service schedule NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 325 of 1833

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IShift lever is in neutral position,

I Heat up switch is OFF,

I Headlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to MA section.

3. Open engine hood and check the following:

IHarness connectors for improper connections

I Vacuum hoses for splits, kinks, or improper connections

I Wiring for improper connections, pinches, or cuts

SEF142I

4. Start engine and warm it up to the normal operating temperature.

EGO TO 2.

2 PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

EGO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONZD30DDTi

EC-50

http://vnx.su/

Page 636 of 1833

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

I Air conditioner switch is OFF,

I Rear defogger switch is OFF,

I Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for

scheduled maintenance.

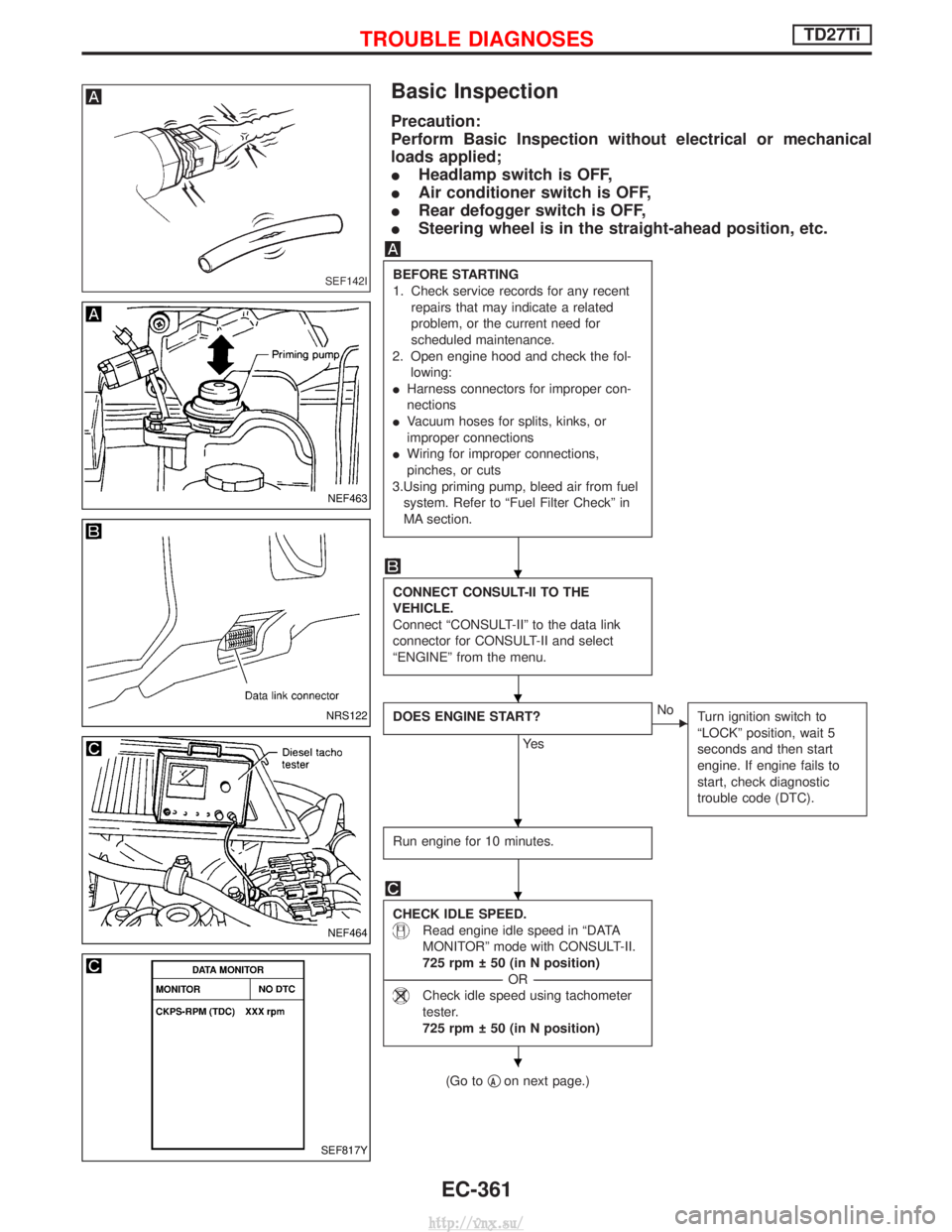

2. Open engine hood and check the fol- lowing:

I Harness connectors for improper con-

nections

I Vacuum hoses for splits, kinks, or

improper connections

I Wiring for improper connections,

pinches, or cuts

3.Using priming pump, bleed air from fuel system. Refer to ªFuel Filter Checkº in

MA section.

CONNECT CONSULT-II TO THE

VEHICLE.

Connect ªCONSULT-IIº to the data link

connector for CONSULT-II and select

ªENGINEº from the menu.

DOES ENGINE START?

Ye s

ENo Turn ignition switch to

ªLOCKº position, wait 5

seconds and then start

engine. If engine fails to

start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

Read engine idle speed in ªDATA

MONITORº mode with CONSULT-II.

725 rpm 50 (in N position)

----------------------------------------------------------------------------------------------------------------------------------- -OR------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachometer

tester.

725 rpm 50 (in N position)

(Go to qAon next page.)

