Combination meter connection NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 692 of 1833

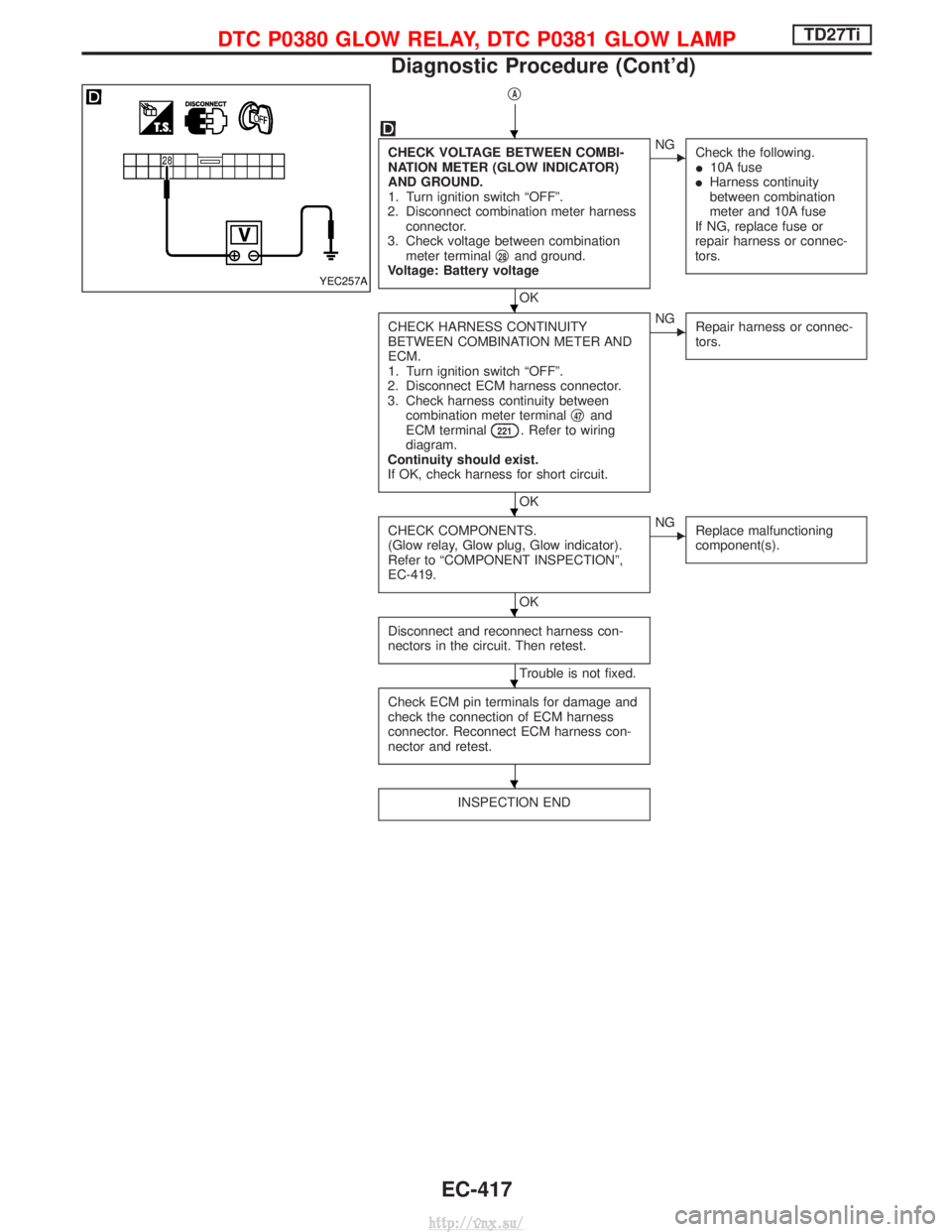

qA

CHECK VOLTAGE BETWEEN COMBI-

NATION METER (GLOW INDICATOR)

AND GROUND.

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector.

3. Check voltage between combination meter terminal q

28and ground.

Voltage: Battery voltage

OK

ENG Check the following.

I10A fuse

I Harness continuity

between combination

meter and 10A fuse

If NG, replace fuse or

repair harness or connec-

tors.

CHECK HARNESS CONTINUITY

BETWEEN COMBINATION METER AND

ECM.

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between combination meter terminal q

47and

ECM terminal221. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short circuit.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENTS.

