AUX NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 38 of 1833

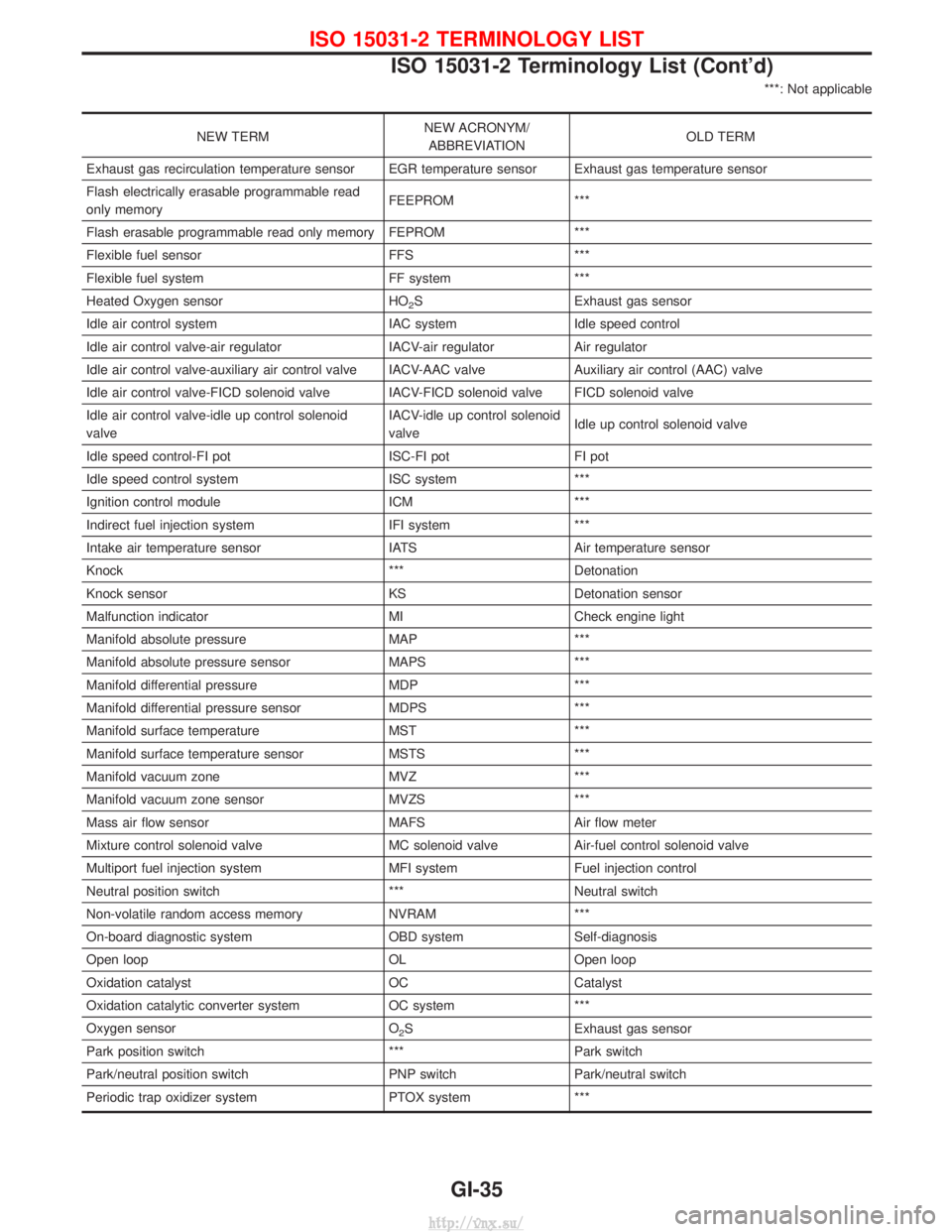

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATION OLD TERM

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable read

only memory FEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO

2S Exhaust gas sensor

Idle air control system IAC systemIdle speed control

Idle air control valve-air regulator IACV-air regulatorAir regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valve IACV-idle up control solenoid

valve

Idle up control solenoid valve

Idle speed control-FI pot ISC-FI potFI pot

Idle speed control system ISC system***

Ignition control module ICM***

Indirect fuel injection system IFI system***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Neutral position switch *** Neutral switch