SEF142I

NEF463

NRS122

NEF464

SEF817Y

H

H

H

H

H

TROUBLE DIAGNOSESTD27Ti

EC-361

http://vnx.su/

Page 833 of 1833

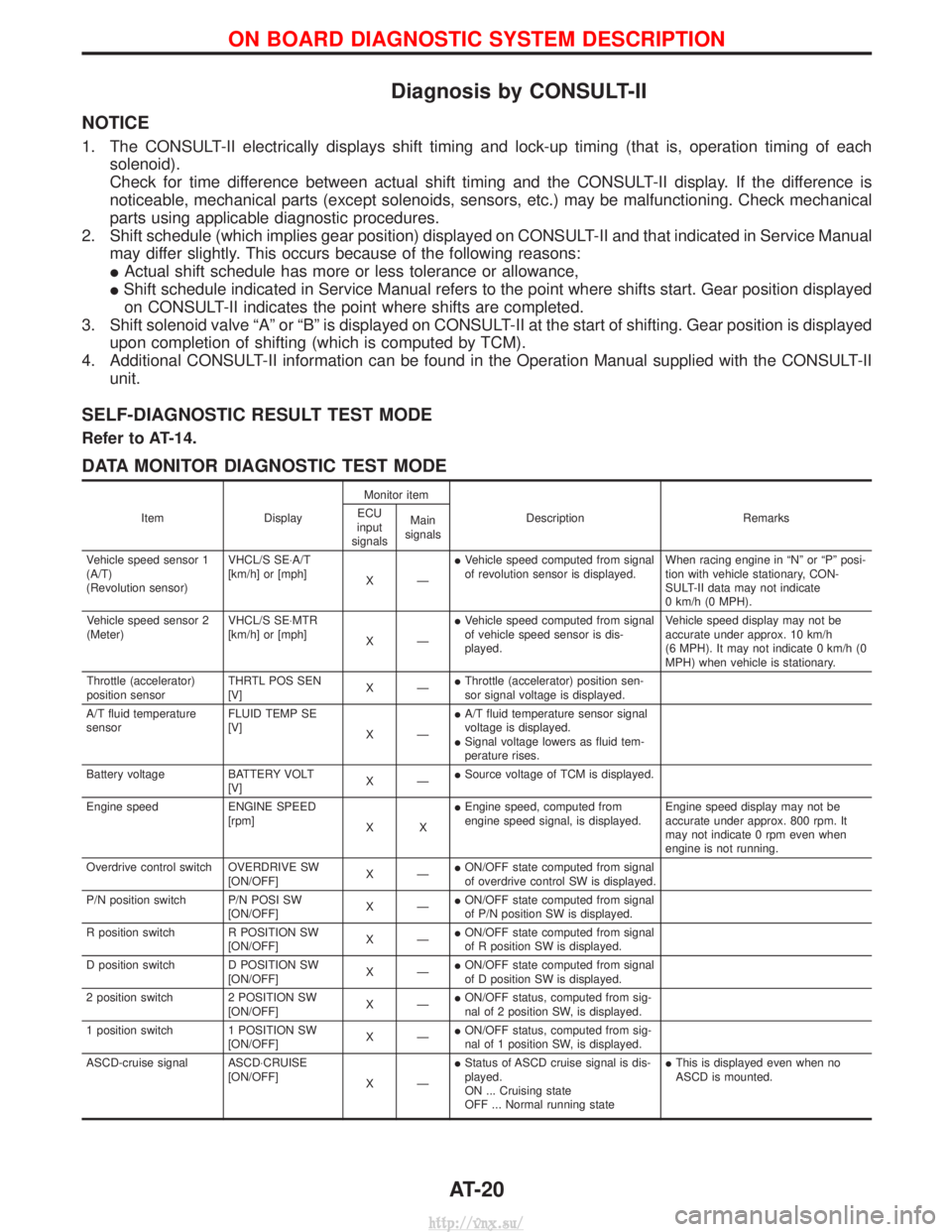

Diagnosis by CONSULT-II

NOTICE

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of eachsolenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Manual may differ slightly. This occurs because of the following reasons:

IActual shift schedule has more or less tolerance or allowance,

I Shift schedule indicated in Service Manual refers to the point where shifts start. Gear position displayed

on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is displayed upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-14.

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks

ECU

input

signals Main

signals

Vehicle speed sensor 1

(A/T)

(Revolution sensor) VHCL/S SE×A/T

[km/h] or [mph]

XÐI

Vehicle speed computed from signal

of revolution sensor is displayed. When racing engine in ªNº or ªPº posi-

tion with vehicle stationary, CON-

SULT-II data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter) VHCL/S SE×MTR

[km/h] or [mph]

XÐI

Vehicle speed computed from signal

of vehicle speed sensor is dis-

played. Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0 km/h (0

MPH) when vehicle is stationary.

Throttle (accelerator)

position sensor THRTL POS SEN

