brake rotor NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 53 of 1833

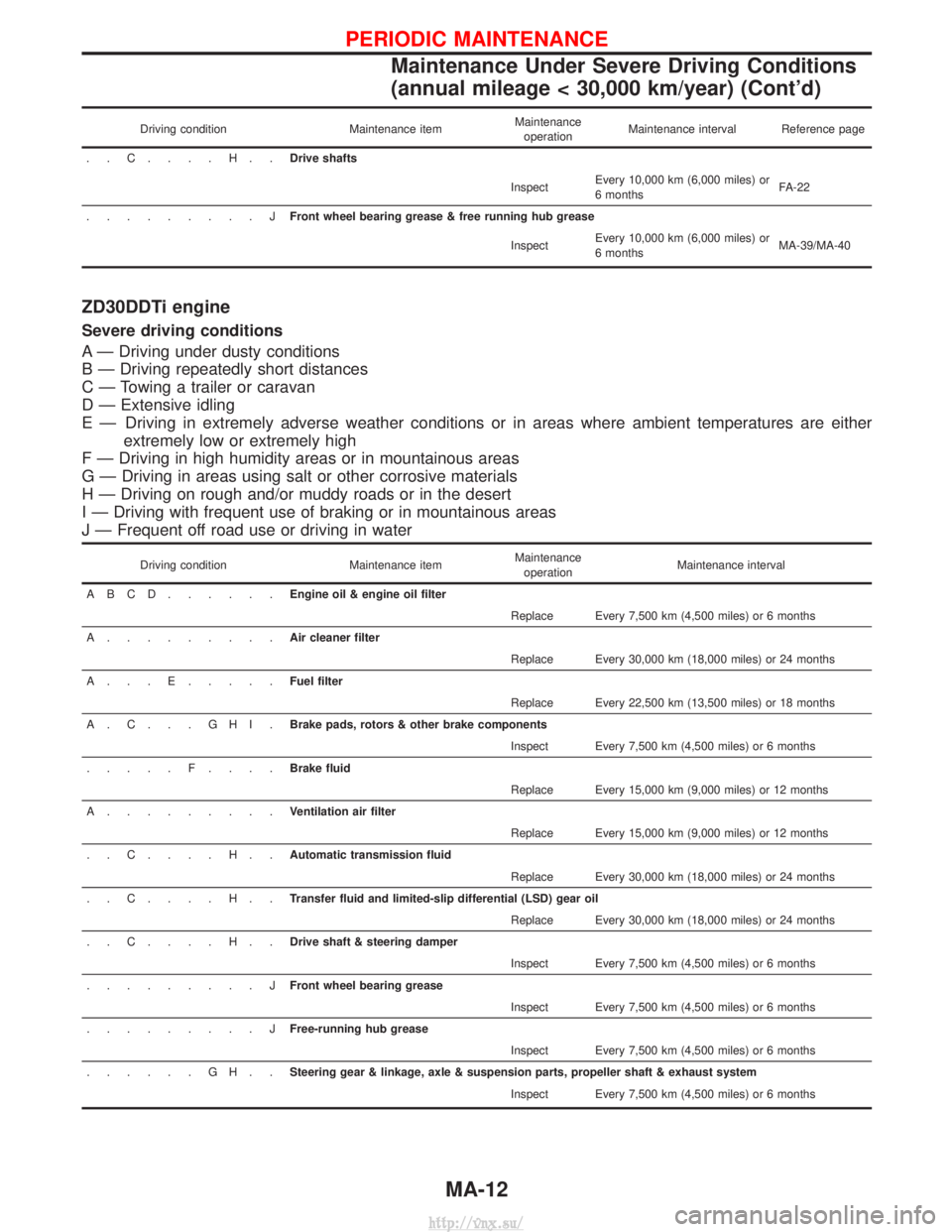

Driving conditionMaintenance itemMaintenance

operation Maintenance interval Reference page

..C....H..Drive shafts InspectEvery 10,000 km (6,000 miles) or

6 months FA-22

.........J Front wheel bearing grease & free running hub grease

InspectEvery 10,000 km (6,000 miles) or

6 months MA-39/MA-40

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shaft & steering damper Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Front wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Free-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) (Cont'd)