Non-volatile random access memory NVRAM ***

On-board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O

2S Exhaust gas sensor

Park position switch ***Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-35

http://vnx.su/

Page 117 of 1833

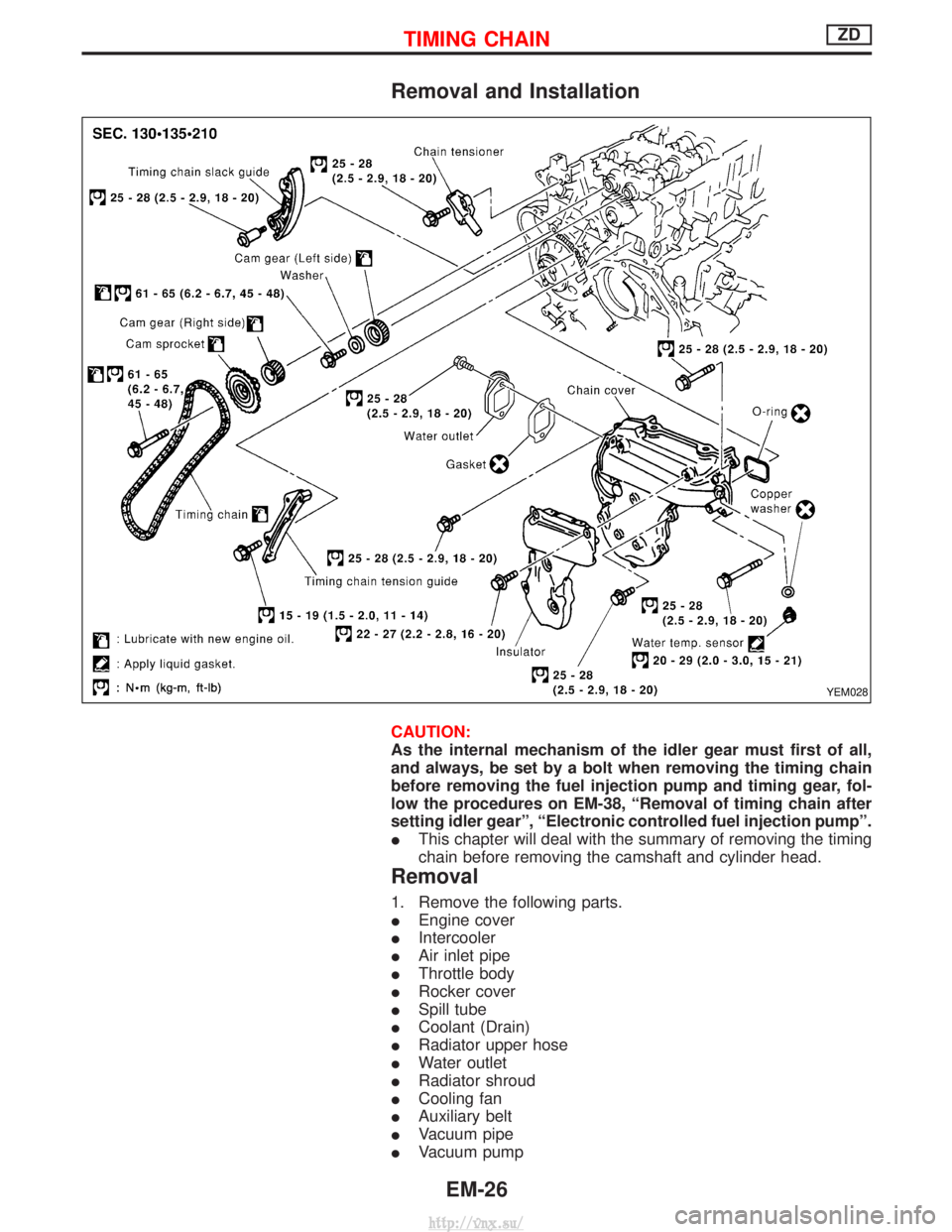

Removal and Installation

CAUTION:

