NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 421 of 1833

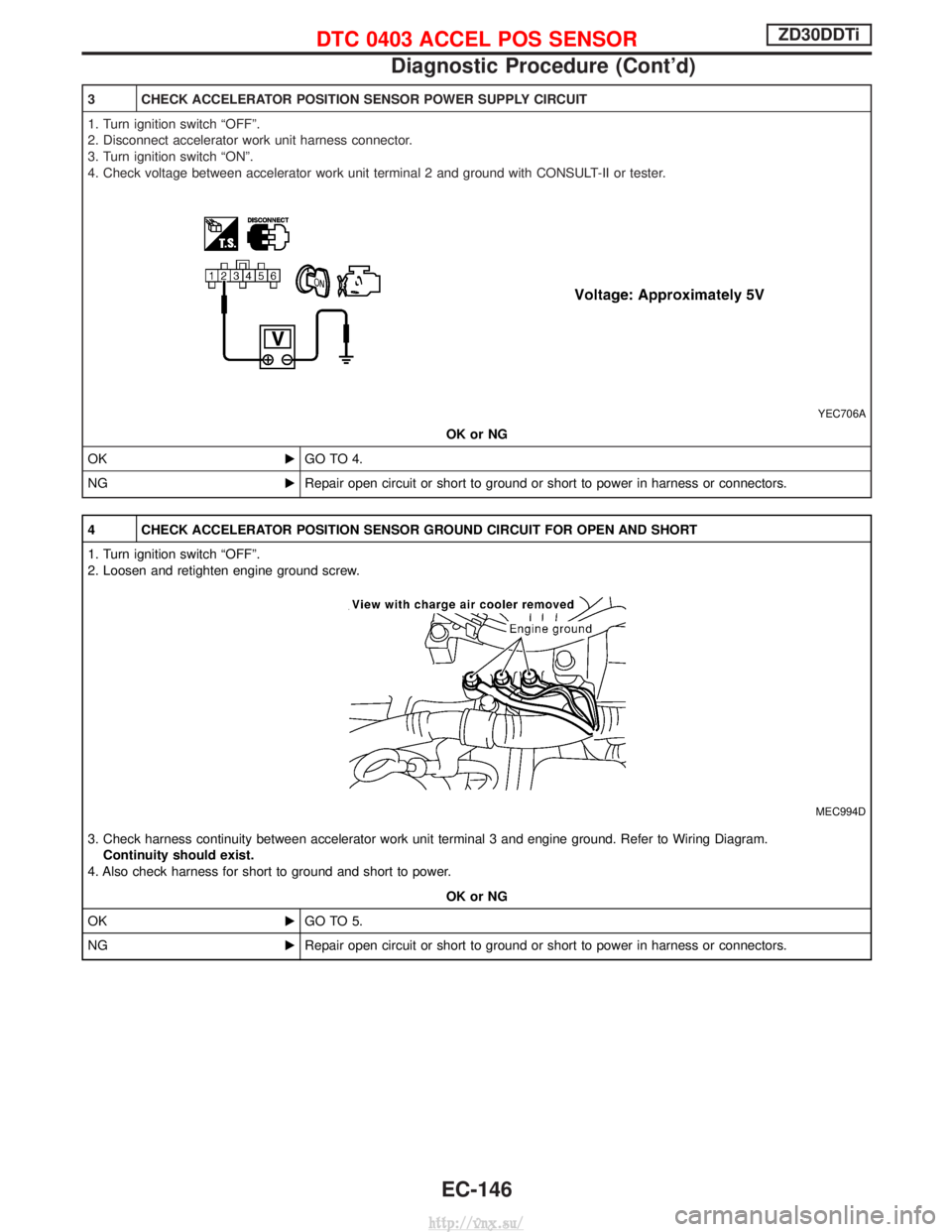

3 CHECK ACCELERATOR POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 2 and ground with CONSULT-II or tester.

YEC706A

OK or NG

OK EGO TO 4.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

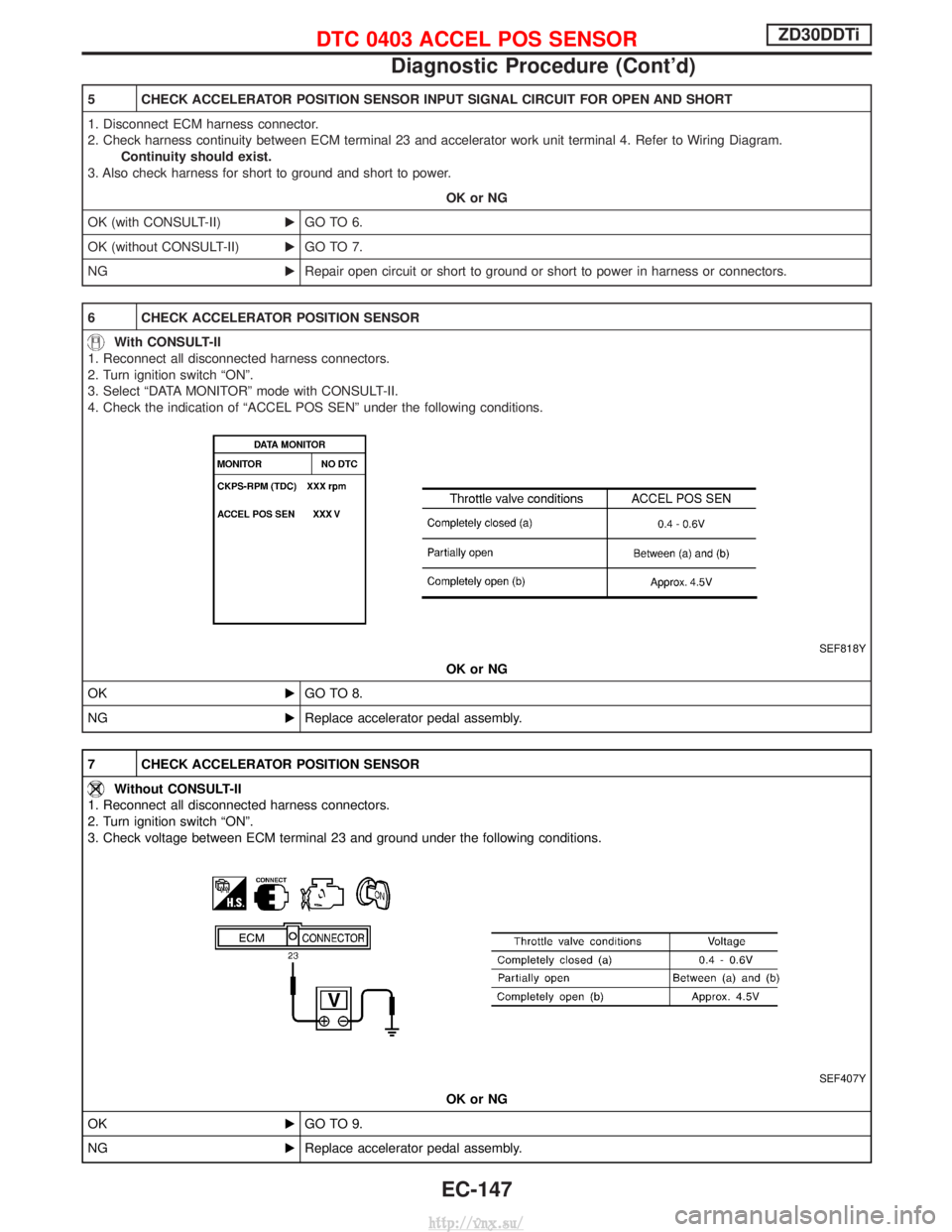

4 CHECK ACCELERATOR POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screw.

MEC994D

3. Check harness continuity between accelerator work unit terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-146

http://vnx.su/

Page 422 of 1833

5 CHECK ACCELERATOR POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 23 and accelerator work unit terminal 4. Refer to Wiring Diagram.Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK (with CONSULT-II) EGO TO 6.

OK (without CONSULT-II) EGO TO 7.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

