Valve clearance NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 42 of 1833

MAINTENANCE

SECTION

MA

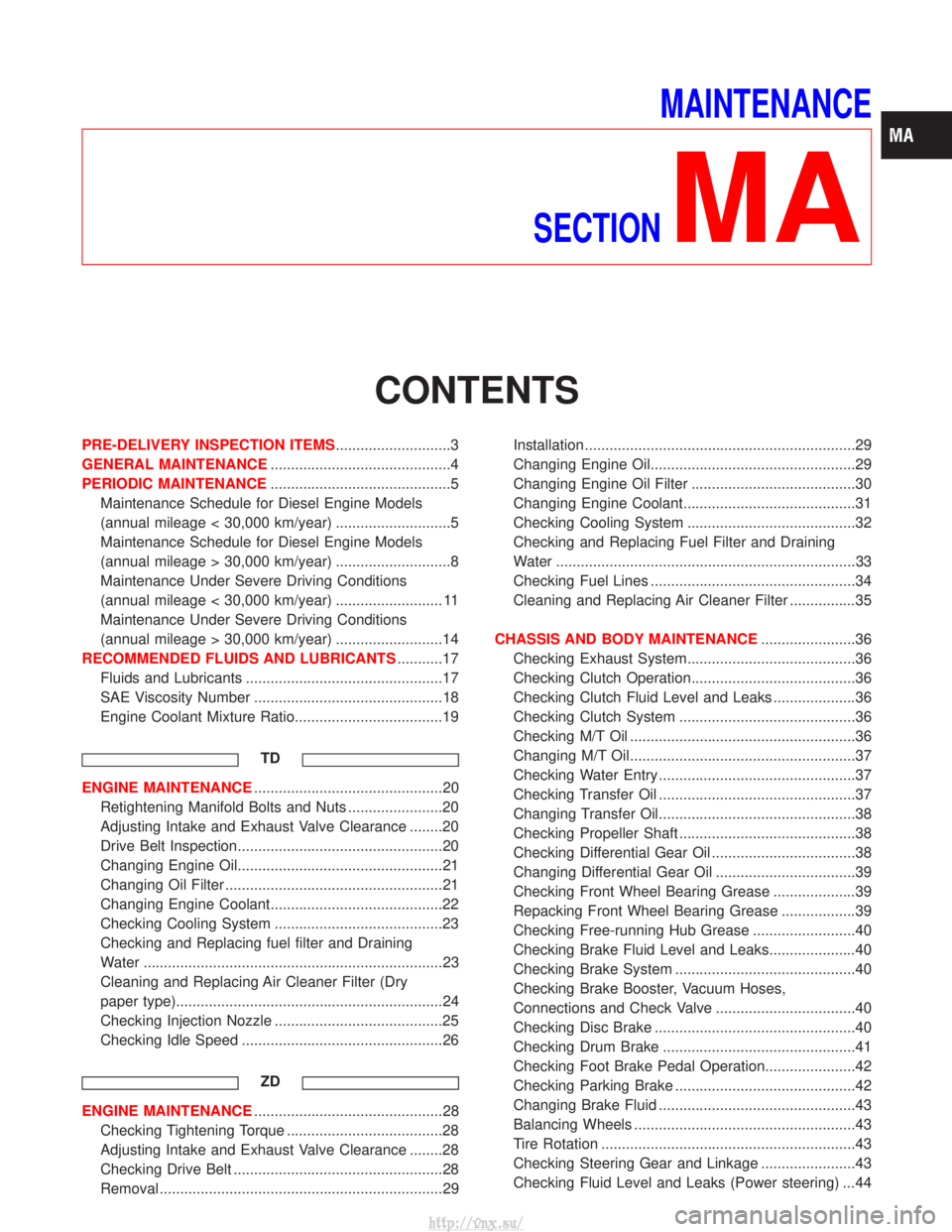

CONTENTS

PRE-DELIVERY INSPECTION ITEMS ............................3

GENERAL MAINTENANCE ............................................4

PERIODIC MAINTENANCE ............................................5

Maintenance Schedule for Diesel Engine Models

(annual mileage < 30,000 km/year) ............................5

Maintenance Schedule for Diesel Engine Models

(annual mileage > 30,000 km/year) ............................8

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) .......................... 11

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) ..........................14

RECOMMENDED FLUIDS AND LUBRICANTS ...........17

Fluids and Lubricants ................................................17

SAE Viscosity Number ..............................................18

Engine Coolant Mixture Ratio....................................19

TD

ENGINE MAINTENANCE ..............................................20

Retightening Manifold Bolts and Nuts .......................20

Adjusting Intake and Exhaust Valve Clearance ........20

Drive Belt Inspection..................................................20

Changing Engine Oil..................................................21

Changing Oil Filter .....................................................21

Changing Engine Coolant..........................................22

Checking Cooling System .........................................23

Checking and Replacing fuel filter and Draining

Water ........................................................................\

.23

Cleaning and Replacing Air Cleaner Filter (Dry

paper type).................................................................24

Checking Injection Nozzle .........................................25

Checking Idle Speed .................................................26

ZD

ENGINE MAINTENANCE ..............................................28

Checking Tightening Torque ......................................28

Adjusting Intake and Exhaust Valve Clearance ........28

Checking Drive Belt ...................................................28

Removal .....................................................................29 Installation ..................................................................29

