heating NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 9 of 1833

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine.

* If two types of diesel fuel are available, use summer or winterfuel properly according to the following temperature conditions.

I Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

I Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

I Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

I Do not use summer fuel at temperature below þ7ÉC (20ÉF).

The cold temperature will cause wax to form in the fuel. As

a result, it may prevent the engine from running smoothly.

I Do not add gasoline or other alternate fuels to diesel fuel.

Precautions for Engine Oils

Prolonged and repeated contact with mineral oil will result in the

removal of natural fats from the skin, leading to dryness, irritation

and dermatitis. In addition, used engine oil contains potentially

harmful contaminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must be provided.

HEALTH PROTECTION PRECAUTIONS

1. Avoid prolonged and repeated contact with oils, particularly

used engine oils.

2. Wear protective clothing, including impervious gloves where practicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly underwear, with oil.

5. Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regularly.

6. First Aid treatment should be obtained immediately for open cuts and wounds.

7. Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

9. Do not use petrol, kerosine, diesel fuel, gas oil, thinners or sol- vents for cleaning skin.

10. If skin disorders develop, obtain medical advice without delay.

11. Where practicable, degrease components prior to handling.

12. Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face shields; in addition

an eye wash facility should be provided.

(For the United Kingdom, see also HSE Cautionary Notice SHW

397 ªEffects of Mineral Oil on the Skinº.)

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt check with the

appropriate local authority and/or manufacturer of the approved

appliance.

PRECAUTIONS

GI-6

http://vnx.su/

Page 27 of 1833

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

IConnectors not fully seated.

I Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

I Wires laying across brackets or moving components.

I Loose, dirty or corroded ground wires.

I Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection by gently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