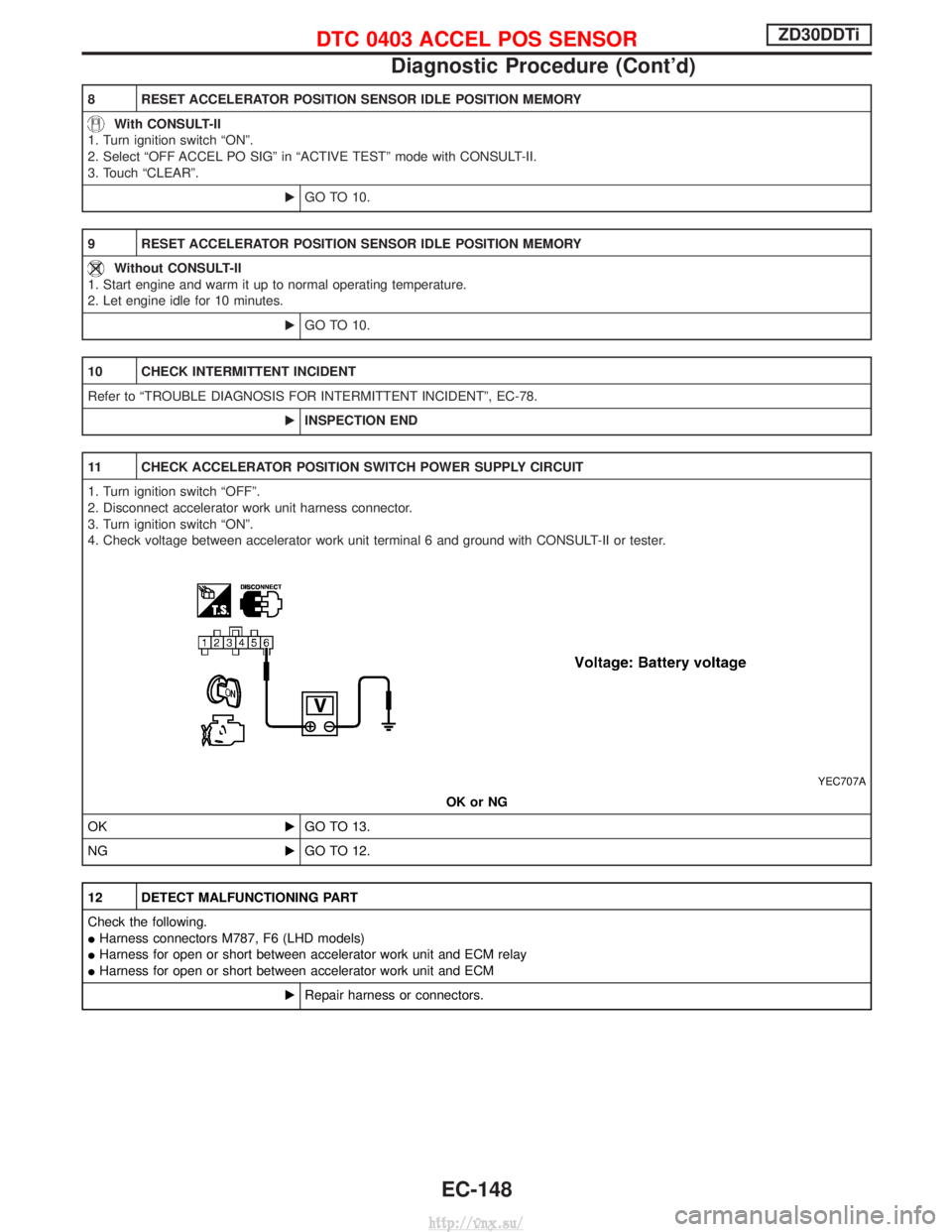

6 CHECK ACCELERATOR POSITION SENSOR

With CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Select ªDATA MONITORº mode with CONSULT-II.

4. Check the indication of ªACCEL POS SENº under the following conditions.

SEF818Y

OK or NG

OK EGO TO 8.

NG EReplace accelerator pedal assembly.

7 CHECK ACCELERATOR POSITION SENSOR

Without CONSULT-II

1. Reconnect all disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Check voltage between ECM terminal 23 and ground under the following conditions.

SEF407Y

OK or NG

OK EGO TO 9.

NG EReplace accelerator pedal assembly.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-147

http://vnx.su/

Page 423 of 1833

8 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

EGO TO 10.

9 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

EGO TO 10.

