Ambient NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 52 of 1833

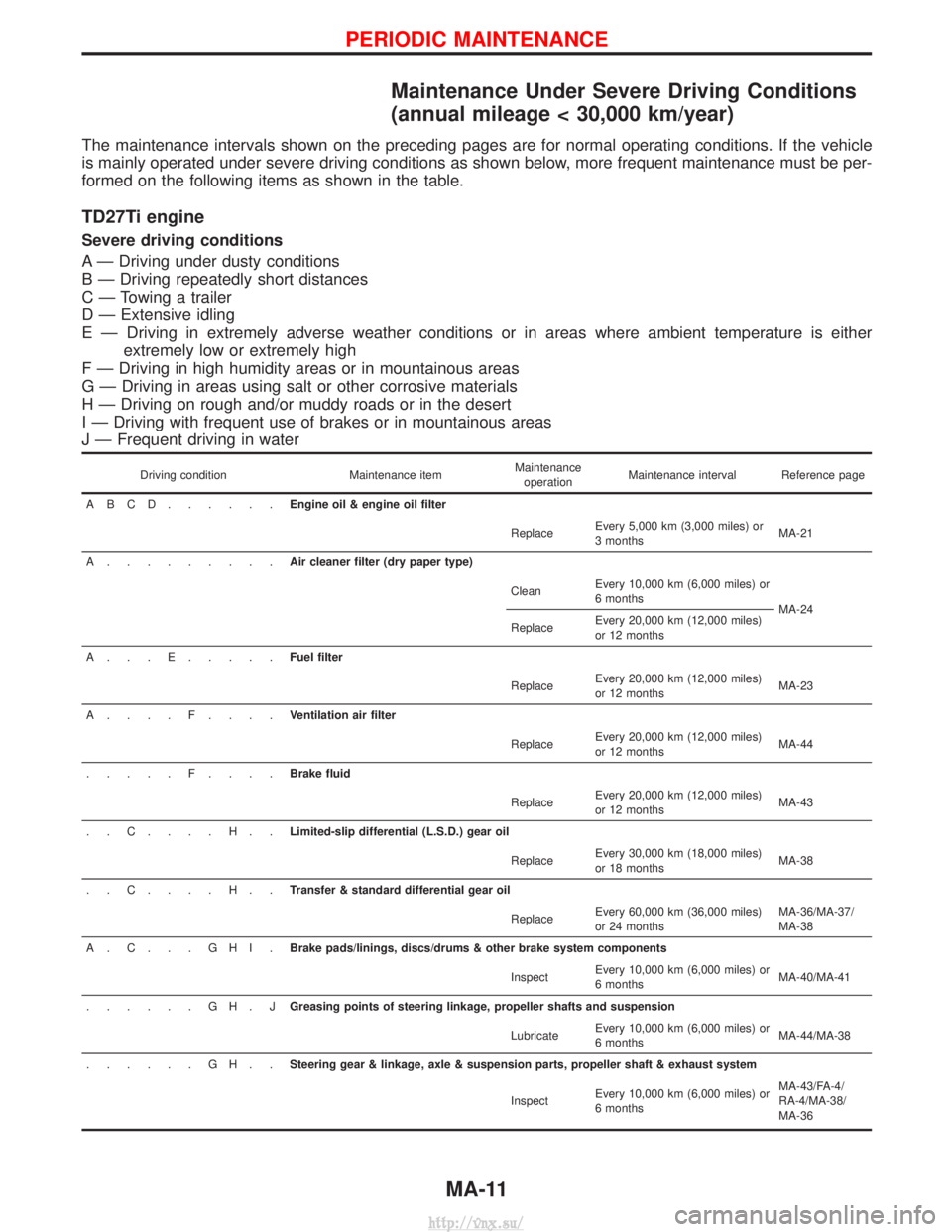

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter ReplaceEvery 5,000 km (3,000 miles) or

3 months MA-21

A.........Air cleaner filter (dry paper type) CleanEvery 10,000 km (6,000 miles) or

6 months

MA-24

Replace Every 20,000 km (12,000 miles)

or 12 months

A...E.....Fuel filter

ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-23

A....F....Ventilation air filter ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-44

.....F....Brake fluid ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil ReplaceEvery 30,000 km (18,000 miles)

or 18 months MA-38

..C....H..Transfer & standard differential gear oil ReplaceEvery 60,000 km (36,000 miles)