(Glow relay, Glow plug, Glow indicator).

Refer to ªCOMPONENT INSPECTIONº,

EC-419.

OK

ENGReplace malfunctioning

component(s).

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC257A

H

H

H

H

H

H

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

Diagnostic Procedure (Cont'd)

EC-417

http://vnx.su/

Page 697 of 1833

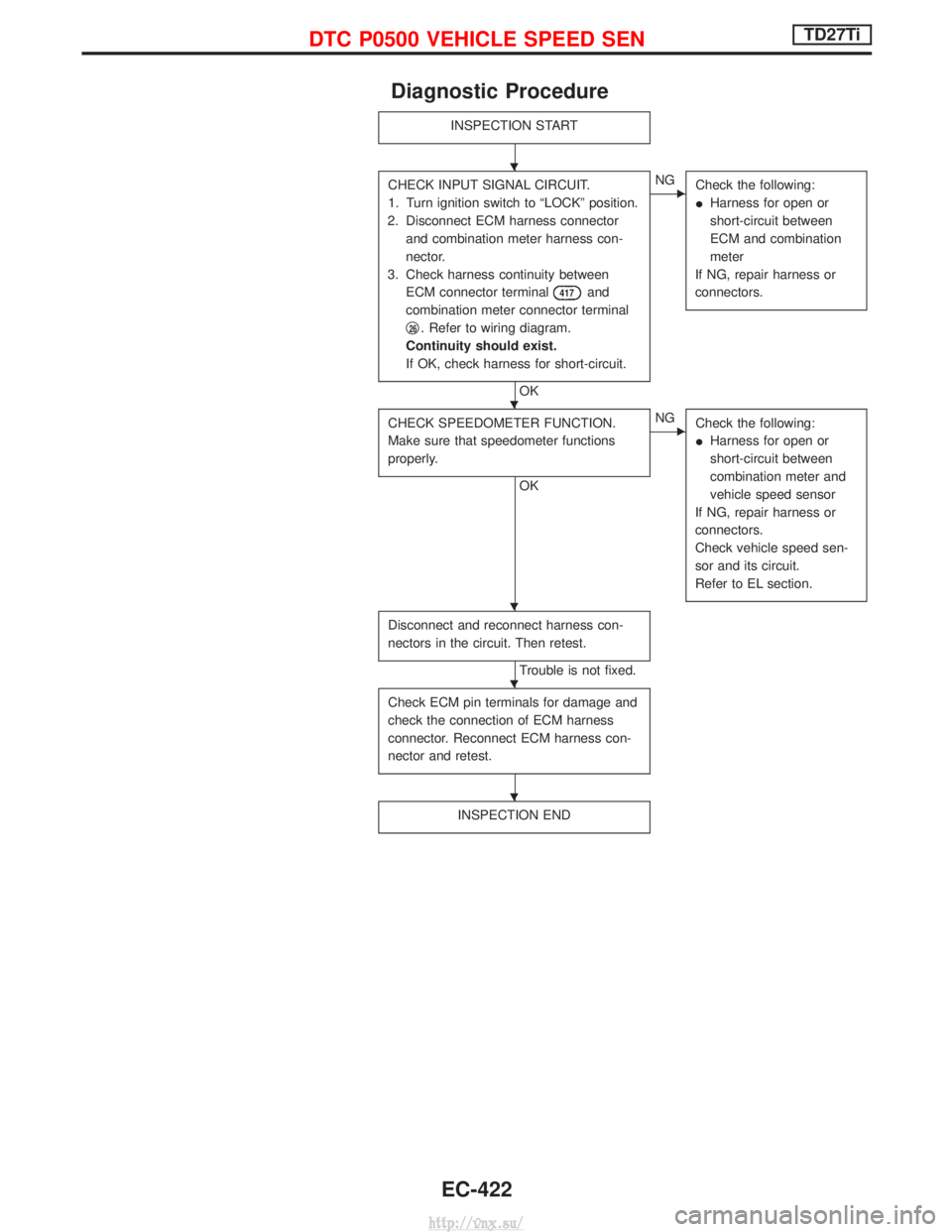

Diagnostic Procedure

INSPECTION START

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and combination meter harness con-

nector.

3. Check harness continuity between ECM connector terminal

417and

combination meter connector terminal

q

26. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following:

IHarness for open or

short-circuit between

ECM and combination

meter

If NG, repair harness or

connectors.

