ecu NISSAN TERRANO 2004 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1010 of 1833

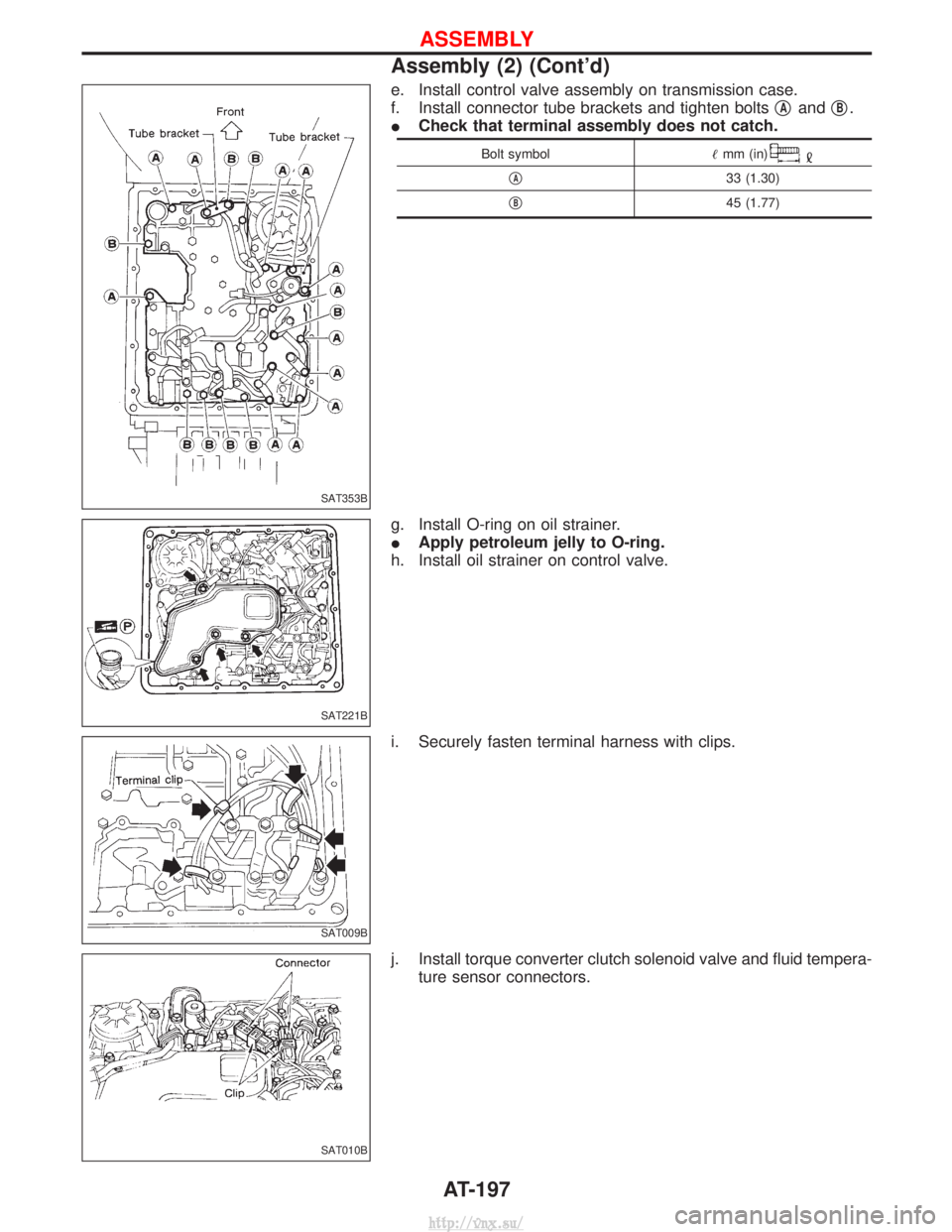

e. Install control valve assembly on transmission case.

f. Install connector tube brackets and tighten boltsq

AandqB.

I Check that terminal assembly does not catch.

Bolt symbol mm (in)

qA33 (1.30)

q

B45 (1.77)

g. Install O-ring on oil strainer.

I Apply petroleum jelly to O-ring.

h. Install oil strainer on control valve.

i. Securely fasten terminal harness with clips.

j. Install torque converter clutch solenoid valve and fluid tempera- ture sensor connectors.

SAT353B

SAT221B

SAT009B

SAT010B

ASSEMBLY

Assembly (2) (Cont'd)