Changing Engine Oil..................................................29

Changing Engine Oil Filter ........................................30

Changing Engine Coolant..........................................31

Checking Cooling System .........................................32

Checking and Replacing Fuel Filter and Draining

Water ........................................................................\

.33

Checking Fuel Lines ..................................................34

Cleaning and Replacing Air Cleaner Filter ................35

CHASSIS AND BODY MAINTENANCE .......................36

Checking Exhaust System.........................................36

Checking Clutch Operation........................................36

Checking Clutch Fluid Level and Leaks ....................36

Checking Clutch System ...........................................36

Checking M/T Oil .......................................................36

Changing M/T Oil.......................................................37

Checking Water Entry ................................................37

Checking Transfer Oil ................................................37

Changing Transfer Oil................................................38

Checking Propeller Shaft ...........................................38

Checking Differential Gear Oil ...................................38

Changing Differential Gear Oil ..................................39

Checking Front Wheel Bearing Grease ....................39

Repacking Front Wheel Bearing Grease ..................39

Checking Free-running Hub Grease .........................40

Checking Brake Fluid Level and Leaks.....................40

Checking Brake System ............................................40

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................40

Checking Disc Brake .................................................40

Checking Drum Brake ...............................................41

Checking Foot Brake Pedal Operation......................42

Checking Parking Brake ............................................42

Changing Brake Fluid ................................................43

Balancing Wheels ......................................................43

Tire Rotation ..............................................................43

Checking Steering Gear and Linkage .......................43

Checking Fluid Level and Leaks (Power steering) ...44

http://vnx.su/

Page 46 of 1833

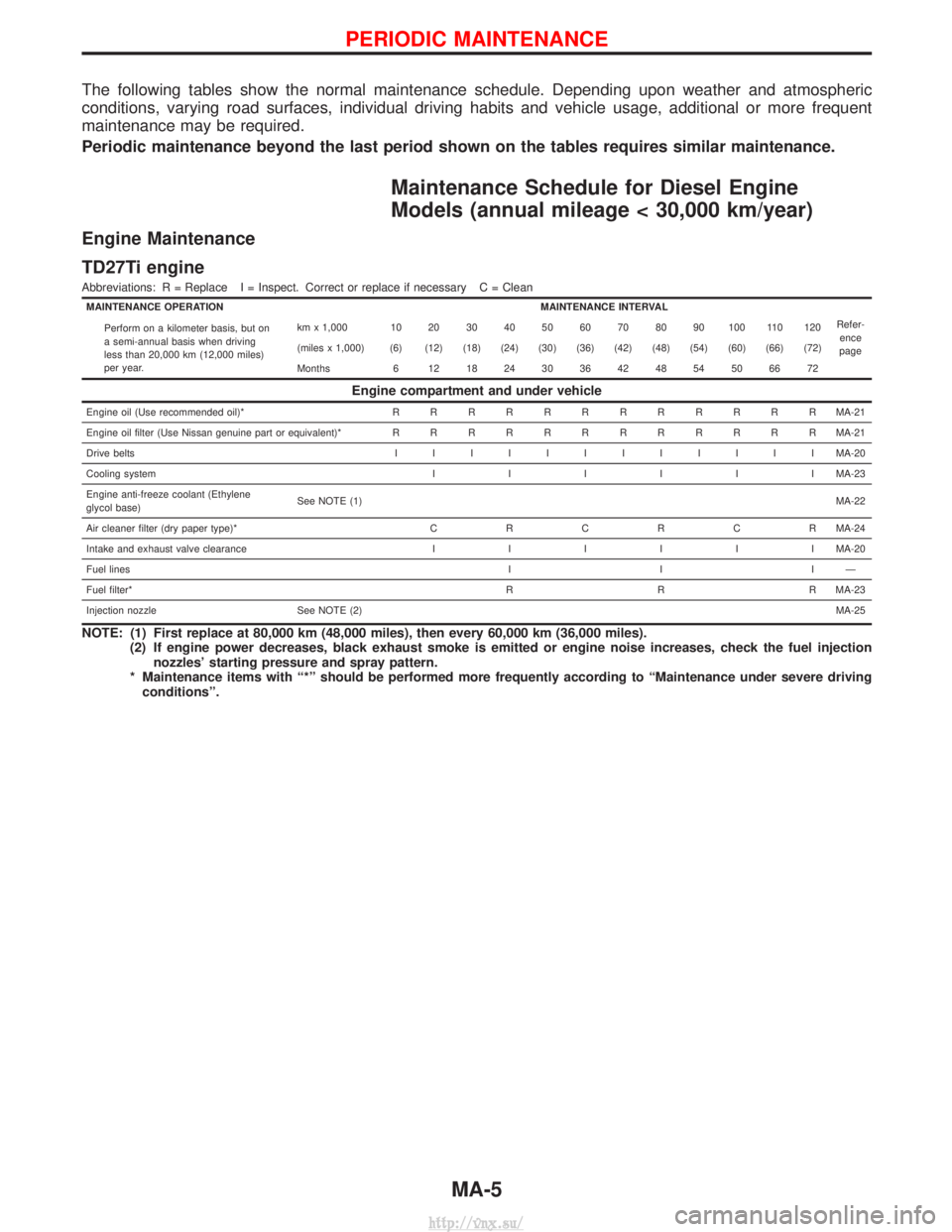

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric

conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent

maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-ence

page

Perform on a kilometer basis, but on

a semi-annual basis when driving

less than 20,000 km (12,000 miles)

per year. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Months 6 12 18 24 30 36 42 48 54 50 66 72

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

RRRRRRRRRRRR MA-21

Engine oil filter (Use Nissan genuine part or equivalent)* RRRRRRRRRRRR MA-21

Drive belts IIIIIIIIIIII MA-20

Cooling system IIIIII MA-23

Engine anti-freeze coolant (Ethylene

glycol base) See NOTE (1)