As the internal mechanism of the idler gear must first of all,

and always, be set by a bolt when removing the timing chain

before removing the fuel injection pump and timing gear, fol-

low the procedures on EM-38, ªRemoval of timing chain after

setting idler gearº, ªElectronic controlled fuel injection pumpº.

IThis chapter will deal with the summary of removing the timing

chain before removing the camshaft and cylinder head.

Removal

1. Remove the following parts.

IEngine cover

I Intercooler

I Air inlet pipe

I Throttle body

I Rocker cover

I Spill tube

I Coolant (Drain)

I Radiator upper hose

I Water outlet

I Radiator shroud

I Cooling fan

I Auxiliary belt

I Vacuum pipe

I Vacuum pump

YEM028

TIMING CHAINZD

EM-26

http://vnx.su/

Page 143 of 1833

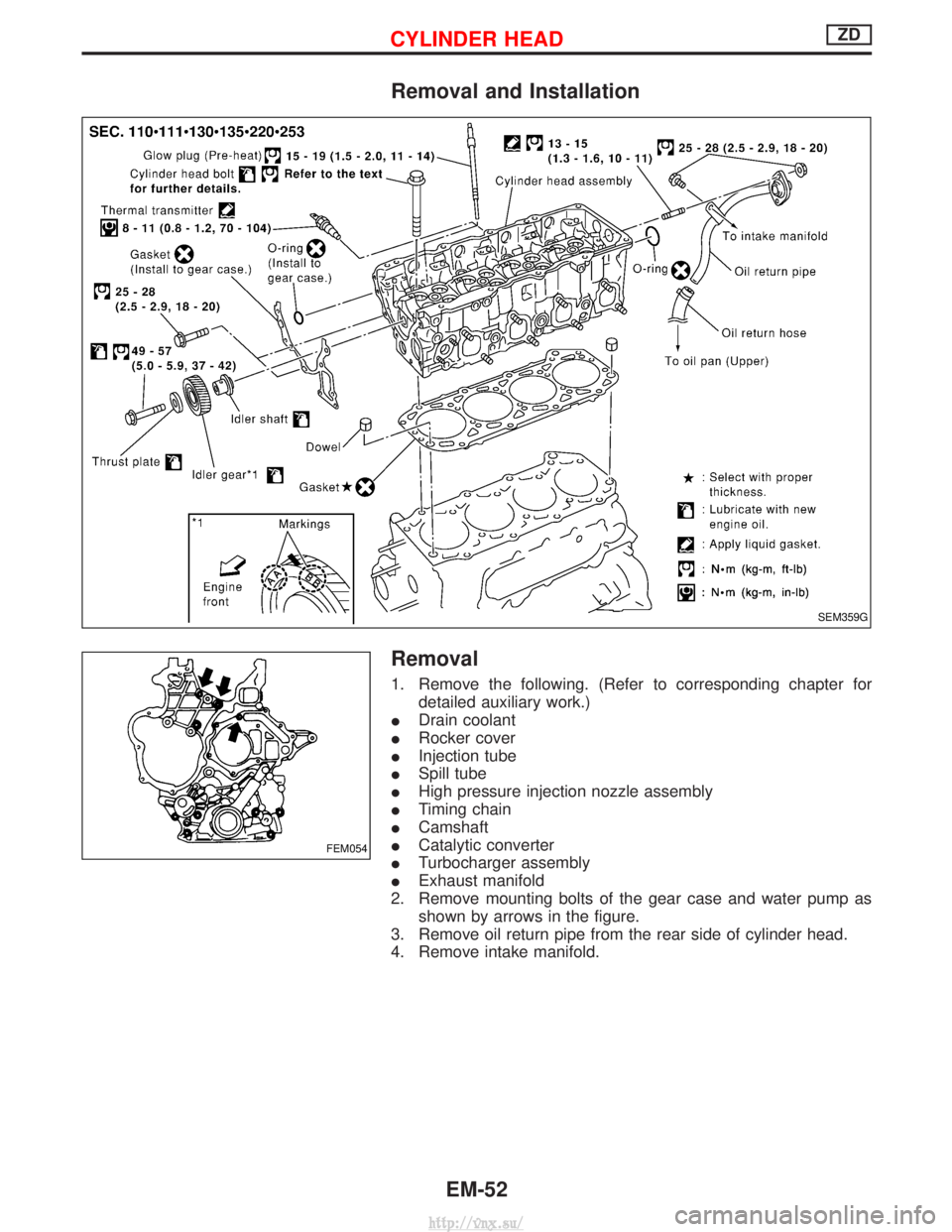

Removal and Installation

Removal

1. Remove the following. (Refer to corresponding chapter fordetailed auxiliary work.)

I Drain coolant

I Rocker cover

I Injection tube

I Spill tube

