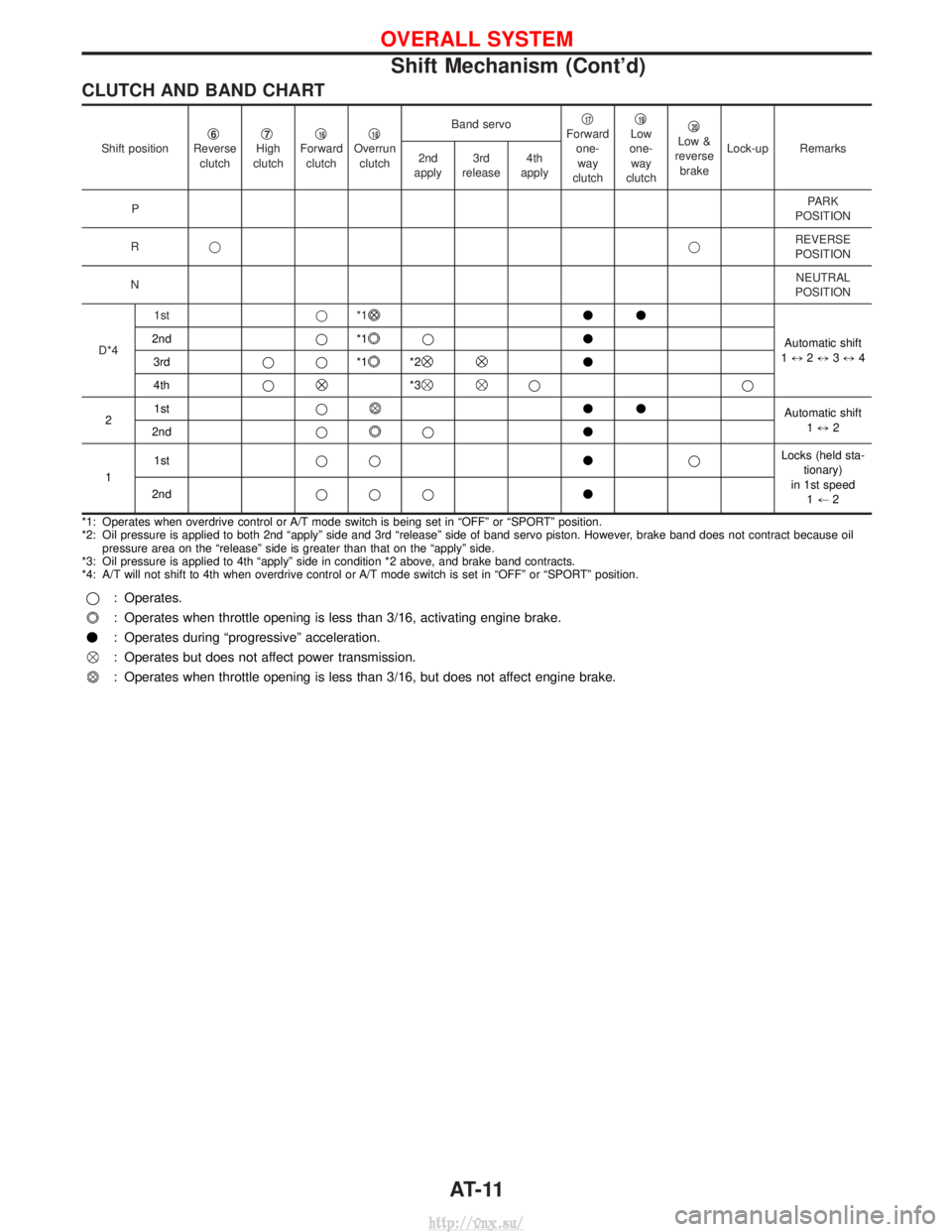

CLUTCH AND BAND CHART

Shift positionq6Reverse

clutch q7High

clutch q16Forward

clutch q18Overrun

clutch Band servo

q

17Forward

one-way

clutch q19Low

one- way

clutch q20Low &

reverse brake Lock-up Remarks

2nd

apply 3rd

release 4th

apply

P PARK

POSITION

R q qREVERSE

POSITION

N NEUTRAL

POSITION

D*4 1st

q*1

vv

Automatic shift

1 ) 2) 3) 4

2nd

q*1

q v

3rd qq*1

*2v

4th q

*3qq

2 1st

q

vv

Automatic shift

1) 2

2nd q

qv

1 1st

qq vqLocks (held sta-

tionary)