or 24 months MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components

InspectEvery 10,000 km (6,000 miles) or

6 months MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

LubricateEvery 10,000 km (6,000 miles) or

6 months MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

InspectEvery 10,000 km (6,000 miles) or

6 months MA-43/FA-4/

RA-4/MA-38/

MA-36

PERIODIC MAINTENANCE

MA-11

http://vnx.su/

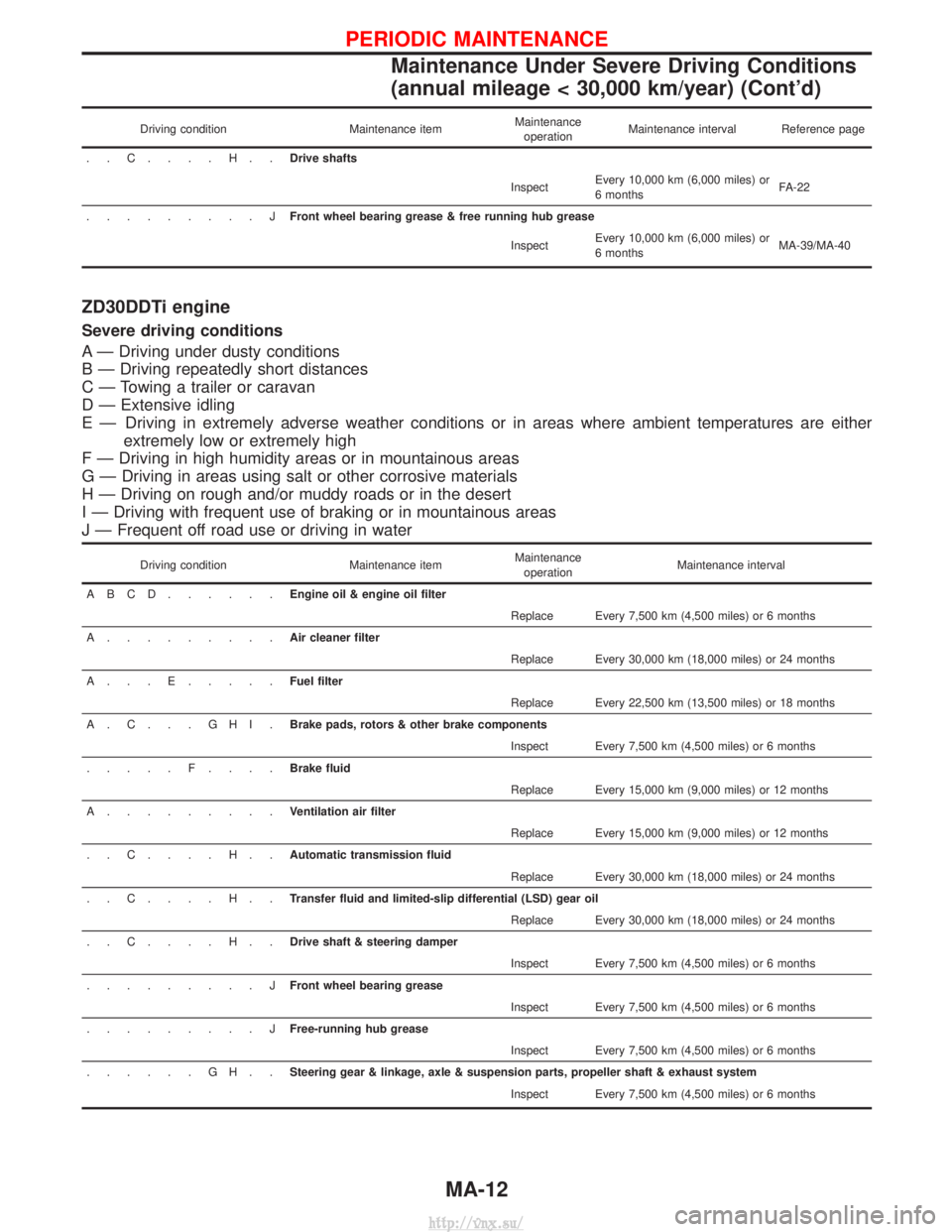

Page 53 of 1833

Driving conditionMaintenance itemMaintenance

operation Maintenance interval Reference page

..C....H..Drive shafts InspectEvery 10,000 km (6,000 miles) or

6 months FA-22

.........J Front wheel bearing grease & free running hub grease

InspectEvery 10,000 km (6,000 miles) or

6 months MA-39/MA-40

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shaft & steering damper Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Front wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Free-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) (Cont'd)