AT-197

http://vnx.su/

Page 1013 of 1833

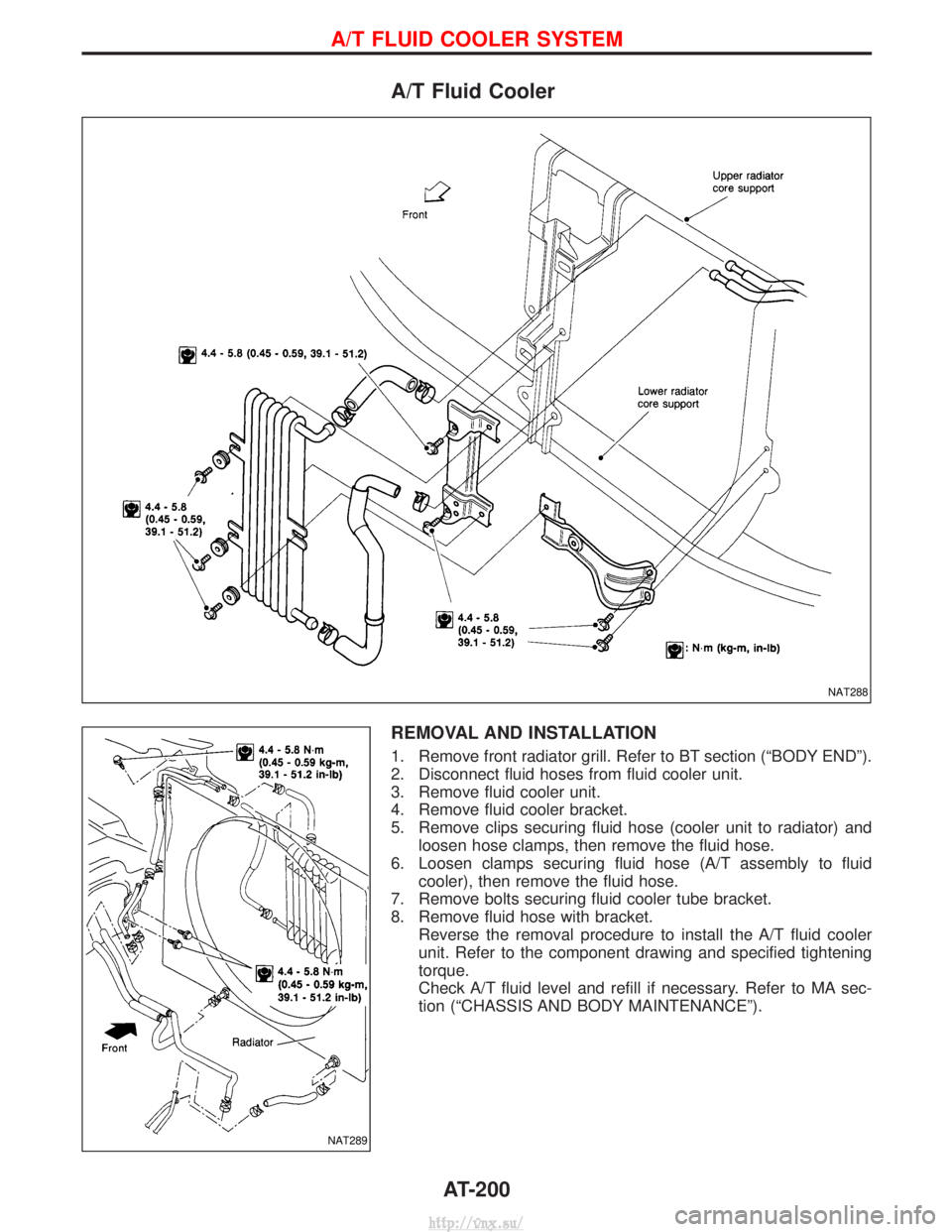

A/T Fluid Cooler

REMOVAL AND INSTALLATION

1. Remove front radiator grill. Refer to BT section (ªBODY ENDº).

2. Disconnect fluid hoses from fluid cooler unit.

3. Remove fluid cooler unit.

4. Remove fluid cooler bracket.

5. Remove clips securing fluid hose (cooler unit to radiator) andloosen hose clamps, then remove the fluid hose.

6. Loosen clamps securing fluid hose (A/T assembly to fluid cooler), then remove the fluid hose.

7. Remove bolts securing fluid cooler tube bracket.

8. Remove fluid hose with bracket. Reverse the removal procedure to install the A/T fluid cooler

unit. Refer to the component drawing and specified tightening

torque.

Check A/T fluid level and refill if necessary. Refer to MA sec-

tion (ªCHASSIS AND BODY MAINTENANCEº).