MA-12

http://vnx.su/

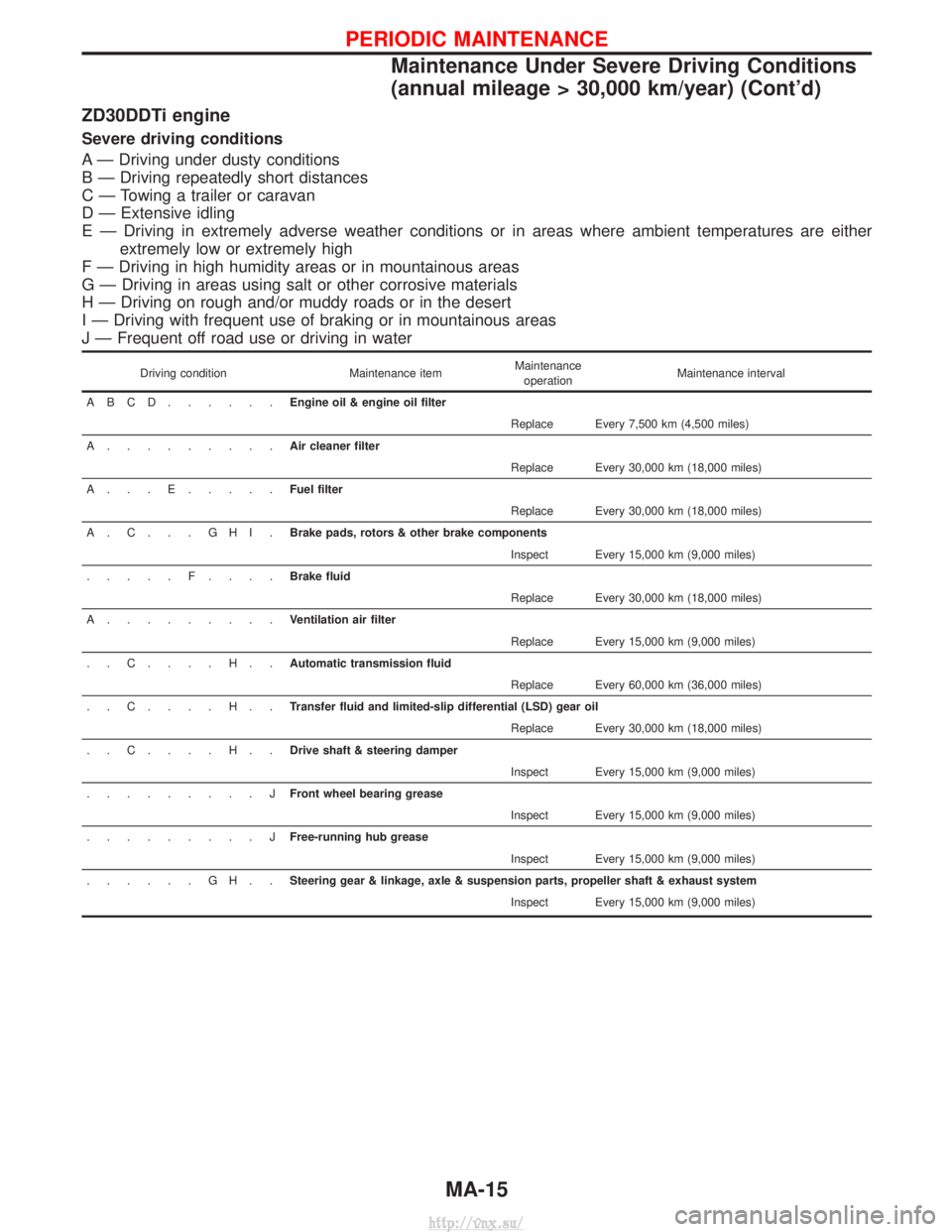

Page 56 of 1833

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles)

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles)

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 15,000 km (9,000 miles)

.....F....Brake fluid Replace Every 30,000 km (18,000 miles)

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles)

..C....H..Automatic transmission fluid Replace Every 60,000 km (36,000 miles)

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles)

..C....H..Drive shaft & steering damper Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) (Cont'd)