MA-22

Air cleaner filter (dry paper type)* CRCRCR MA-24

Intake and exhaust valve clearance IIIIII MA-20

Fuel lines IIIÐ

Fuel filter* R R R MA-23

Injection nozzle See NOTE (2) MA-25

NOTE: (1) First replace at 80,000 km (48,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injectionnozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

PERIODIC MAINTENANCE

MA-5

http://vnx.su/

Page 47 of 1833

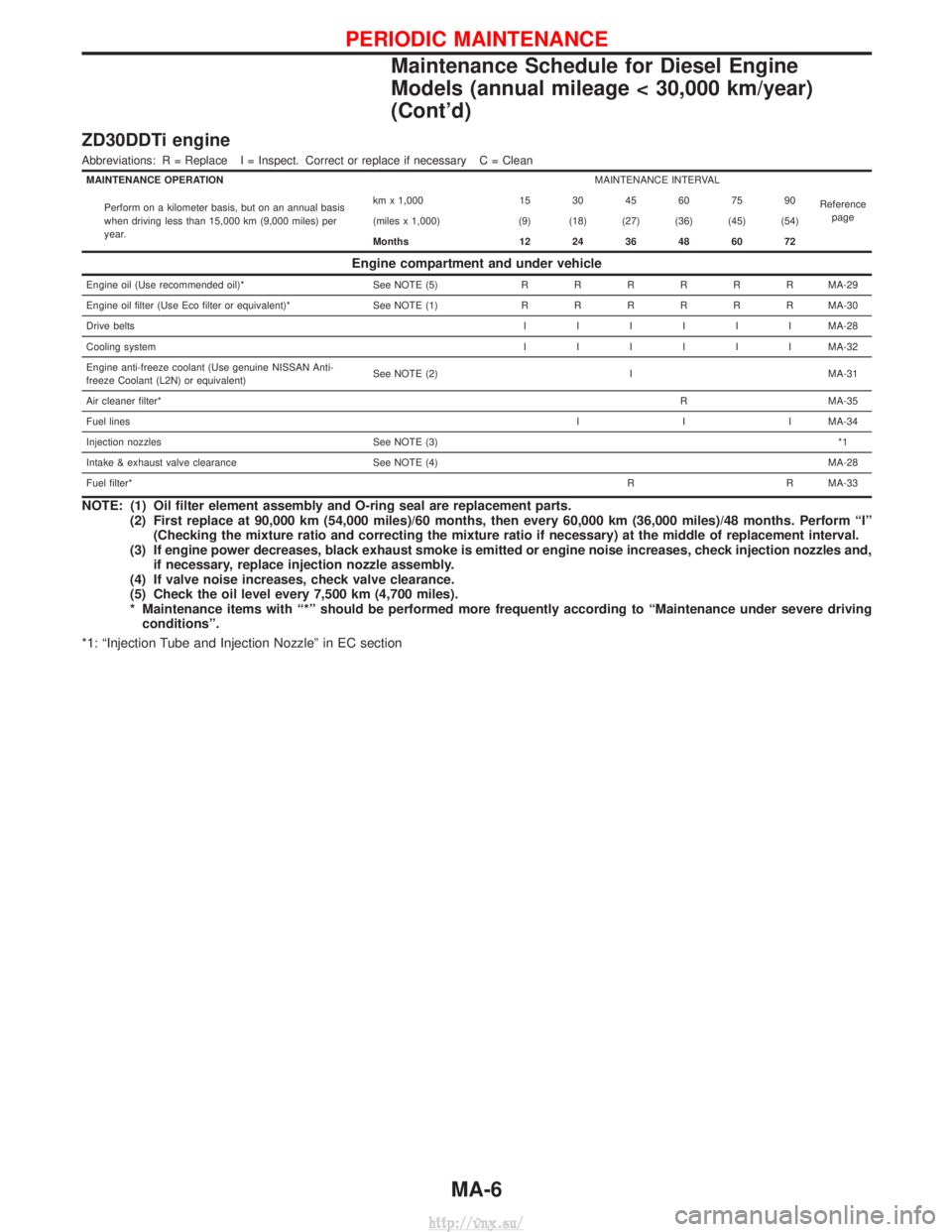

ZD30DDTi engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Referencepage

Perform on a kilometer basis, but on an annual basis

when driving less than 15,000 km (9,000 miles) per

year. km x 1,000 15 30 45 60 75 90

(miles x 1,000) (9) (18) (27) (36) (45) (54)

Months 12 24 36 48 60 72

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

See NOTE (5)RRRRRR MA-29

Engine oil filter (Use Eco filter or equivalent)* See NOTE (1)RRRRRR MA-30

Drive belts IIIIIIMA-28

Cooling system IIIIIIMA-32

Engine anti-freeze coolant (Use genuine NISSAN Anti-

freeze Coolant (L2N) or equivalent) See NOTE (2)

IMA-31

Air cleaner filter* RMA-35

Fuel lines III MA-34

Injection nozzles See NOTE (3) *1

Intake & exhaust valve clearance See NOTE (4) MA-28

Fuel filter* RR MA-33

NOTE: (1) Oil filter element assembly and O-ring seal are replacement parts.

(2) First replace at 90,000 km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform ªIº(Checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(3) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check injection nozzles and, if necessary, replace injection nozzle assembly.

(4) If valve noise increases, check valve clearance.

(5) Check the oil level every 7,500 km (4,700 miles).