NAT288

NAT289

A/T FLUID COOLER SYSTEM

AT-200

http://vnx.su/

Page 1024 of 1833

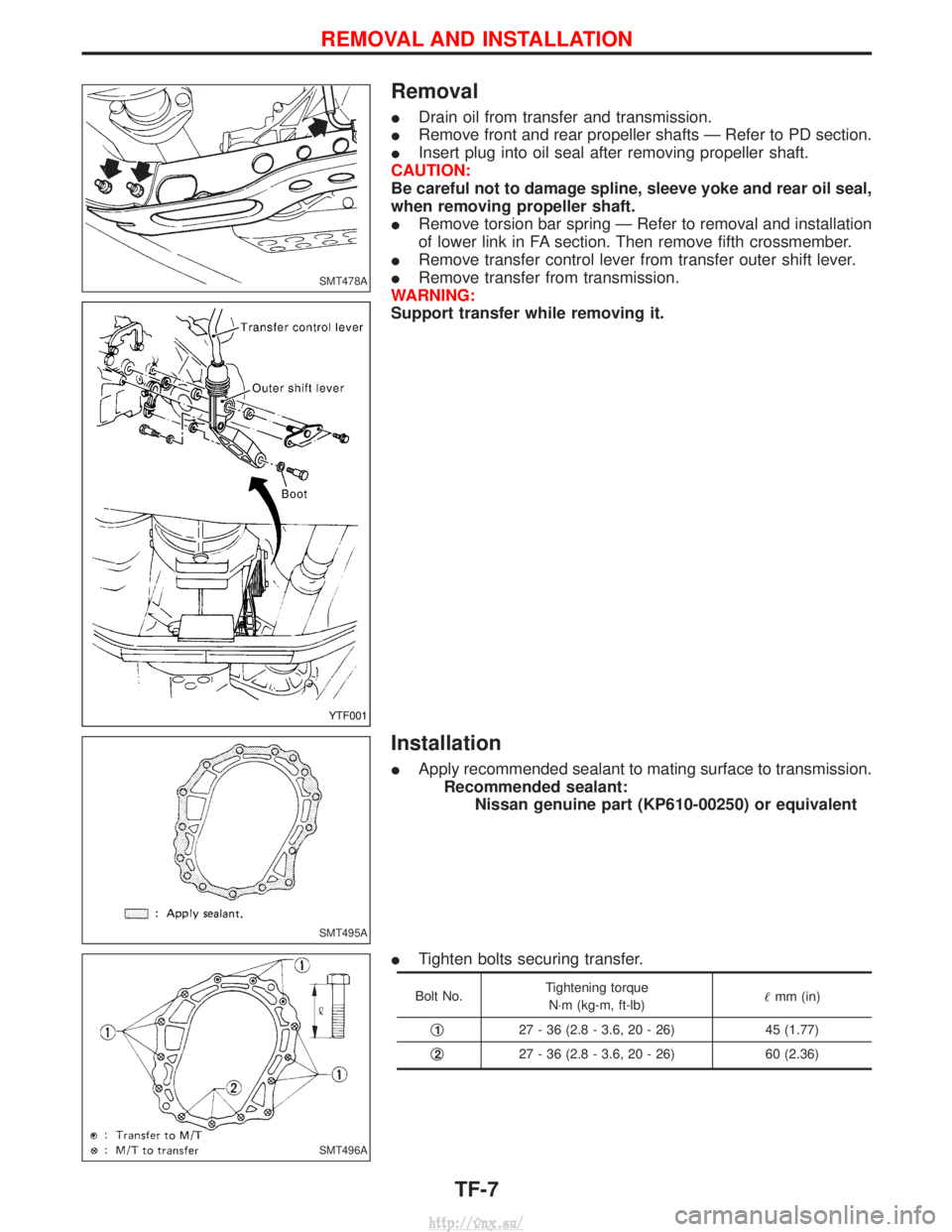

Removal

IDrain oil from transfer and transmission.

I Remove front and rear propeller shafts Ð Refer to PD section.

I Insert plug into oil seal after removing propeller shaft.

CAUTION:

Be careful not to damage spline, sleeve yoke and rear oil seal,

when removing propeller shaft.

I Remove torsion bar spring Ð Refer to removal and installation

of lower link in FA section. Then remove fifth crossmember.

I Remove transfer control lever from transfer outer shift lever.

I Remove transfer from transmission.

WARNING:

Support transfer while removing it.

Installation

I Apply recommended sealant to mating surface to transmission.

Recommended sealant: Nissan genuine part (KP610-00250) or equivalent

I Tighten bolts securing transfer.

Bolt No. Tightening torque

N×m (kg-m, ft-lb)

mm (in)

q

127 - 36 (2.8 - 3.6, 20 - 26) 45 (1.77)

q

227 - 36 (2.8 - 3.6, 20 - 26) 60 (2.36)

SMT478A

YTF001

SMT495A

SMT496A

REMOVAL AND INSTALLATION

TF-7

http://vnx.su/

Page 1030 of 1833

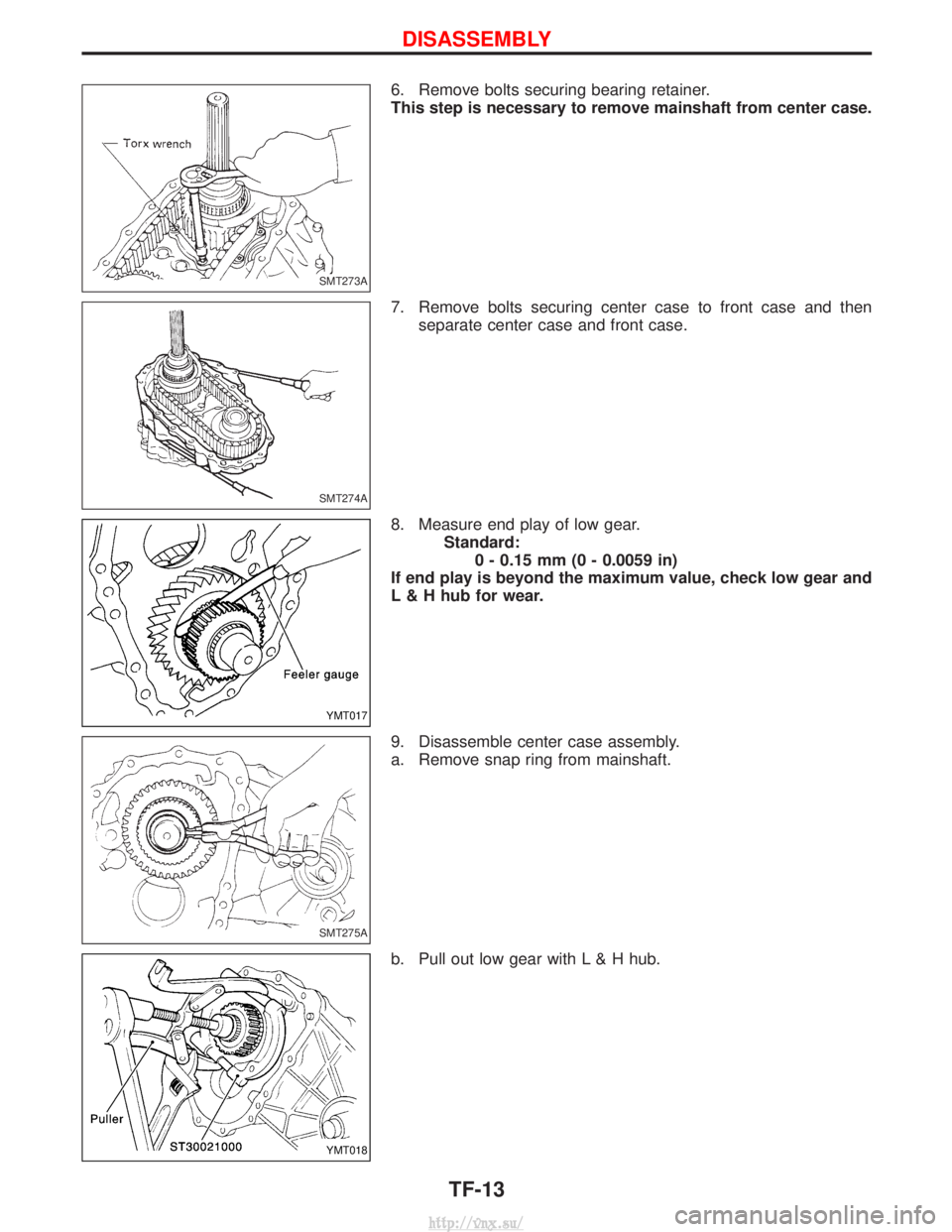

6. Remove bolts securing bearing retainer.

This step is necessary to remove mainshaft from center case.