MA-12

http://vnx.su/

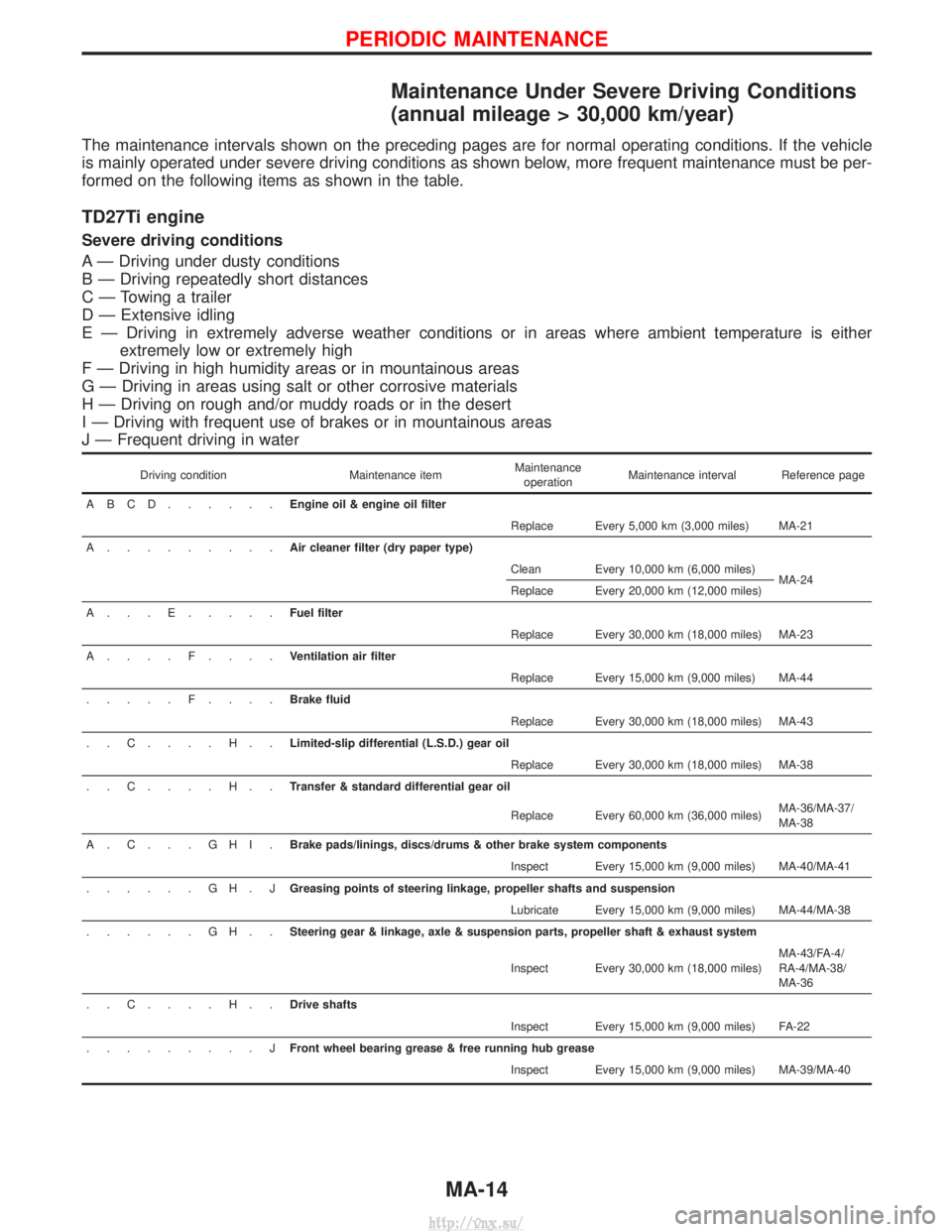

Page 55 of 1833

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter Replace Every 5,000 km (3,000 miles) MA-21

A.........Air cleaner filter (dry paper type) Clean Every 10,000 km (6,000 miles)MA-24

Replace Every 20,000 km (12,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles) MA-23

A....F....Ventilation air filter Replace Every 15,000 km (9,000 miles) MA-44

.....F....Brake fluid Replace Every 30,000 km (18,000 miles) MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil Replace Every 30,000 km (18,000 miles) MA-38

..C....H..Transfer & standard differential gear oil

Replace Every 60,000 km (36,000 miles)MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components Inspect Every 15,000 km (9,000 miles) MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

Lubricate Every 15,000 km (9,000 miles) MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

Inspect Every 30,000 km (18,000 miles)MA-43/FA-4/

RA-4/MA-38/

MA-36

..C....H..Drive shafts Inspect Every 15,000 km (9,000 miles) FA-22

.........J Front wheel bearing grease & free running hub grease

Inspect Every 15,000 km (9,000 miles) MA-39/MA-40

PERIODIC MAINTENANCE

MA-14

http://vnx.su/

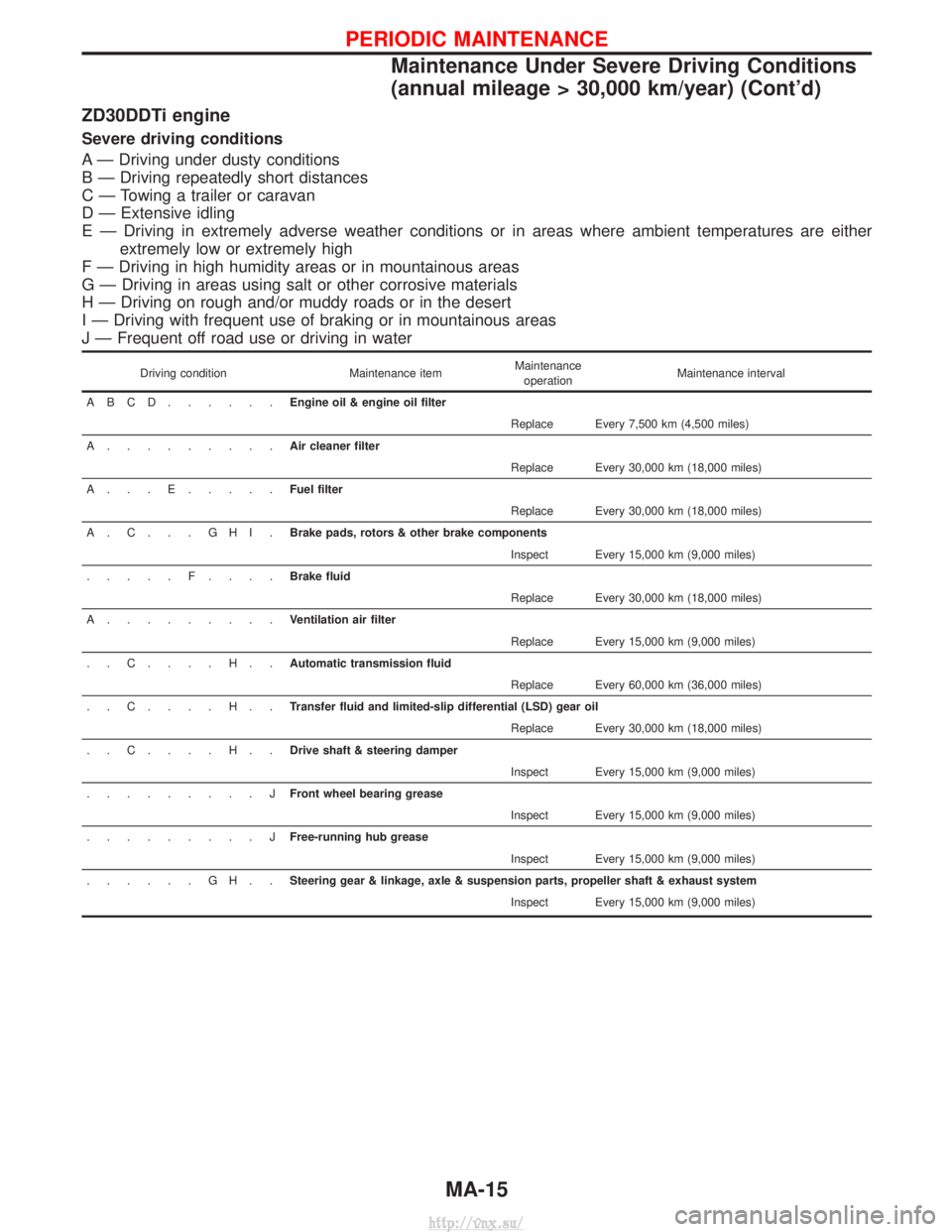

Page 56 of 1833

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles)