MA-15

http://vnx.su/

Page 81 of 1833

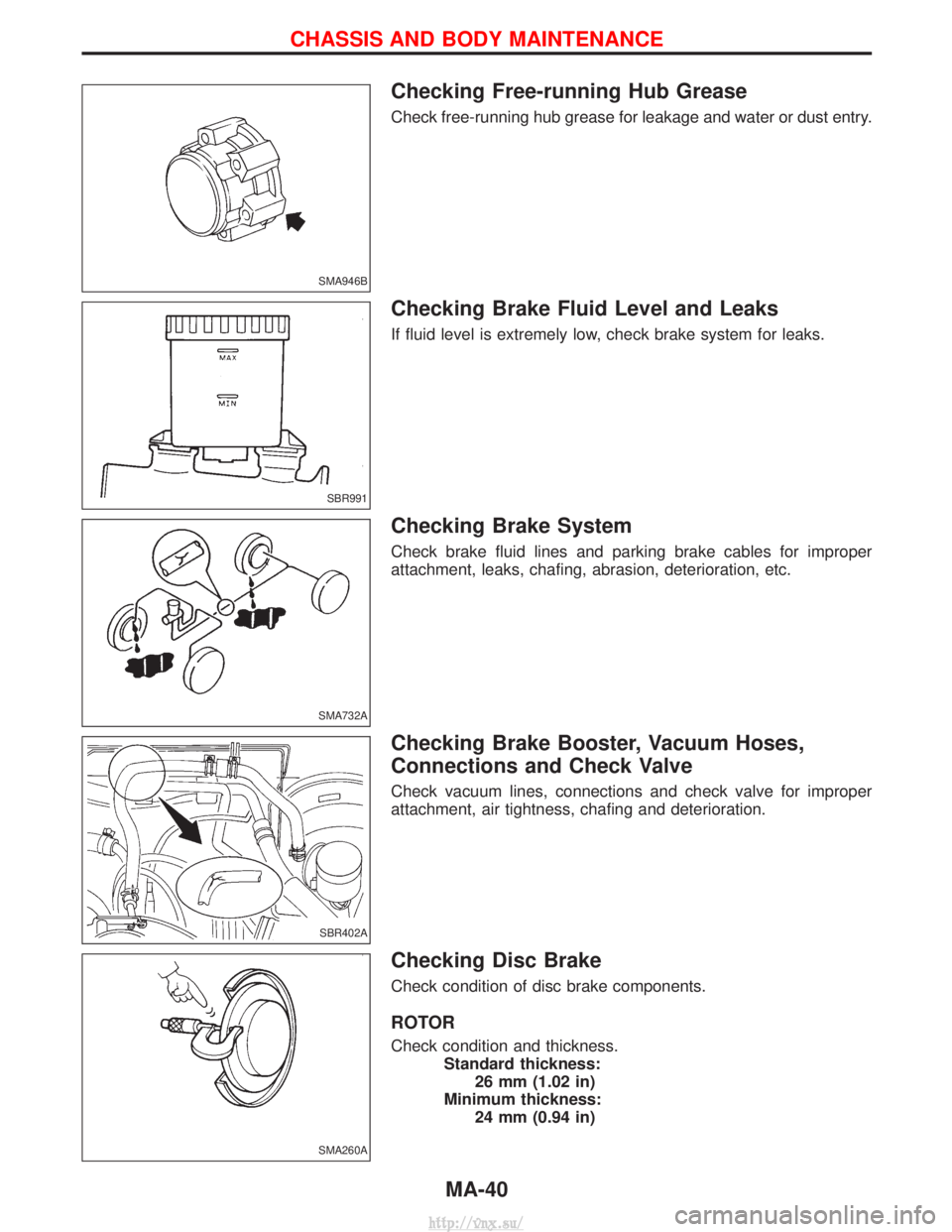

Checking Free-running Hub Grease

Check free-running hub grease for leakage and water or dust entry.

Checking Brake Fluid Level and Leaks

If fluid level is extremely low, check brake system for leaks.

Checking Brake System

Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasion, deterioration, etc.

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, chafing and deterioration.

Checking Disc Brake

Check condition of disc brake components.

ROTOR

Check condition and thickness.Standard thickness:26 mm (1.02 in)

Minimum thickness: 24 mm (0.94 in)