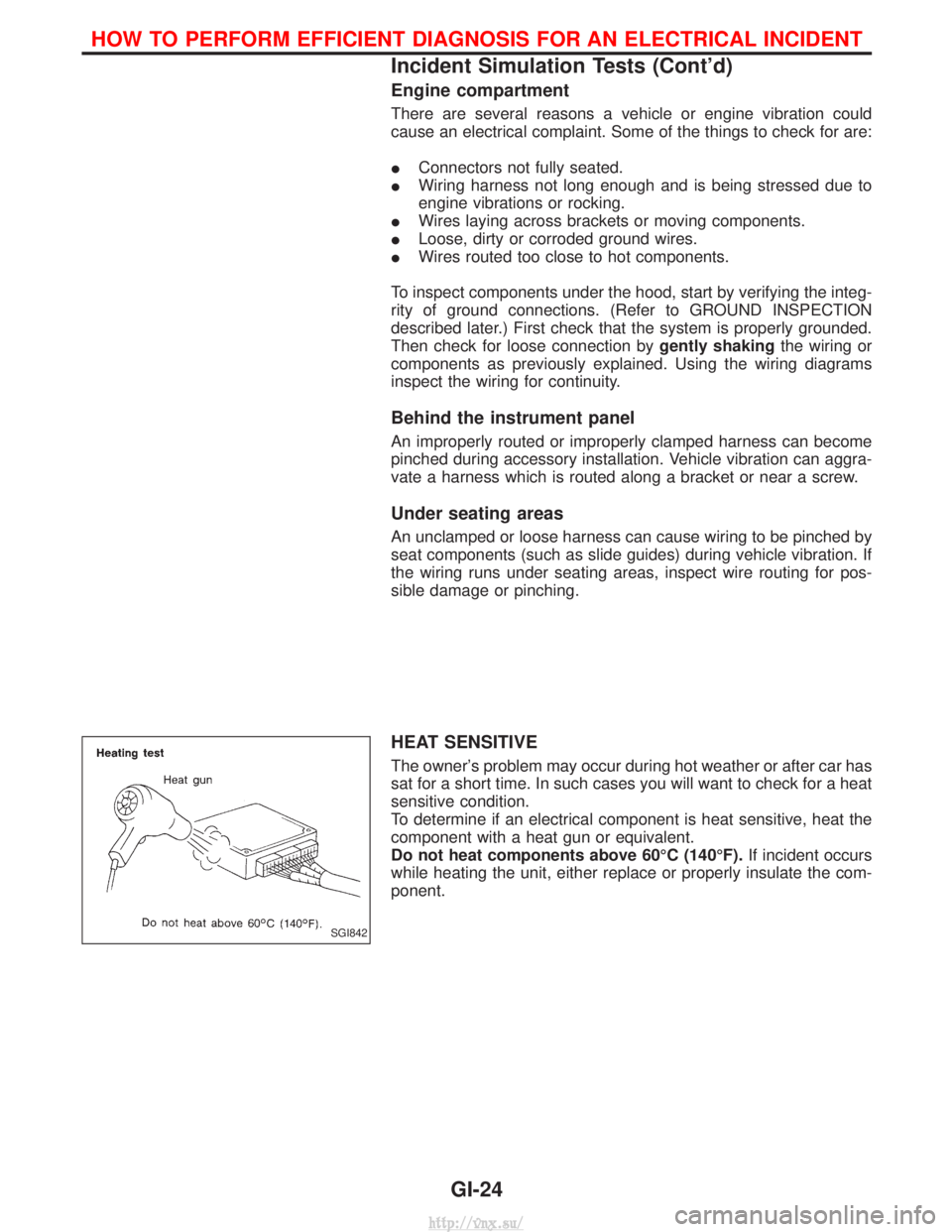

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF). If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

http://vnx.su/

Page 155 of 1833

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

5. Disconnect harness connectors from alternator and air com-pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move har- nesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and removerear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mounting bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem- bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to trans- mission.