7. Remove bolts securing center case to front case and thenseparate center case and front case.

8. Measure end play of low gear. Standard:0 - 0.15 mm (0 - 0.0059 in)

If end play is beyond the maximum value, check low gear and

L & H hub for wear.

9. Disassemble center case assembly.

a. Remove snap ring from mainshaft.

b. Pull out low gear with L & H hub.

SMT273A

SMT274A

YMT017

SMT275A

YMT018

DISASSEMBLY

TF-13

http://vnx.su/

Page 1032 of 1833

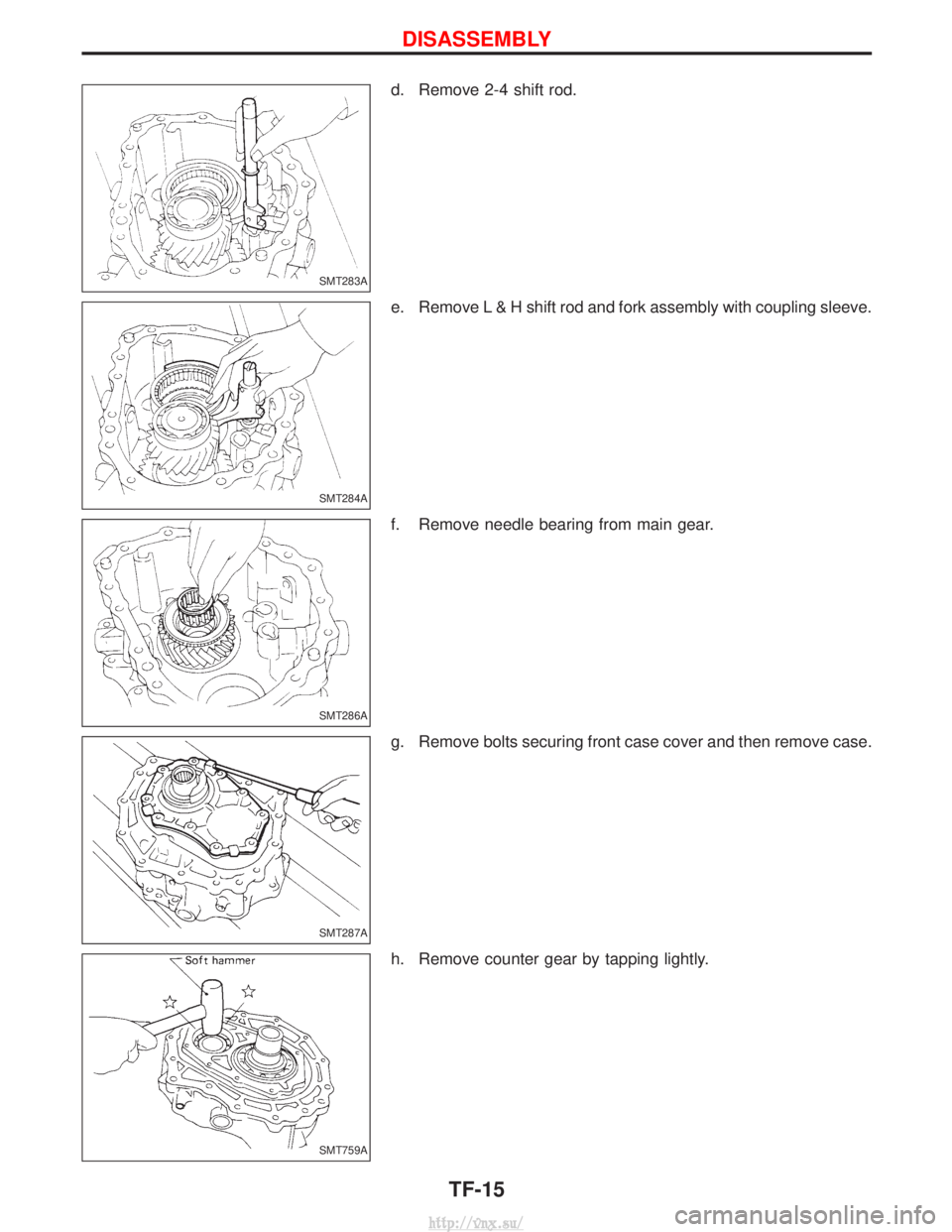

d. Remove 2-4 shift rod.

e. Remove L & H shift rod and fork assembly with coupling sleeve.

f. Remove needle bearing from main gear.

g. Remove bolts securing front case cover and then remove case.

h. Remove counter gear by tapping lightly.