SMA946B

SBR991

SMA732A

SBR402A

SMA260A

CHASSIS AND BODY MAINTENANCE

MA-40

http://vnx.su/

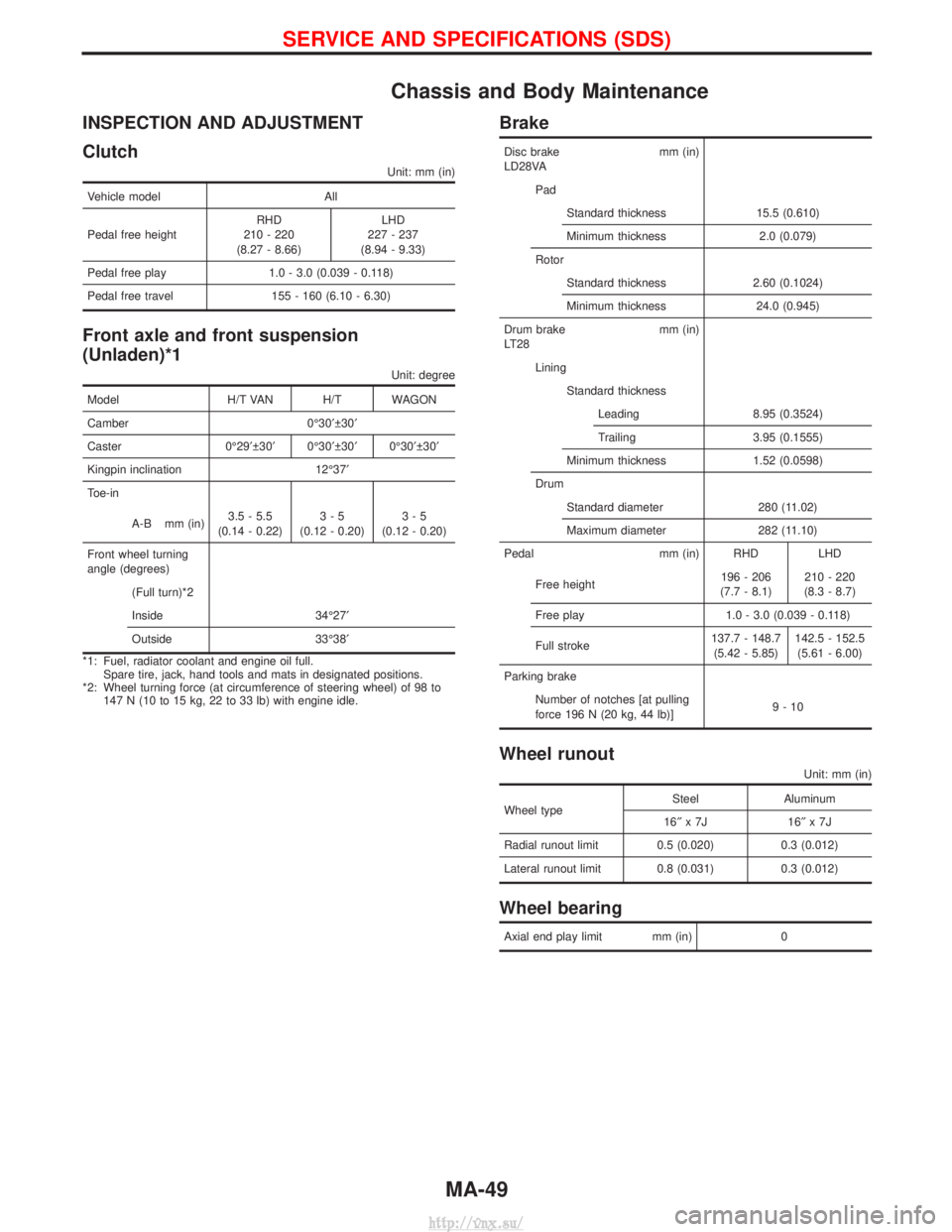

Page 90 of 1833

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle modelAll

Pedal free height RHD

210 - 220

(8.27 - 8.66) LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢ 0É30¢ 30¢ 0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in) 3.5 - 5.5

(0.14 - 0.22) 3-5

(0.12 - 0.20) 3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees) (Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

PadStandard thickness 15.5 (0.610)

Minimum thickness 2.0 (0.079)

Rotor Standard thickness 2.60 (0.1024)

Minimum thickness 24.0 (0.945)

Drum brake mm (in)

LT28 LiningStandard thicknessLeading 8.95 (0.3524)

Trailing 3.95 (0.1555)

Minimum thickness 1.52 (0.0598)

Drum Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke 137.7 - 148.7

(5.42 - 5.85) 142.5 - 152.5

(5.61 - 6.00)

Parking brake Number of notches [at pulling

force 196 N (20 kg, 44 lb)] 9-10

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16² x7J 16 ²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

SERVICE AND SPECIFICATIONS (SDS)