in 1st speed 1+ 2

2nd

qqq v

*1: Operates when overdrive control or A/T mode switch is being set in ªOFFº or ªSPORTº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract because oil pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control or A/T mode switch is set in ªOFFº or ªSPORTº position.

q : Operates.

: Operates when throttle opening is less than 3/16, activating engine brake.

v : Operates during ªprogressiveº acceleration.

: Operates but does not affect power transmission.

: Operates when throttle opening is less than 3/16, but does not affect engine brake.

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-11

http://vnx.su/

Page 844 of 1833

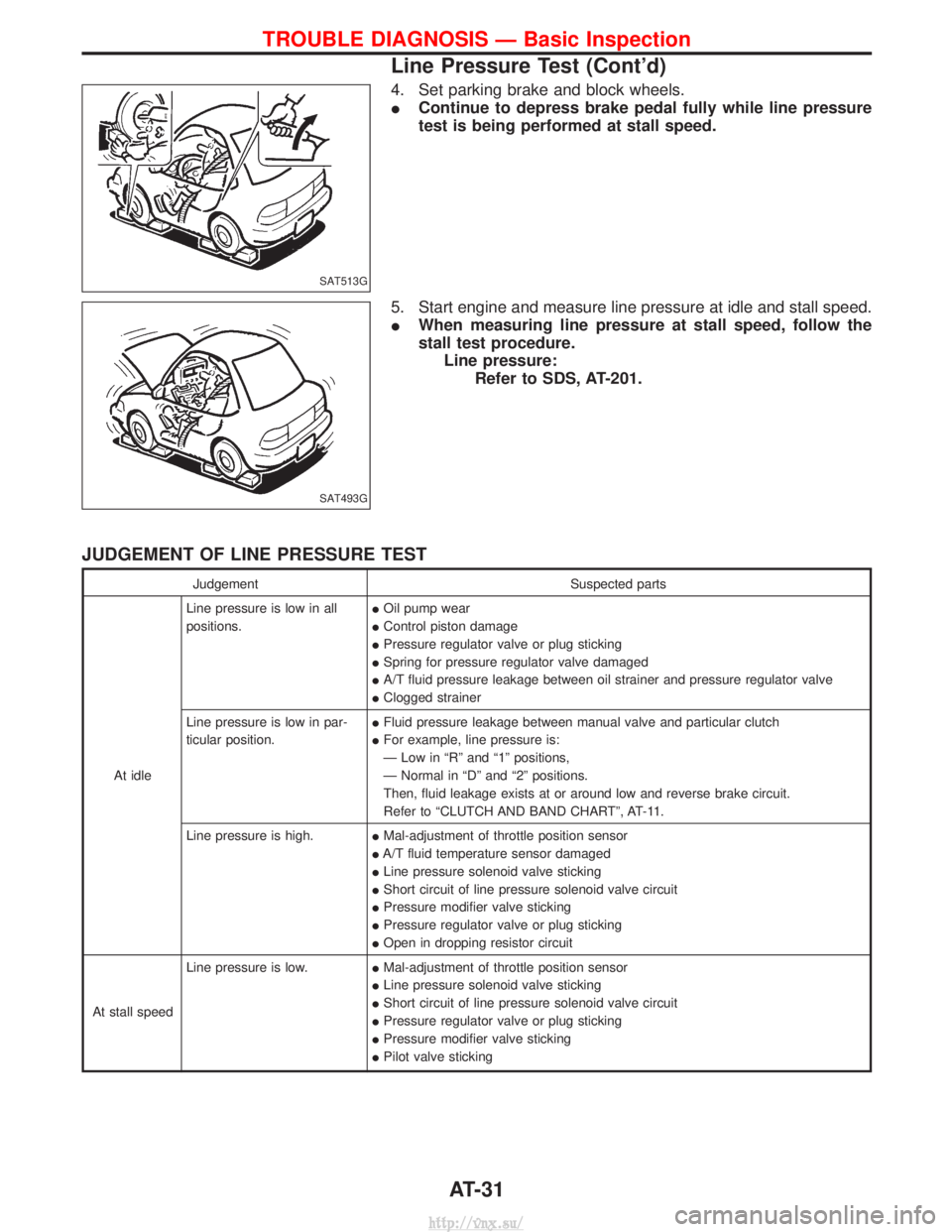

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

5. Start engine and measure line pressure at idle and stall speed.

I When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-201.

JUDGEMENT OF LINE PRESSURE TEST

Judgement Suspected parts

At idle Line pressure is low in all

positions.

I

Oil pump wear

I Control piston damage

I Pressure regulator valve or plug sticking

I Spring for pressure regulator valve damaged

I A/T fluid pressure leakage between oil strainer and pressure regulator valve

I Clogged strainer

Line pressure is low in par-

ticular position. I

Fluid pressure leakage between manual valve and particular clutch

I For example, line pressure is:

Ð Low in ªRº and ª1º positions,

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-11.

Line pressure is high. IMal-adjustment of throttle position sensor

I A/T fluid temperature sensor damaged

I Line pressure solenoid valve sticking

I Short circuit of line pressure solenoid valve circuit

I Pressure modifier valve sticking

I Pressure regulator valve or plug sticking

I Open in dropping resistor circuit

At stall speed Line pressure is low.

IMal-adjustment of throttle position sensor

I Line pressure solenoid valve sticking

I Short circuit of line pressure solenoid valve circuit

I Pressure regulator valve or plug sticking

I Pressure modifier valve sticking

I Pilot valve sticking

SAT513G

SAT493G

TROUBLE DIAGNOSIS Ð Basic Inspection

Line Pressure Test (Cont'd)