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

*1: ªInjection Tube and Injection Nozzleº in EC section

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

(Cont'd)

MA-6

http://vnx.su/

Page 49 of 1833

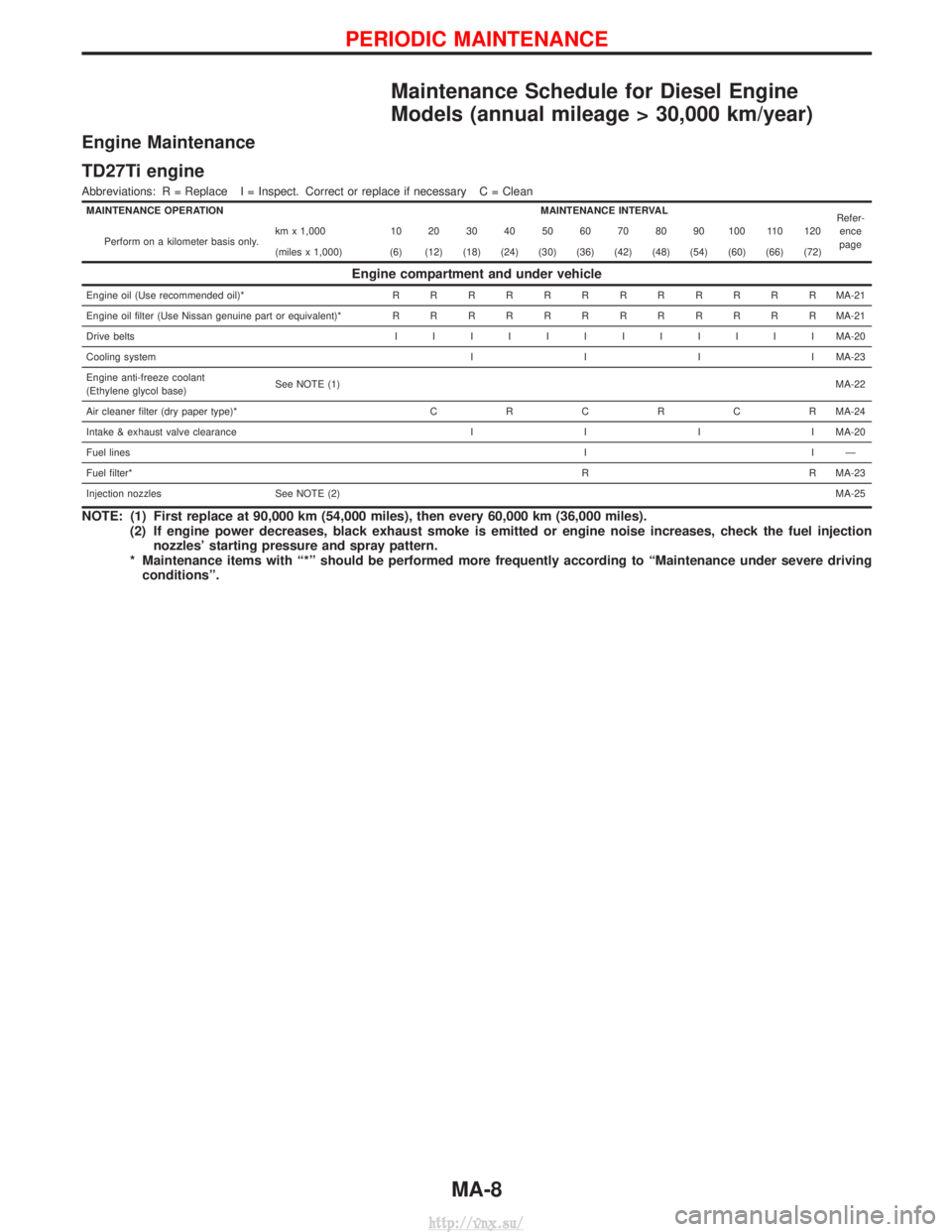

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page

Perform on a kilometer basis only. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

RRRRRRRRRRRR MA-21

Engine oil filter (Use Nissan genuine part or equivalent)* RRRRRRRRRRRR MA-21

Drive belts IIIIIIIIIIII MA-20

Cooling system IIIIMA-23

Engine anti-freeze coolant

(Ethylene glycol base) See NOTE (1)

MA-22

Air cleaner filter (dry paper type)* CRCRCR MA-24

Intake & exhaust valve clearance IIIIMA-20

Fuel lines IIÐ

Fuel filter* R R MA-23

Injection nozzles See NOTE (2) MA-25

NOTE: (1) First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injectionnozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

