engine NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 2 of 1833

Edition: February 2004

Release: February 2004 (01)

Publication No.: SM4E00-1R20E0E

Reference No.: 7711347141

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE S.A.S.

2004 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

http://vnx.su/

Page 3 of 1833

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

TERRANO, model R20 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

fications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not specifically recommended by NISSAN must

first completely satisfy himself that neither his safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering SectionParis, France

http://vnx.su/

Page 4 of 1833

GENERAL INFORMATIONSECTION

GI

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL ........................................8

HOW TO READ WIRING DIAGRAMS ..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL .......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................22 Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES ..................................................................25

CONSULT-II CHECKING SYSTEM ...............................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............26

Checking Equipment..................................................26

IDENTIFICATION INFORMATION .................................27

Model Variation ..........................................................27

Identification Number .................................................28

Dimensions ................................................................30

Wheels and Tires .......................................................30

LIFTING POINTS AND TOW TRUCK TOWING ...........31

Garage Jack and Safety Stand .................................31

Screw Jack ................................................................31

4-pole Lift ...................................................................32

Tow Truck Towing ......................................................32

ISO 15031-2 TERMINOLOGY LIST ..............................34

ISO 15031-2 Terminology List ...................................34

TIGHTENING TORQUE OF STANDARD BOLTS ........37

http://vnx.su/

Page 5 of 1833

Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

1. Do not operate the engine for an extended period of time with-out proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

2. Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting and towing

before working on the vehicle.

These operations should be done on a level surface.

3. When removing a heavy component such as the engine or transaxle/transmission, take care not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

4. Before starting repairs which do not require battery power, always turn off the ignition switch, then disconnect the ground

cable from the battery to prevent accidental short circuit.

5. To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold, tail pipe and muffler. Do

not remove the radiator cap when the engine is hot.

SGI285

SGI231

SGI232

SGI233

PRECAUTIONS

GI-2

http://vnx.su/

Page 7 of 1833

insulation (either just before the harness connectors or for

the complete harness), for easy identification.

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel. The

indicator blinks when the ignition switch is in ªOFFº or ªACCº posi-

tion. Therefore, NATS warns outsiders that the vehicle is equipped

with the anti-theft system.

IWhen NATS detects trouble, the malfunction indicator lamp

(MIL) blinks.

This blinking indicates that the anti-theft is not functioning, so

prompt service is required.

I If the malfunction indicator lamp comes on while the engine is

running, return the vehicle to the workshop before turning the

ignition switch ªOFFº.

Once the ignition switch is turned ªOFFº, the engine can not be

started.

I When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs) CON-

SULT-II hardware and CONSULT-II NATS software is neces-

sary.

Regarding the procedures of NATS initialization and NATS igni-

tion key ID registration, refer to CONSULT-II operation manual,

NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

I When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner.

A maximum of five key IDs can be registered into NATS.

I When failing to start the engine first-time using the key of

NATS, starts as follows:

(1) Turn ignition key to ªOFFº.

(2) Wait approx. 5 seconds.

(3) Turn ignition key to ªSTARTº again while keeping the key

apart from any others on key-chain.

SGI916

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System) (Cont'd)

GI-4

http://vnx.su/

Page 8 of 1833

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector forthe multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriouslydamage the catalytic converter.

2. When checking for ignition spark or measuring engine compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam- mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions forproper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start- ing.

3. If engine had been operating at high rpm for an extended period of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

http://vnx.su/

Page 9 of 1833

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine.

* If two types of diesel fuel are available, use summer or winterfuel properly according to the following temperature conditions.

I Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

I Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

I Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

I Do not use summer fuel at temperature below þ7ÉC (20ÉF).

The cold temperature will cause wax to form in the fuel. As

a result, it may prevent the engine from running smoothly.

I Do not add gasoline or other alternate fuels to diesel fuel.

Precautions for Engine Oils

Prolonged and repeated contact with mineral oil will result in the

removal of natural fats from the skin, leading to dryness, irritation

and dermatitis. In addition, used engine oil contains potentially

harmful contaminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must be provided.

HEALTH PROTECTION PRECAUTIONS

1. Avoid prolonged and repeated contact with oils, particularly

used engine oils.

2. Wear protective clothing, including impervious gloves where practicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly underwear, with oil.

5. Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regularly.

6. First Aid treatment should be obtained immediately for open cuts and wounds.

7. Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

9. Do not use petrol, kerosine, diesel fuel, gas oil, thinners or sol- vents for cleaning skin.

10. If skin disorders develop, obtain medical advice without delay.

11. Where practicable, degrease components prior to handling.

12. Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face shields; in addition

an eye wash facility should be provided.

(For the United Kingdom, see also HSE Cautionary Notice SHW

397 ªEffects of Mineral Oil on the Skinº.)

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt check with the

appropriate local authority and/or manufacturer of the approved

appliance.

PRECAUTIONS

GI-6

http://vnx.su/

Page 10 of 1833

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution of the environment

will vary from country to country.