[V]

XÐI

Throttle (accelerator) position sen-

sor signal voltage is displayed.

A/T fluid temperature

sensor FLUID TEMP SE

[V]

XÐI

A/T fluid temperature sensor signal

voltage is displayed.

I Signal voltage lowers as fluid tem-

perature rises.

Battery voltage BATTERY VOLT [V]XÐI

Source voltage of TCM is displayed.

Engine speed ENGINE SPEED [rpm]XXI

Engine speed, computed from

engine speed signal, is displayed. Engine speed display may not be

accurate under approx. 800 rpm. It

may not indicate 0 rpm even when

engine is not running.

Overdrive control switch OVERDRIVE SW [ON/OFF]XÐI

ON/OFF state computed from signal

of overdrive control SW is displayed.

P/N position switch P/N POSI SW [ON/OFF]XÐI

ON/OFF state computed from signal

of P/N position SW is displayed.

R position switch R POSITION SW [ON/OFF]XÐI

ON/OFF state computed from signal

of R position SW is displayed.

D position switch D POSITION SW [ON/OFF]XÐI

ON/OFF state computed from signal

of D position SW is displayed.

2 position switch 2 POSITION SW [ON/OFF]XÐI

ON/OFF status, computed from sig-

nal of 2 position SW, is displayed.

1 position switch 1 POSITION SW [ON/OFF]XÐI

ON/OFF status, computed from sig-

nal of 1 position SW, is displayed.

ASCD-cruise signal ASCD×CRUISE [ON/OFF]XÐI

Status of ASCD cruise signal is dis-

played.