PERIODIC MAINTENANCE

MA-8

http://vnx.su/

Page 50 of 1833

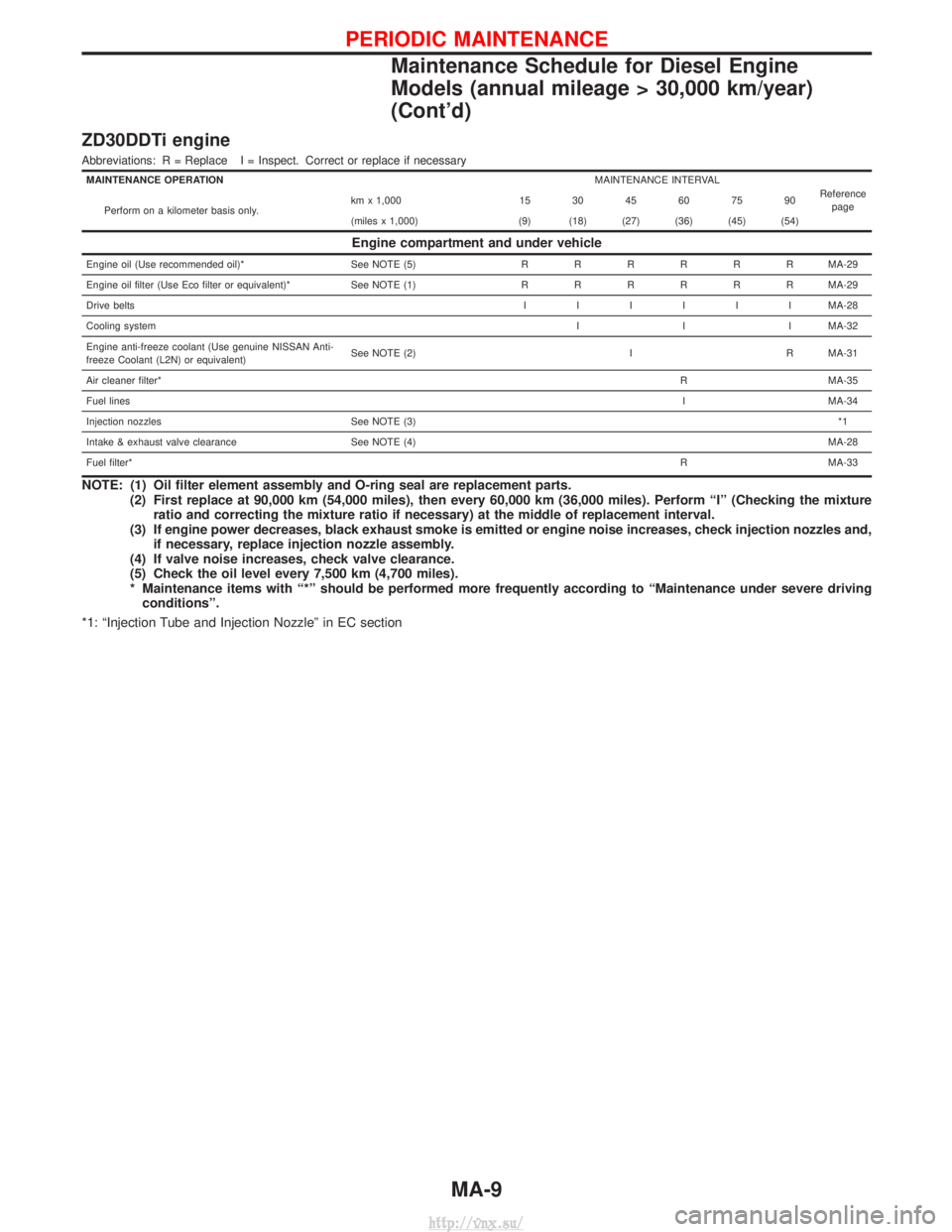

ZD30DDTi engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Referencepage

Perform on a kilometer basis only. km x 1,000 15 30 45 60 75 90

(miles x 1,000) (9) (18) (27) (36) (45) (54)

Engine compartment and under vehicle

Engine oil (Use recommended oil)*

See NOTE (5)RRRRRR MA-29

Engine oil filter (Use Eco filter or equivalent)* See NOTE (1) RRRRRRMA-29

Drive belts IIIIIIMA-28

Cooling system I I I MA-32

Engine anti-freeze coolant (Use genuine NISSAN Anti-

freeze Coolant (L2N) or equivalent) See NOTE (2) I R MA-31

Air cleaner filter* R MA-35

Fuel lines I MA-34

Injection nozzles See NOTE (3) *1

Intake & exhaust valve clearance See NOTE (4) MA-28

Fuel filter* R MA-33

NOTE: (1) Oil filter element assembly and O-ring seal are replacement parts.

(2) First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles). Perform ªIº (Checking the mixtureratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(3) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check injection nozzles and, if necessary, replace injection nozzle assembly.

(4) If valve noise increases, check valve clearance.

(5) Check the oil level every 7,500 km (4,700 miles).

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving conditionsº.

*1: ªInjection Tube and Injection Nozzleº in EC section

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

(Cont'd)