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles)

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 15,000 km (9,000 miles)

.....F....Brake fluid Replace Every 30,000 km (18,000 miles)

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles)

..C....H..Automatic transmission fluid Replace Every 60,000 km (36,000 miles)

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles)

..C....H..Drive shaft & steering damper Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) (Cont'd)

MA-15

http://vnx.su/

Page 58 of 1833

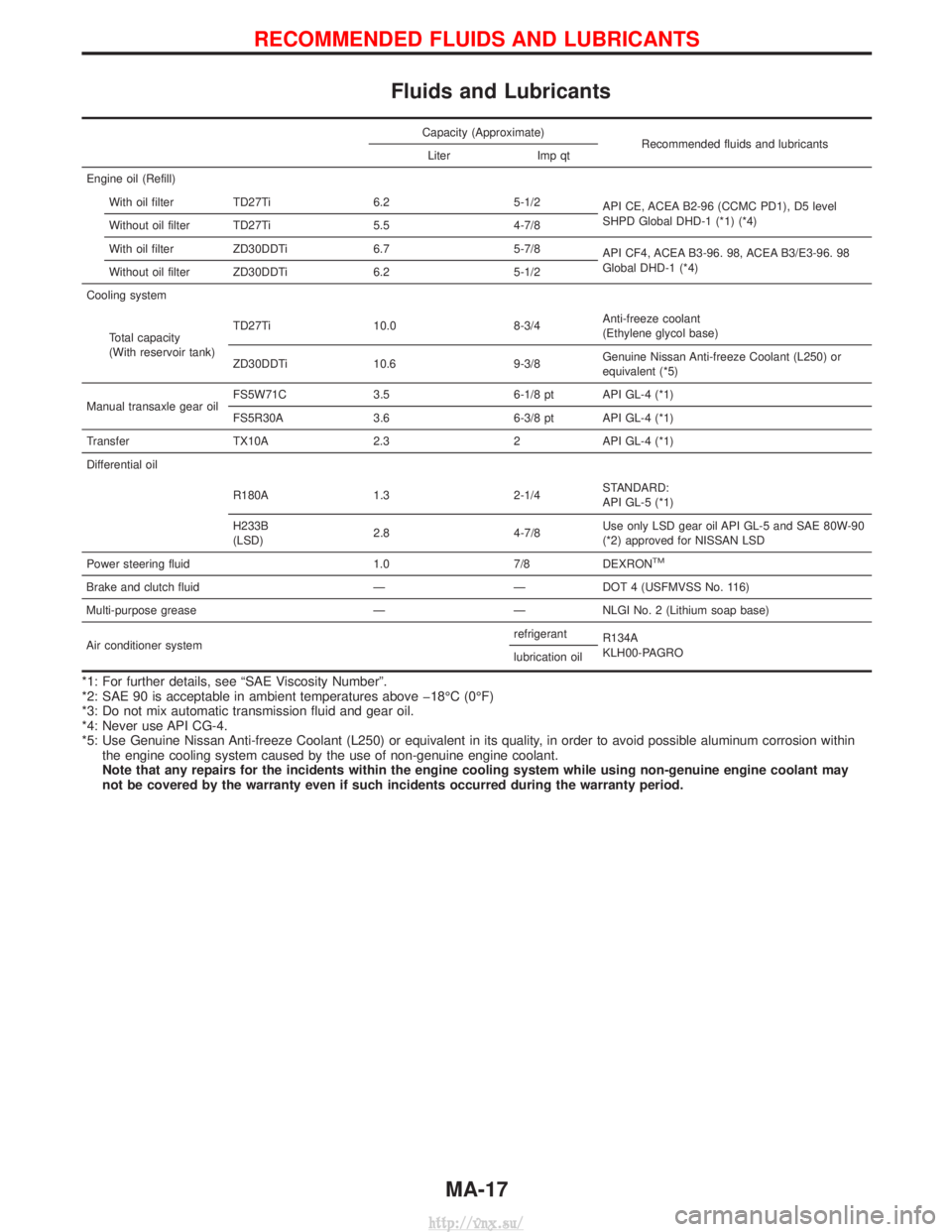

Fluids and Lubricants

Capacity (Approximate)Recommended fluids and lubricants

Liter Imp qt

Engine oil (Refill) With oil filter TD27Ti 6.2 5-1/2 API CE, ACEA B2-96 (CCMC PD1), D5 level

SHPD Global DHD-1 (*1) (*4)

Without oil filter TD27Ti 5.5 4-7/8

With oil filter ZD30DDTi 6.7 5-7/8 API CF4, ACEA B3-96. 98, ACEA B3/E3-96. 98

Global DHD-1 (*4)

Without oil filter ZD30DDTi 6.2 5-1/2

Cooling system

Total capacity

(With reservoir tank) TD27Ti 10.0 8-3/4

Anti-freeze coolant

(Ethylene glycol base)