10 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

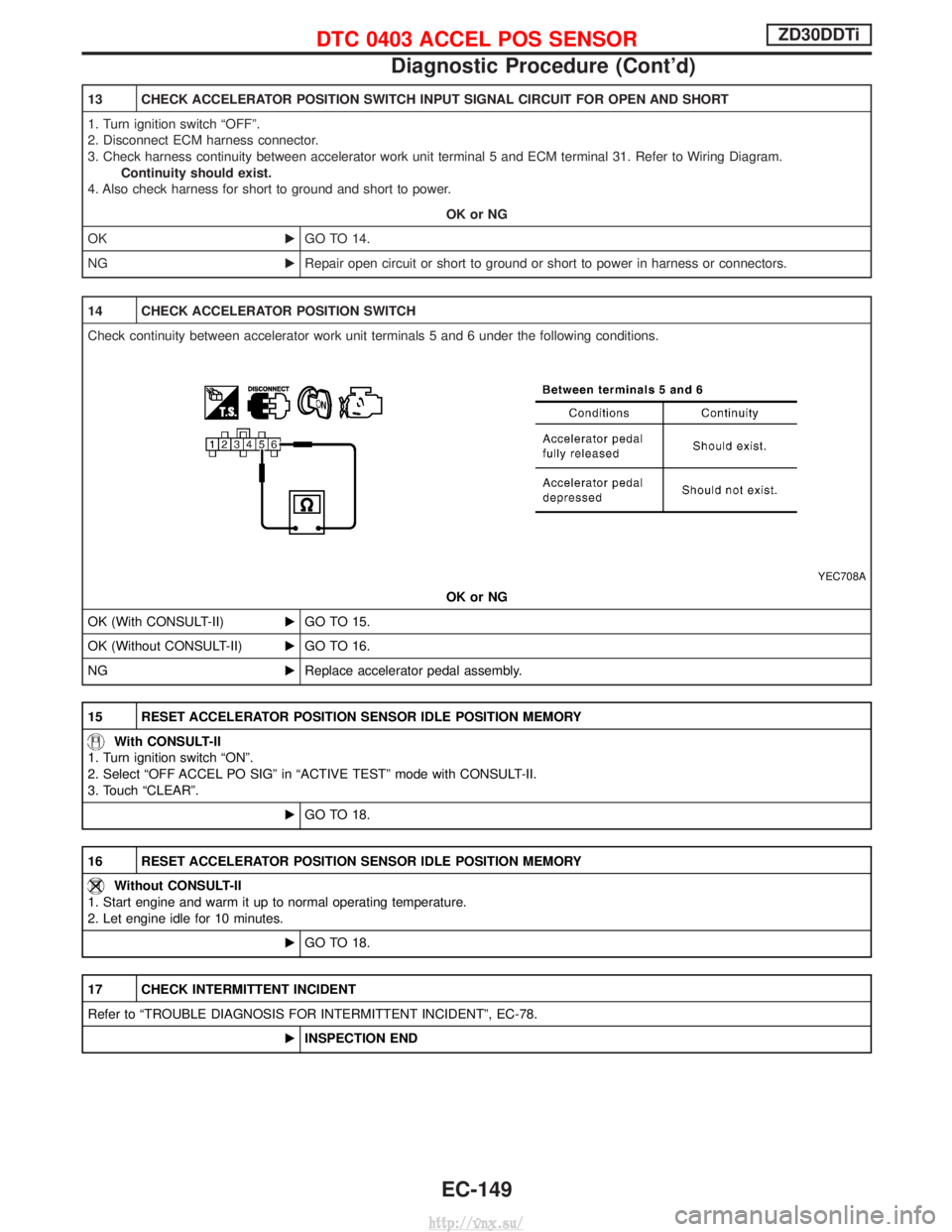

11 CHECK ACCELERATOR POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator work unit harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between accelerator work unit terminal 6 and ground with CONSULT-II or tester.

YEC707A

OK or NG

OK EGO TO 13.

NG EGO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F6 (LHD models)

I Harness for open or short between accelerator work unit and ECM relay

I Harness for open or short between accelerator work unit and ECM

ERepair harness or connectors.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-148

http://vnx.su/

Page 424 of 1833

13 CHECK ACCELERATOR POSITION SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between accelerator work unit terminal 5 and ECM terminal 31. Refer to Wiring Diagram.Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 14.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

14 CHECK ACCELERATOR POSITION SWITCH

Check continuity between accelerator work unit terminals 5 and 6 under the following conditions.

YEC708A

OK or NG

OK (With CONSULT-II) EGO TO 15.

OK (Without CONSULT-II) EGO TO 16.

NG EReplace accelerator pedal assembly.

15 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

EGO TO 18.

16 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

EGO TO 18.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-149

http://vnx.su/

Page 425 of 1833

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I An excessively high voltage from the mass air flow sensor is

sent to ECM when engine is running. I

Air duct

I Charge air cooler

I Variable nozzle turbocharger control system

I Variable nozzle turbocharger

I Mass air flow sensor

I Harness or connectors

(The mass air flow sensor circuit is shorted.)

DTC Confirmation Procedure

NOTE:

If DTC 0406 ªINT AIR VOLº displayed with DTC 0102 ªMASS

AIR FLOW SENº, perform trouble diagnosis for DTC 0102

ªMASS AIR FLOW SENº first. (See EC-88.)