MA-49

http://vnx.su/

Page 1129 of 1833

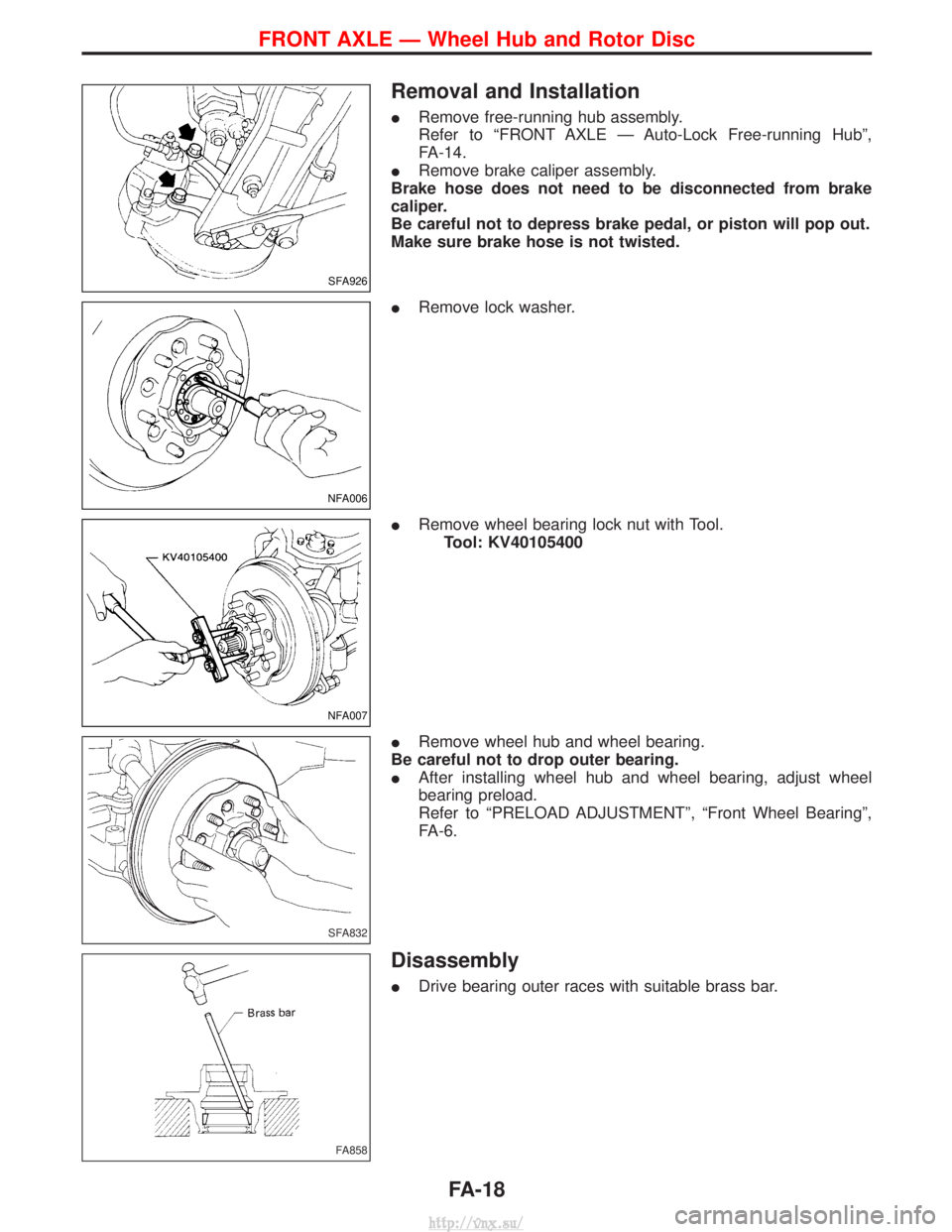

Removal and Installation

IRemove free-running hub assembly.

Refer to ªFRONT AXLE Ð Auto-Lock Free-running Hubº,

FA-14.

I Remove brake caliper assembly.

Brake hose does not need to be disconnected from brake

caliper.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

I Remove lock washer.

I Remove wheel bearing lock nut with Tool.

Tool: KV40105400

I Remove wheel hub and wheel bearing.

Be careful not to drop outer bearing.

I After installing wheel hub and wheel bearing, adjust wheel

bearing preload.

Refer to ªPRELOAD ADJUSTMENTº, ªFront Wheel Bearingº,

FA-6.

Disassembly

IDrive bearing outer races with suitable brass bar.