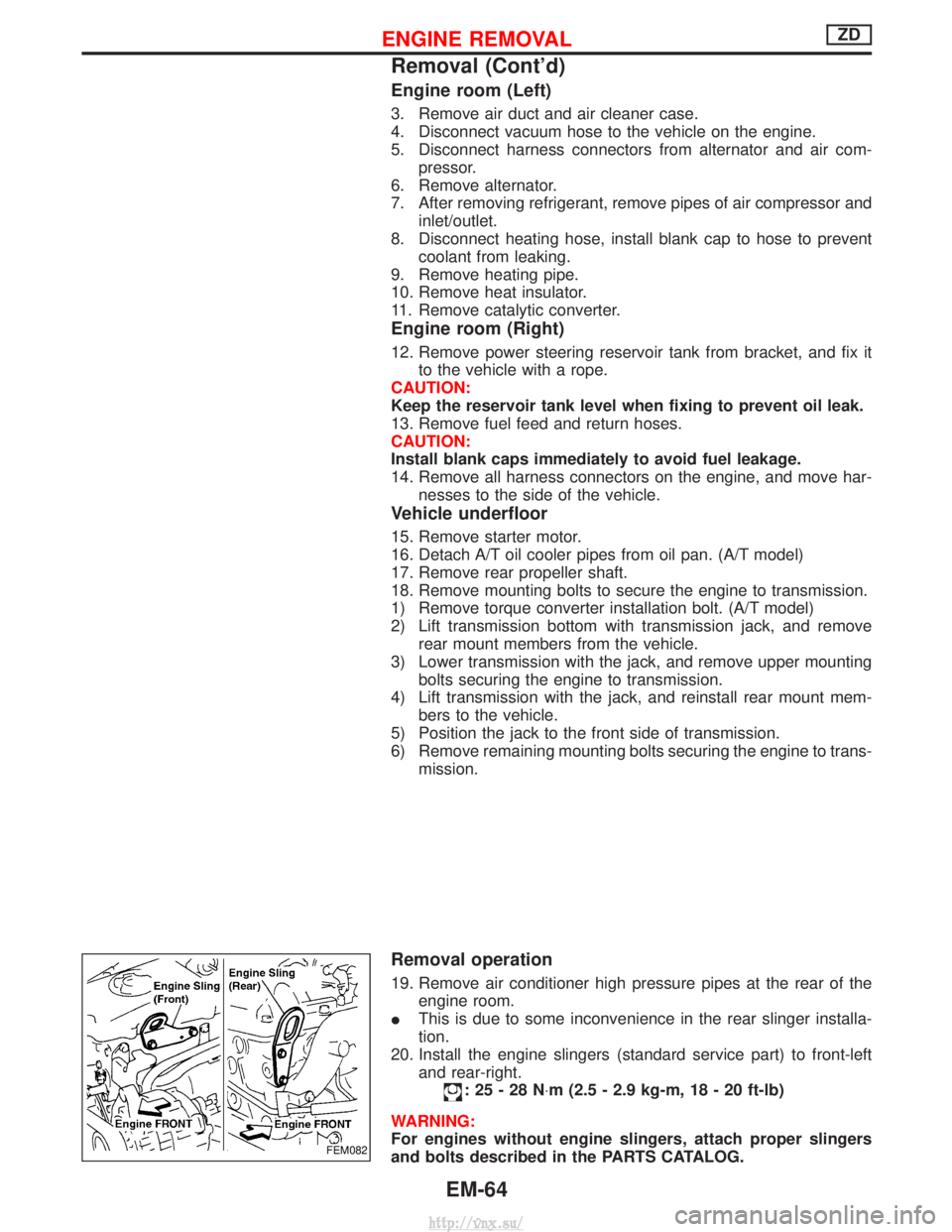

Removal operation

19. Remove air conditioner high pressure pipes at the rear of theengine room.

I This is due to some inconvenience in the rear slinger installa-

tion.

20. Install the engine slingers (standard service part) to front-left and rear-right.

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-64

http://vnx.su/

Page 277 of 1833

DTC Confirmation Procedure ..................................105

Wiring Diagram ........................................................106

Diagnostic Procedure ..............................................107

DTC 0208 OVER HEAT ...............................................109

Description ...............................................................109

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

109

ECM Terminals and Reference Value ..................... 110

On Board Diagnosis Logic....................................... 110

Overall Function Check ........................................... 111

Wiring Diagram ........................................................ 112

Diagnostic Procedure .............................................. 114

Main 12 Causes of Overheating..............................120

DTC 0301 ECM 2.........................................................121 Description ...............................................................121

On Board Diagnosis Logic.......................................121

DTC Confirmation Procedure ..................................121

Diagnostic Procedure ..............................................122

DTC 0402 P9×FUEL TEMP SEN .................................123

Description ...............................................................123

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

124

ECM Terminals and Reference Value .....................124

On Board Diagnosis Logic.......................................124

DTC Confirmation Procedure ..................................125

Wiring Diagram ........................................................126

Diagnostic Procedure ..............................................128

DTC 0403 ACCEL POS SENSOR ..............................130

Description ...............................................................130

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

131

ECM Terminals and Reference Value .....................131

On Board Diagnosis Logic.......................................132

DTC Confirmation Procedure ..................................132

Wiring Diagram ........................................................133

Diagnostic Procedure ..............................................137

DTC 0406 INT AIR VOL ..............................................150

On Board Diagnosis Logic.......................................150

DTC Confirmation Procedure ..................................150

Diagnostic Procedure ..............................................151

DTC 0407 CRANK POS SEN (TDC) ..........................152

Description ...............................................................152

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

152

ECM Terminals and Reference Value .....................152

On Board Diagnosis Logic.......................................153

DTC Confirmation Procedure ..................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................156

DTC 0504 A/T COMM LINE ........................................160

System Description ..................................................160

ECM Terminals and Reference Value .....................160 On Board Diagnosis Logic.......................................160