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle.

5) Maintain the engine speed more than 4,000 rpm for at least 10

seconds.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-151.

WITHOUT CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Drive vehicle.

3) Maintain the engine speed more than 4,000 rpm for at least 10 seconds.

4) Stop vehicle.

5) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-151.SEF817Y

DTC 0406 INT AIR VOLZD30DDTi

EC-150

http://vnx.su/

Page 426 of 1833

Diagnostic Procedure

1 CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.OK or NG

OK EGO TO 2.

NG ERepair or replace.

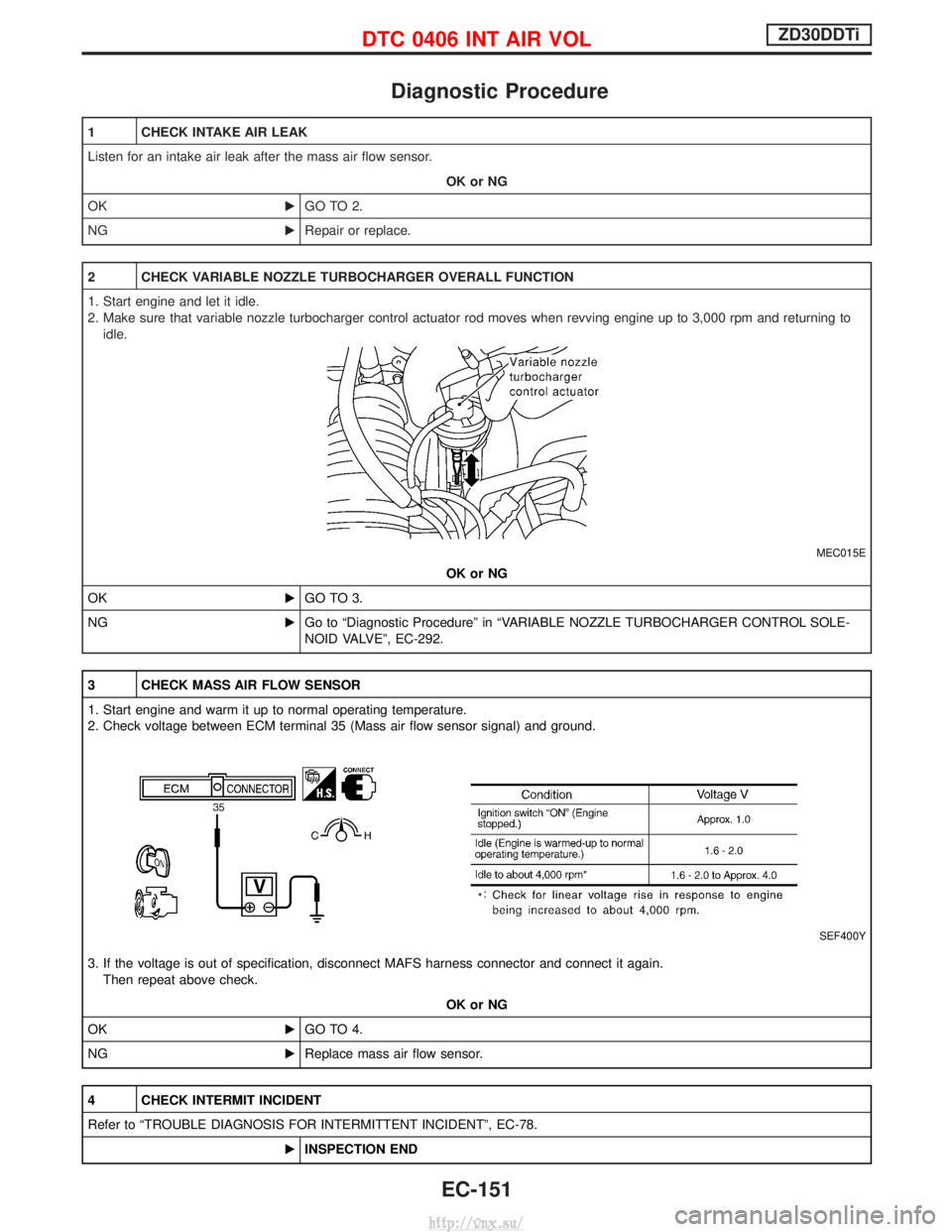

2 CHECK VARIABLE NOZZLE TURBOCHARGER OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that variable nozzle turbocharger control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

MEC015E

OK or NG

OK EGO TO 3.