SMT283A

SMT284A

SMT286A

SMT287A

SMT759A

DISASSEMBLY

TF-15

http://vnx.su/

Page 1063 of 1833

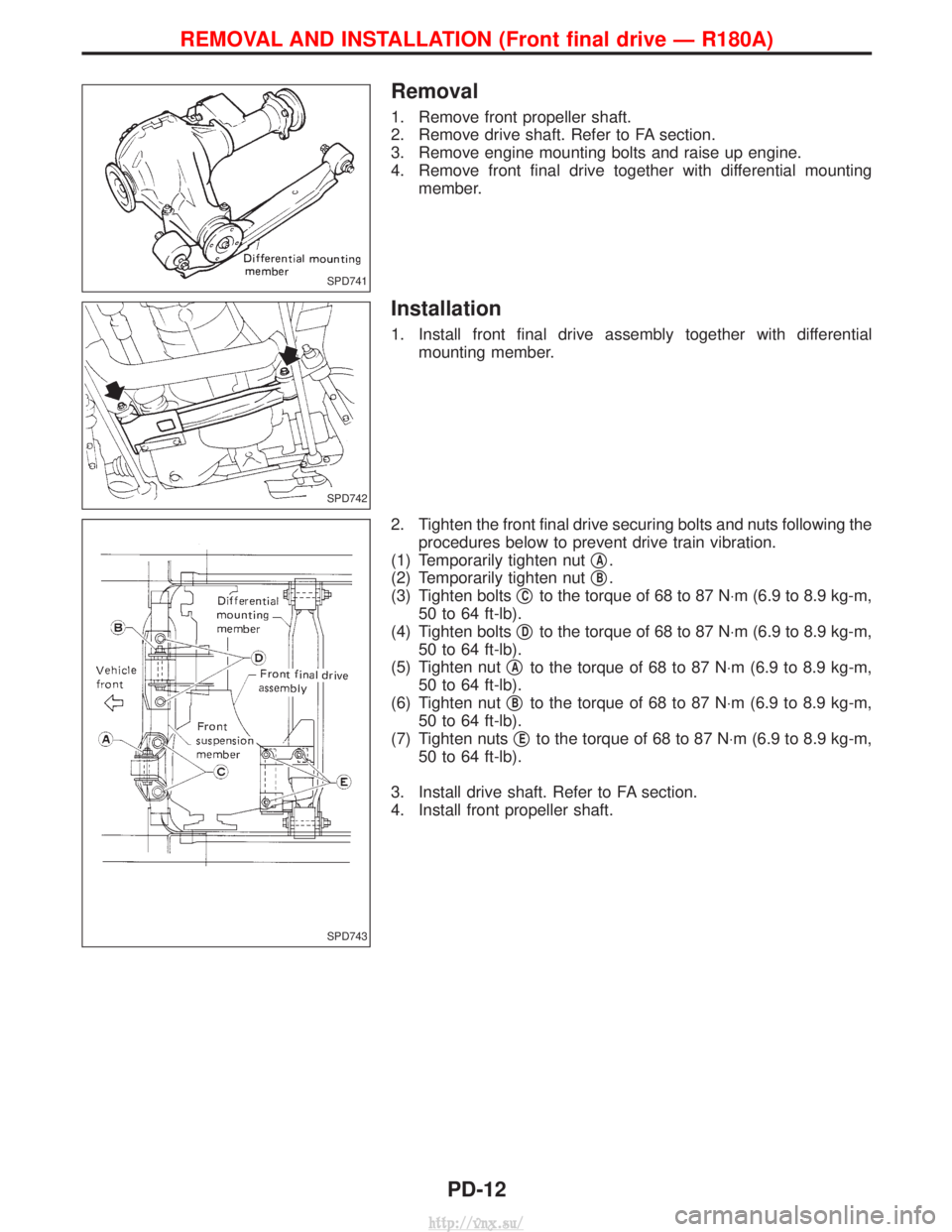

Removal

1. Remove front propeller shaft.

2. Remove drive shaft. Refer to FA section.

3. Remove engine mounting bolts and raise up engine.

4. Remove front final drive together with differential mountingmember.

Installation

1. Install front final drive assembly together with differentialmounting member.

2. Tighten the front final drive securing bolts and nuts following the procedures below to prevent drive train vibration.

(1) Temporarily tighten nut q

A.

(2) Temporarily tighten nut q

B.

(3) Tighten bolts q

Cto the torque of 68 to 87 N

×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(4) Tighten bolts q

Dto the torque of 68 to 87 N

×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(5) Tighten nut q

Ato the torque of 68 to 87 N

×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(6) Tighten nut q

Bto the torque of 68 to 87 N

×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

(7) Tighten nuts q

Eto the torque of 68 to 87 N

×m (6.9 to 8.9 kg-m,

50 to 64 ft-lb).

3. Install drive shaft. Refer to FA section.

4. Install front propeller shaft.

SPD741

SPD742

SPD743

REMOVAL AND INSTALLATION (Front final drive Ð R180A)