AT-31

http://vnx.su/

Page 856 of 1833

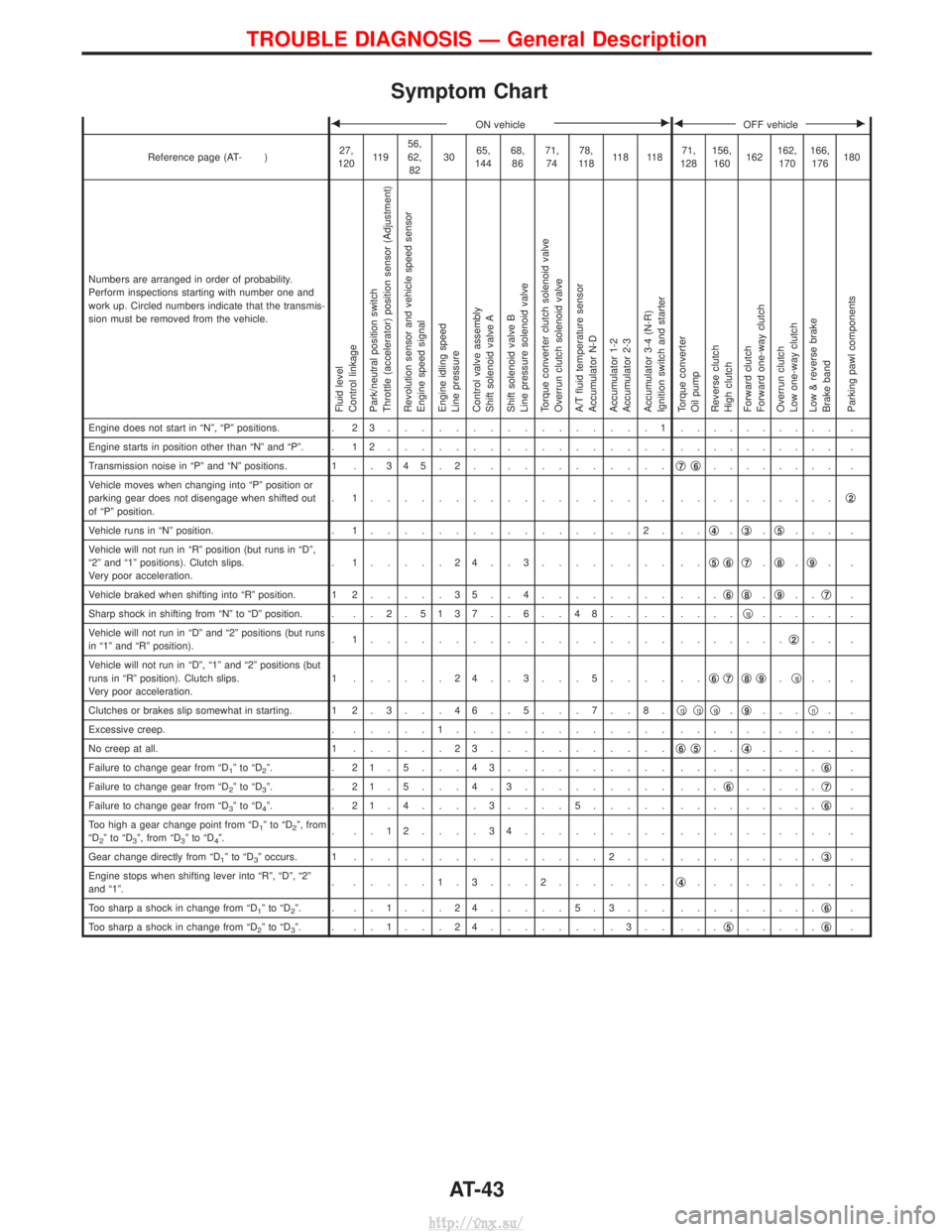

Symptom Chart

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

120 11 9 56,

62,

82 30

65,

144 68,

86 71,

74 78,

11 8 11 8 11 8 71,

128 156,

160 162162,

170 166,

176 180

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Engine does not start in ªNº, ªPº positions. . 2 3................1. ......... .

Engine starts in position other than ªNº and ªPº. . 1 2 ................. . ......... .

Transmission noise in ªPº and ªNº positions. 1 . . 3 4 5 . 2 ............q

7q6........ .

Vehicle moves when changing into ªPº position or

parking gear does not disengage when shifted out

of ªPº position. . 1.................. .

.........q

2

Vehicle runs in ªNº position.

. 1................2. .. q4.q3.q5... .

Vehicle will not run in ªRº position (but runs in ªDº,

ª2º and ª1º positions). Clutch slips.

Very poor acceleration. . 1.....24..3........ ..

q

5q6q7.q8.q9..

Vehicle braked when shifting into ªRº position. 1 2 .....35..4........ ... q

6q8.q9.. q7.

Sharp shock in shifting from ªNº to ªDº position. . . . 2 . 5137 . . 6 . . 48.... ....q

10..... .

Vehicle will not run in ªDº and ª2º positions (but runs

in ª1º and ªRº position). . 1.................. .

......q

2.. .

Vehicle will not run in ªDº, ª1º and ª2º positions (but

runs in ªRº position). Clutch slips.

Very poor acceleration. 1 ......24..3...5.... ..

q

6q7q8q9.q10.. .

Clutches or brakes slip somewhat in starting. 1 2 . 3 . . . 4 6 . . 5 . . . 7 . . 8 . q

13q12q10.q9... q11..