NG EGo to ªDiagnostic Procedureº in ªVARIABLE NOZZLE TURBOCHARGER CONTROL SOLE-

NOID VALVEº, EC-292.

3 CHECK MASS AIR FLOW SENSOR

1. Start engine and warm it up to normal operating temperature.

2. Check voltage between ECM terminal 35 (Mass air flow sensor signal) and ground.

SEF400Y

3. If the voltage is out of specification, disconnect MAFS harness connector and connect it again.

Then repeat above check.

OK or NG

OK EGO TO 4.

NG EReplace mass air flow sensor.

4 CHECK INTERMIT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0406 INT AIR VOLZD30DDTi

EC-151

http://vnx.su/

Page 427 of 1833

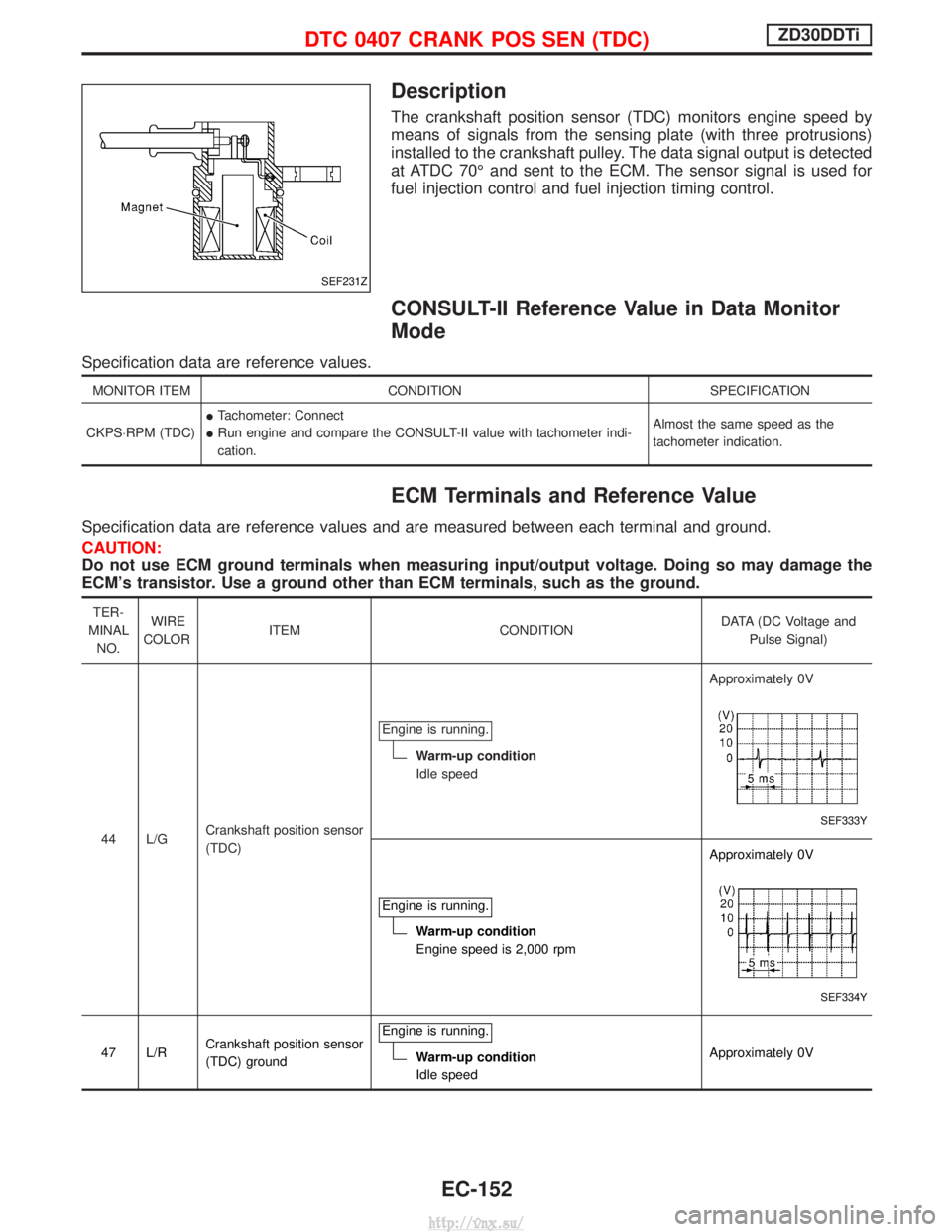

Description

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with three protrusions)

installed to the crankshaft pulley. The data signal output is detected

at ATDC 70É and sent to the ECM. The sensor signal is used for

fuel injection control and fuel injection timing control.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEMCONDITION SPECIFICATION

CKPS×RPM (TDC) I

Tachometer: Connect

I Run engine and compare the CONSULT-II value with tachometer indi-

cation. Almost the same speed as the

tachometer indication.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage and

Pulse Signal)

44 L/G Crankshaft position sensor

(TDC) Engine is running.