PD-12

http://vnx.su/

Page 1070 of 1833

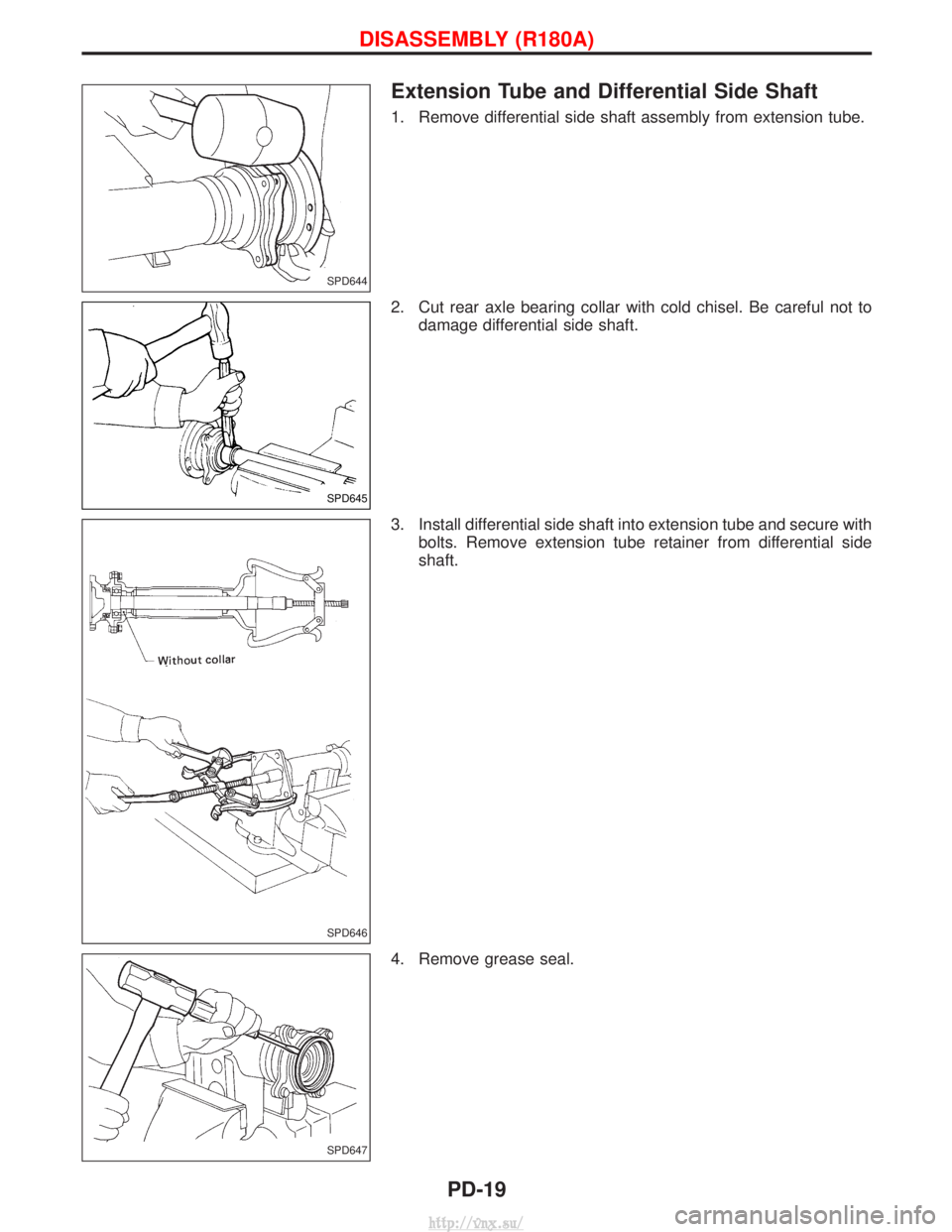

Extension Tube and Differential Side Shaft

1. Remove differential side shaft assembly from extension tube.

2. Cut rear axle bearing collar with cold chisel. Be careful not todamage differential side shaft.

3. Install differential side shaft into extension tube and secure with bolts. Remove extension tube retainer from differential side

shaft.

4. Remove grease seal.

SPD644

SPD645

SPD646

SPD647

DISASSEMBLY (R180A)