ZD30DDTi 10.6 9-3/8 Genuine Nissan Anti-freeze Coolant (L250) or

equivalent (*5)

Manual transaxle gear oil FS5W71C 3.5 6-1/8 pt API GL-4 (*1)

FS5R30A 3.6 6-3/8 pt API GL-4 (*1)

Transfer TX10A 2.3 2 API GL-4 (*1)

Differential oil

R180A 1.3 2-1/4 STANDARD:

API GL-5 (*1)

H233B

(LSD) 2.8 4-7/8 Use only LSD gear oil API GL-5 and SAE 80W-90

(*2) approved for NISSAN LSD

Power steering fluid 1.0 7/8 DEXRON

TM

Brake and clutch fluid ÐÐDOT 4 (USFMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioner system refrigerant

R134A

KLH00-PAGRO

lubrication oil

*1: For further details, see ªSAE Viscosity Numberº.

*2: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF)

*3: Do not mix automatic transmission fluid and gear oil.

*4: Never use API CG-4.

*5: Use Genuine Nissan Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may

not be covered by the warranty even if such incidents occurred during the warranty period.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

http://vnx.su/

Page 59 of 1833

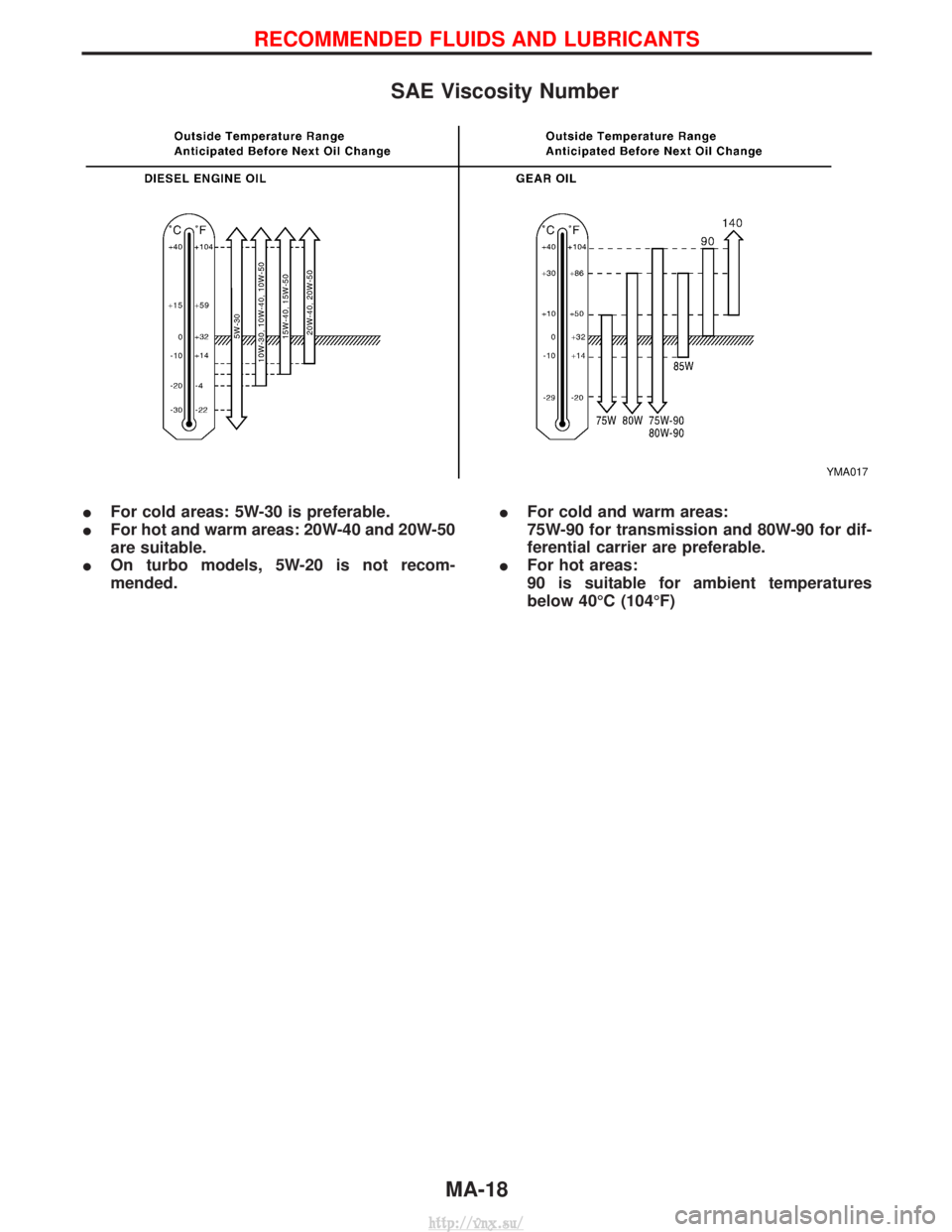

SAE Viscosity Number

IFor cold areas: 5W-30 is preferable.

I For hot and warm areas: 20W-40 and 20W-50

are suitable.

I On turbo models, 5W-20 is not recom-

mended. I

For cold and warm areas:

75W-90 for transmission and 80W-90 for dif-

ferential carrier are preferable.