DTC Confirmation Procedure ..................................161

Overall Function Check ...........................................161

Wiring Diagram ........................................................162

Diagnostic Procedure ..............................................164

DTC 0701 P1×CAM POS SEN .....................................166

Description ...............................................................166

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

167

ECM Terminals and Reference Value .....................167

On Board Diagnosis Logic.......................................167

DTC Confirmation Procedure ..................................168

Wiring Diagram ........................................................169

Diagnostic Procedure ..............................................171

DTC 0702 P2×TDC PULSE SIG ..................................173

Description ...............................................................173

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

174

ECM Terminals and Reference Value .....................174

On Board Diagnosis Logic.......................................174

DTC Confirmation Procedure ..................................175

Wiring Diagram ........................................................176

Diagnostic Procedure ..............................................178

DTC 0703 P3×PUMP COMM LINE ..............................180

Description ...............................................................180

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

181

ECM Terminals and Reference Value .....................181

On Board Diagnosis Logic.......................................181

DTC Confirmation Procedure ..................................182

Wiring Diagram ........................................................183

Diagnostic Procedure ..............................................185

DTC 0704 P4×SPILL/V CIRC, DTC 0706 P6×SPILL

VA LV E ........................................................................\

..187

Description ...............................................................187

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

188

ECM Terminals and Reference Value .....................188

On Board Diagnosis Logic.......................................188

DTC Confirmation Procedure ..................................189

Wiring Diagram ........................................................190

Diagnostic Procedure ..............................................192

DTC 0705 P5×PUMP C/MODULE ................................194

Description ...............................................................194

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................\

195

ECM Terminals and Reference Value .....................195

On Board Diagnosis Logic.......................................195

DTC Confirmation Procedure ..................................196

Diagnostic Procedure ..............................................196

DTC 0707 P7×F/INJ TIMG FB .....................................197

Description ...............................................................197

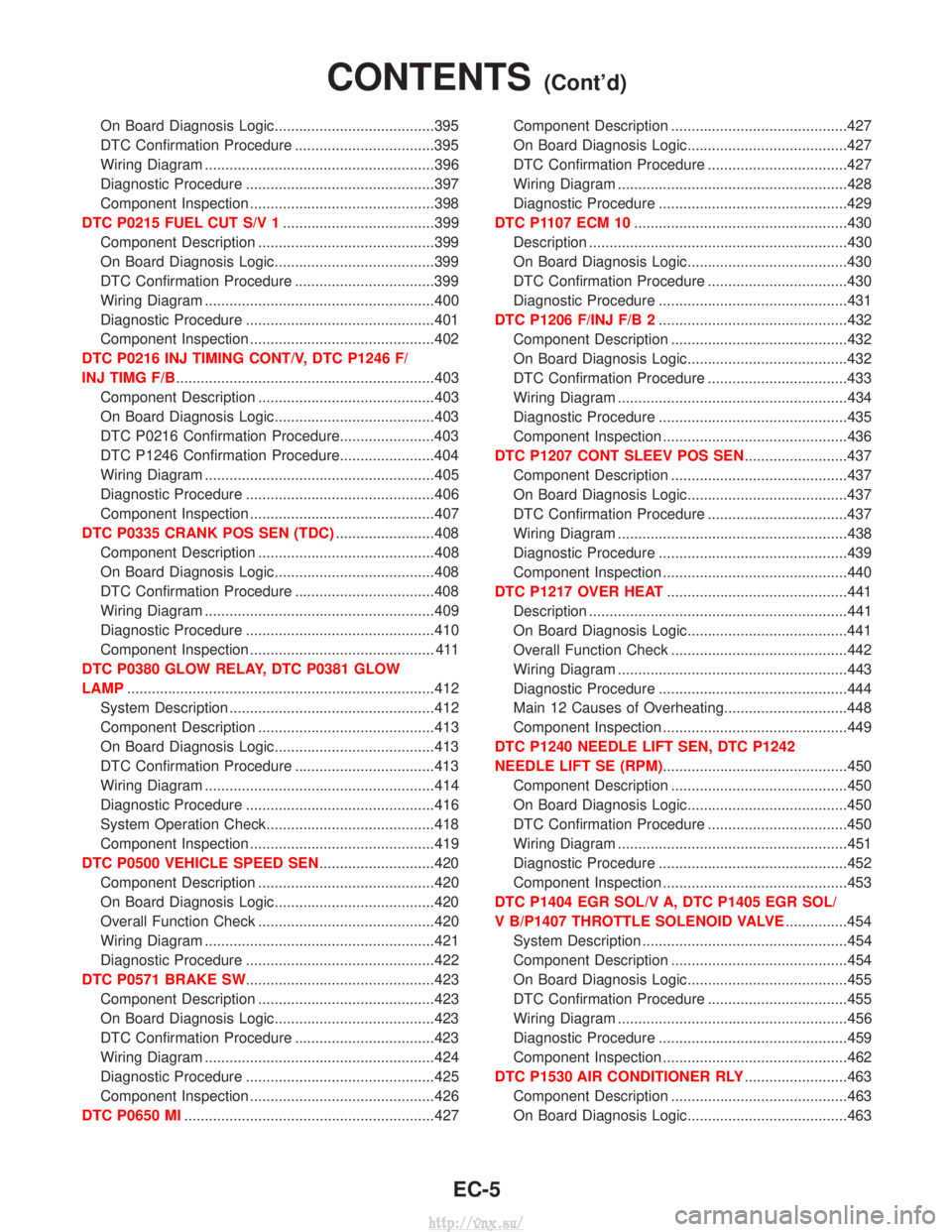

CONTENTS(Cont'd)