PD-19

http://vnx.su/

Page 1137 of 1833

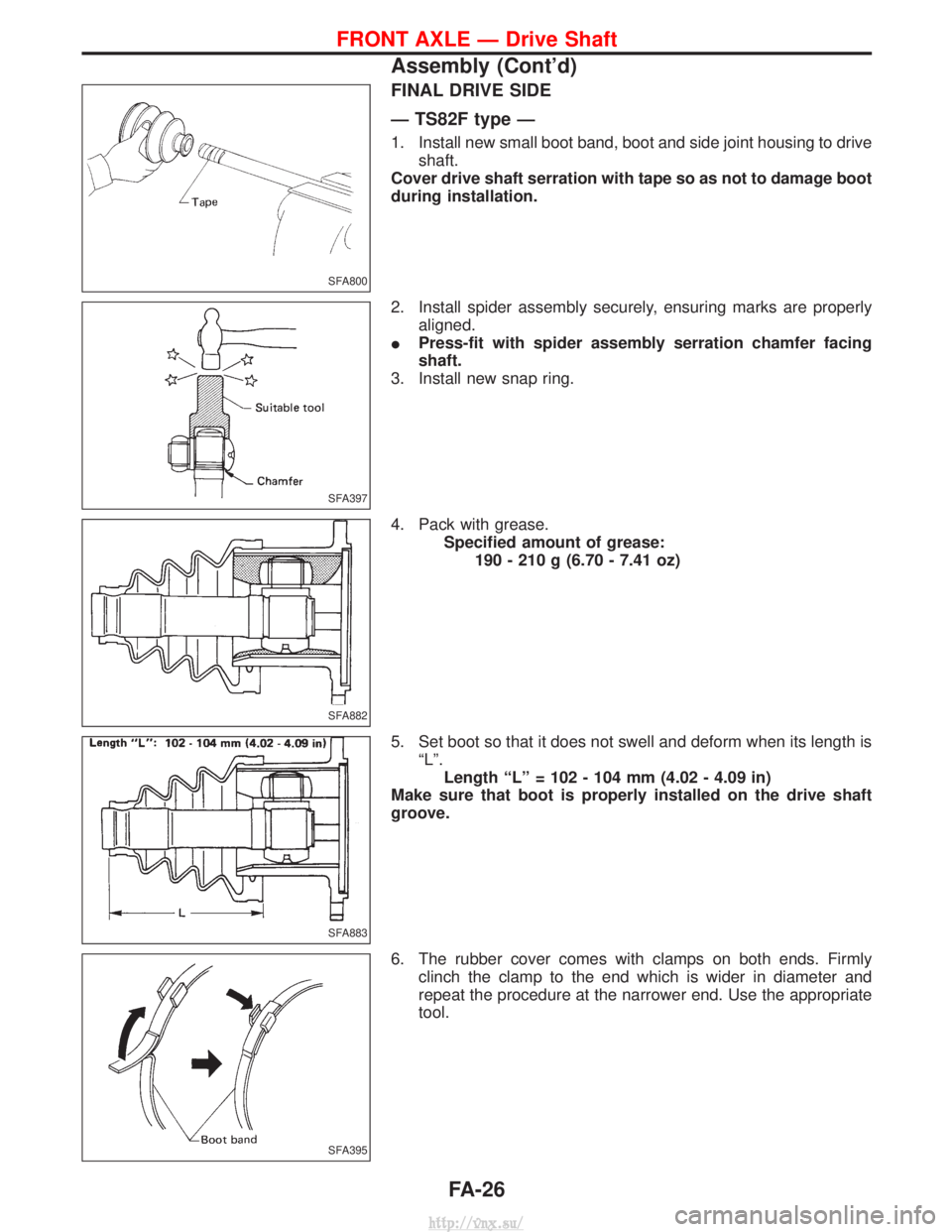

FINAL DRIVE SIDE

Ð TS82F type Ð

1. Install new small boot band, boot and side joint housing to driveshaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

2. Install spider assembly securely, ensuring marks are properly aligned.

I Press-fit with spider assembly serration chamfer facing

shaft.

3. Install new snap ring.

4. Pack with grease. Specified amount of grease:190 - 210 g (6.70 - 7.41 oz)

5. Set boot so that it does not swell and deform when its length is ªLº.Length ªLº = 102 - 104 mm (4.02 - 4.09 in)

Make sure that boot is properly installed on the drive shaft

groove.

6. The rubber cover comes with clamps on both ends. Firmly clinch the clamp to the end which is wider in diameter and

repeat the procedure at the narrower end. Use the appropriate

tool.

SFA800

SFA397

SFA882

SFA883

SFA395

FRONT AXLE Ð Drive Shaft

Assembly (Cont'd)

FA-26

http://vnx.su/

Page 1138 of 1833

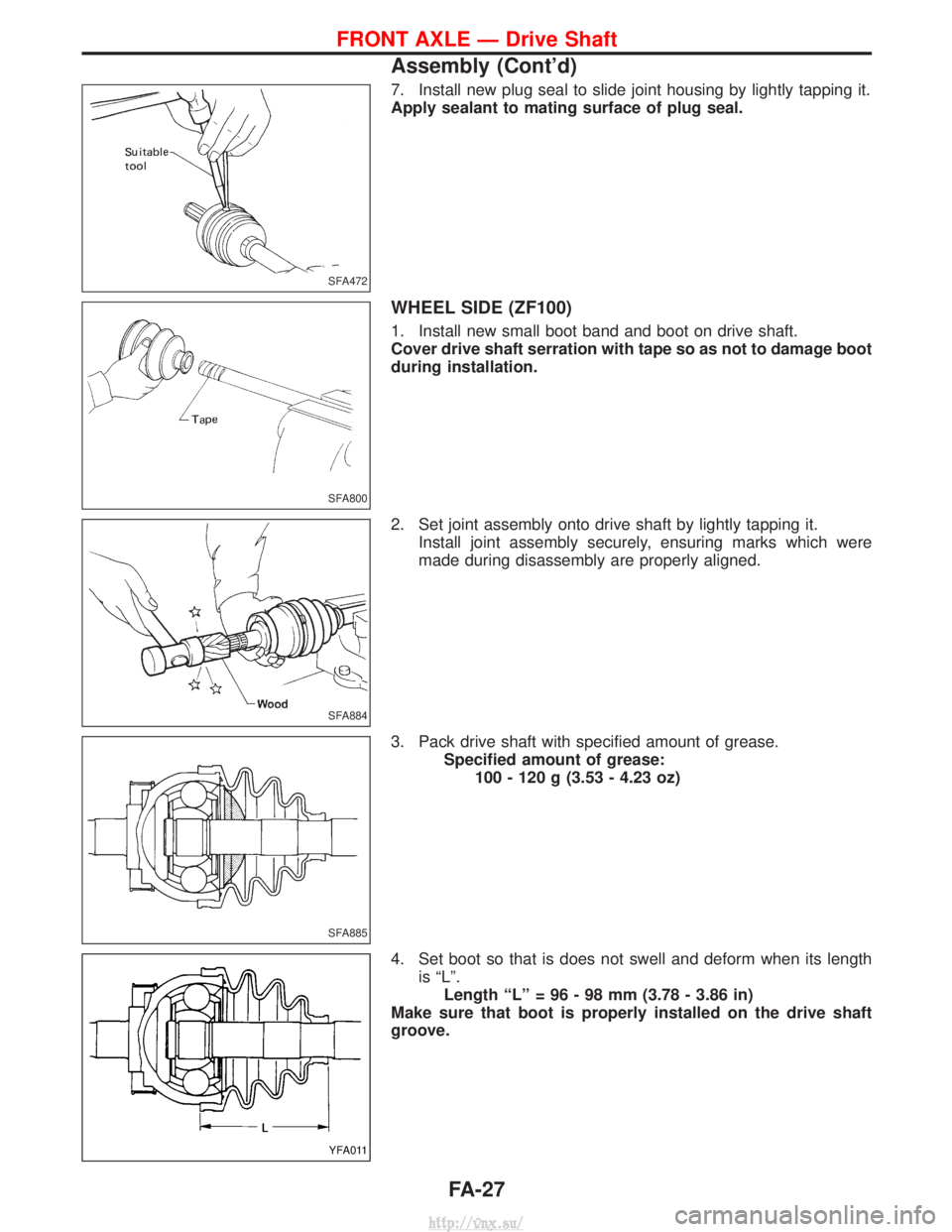

7. Install new plug seal to slide joint housing by lightly tapping it.

Apply sealant to mating surface of plug seal.