I For hot areas:

90 is suitable for ambient temperatures

below 40ÉC (104ÉF)

YMA017

RECOMMENDED FLUIDS AND LUBRICANTS

MA-18

http://vnx.su/

Page 182 of 1833

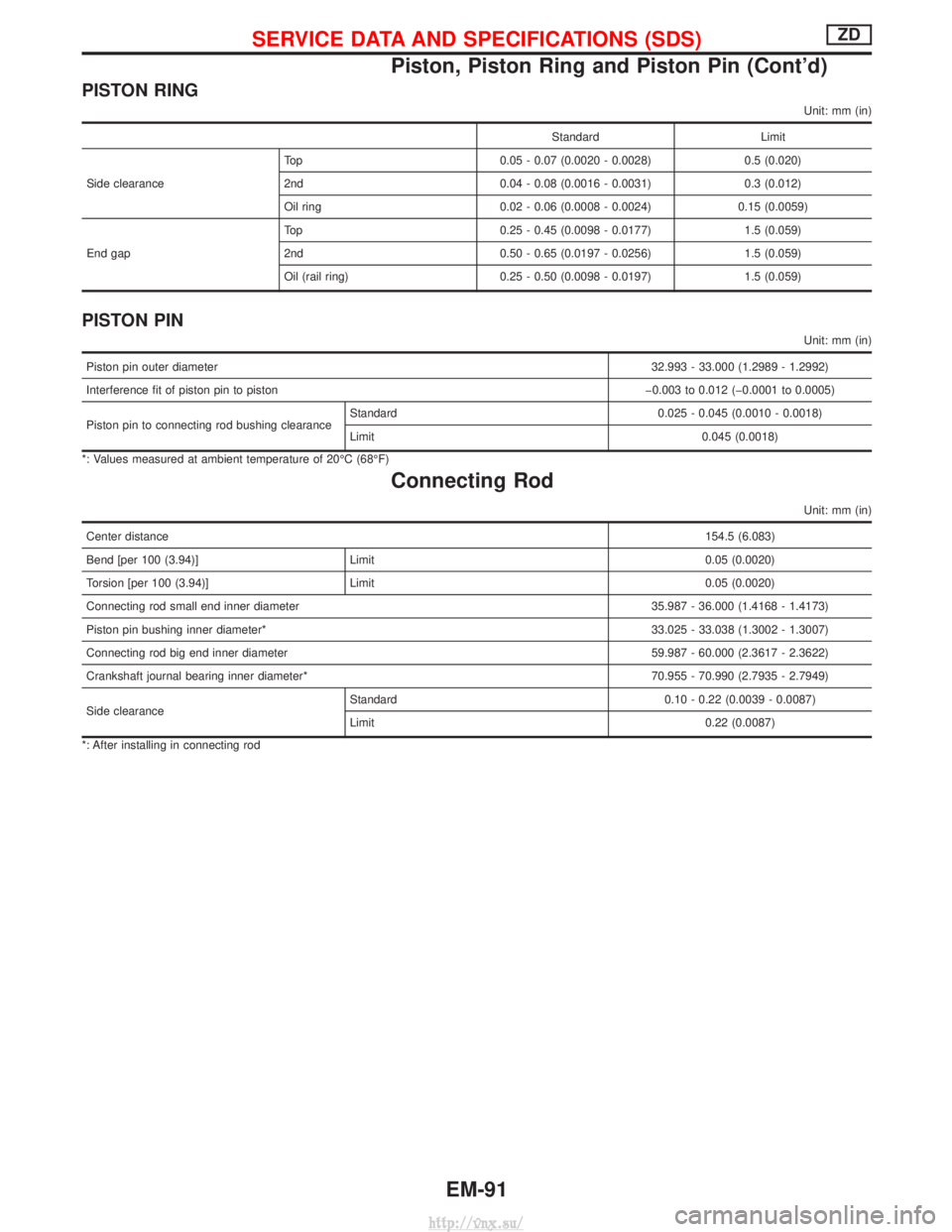

PISTON RING

Unit: mm (in)

StandardLimit

Side clearance Top

0.05 - 0.07 (0.0020 - 0.0028) 0.5 (0.020)

2nd 0.04 - 0.08 (0.0016 - 0.0031) 0.3 (0.012)

Oil ring 0.02 - 0.06 (0.0008 - 0.0024) 0.15 (0.0059)

End gap Top

0.25 - 0.45 (0.0098 - 0.0177) 1.5 (0.059)

2nd 0.50 - 0.65 (0.0197 - 0.0256) 1.5 (0.059)

Oil (rail ring) 0.25 - 0.50 (0.0098 - 0.0197) 1.5 (0.059)

PISTON PIN

Unit: mm (in)

Piston pin outer diameter 32.993 - 33.000 (1.2989 - 1.2992)

Interference fit of piston pin to piston þ0.003 to 0.012 (þ0.0001 to 0.0005)

Piston pin to connecting rod bushing clearance Standard 0.025 - 0.045 (0.0010 - 0.0018)

Limit 0.045 (0.0018)

*: Values measured at ambient temperature of 20ÉC (68ÉF)

Connecting Rod

Unit: mm (in)

Center distance 154.5 (6.083)

Bend [per 100 (3.94)] Limit 0.05 (0.0020)

Torsion [per 100 (3.94)] Limit 0.05 (0.0020)

Connecting rod small end inner diameter 35.987 - 36.000 (1.4168 - 1.4173)

Piston pin bushing inner diameter* 33.025 - 33.038 (1.3002 - 1.3007)

Connecting rod big end inner diameter 59.987 - 60.000 (2.3617 - 2.3622)

Crankshaft journal bearing inner diameter* 70.955 - 70.990 (2.7935 - 2.7949)

Side clearance Standard 0.10 - 0.22 (0.0039 - 0.0087)

Limit 0.22 (0.0087)

*: After installing in connecting rod

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

Piston, Piston Ring and Piston Pin (Cont'd)