MA-9

http://vnx.su/

Page 61 of 1833

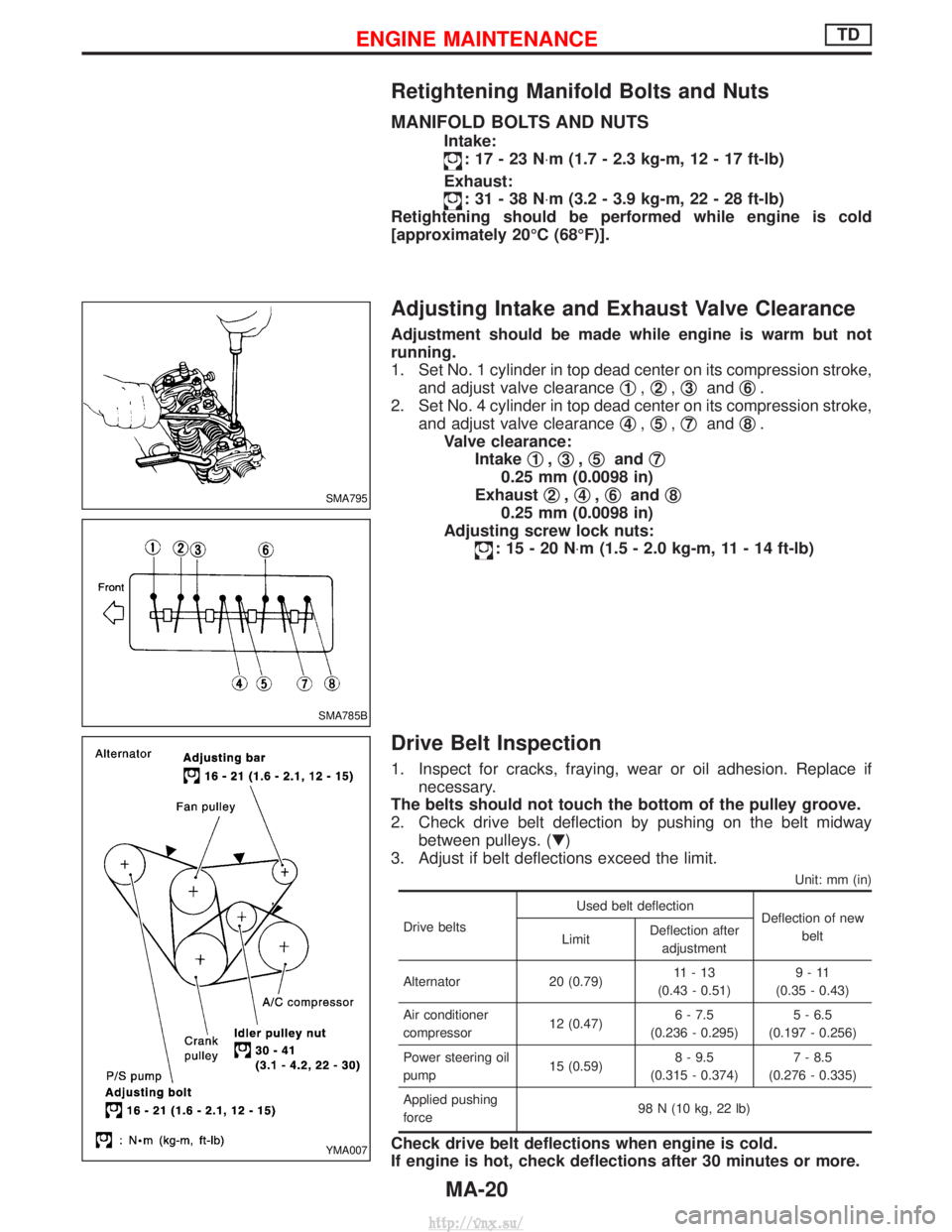

Retightening Manifold Bolts and Nuts

MANIFOLD BOLTS AND NUTS

Intake:

:17-23N×m (1.7 - 2.3 kg-m, 12 - 17 ft-lb)

Exhaust:

:31-38N ×m (3.2 - 3.9 kg-m, 22 - 28 ft-lb)

Retightening should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Adjusting Intake and Exhaust Valve Clearance

Adjustment should be made while engine is warm but not

running.

1. Set No. 1 cylinder in top dead center on its compression stroke, and adjust valve clearance q

1,q2,q3and q6.

2. Set No. 4 cylinder in top dead center on its compression stroke, and adjust valve clearance q

4,q5,q7and q8.

Valve clearance: Intake q

1,q3,q5and q7

0.25 mm (0.0098 in)

Exhaust q

2,q4,q6and q8

0.25 mm (0.0098 in)

Adjusting screw lock nuts:

:15-20N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

Drive Belt Inspection

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if

necessary.

The belts should not touch the bottom of the pulley groove.

2. Check drive belt deflection by pushing on the belt midway between pulleys. (H)

3. Adjust if belt deflections exceed the limit.

Unit: mm (in)

Drive belts Used belt deflection

Deflection of new

belt

Limit Deflection after

adjustment

Alternator 20 (0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner

compressor 12 (0.47)6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering oil

pump 15 (0.59)8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Check drive belt deflections when engine is cold.

If engine is hot, check deflections after 30 minutes or more.