I High pressure injection nozzle assembly

I Timing chain

I Camshaft

I Catalytic converter

I Turbocharger assembly

I Exhaust manifold

2. Remove mounting bolts of the gear case and water pump as shown by arrows in the figure.

3. Remove oil return pipe from the rear side of cylinder head.

4. Remove intake manifold.

SEM359G

FEM054

CYLINDER HEADZD

EM-52

http://vnx.su/

Page 826 of 1833

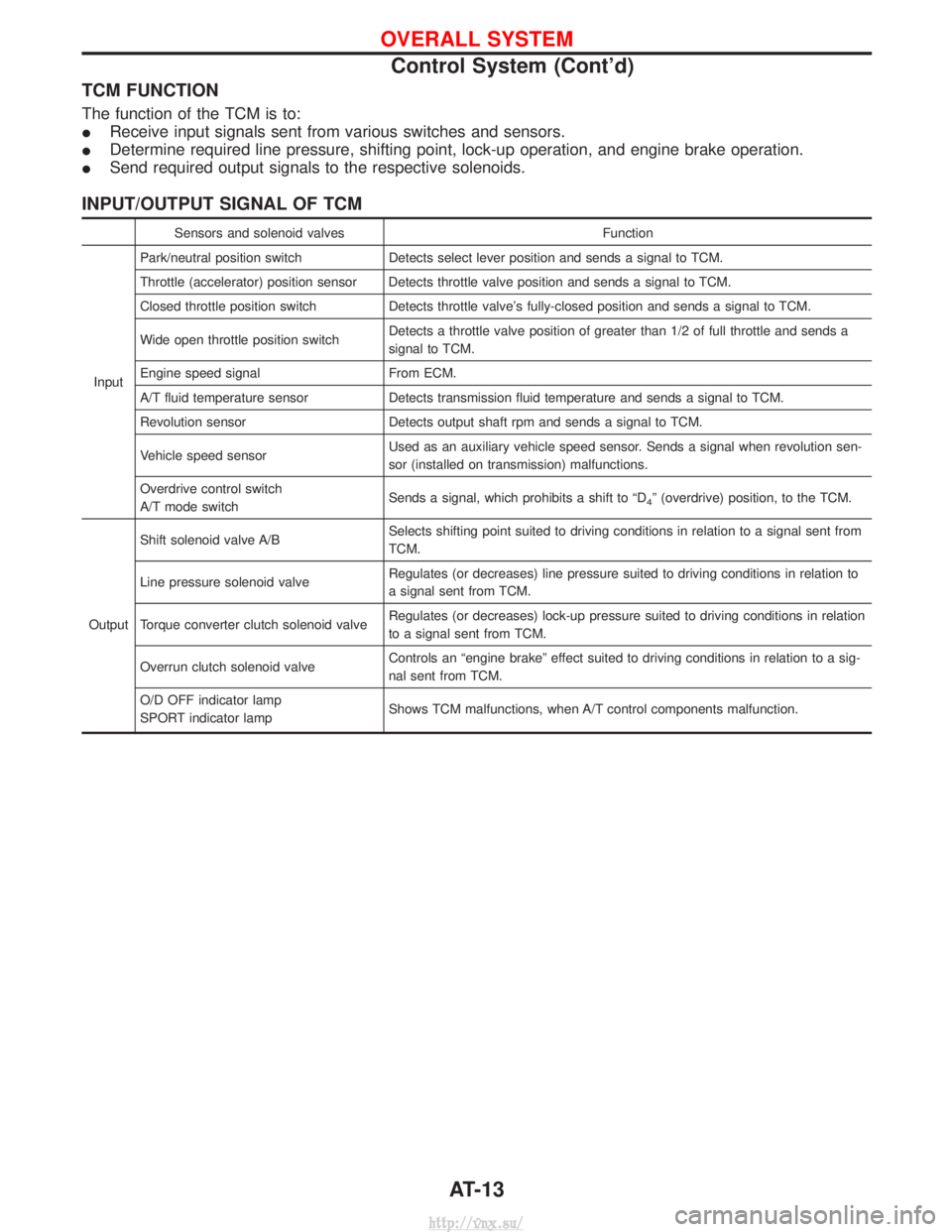

TCM FUNCTION

The function of the TCM is to:

IReceive input signals sent from various switches and sensors.

I Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

I Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Sensors and solenoid valves Function

Input Park/neutral position switch

Detects select lever position and sends a signal to TCM.

Throttle (accelerator) position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve's fully-closed position and sends a signal to TCM.

Wide open throttle position switch Detects a throttle valve position of greater than 1/2 of full throttle and sends a

signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensor Used as an auxiliary vehicle speed sensor. Sends a signal when revolution sen-

sor (installed on transmission) malfunctions.

Overdrive control switch

A/T mode switch Sends a signal, which prohibits a shift to ªD

4º (overdrive) position, to the TCM.

Output Shift solenoid valve A/B

Selects shifting point suited to driving conditions in relation to a signal sent from

TCM.

Line pressure solenoid valve Regulates (or decreases) line pressure suited to driving conditions in relation to

a signal sent from TCM.

Torque converter clutch solenoid valve Regulates (or decreases) lock-up pressure suited to driving conditions in relation

to a signal sent from TCM.

Overrun clutch solenoid valve Controls an ªengine brakeº effect suited to driving conditions in relation to a sig-

nal sent from TCM.

O/D OFF indicator lamp

SPORT indicator lamp Shows TCM malfunctions, when A/T control components malfunction.

OVERALL SYSTEM

Control System (Cont'd)