EM-91

http://vnx.su/

Page 1428 of 1833

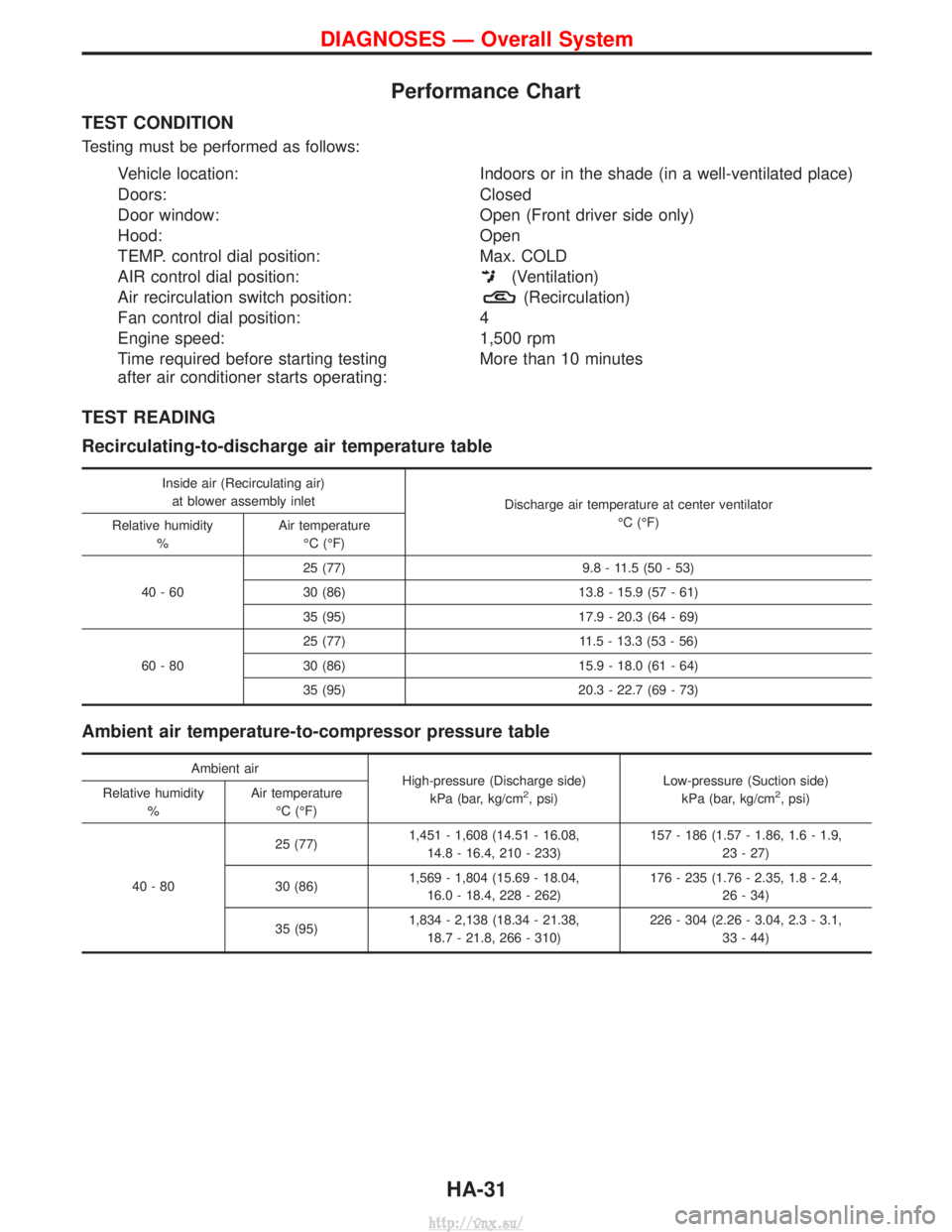

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location:Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control dial position: Max. COLD

AIR control dial position:

(Ventilation)

Air recirculation switch position:

(Recirculation)

Fan control dial position: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating: More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

% Air temperature

ÉC (ÉF)

40-60 25 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-80 25 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi) Low-pressure (Suction side)

kPa (bar, kg/cm2, psi)

Relative humidity

% Air temperature

ÉC (ÉF)

40-80 25 (77)

1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233) 157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86) 1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262) 176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95) 1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310) 226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-31