SMA795

SMA785B

YMA007

ENGINE MAINTENANCETD

MA-20

http://vnx.su/

Page 67 of 1833

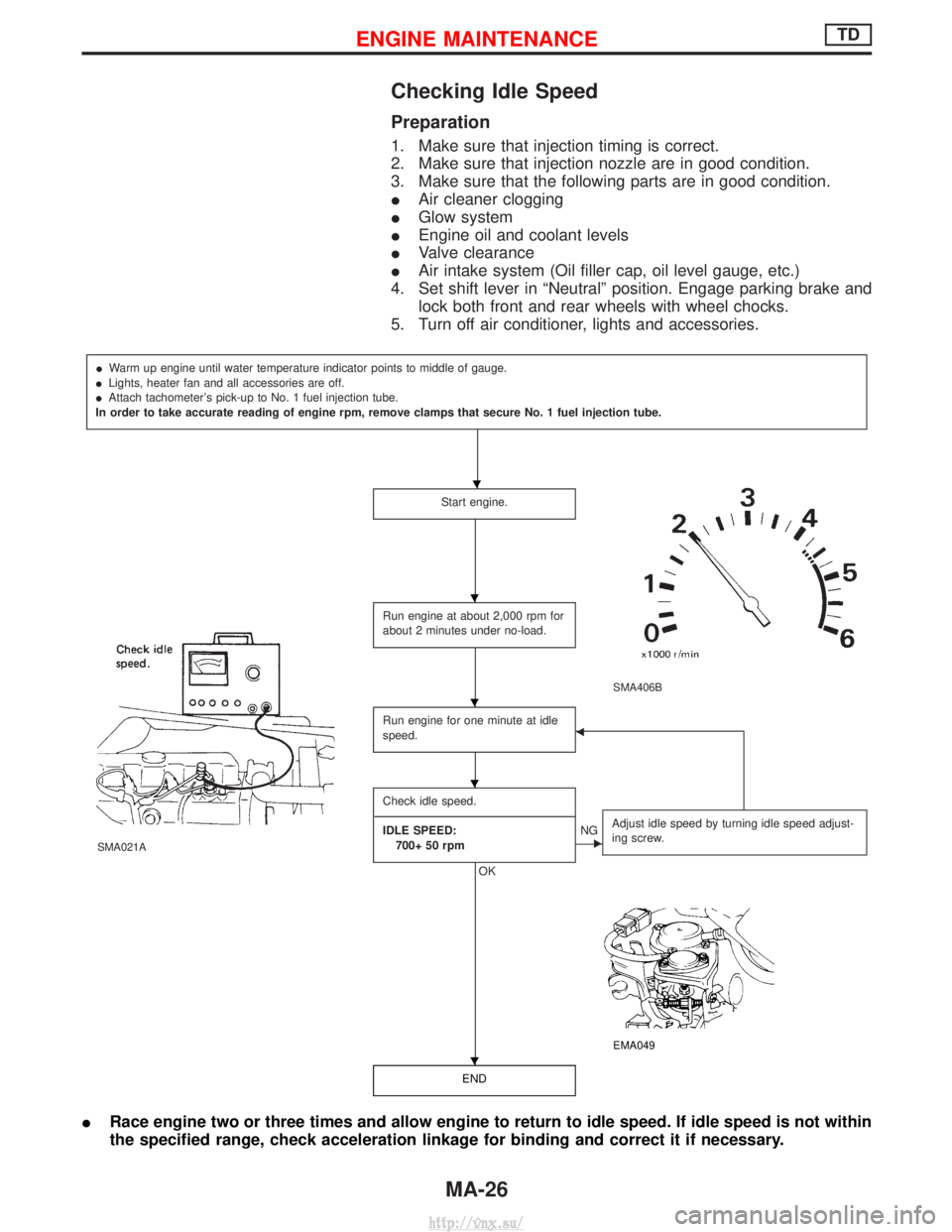

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

I Glow system

I Engine oil and coolant levels

I Valve clearance

I Air intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

I Warm up engine until water temperature indicator points to middle of gauge.

I Lights, heater fan and all accessories are off.

I Attach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- IDLE SPEED: 700+ 50 rpm

OK

ENG Adjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

I

Race engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

http://vnx.su/

Page 69 of 1833

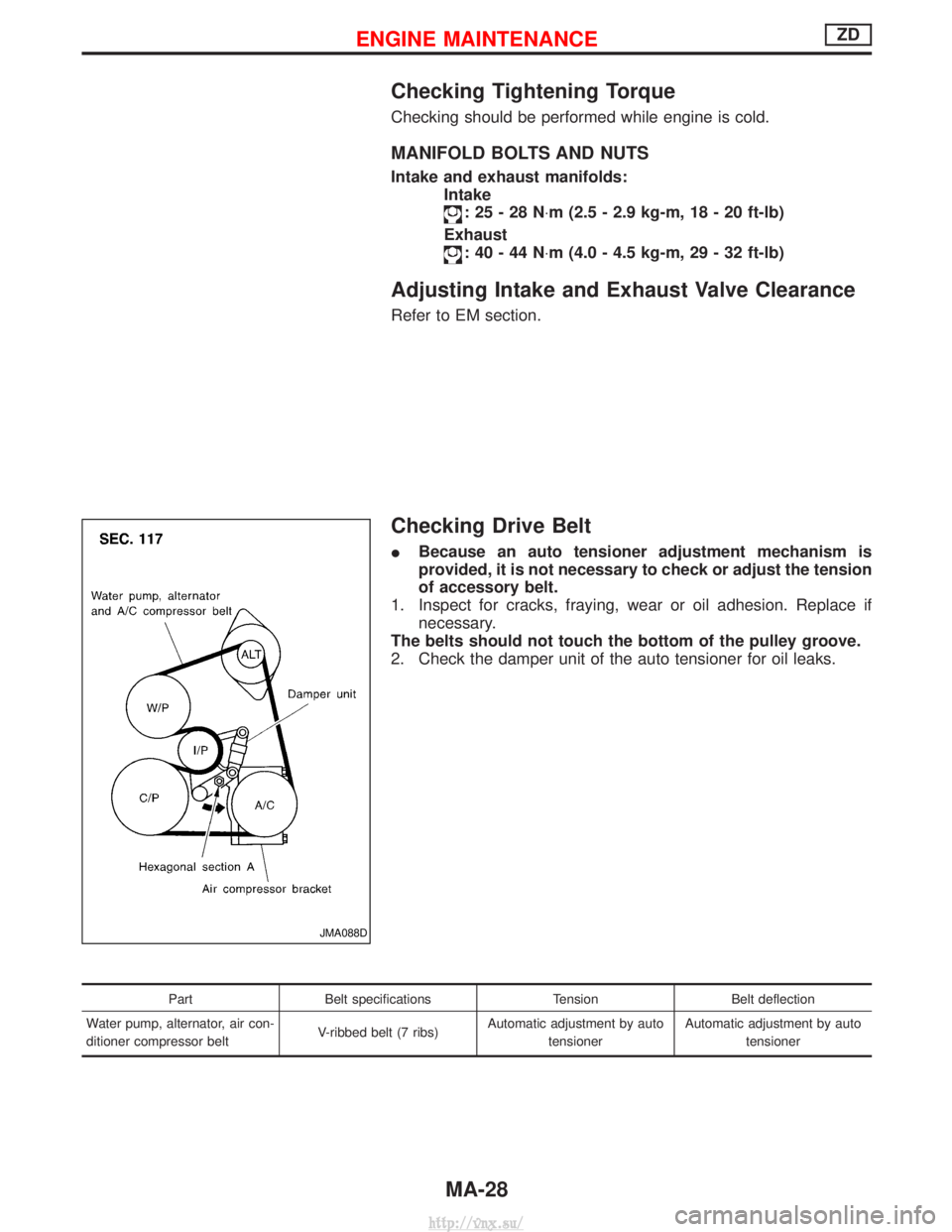

Checking Tightening Torque

Checking should be performed while engine is cold.