CHECK SPEEDOMETER FUNCTION.

Make sure that speedometer functions

properly.

OK

ENG Check the following:

IHarness for open or

short-circuit between

combination meter and

vehicle speed sensor

If NG, repair harness or

connectors.

Check vehicle speed sen-

sor and its circuit.

Refer to EL section.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

H

H

H

H

H

DTC P0500 VEHICLE SPEED SENTD27Ti

EC-422

http://vnx.su/

Page 704 of 1833

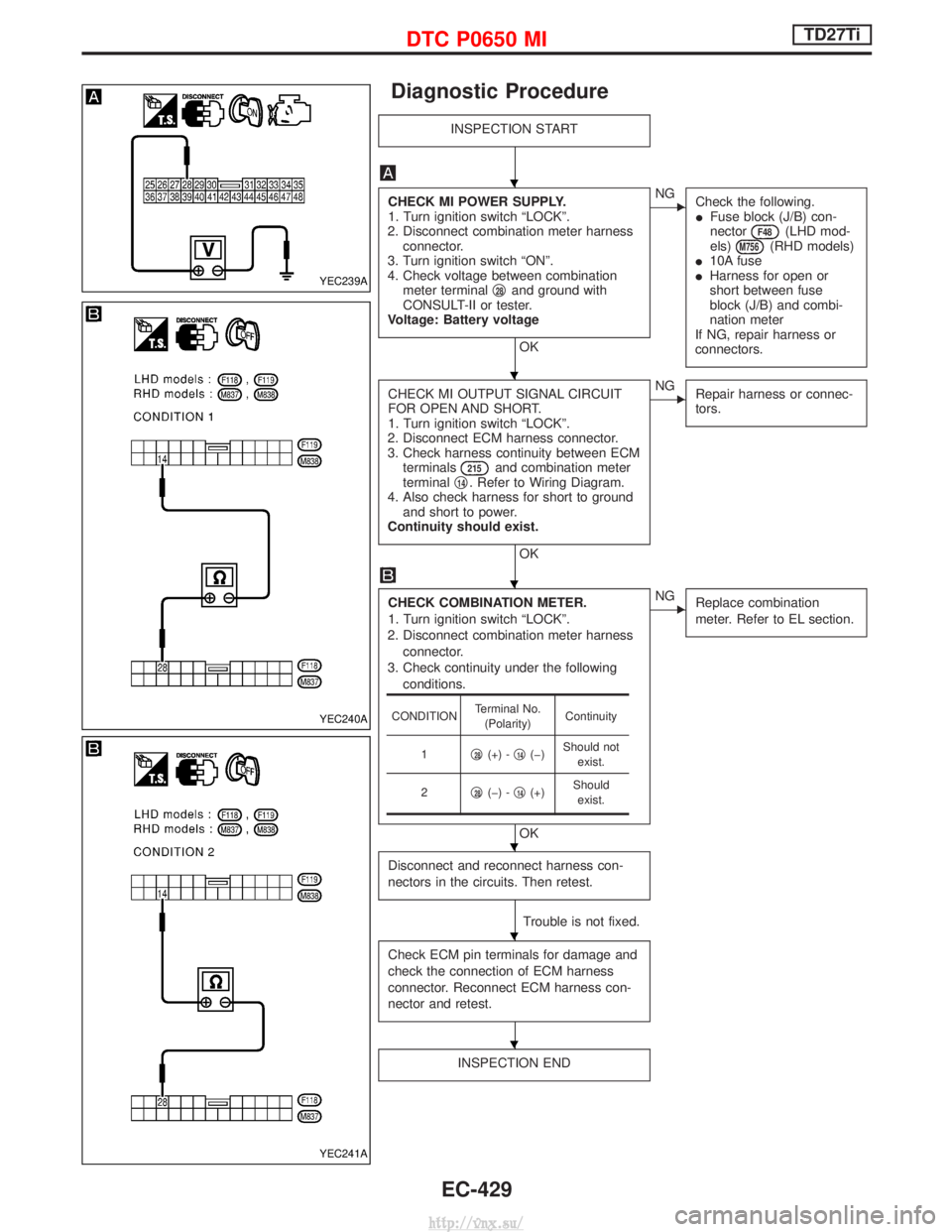

Diagnostic Procedure

INSPECTION START

CHECK MI POWER SUPPLY.

1. Turn ignition switch ªLOCKº.

2. Disconnect combination meter harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal q

28and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG Check the following.