WHEEL SIDE (ZF100)

1. Install new small boot band and boot on drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

2. Set joint assembly onto drive shaft by lightly tapping it.Install joint assembly securely, ensuring marks which were

made during disassembly are properly aligned.

3. Pack drive shaft with specified amount of grease. Specified amount of grease:100 - 120 g (3.53 - 4.23 oz)

4. Set boot so that is does not swell and deform when its length is ªLº.Length ªLº = 96 - 98 mm (3.78 - 3.86 in)

Make sure that boot is properly installed on the drive shaft

groove.

SFA472

SFA800

SFA884

SFA885

YFA011

FRONT AXLE Ð Drive Shaft

Assembly (Cont'd)

FA-27

http://vnx.su/

Page 1139 of 1833

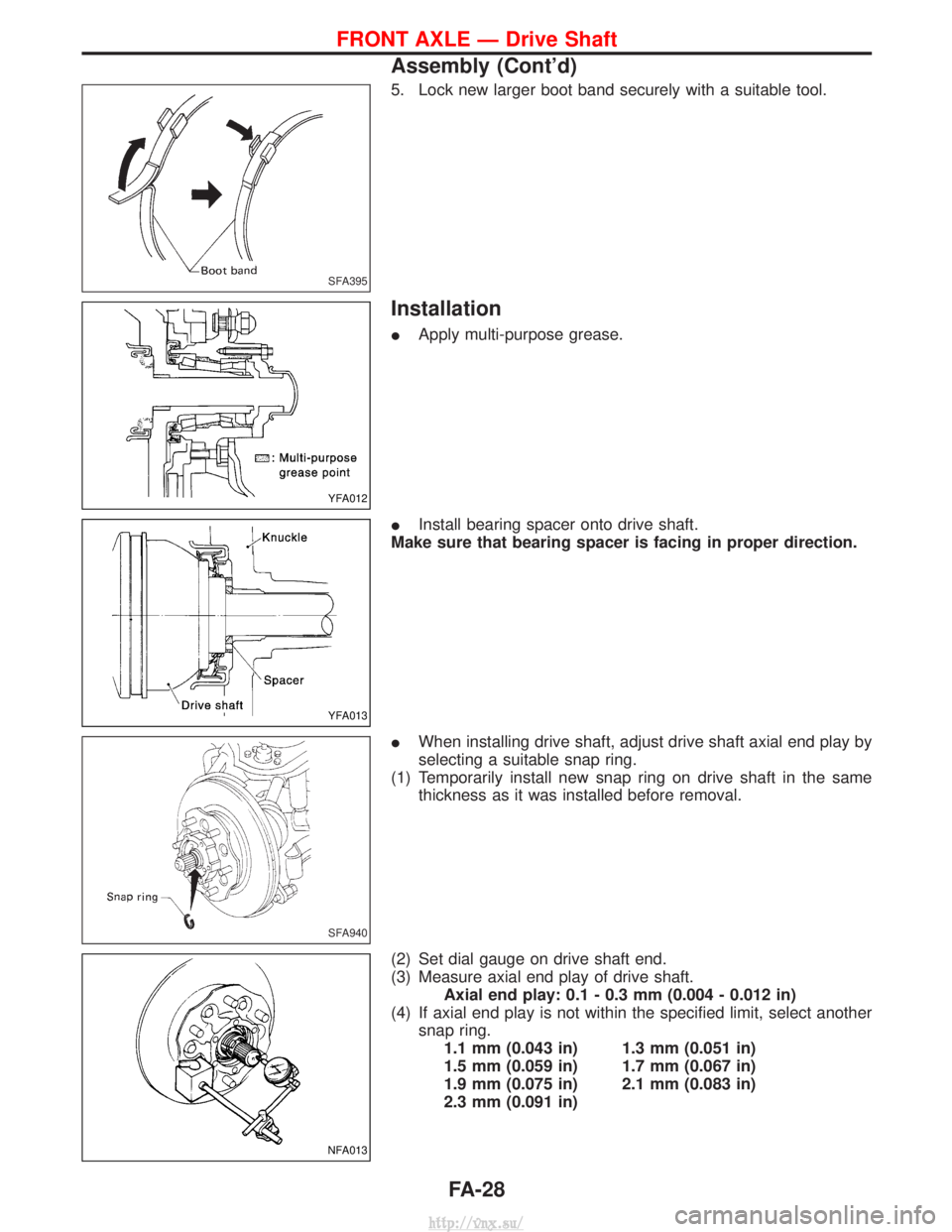

5. Lock new larger boot band securely with a suitable tool.

Installation

IApply multi-purpose grease.

I Install bearing spacer onto drive shaft.

Make sure that bearing spacer is facing in proper direction.

I When installing drive shaft, adjust drive shaft axial end play by

selecting a suitable snap ring.

(1) Temporarily install new snap ring on drive shaft in the same thickness as it was installed before removal.

(2) Set dial gauge on drive shaft end.

(3) Measure axial end play of drive shaft. Axial end play: 0.1 - 0.3 mm (0.004 - 0.012 in)

(4) If axial end play is not within the specified limit, select another snap ring.1.1 mm (0.043 in) 1.3 mm (0.051 in)

1.5 mm (0.059 in) 1.7 mm (0.067 in)

1.9 mm (0.075 in) 2.1 mm (0.083 in)

2.3 mm (0.091 in)

SFA395

YFA012

YFA013

SFA940

NFA013

FRONT AXLE Ð Drive Shaft

Assembly (Cont'd)

FA-28

http://vnx.su/