SFA926

NFA006

NFA007

SFA832

FA858

FRONT AXLE Ð Wheel Hub and Rotor Disc

FA-18

http://vnx.su/

Page 1153 of 1833

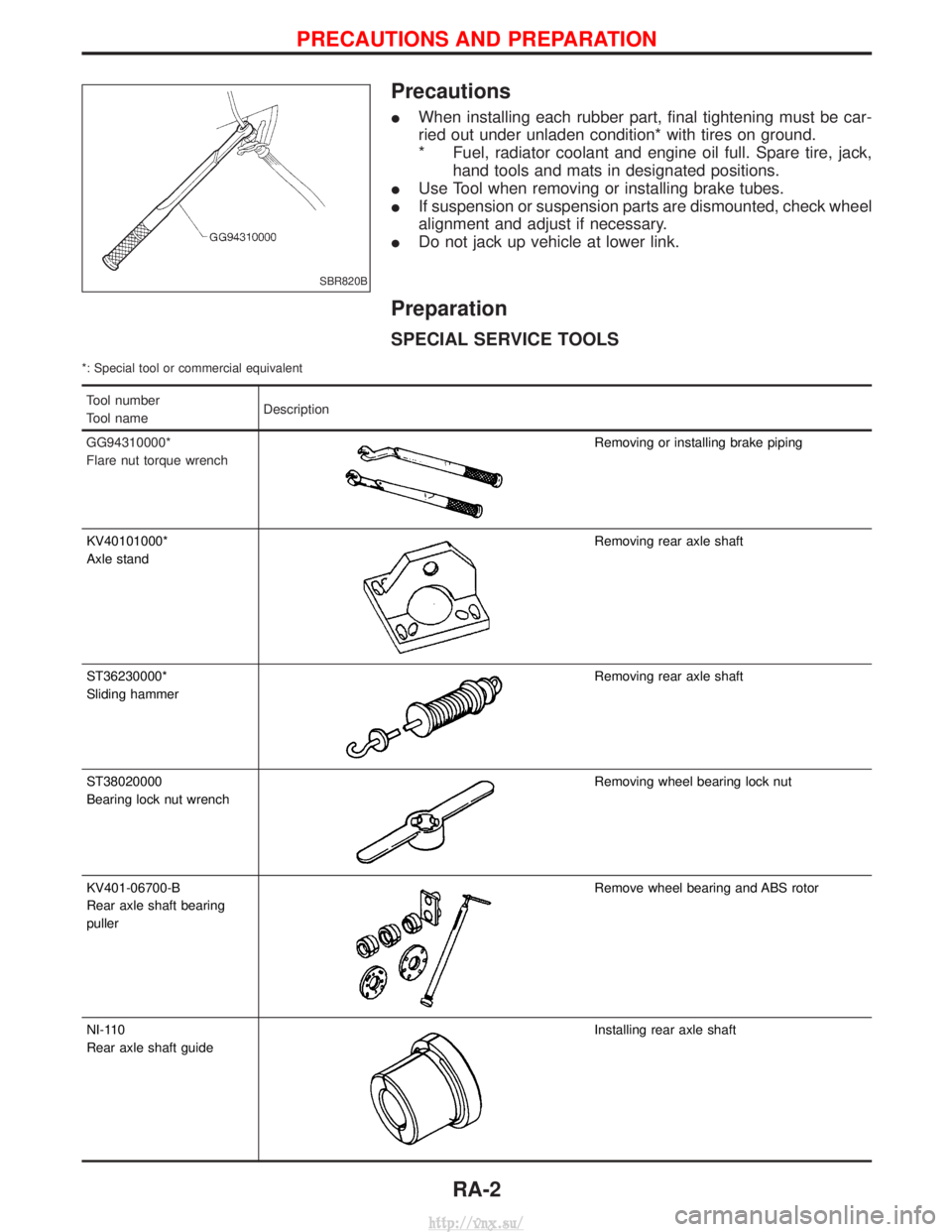

Precautions

IWhen installing each rubber part, final tightening must be car-

ried out under unladen condition* with tires on ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

I Use Tool when removing or installing brake tubes.

I If suspension or suspension parts are dismounted, check wheel

alignment and adjust if necessary.

I Do not jack up vehicle at lower link.

Preparation

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool name Description

GG94310000*

Flare nut torque wrench

Removing or installing brake piping

KV40101000*

Axle stand

Removing rear axle shaft

ST36230000*

Sliding hammer

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

Removing wheel bearing lock nut

KV401-06700-B

Rear axle shaft bearing

puller

Remove wheel bearing and ABS rotor

NI-110

Rear axle shaft guide

Installing rear axle shaft

SBR820B

PRECAUTIONS AND PREPARATION

RA-2

http://vnx.su/

Page 1158 of 1833

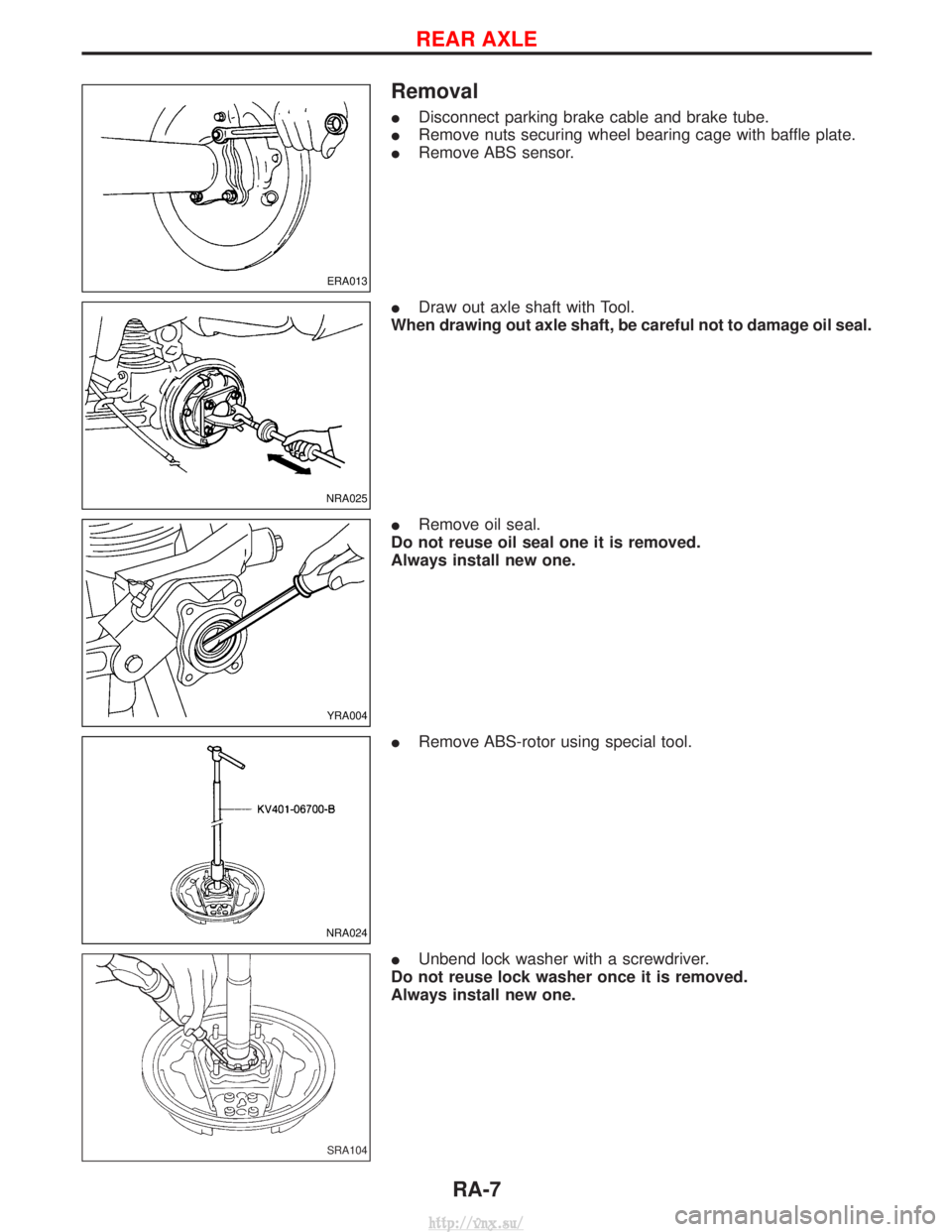

Removal

IDisconnect parking brake cable and brake tube.