Warm-up condition

Idle speed

Approximately 0V

SEF333Y

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 0V

SEF334Y

47 L/R

Crankshaft position sensor

(TDC) ground Engine is running.Warm-up condition

Idle speed

Approximately 0V

SEF231Z

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-152

http://vnx.su/

Page 428 of 1833

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I An improper signal from the sensor is sent to ECM during

engine running and cranking. I

Harness or connectors

(The sensor circuit is open.)

I Crankshaft position sensor (TDC)

DTC Confirmation Procedure

Before performing the following procedure, confirm that bat-

tery voltage is more than 10V.

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-156.

WITHOUT CONSULT-II

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-156.

SEF817Y

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-153

http://vnx.su/

Page 429 of 1833

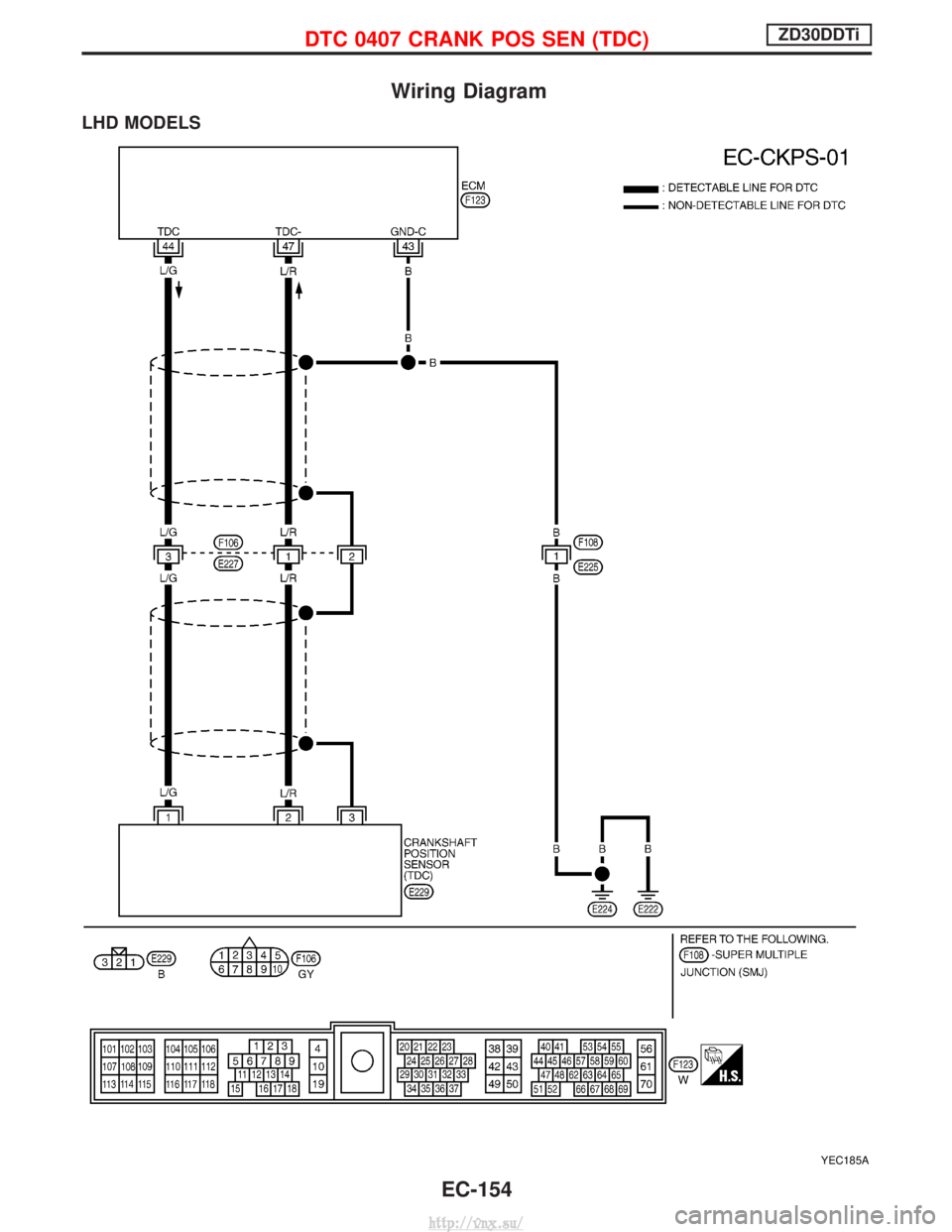

Wiring Diagram

LHD MODELS

YEC185A

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-154

http://vnx.su/

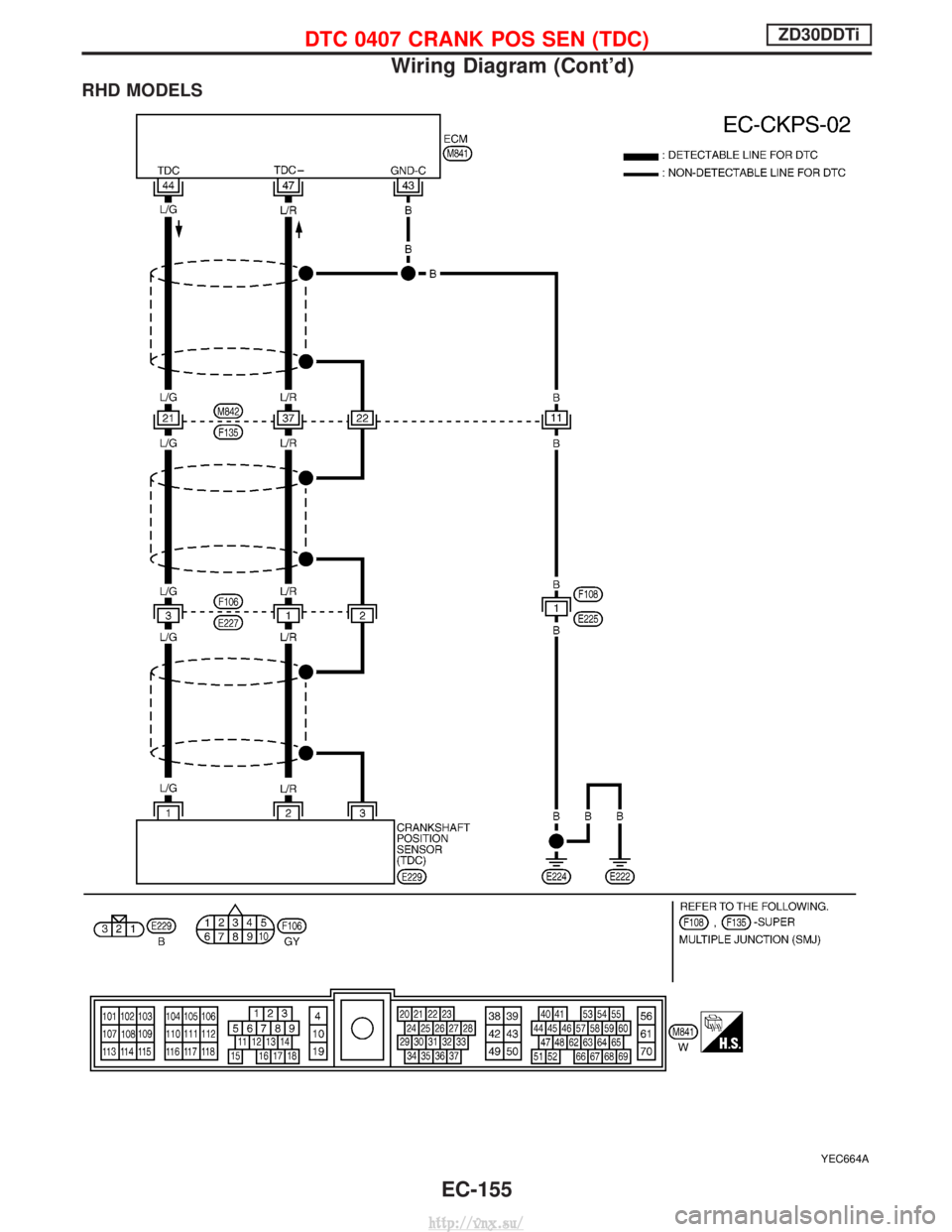

Page 430 of 1833

RHD MODELS

YEC664A

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

Wiring Diagram (Cont'd)EC-155

http://vnx.su/