IFuse block (J/B) con-

nector

F48(LHD mod-

els)M756(RHD models)

I 10A fuse

I Harness for open or

short between fuse

block (J/B) and combi-

nation meter

If NG, repair harness or

connectors.

CHECK MI OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT.

1. Turn ignition switch ªLOCKº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals

215and combination meter

terminal q14. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

Continuity should exist.

OK

ENG Repair harness or connec-

tors.

CHECK COMBINATION METER.

1. Turn ignition switch ªLOCKº.

2. Disconnect combination meter harness connector.

3. Check continuity under the following conditions.

OK

ENG Replace combination

meter. Refer to EL section.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

CONDITION Terminal No.

(Polarity) Continuity

1 q

28(+) -q14(þ) Should not

exist.

2 q

28(þ) -q14(+) Should

exist.

YEC239A

YEC240A

YEC241A

H

H

H

H

H

H

DTC P0650 MITD27Ti

EC-429

http://vnx.su/

Page 1236 of 1833

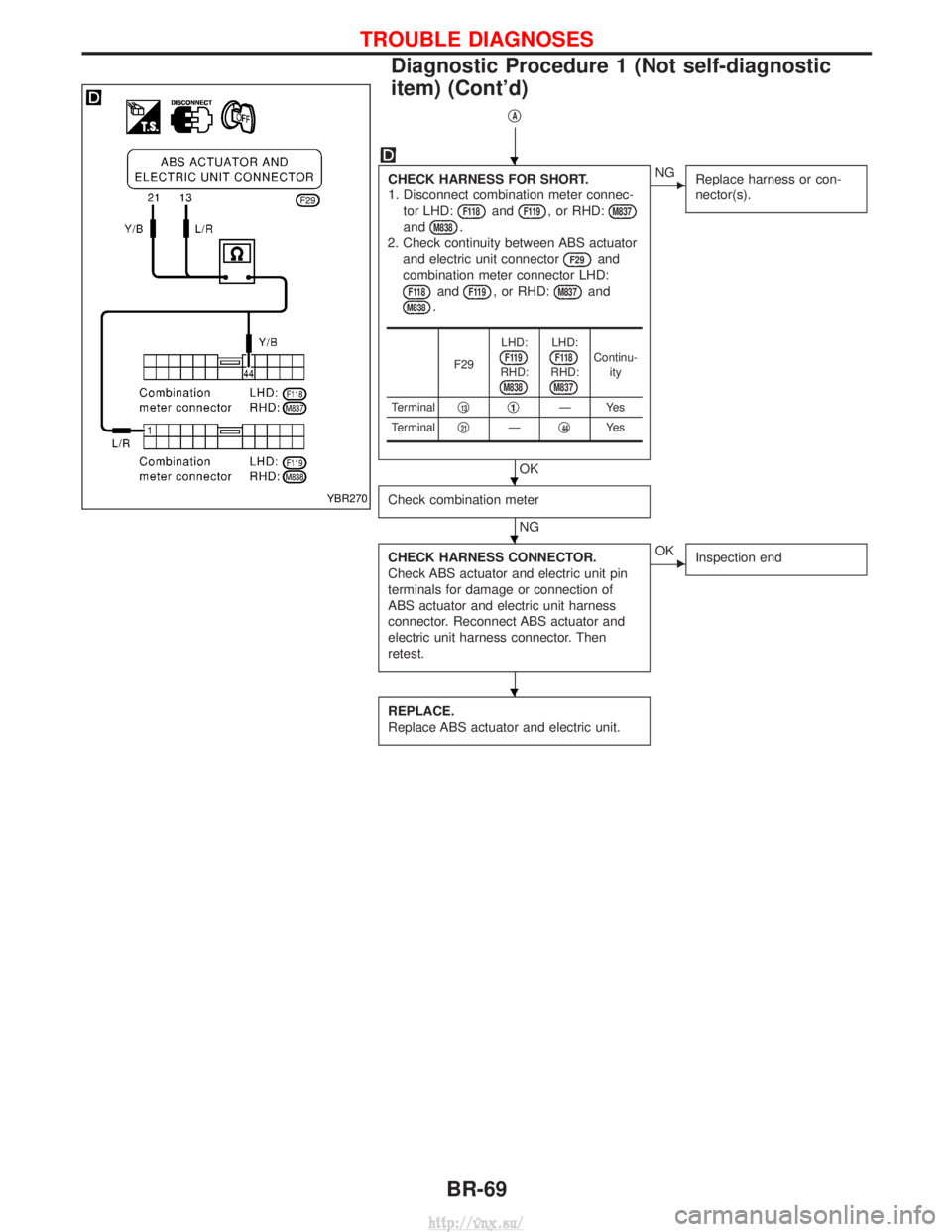

qA

CHECK HARNESS FOR SHORT.