ON ... Cruising state

OFF ... Normal running state I

This is displayed even when no

ASCD is mounted.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-20

http://vnx.su/

Page 1014 of 1833

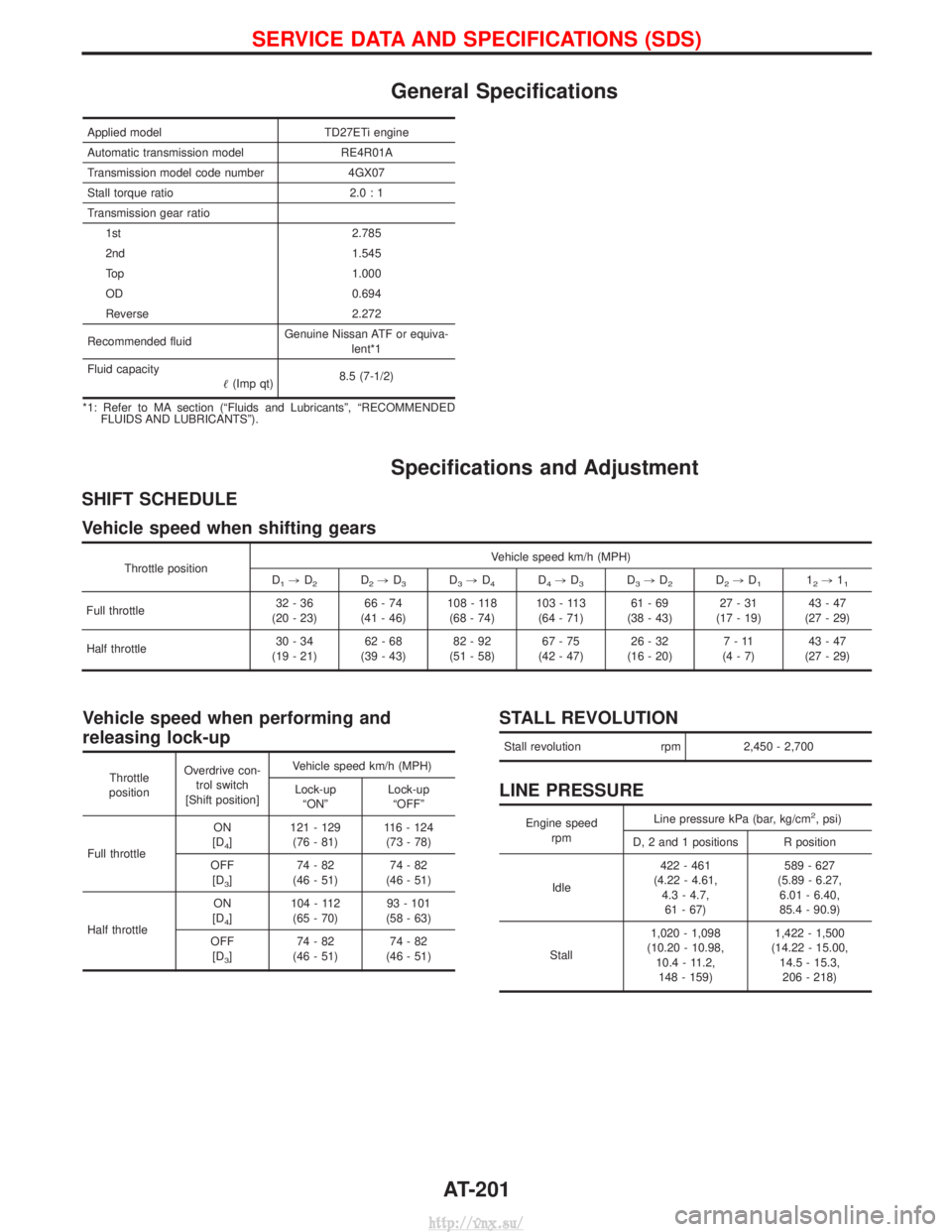

General Specifications

Applied modelTD27ETi engine

Automatic transmission model RE4R01A

Transmission model code number 4GX07

Stall torque ratio 2.0 : 1

Transmission gear ratio 1st 2.785

2nd 1.545

Top 1.000

OD 0.694

Reverse 2.272

Recommended fluid Genuine Nissan ATF or equiva-

lent*1

Fluid capacity (Imp qt) 8.5 (7-1/2)

*1: Refer to MA section (ªFluids and Lubricantsº, ªRECOMMENDED FLUIDS AND LUBRICANTSº).