PRECAUTIONS

Precautions for Engine Oils (Cont'd)GI-7

http://vnx.su/

Page 12 of 1833

7. The followingSYMBOLS AND ABBREVIATIONS are used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem- bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H : Select with proper thickness.

I : Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. The UNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system. ªExampleºTightening torque:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9. TROUBLE DIAGNOSES are included in sections dealing with complicated components.

10. SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

11. The captions WARNINGandCAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

I WARNING indicates the possibility of personal injury if instructions are not followed.

I CAUTION indicates the possibility of component damage if instructions are not followed.

I BOLD TYPED STATEMENTS exceptWARNING andCAUTION give you helpful information.

HOW TO USE THIS MANUAL

GI-9

http://vnx.su/

Page 19 of 1833

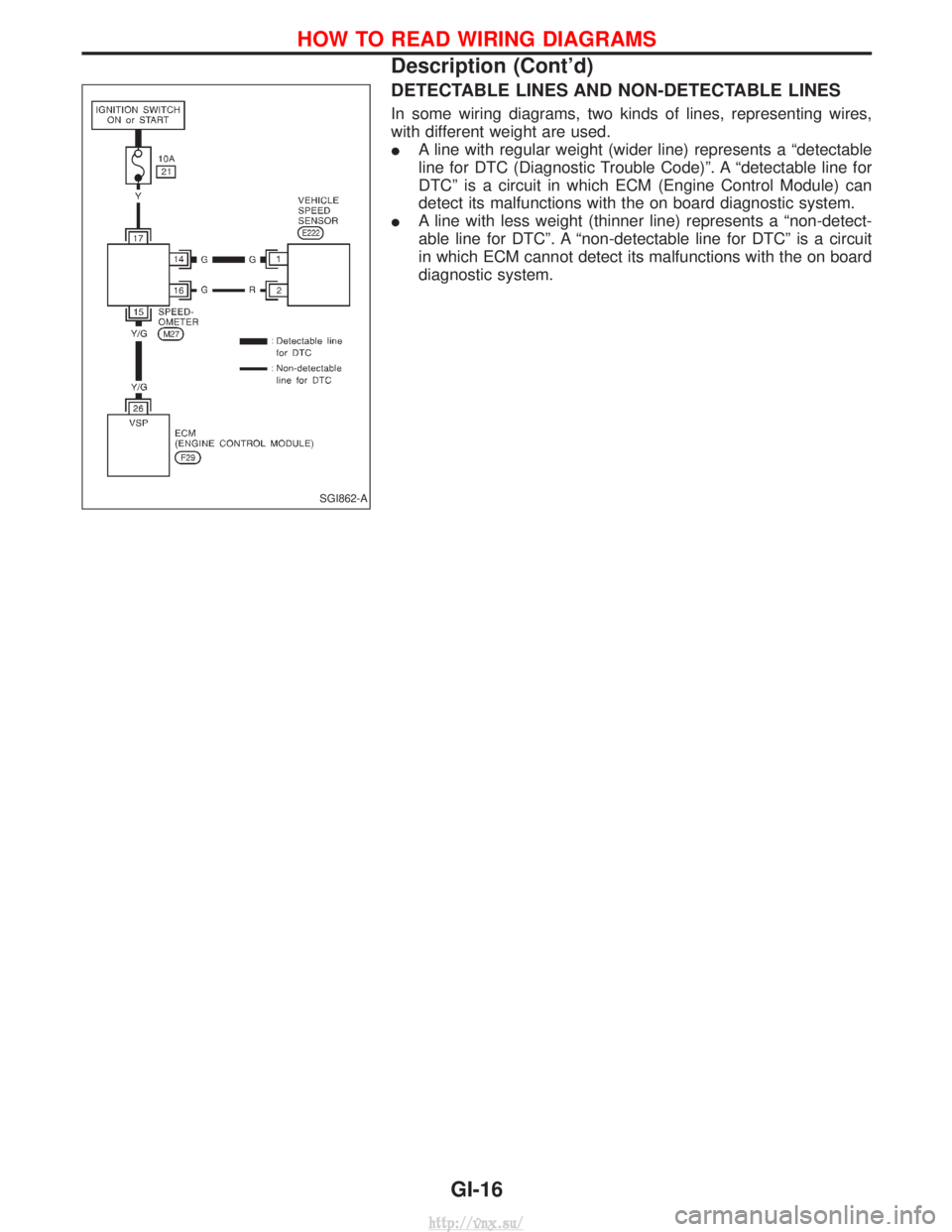

DETECTABLE LINES AND NON-DETECTABLE LINES

In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

IA line with regular weight (wider line) represents a ªdetectable

line for DTC (Diagnostic Trouble Code)º. A ªdetectable line for

DTCº is a circuit in which ECM (Engine Control Module) can

detect its malfunctions with the on board diagnostic system.

I A line with less weight (thinner line) represents a ªnon-detect-

able line for DTCº. A ªnon-detectable line for DTCº is a circuit

in which ECM cannot detect its malfunctions with the on board

diagnostic system.

SGI862-A

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-16

http://vnx.su/