I Remove nuts securing wheel bearing cage with baffle plate.

I Remove ABS sensor.

I Draw out axle shaft with Tool.

When drawing out axle shaft, be careful not to damage oil seal.

I Remove oil seal.

Do not reuse oil seal one it is removed.

Always install new one.

I Remove ABS-rotor using special tool.

I Unbend lock washer with a screwdriver.

Do not reuse lock washer once it is removed.

Always install new one.

ERA013

NRA025

YRA004

NRA024

SRA104

REAR AXLE

RA-7

http://vnx.su/

Page 1161 of 1833

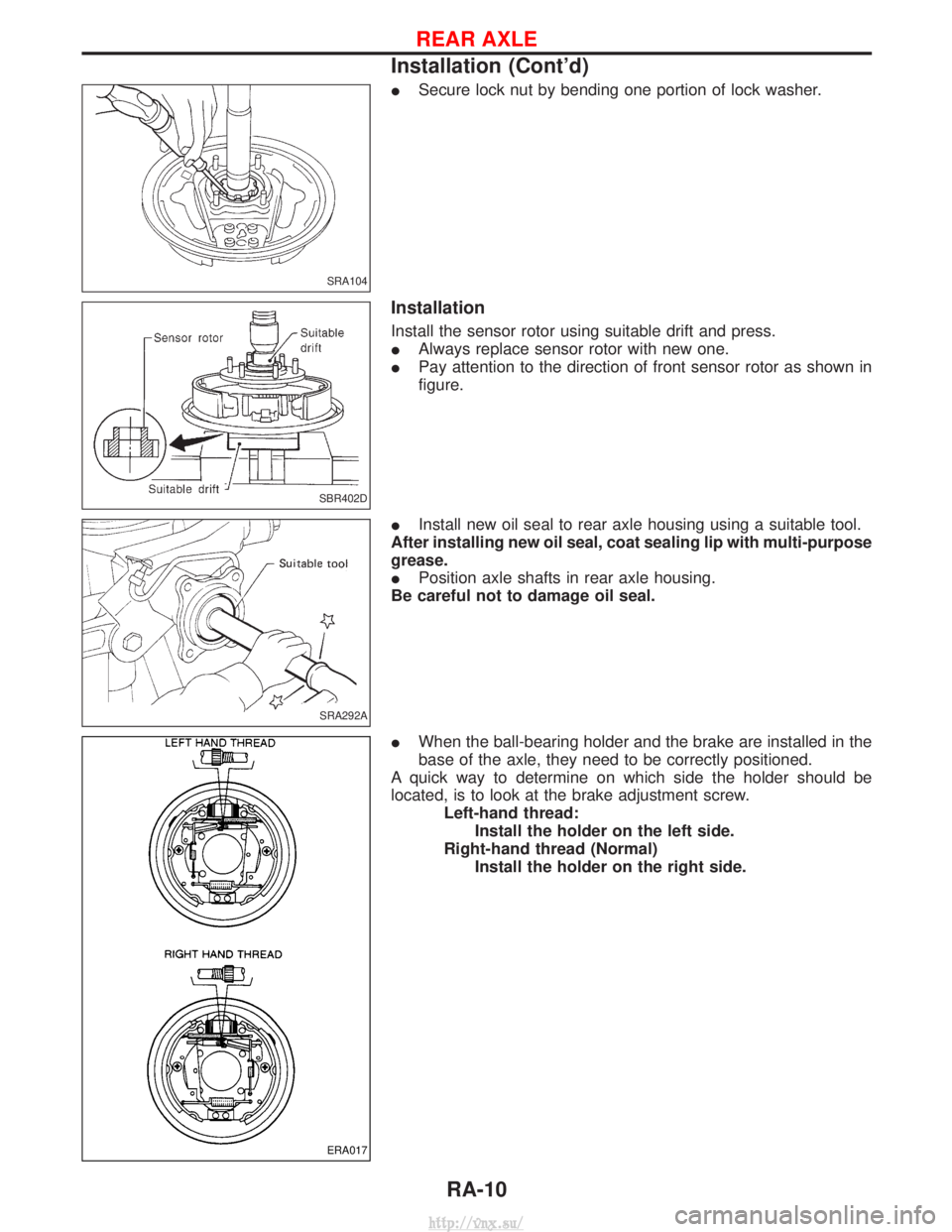

ISecure lock nut by bending one portion of lock washer.

Installation

Install the sensor rotor using suitable drift and press.

IAlways replace sensor rotor with new one.

I Pay attention to the direction of front sensor rotor as shown in

figure.

I Install new oil seal to rear axle housing using a suitable tool.

After installing new oil seal, coat sealing lip with multi-purpose

grease.