1. Disconnect combination meter connec-tor LHD:

F118andF119, or RHD:M837

andM838.

2. Check continuity between ABS actuator and electric unit connector

F29and

combination meter connector LHD:

F118andF119, or RHD:M837and

M838.

OK

ENG Replace harness or con-

nector(s).

Check combination meter

NG

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

EOK Inspection end

REPLACE.

Replace ABS actuator and electric unit.

F29 LHD:F119RHD:M838

LHD:F118RHD:M837

Continu-

ity

Terminal q

13q1ÐYes

Terminal q

21Ðq44Ye s

YBR270

H

H

H

H

TROUBLE DIAGNOSES

Diagnostic Procedure 1 (Not self-diagnostic

item) (Cont'd)

BR-69

http://vnx.su/

Page 1628 of 1833

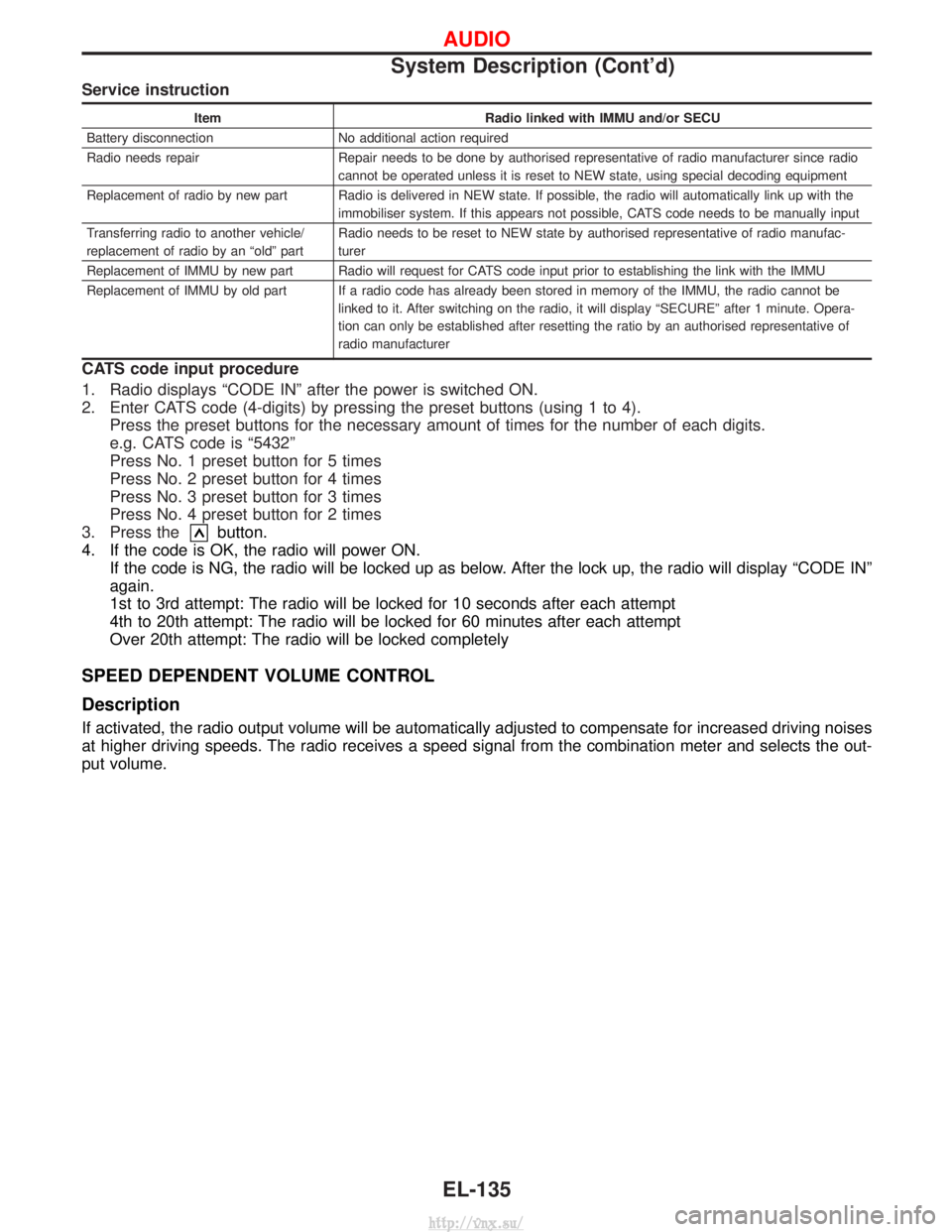

Service instruction

ItemRadio linked with IMMU and/or SECU

Battery disconnection No additional action required

Radio needs repair Repair needs to be done by authorised representative of radio manufacturer since radio cannot be operated unless it is reset to NEW state, using special decoding equipment

Replacement of radio by new part Radio is delivered in NEW state. If possible, the radio will automatically link up with the immobiliser system. If this appears not possible, CATS code needs to be manually input

Transferring radio to another vehicle/

replacement of radio by an ªoldº part Radio needs to be reset to NEW state by authorised representative of radio manufac-

turer

Replacement of IMMU by new part Radio will request for CATS code input prior to establishing the link with the IMMU

Replacement of IMMU by old part If a radio code has already been stored in memory of the IMMU, the radio cannot be linked to it. After switching on the radio, it will display ªSECUREº after 1 minute. Opera-

tion can only be established after resetting the ratio by an authorised representative of

radio manufacturer

CATS code input procedure

1. Radio displays ªCODE INº after the power is switched ON.

2. Enter CATS code (4-digits) by pressing the preset buttons (using 1 to 4).Press the preset buttons for the necessary amount of times for the number of each digits.

e.g. CATS code is ª5432º

Press No. 1 preset button for 5 times

Press No. 2 preset button for 4 times

Press No. 3 preset button for 3 times

Press No. 4 preset button for 2 times

3. Press the

button.

4. If the code is OK, the radio will power ON. If the code is NG, the radio will be locked up as below. After the lock up, the radio will display ªCODE INº

again.

1st to 3rd attempt: The radio will be locked for 10 seconds after each attempt

4th to 20th attempt: The radio will be locked for 60 minutes after each attempt

Over 20th attempt: The radio will be locked completely

SPEED DEPENDENT VOLUME CONTROL

Description

If activated, the radio output volume will be automatically adjusted to compensate for increased driving noises

at higher driving speeds. The radio receives a speed signal from the combination meter and selects the out-

put volume.

AUDIO

System Description (Cont'd)

EL-135

http://vnx.su/

Page 1831 of 1833

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ..................................EL-8, 10