AT-13

http://vnx.su/

Page 869 of 1833

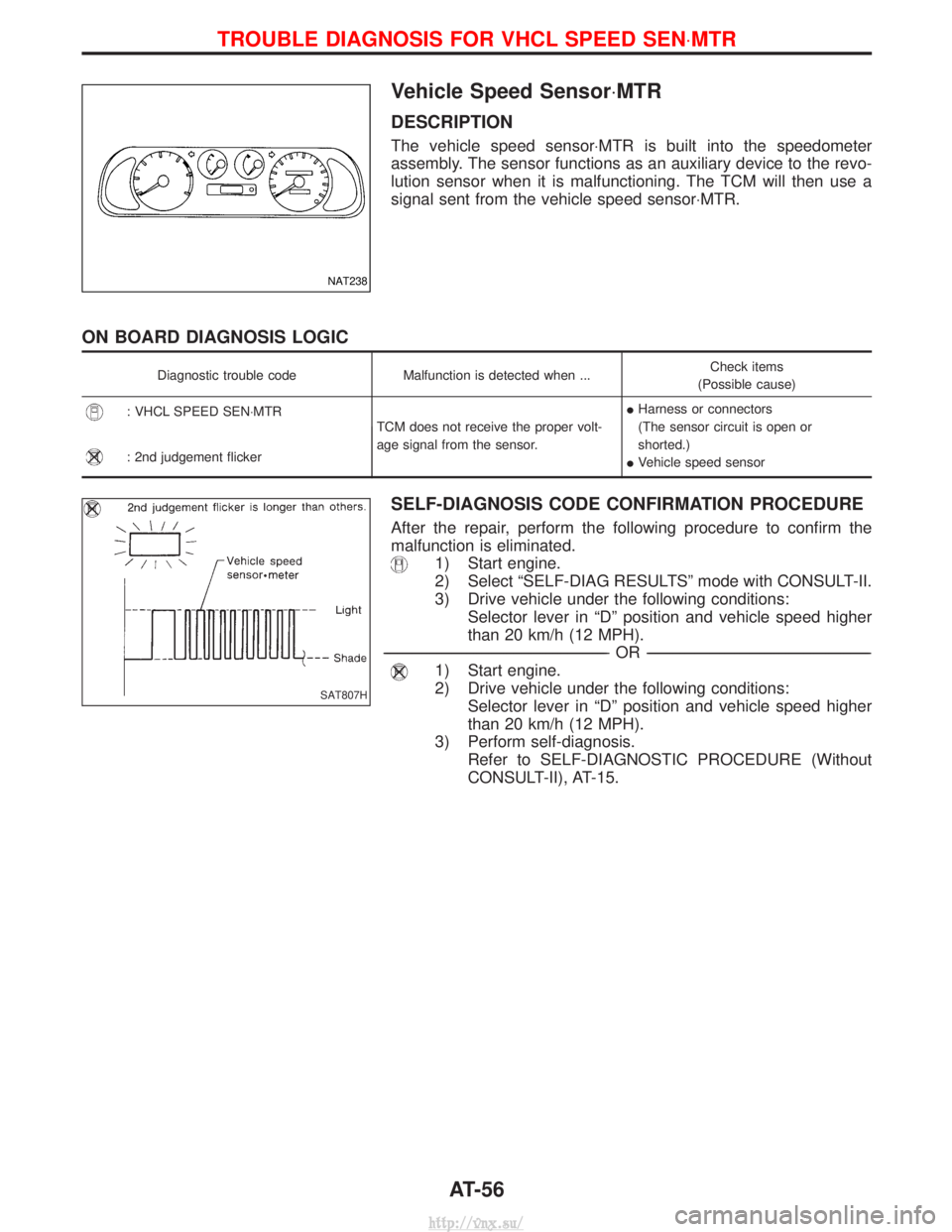

Vehicle Speed Sensor×MTR

DESCRIPTION

The vehicle speed sensor×MTR is built into the speedometer

assembly. The sensor functions as an auxiliary device to the revo-

lution sensor when it is malfunctioning. The TCM will then use a

signal sent from the vehicle speed sensor×MTR.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble codeMalfunction is detected when ... Check items

(Possible cause)

: VHCL SPEED SEN×MTR TCM does not receive the proper volt-

age signal from the sensor.I

Harness or connectors

(The sensor circuit is open or

shorted.)

I Vehicle speed sensor

: 2nd judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher

than 20 km/h (12 MPH).

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- -OR------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher

than 20 km/h (12 MPH).

3) Perform self-diagnosis. Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-15.

NAT238

SAT807H

TROUBLE DIAGNOSIS FOR VHCL SPEED SEN ×MTR

AT-56

http://vnx.su/

Page 1642 of 1833

Inspection

SPEAKER

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminalsq

1andq2.

I The resistance should be2-4 W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminals q

1andq2.

I A momentary hum or pop should be heard.

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

IIf reception improves, check antenna ground (at body surface).

I If reception does not improve, check main feeder cable for short circuit or open circuit.

RADIO

All voltage inspections are made with:

IIgnition switch ON or ACC

I Radio ON

I Radio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-149

http://vnx.su/