Excessive creep. . .....1............. . ......... .

No creep at all. 1 ......23........... q

6q5..q4..... .

Failure to change gear from ªD

1ºtoªD2º. . 21.5...43.......... . ........q6.

Failure to change gear from ªD

2ºtoªD3º. . 21.5...4.3......... ... q6.....q7.

Failure to change gear from ªD

3ºtoªD4º. . 21.4....3....5..... . ........q6.

Too high a gear change point from ªD

1ºtoªD2º, from

ªD2ºtoªD3º, from ªD3ºtoªD4º. . ..12....34......... .

......... .

Gear change directly from ªD

1ºtoªD3º occurs. 1 ...............2... . ........q3.

Engine stops when shifting lever into ªRº, ªDº, ª2º

and ª1º. . .....1.3...2.......

q

4......... .

Too sharp a shock in change from ªD

1ºtoªD2º. . ..1...24.....5.3... . ........q6.

Too sharp a shock in change from ªD

2ºtoªD3º. . ..1...24........3.. ... q5.....q6.

TROUBLE DIAGNOSIS Ð General Description

AT-43

http://vnx.su/

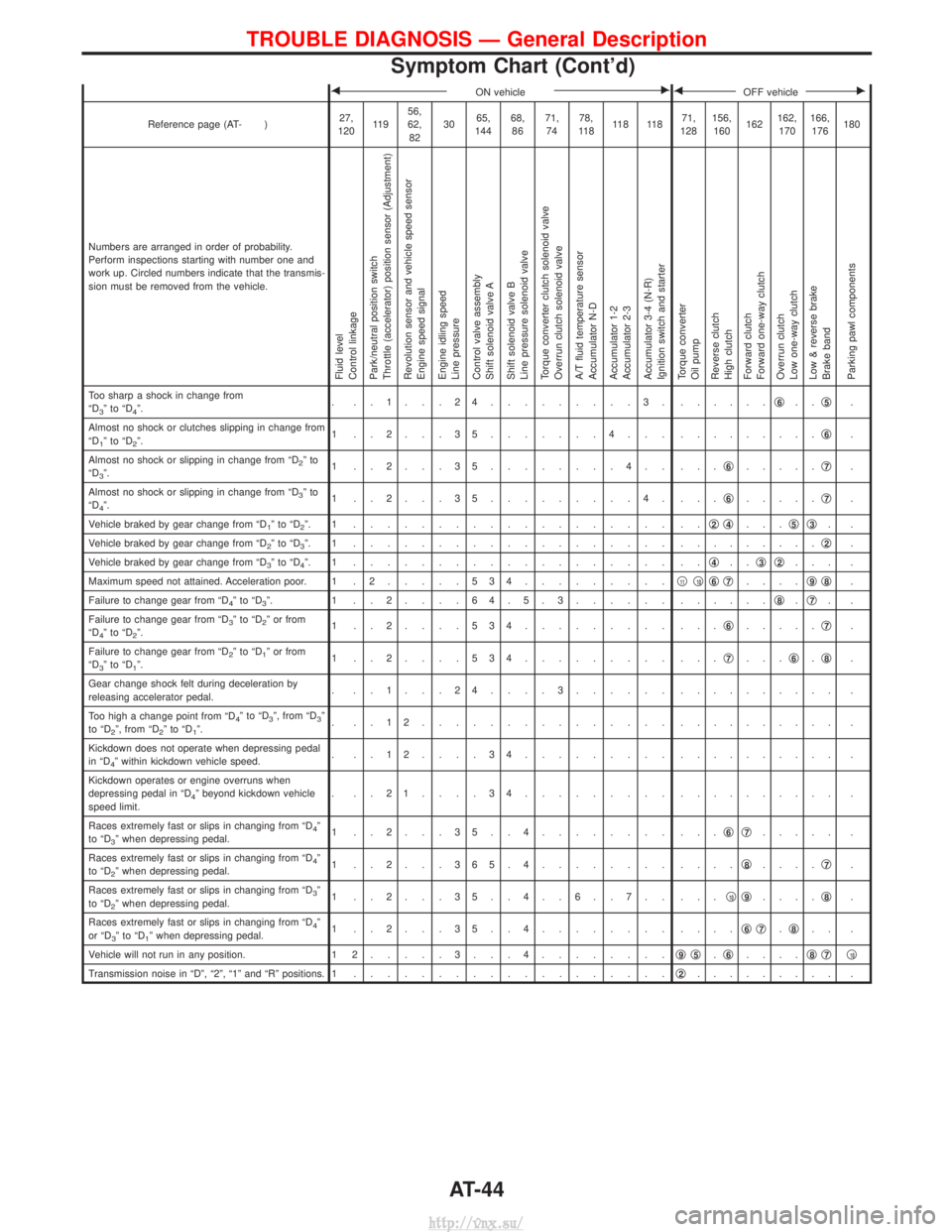

Page 857 of 1833

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

120 11 9 56,

62,

82 30

65,

144 68,

86 71,

74 78,

11 8 11 8 11 8 71,

128 156,

160 162162,

170 166,

176 180

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Too sharp a shock in change from

ªD3ºtoªD4º. . ..1...24.........3. .

.....q6..q5.

Almost no shock or clutches slipping in change from

ªD

1ºtoªD2º. 1 ..2...35.......4... .

........q6.

Almost no shock or slipping in change from ªD

2ºto

ªD3º. 1 ..2...35........4.. ...

q6.....q7.

Almost no shock or slipping in change from ªD

3ºto

ªD4º. 1 ..2...35.........4. ...

q6.....q7.

Vehicle braked by gear change from ªD

1ºtoªD2º. 1 ................... .. q2q4...q5q3..

Vehicle braked by gear change from ªD

2ºtoªD3º. 1 ................... . ........q2.