http://vnx.su/

Page 1430 of 1833

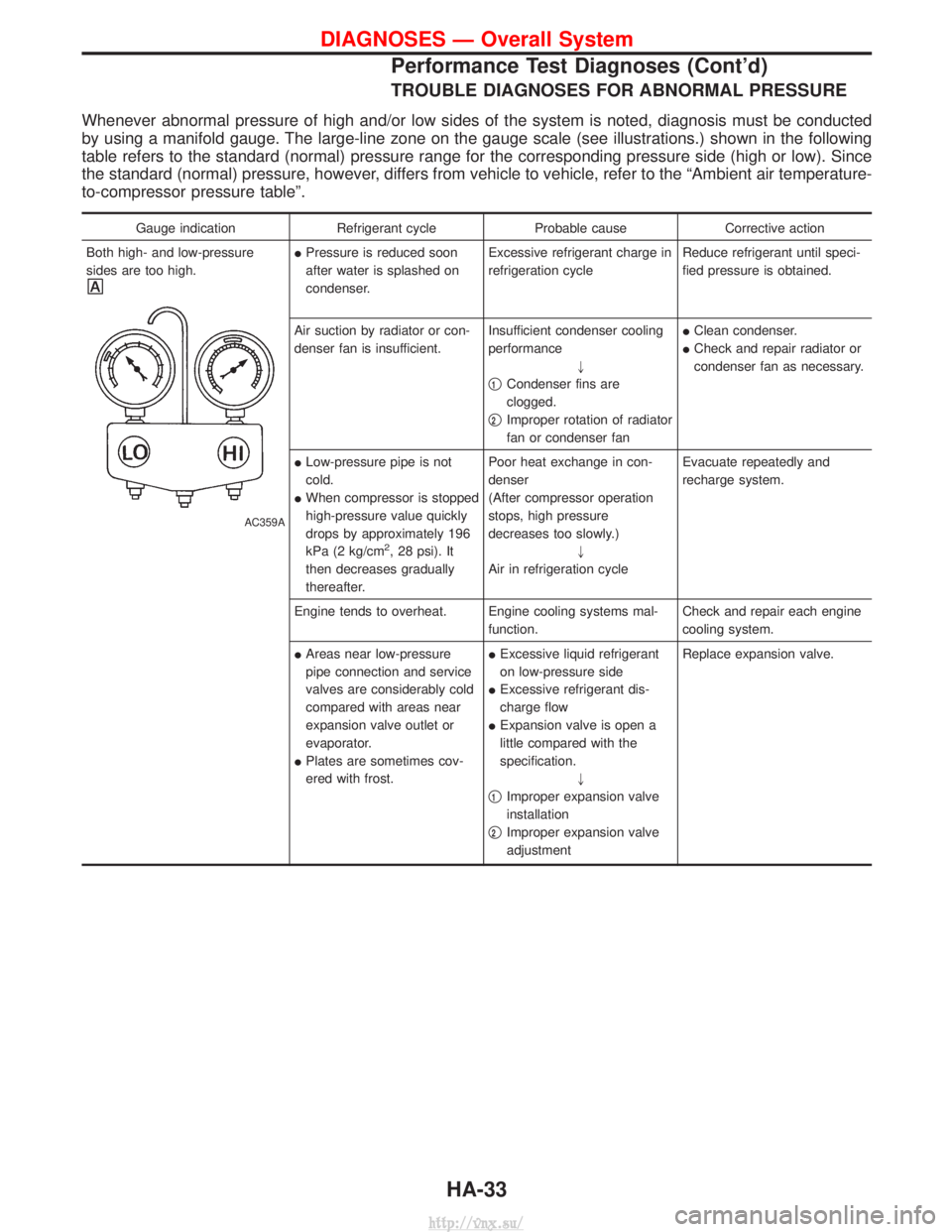

TROUBLE DIAGNOSES FOR ABNORMAL PRESSURE

Whenever abnormal pressure of high and/or low sides of the system is noted, diagnosis must be conducted

by using a manifold gauge. The large-line zone on the gauge scale (see illustrations.) shown in the following

table refers to the standard (normal) pressure range for the corresponding pressure side (high or low). Since

the standard (normal) pressure, however, differs from vehicle to vehicle, refer to the ªAmbient air temperature-

to-compressor pressure tableº.

Gauge indicationRefrigerant cycleProbable causeCorrective action

Both high- and low-pressure

sides are too high.

AC359A

I Pressure is reduced soon

after water is splashed on

condenser. Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by radiator or con-

denser fan is insufficient. Insufficient condenser cooling

performance

"

q

1Condenser fins are

clogged.

q

2Improper rotation of radiator

fan or condenser fan I

Clean condenser.

I Check and repair radiator or

condenser fan as necessary.

I Low-pressure pipe is not

cold.

I When compressor is stopped

high-pressure value quickly

drops by approximately 196

kPa (2 kg/cm

2, 28 psi). It

then decreases gradually

thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycle Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal- function.Check and repair each engine

cooling system.

I Areas near low-pressure

pipe connection and service

valves are considerably cold

compared with areas near

expansion valve outlet or

evaporator.

I Plates are sometimes cov-

ered with frost. I

Excessive liquid refrigerant

on low-pressure side

I Excessive refrigerant dis-

charge flow

I Expansion valve is open a

little compared with the

specification.

"

q

1Improper expansion valve

installation

q

2Improper expansion valve

adjustment Replace expansion valve.

DIAGNOSES Ð Overall System

Performance Test Diagnoses (Cont'd)

HA-33

http://vnx.su/

Page 1576 of 1833

![NISSAN TERRANO 2004 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA NISSAN TERRANO 2004 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or STA](/img/5/57394/w960_57394-1575.png)

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

Ithrough 10A fuse [No. 16, located in the fuse block (J/B)]

I to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 12, located in the fuse block (J/B)]

I to combination meter terminal 28.

Ground is supplied

I through body grounds F36, F47 (LHD models) or M33, M754 (RHD models)

I to combination meter terminal 29.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

Thermal transmitter provides a engine coolant temperature signal to combination meter for water temperature

gauge.

TACHOMETER

The tachometer indicates engine speed in revolution per minutes (rpm). ECM provides an engine speed sig-

nal to combination meter for tachometer.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

Ifrom body grounds B10 and B18

I through terminal 3 of the fuel level sensor unit and

I through terminal 2 (TD27Ti engine) or 1 (ZD30DDTi engine) of the fuel level sensor unit

I to combination meter terminal 13 for the fuel gauge.

SPEEDOMETER

The combination meter receives a signal from vehicle speed sensor. The speedometer converts the signal into

the vehicle speed displayed.

AMBIENT TEMPERATURE GAUGE

Ambient temperature sensor provides the signal for ambient temperature to combination meter.

METER AND GAUGES

System Description (Cont'd)

EL-83

http://vnx.su/