Specifications and Adjustment

SHIFT SCHEDULE

Vehicle speed when shifting gears

Throttle position Vehicle speed km/h (MPH)

D1, D2D2,D3D3,D4D4,D3D3,D2D2,D112,11

Full throttle 32-36

(20 - 23) 66-74

(41 - 46) 108 - 118

(68 - 74) 103 - 113

(64 - 71) 61-69

(38 - 43) 27-31

(17 - 19) 43-47

(27 - 29)

Half throttle 30-34

(19 - 21) 62-68

(39 - 43) 82-92

(51 - 58) 67-75

(42 - 47) 26-32

(16 - 20) 7-11

(4-7) 43-47

(27 - 29)

Vehicle speed when performing and

releasing lock-up

Throttle

position Overdrive con-

trol switch

[Shift position] Vehicle speed km/h (MPH)

Lock-up ªONº Lock-up

ªOFFº

Full throttle ON

[D

4] 121 - 129

(76 - 81) 116 - 124

(73 - 78)

OFF [D

3] 74-82

(46 - 51) 74-82

(46 - 51)

Half throttle ON

[D

4] 104 - 112

(65 - 70) 93 - 101

(58 - 63)

OFF [D

3] 74-82

(46 - 51) 74-82

(46 - 51)

STALL REVOLUTION

Stall revolution rpm2,450 - 2,700

LINE PRESSURE

Engine speed

rpm Line pressure kPa (bar, kg/cm2, psi)

D, 2 and 1 positions R position

Idle 422 - 461

(4.22 - 4.61, 4.3 - 4.7,61 - 67) 589 - 627

(5.89 - 6.27, 6.01 - 6.40,

85.4 - 90.9)

Stall 1,020 - 1,098

(10.20 - 10.98, 10.4 - 11.2,148 - 159) 1,422 - 1,500

(14.22 - 15.00, 14.5 - 15.3,206 - 218)