MANIFOLD BOLTS AND NUTS

Intake and exhaust manifolds:Intake

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

Exhaust

:40-44N ×m (4.0 - 4.5 kg-m, 29 - 32 ft-lb)

Adjusting Intake and Exhaust Valve Clearance

Refer to EM section.

Checking Drive Belt

IBecause an auto tensioner adjustment mechanism is

provided, it is not necessary to check or adjust the tension

of accessory belt.

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if necessary.

The belts should not touch the bottom of the pulley groove.

2. Check the damper unit of the auto tensioner for oil leaks.

Part Belt specifications TensionBelt deflection

Water pump, alternator, air con-

ditioner compressor belt V-ribbed belt (7 ribs)Automatic adjustment by auto

tensioner Automatic adjustment by auto

tensioner

JMA088D

ENGINE MAINTENANCEZD

MA-28

http://vnx.su/

Page 89 of 1833

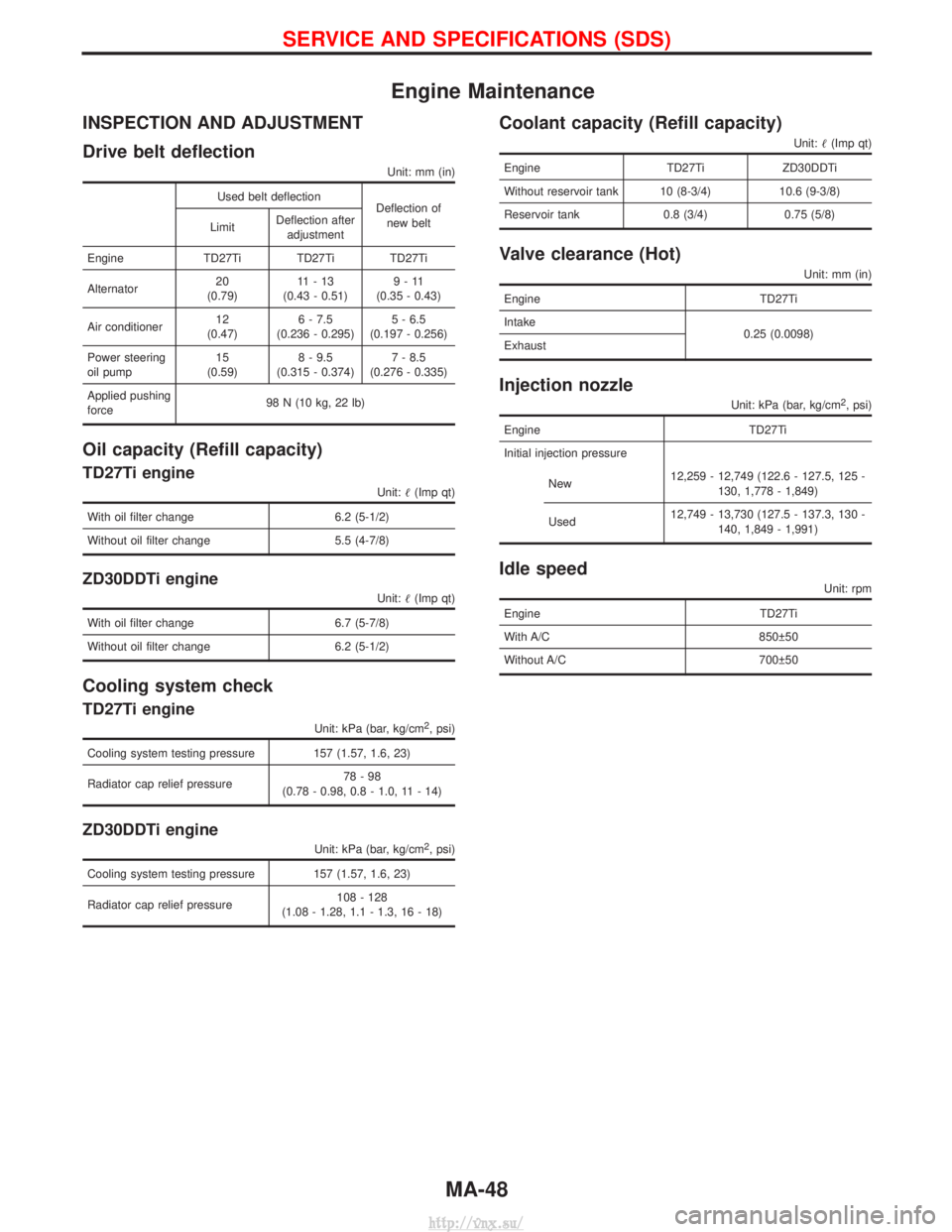

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 92 of 1833

ENGINE MECHANICAL

SECTION

EM

CONTENTS

ZD

PRECAUTIONS ...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION ................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE ....10

INTERCOOLER ............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD ......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER ............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD ..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER ..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER ...........................................22

Removal and Installation ...........................................22

VACUUM PUMP ............................................................24

Removal and Installation ...........................................24

TIMING CHAIN ..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT ...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33 VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS

.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR ...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT ..........................................50

CYLINDER HEAD ..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL .......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK .......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS) ..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ........................................................................\

..84

Valve Seat..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

http://vnx.su/