Vehicle braked by gear change from ªD

3ºtoªD4º. 1 ................... .. q4..q3q2... .

Maximum speed not attained. Acceleration poor. 1 . 2 .....534.........q

11q10q6q7....q9q8.

Failure to change gear from ªD

4ºtoªD3º. 1 ..2....64.5.3...... . .....q8.q7..

Failure to change gear from ªD

3ºtoªD2º or from

ªD4ºtoªD2º. 1 ..2....534......... ...

q6.....q7.

Failure to change gear from ªD

2ºtoªD1º or from

ªD3ºtoªD1º. 1 ..2....534......... ...

q7...q6.q8.

Gear change shock felt during deceleration by

releasing accelerator pedal. . ..1...24....3...... .

......... .

Too high a change point from ªD

4ºtoªD3º, from ªD3º

to ªD2º, from ªD2ºtoªD1º. . ..12............... .

......... .

Kickdown does not operate when depressing pedal

in ªD

4º within kickdown vehicle speed. . ..12....34......... .

......... .

Kickdown operates or engine overruns when

depressing pedal in ªD

4º beyond kickdown vehicle

speed limit. . ..21....34......... .

......... .

Races extremely fast or slips in changing from ªD

4º

to ªD3º when depressing pedal. 1 ..2...35..4........ ...

q6q7..... .

Races extremely fast or slips in changing from ªD

4º

to ªD2º when depressing pedal. 1 ..2...365.4........ ....

q8....q7.

Races extremely fast or slips in changing from ªD

3º

to ªD2º when depressing pedal. 1 ..2...35..4..6..7.. ...

q10q9....q8.

Races extremely fast or slips in changing from ªD

4º

or ªD3ºtoªD1º when depressing pedal. 1 ..2...35..4........ ....

q6q7.q8.. .

Vehicle will not run in any position. 1 2 .....3...4........ q

9q5.q6.... q8q7q10

Transmission noise in ªDº, ª2º, ª1º and ªRº positions. 1

................... q2......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-44

http://vnx.su/