Power window.......................................EL-156, 158

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (ElectronicFuel Injection Pump) ................................EC-180

Pump control module (Electronic Fuel Injection Pump).........................................EC-194

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal andinstallation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-32

Rear fog lamp .................................................EL-58

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger .................EL-125, 132, 133

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-145

Removal and installation (A/T)......................AT-121

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-156

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-52, 119

R/FOG - Wiring diagram .................................EL-58

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-31

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner ...............................RS-2, 11

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37 Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 347

Shift control (Transfer) ..............................TF-11, 24

Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-201

Shift solenoid valve A (A/T).............................AT-65

Shift solenoid valve B (A/T) ............................AT-68

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-20

Side air bag (satellite) sensor ........................RS-15

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-184

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-86

Spill valve .....................................................EC-187

Spiral cable.....................................................RS-16

SROOF - Wiring diagram .............................EL-153

SRS - See Supplemental Restraint System ..........................................................RS-8

SRS - Wiring diagram ....................................RS-34

SRS Trouble diagnoses .................................RS-28

S/SIG - Wiring diagram ................................EC-253

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 201

Standardized relay ............................................EL-6

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-253

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-27

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-52

Stop lamp switch ..................................EC-209, 426

STOP/L - Wiring diagram................................EL-52

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sunroof............................................................BT-40

Sunroof, electric ............................................EL-153

Super lock ....................EL-171, 179, 180, 182, 192

Supplemental Restraint System .......................RS-8

Swirl control valve control solenoid valve .........................................................EC-271

SWL/V - Wiring diagram ..............................EC-273

Symptom matrix chart ............................EC-56, 363

ALPHABETICAL INDEX

IDX-6

http://vnx.su/