I Position axle shafts in rear axle housing.

Be careful not to damage oil seal.

I When the ball-bearing holder and the brake are installed in the

base of the axle, they need to be correctly positioned.

A quick way to determine on which side the holder should be

located, is to look at the brake adjustment screw. Left-hand thread:Install the holder on the left side.

Right-hand thread (Normal) Install the holder on the right side.

SRA104

SBR402D

SRA292A

ERA017

REAR AXLE

Installation (Cont'd)

RA-10

http://vnx.su/

Page 1170 of 1833

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

I Never reuse drained brake fluid.

I Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

I To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

I Never use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

I Use flare nut wrench when removing and installing brake

tubes.

I Always torque brake lines when installing.

I Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

I Clean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

I Avoid prolonged and repeated skin contact with brake

fluid.

I Wear protective clothing, including impervious gloves.

I Where there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

http://vnx.su/

Page 1171 of 1833

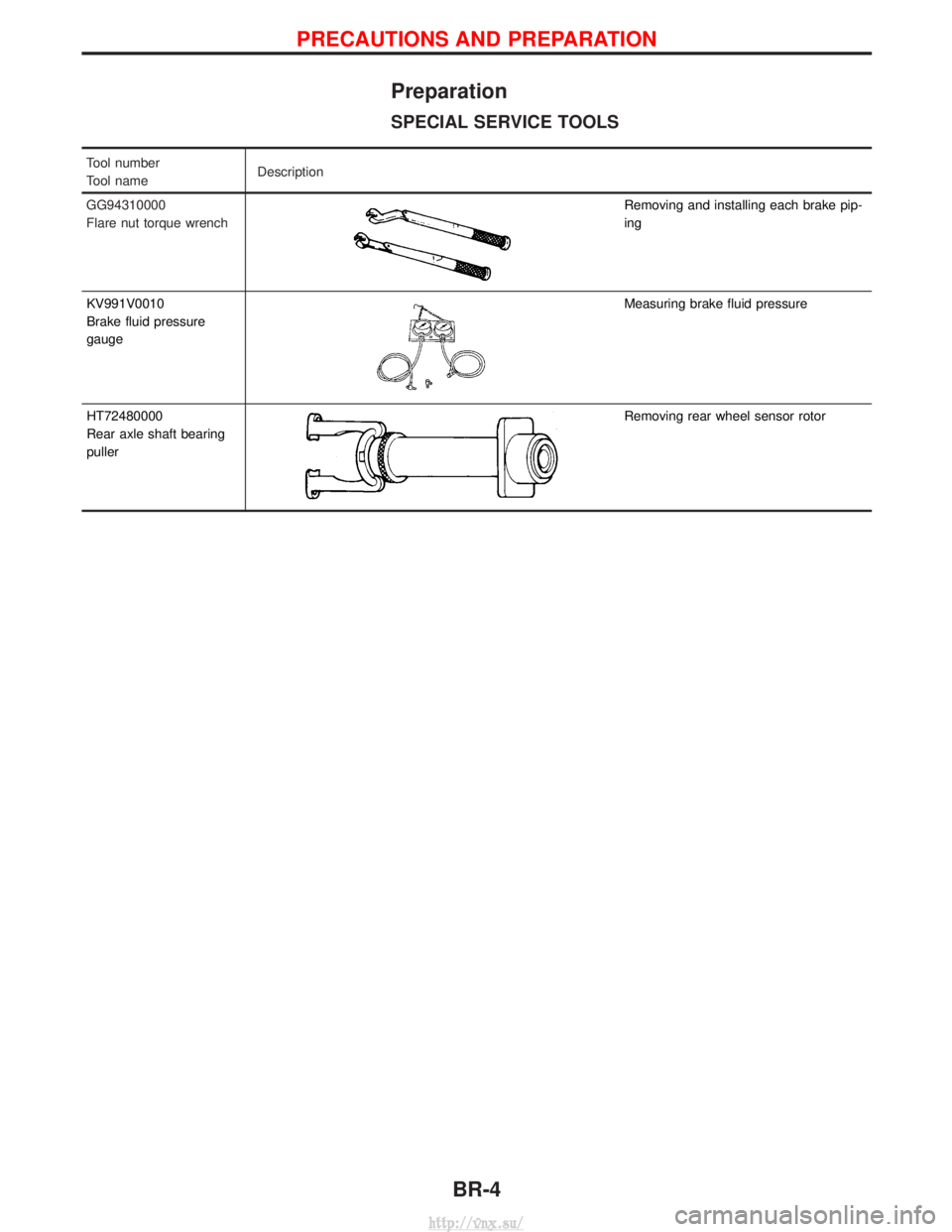

Preparation

SPECIAL SERVICE TOOLS

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

Removing and installing each brake pip-

ing

KV991V0010

Brake fluid pressure

gauge

Measuring brake fluid pressure

HT72480000

Rear axle shaft bearing

puller

Removing rear wheel sensor rotor

PRECAUTIONS AND PREPARATION

BR-4

http://vnx.su/