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-201

http://vnx.su/

Page 1831 of 1833

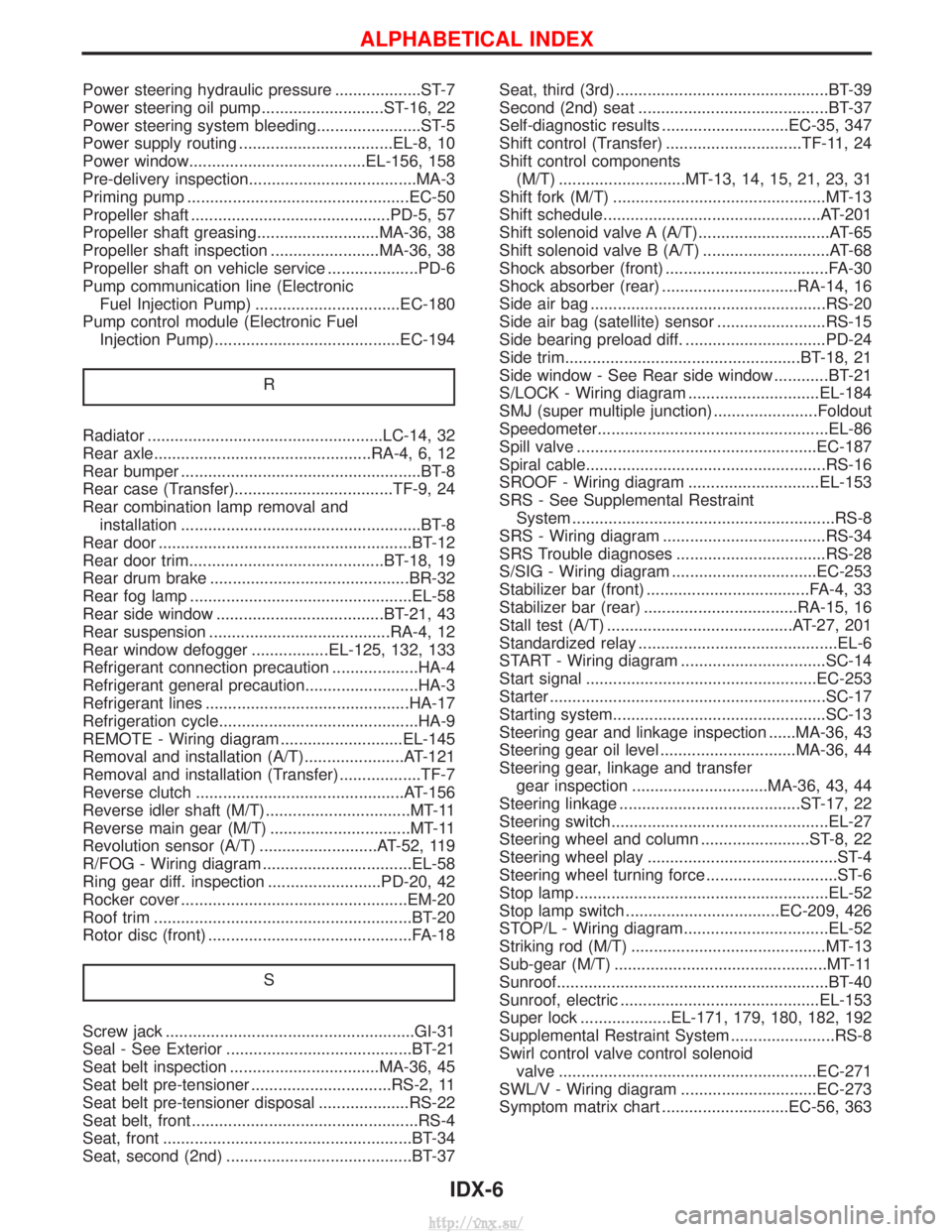

Power steering hydraulic pressure ...................ST-7

Power steering oil pump ...........................ST-16, 22

Power steering system bleeding.......................ST-5

Power supply routing ..................................EL-8, 10

Power window.......................................EL-156, 158

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (ElectronicFuel Injection Pump) ................................EC-180

Pump control module (Electronic Fuel Injection Pump).........................................EC-194

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal andinstallation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-32

Rear fog lamp .................................................EL-58

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger .................EL-125, 132, 133

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-145

Removal and installation (A/T)......................AT-121

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-156

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-52, 119

R/FOG - Wiring diagram .................................EL-58

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-31

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner ...............................RS-2, 11

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37 Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 347

Shift control (Transfer) ..............................TF-11, 24

Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-201

Shift solenoid valve A (A/T).............................AT-65

Shift solenoid valve B (A/T) ............................AT-68

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-20

Side air bag (satellite) sensor ........................RS-15

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-184

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-86

Spill valve .....................................................EC-187

Spiral cable.....................................................RS-16

SROOF - Wiring diagram .............................EL-153

SRS - See Supplemental Restraint System ..........................................................RS-8

SRS - Wiring diagram ....................................RS-34

SRS Trouble diagnoses .................................RS-28

S/SIG - Wiring diagram ................................EC-253

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 201

Standardized relay ............................................EL-6

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-253

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-27

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-52

Stop lamp switch ..................................EC-209, 426

STOP/L - Wiring diagram................................EL-52

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sunroof............................................................BT-40

Sunroof, electric ............................................EL-153

Super lock ....................EL-171, 179, 180, 182, 192

Supplemental Restraint System .......................RS-8

Swirl control valve control solenoid valve .........................................................EC-271

SWL/V - Wiring diagram ..............................EC-273

Symptom matrix chart ............................EC-56, 363

ALPHABETICAL INDEX

IDX-6

http://vnx.su/