EC-2

http://vnx.su/

Page 280 of 1833

On Board Diagnosis Logic.......................................395

DTC Confirmation Procedure ..................................395

Wiring Diagram ........................................................396

Diagnostic Procedure ..............................................397

Component Inspection .............................................398

DTC P0215 FUEL CUT S/V 1 .....................................399

Component Description ...........................................399

On Board Diagnosis Logic.......................................399

DTC Confirmation Procedure ..................................399

Wiring Diagram ........................................................400

Diagnostic Procedure ..............................................401

Component Inspection .............................................402

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/

INJ TIMG F/B ...............................................................403

Component Description ...........................................403

On Board Diagnosis Logic.......................................403

DTC P0216 Confirmation Procedure.......................403

DTC P1246 Confirmation Procedure.......................404

Wiring Diagram ........................................................405

Diagnostic Procedure ..............................................406

Component Inspection .............................................407

DTC P0335 CRANK POS SEN (TDC) ........................408

Component Description ...........................................408

On Board Diagnosis Logic.......................................408

DTC Confirmation Procedure ..................................408

Wiring Diagram ........................................................409

Diagnostic Procedure ..............................................410

Component Inspection ............................................. 411

DTC P0380 GLOW RELAY, DTC P0381 GLOW

LAMP ........................................................................\

...412

System Description ..................................................412

Component Description ...........................................413

On Board Diagnosis Logic.......................................413

DTC Confirmation Procedure ..................................413

Wiring Diagram ........................................................414

Diagnostic Procedure ..............................................416

System Operation Check.........................................418

Component Inspection .............................................419

DTC P0500 VEHICLE SPEED SEN ............................420

Component Description ...........................................420

On Board Diagnosis Logic.......................................420

Overall Function Check ...........................................420

Wiring Diagram ........................................................421

Diagnostic Procedure ..............................................422

DTC P0571 BRAKE SW ..............................................423

Component Description ...........................................423

On Board Diagnosis Logic.......................................423

DTC Confirmation Procedure ..................................423

Wiring Diagram ........................................................424

Diagnostic Procedure ..............................................425

Component Inspection .............................................426

DTC P0650 MI .............................................................427 Component Description ...........................................427

On Board Diagnosis Logic.......................................427

DTC Confirmation Procedure ..................................427

Wiring Diagram ........................................................428

Diagnostic Procedure ..............................................429

DTC P1107 ECM 10 ....................................................430

Description ...............................................................430

On Board Diagnosis Logic.......................................430

DTC Confirmation Procedure ..................................430

Diagnostic Procedure ..............................................431

DTC P1206 F/INJ F/B 2 ..............................................432

Component Description ...........................................432

On Board Diagnosis Logic.......................................432

DTC Confirmation Procedure ..................................433

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................435

Component Inspection .............................................436

DTC P1207 CONT SLEEV POS SEN .........................437

Component Description ...........................................437

On Board Diagnosis Logic.......................................437

DTC Confirmation Procedure ..................................437

Wiring Diagram ........................................................438

Diagnostic Procedure ..............................................439

Component Inspection .............................................440

DTC P1217 OVER HEAT ............................................441

Description ...............................................................441

On Board Diagnosis Logic.......................................441

Overall Function Check ...........................................442

Wiring Diagram ........................................................443

Diagnostic Procedure ..............................................444

Main 12 Causes of Overheating..............................448

Component Inspection .............................................449

DTC P1240 NEEDLE LIFT SEN, DTC P1242

NEEDLE LIFT SE (RPM) .............................................450

Component Description ...........................................450

On Board Diagnosis Logic.......................................450

DTC Confirmation Procedure ..................................450

Wiring Diagram ........................................................451

Diagnostic Procedure ..............................................452

Component Inspection .............................................453

DTC P1404 EGR SOL/V A, DTC P1405 EGR SOL/

V B/P1407 THROTTLE SOLENOID VALVE ...............454

System Description ..................................................454

Component Description ...........................................454

On Board Diagnosis Logic.......................................455

DTC Confirmation Procedure ..................................455

Wiring Diagram ........................................................456

Diagnostic Procedure ..............................................459

Component Inspection .............................................462

DTC P1530 AIR CONDITIONER RLY .........................463

Component Description ...........................................463

On Board Diagnosis Logic.......................................463

CONTENTS(Cont'd)

EC-5

http://vnx.su/

Page 385 of 1833

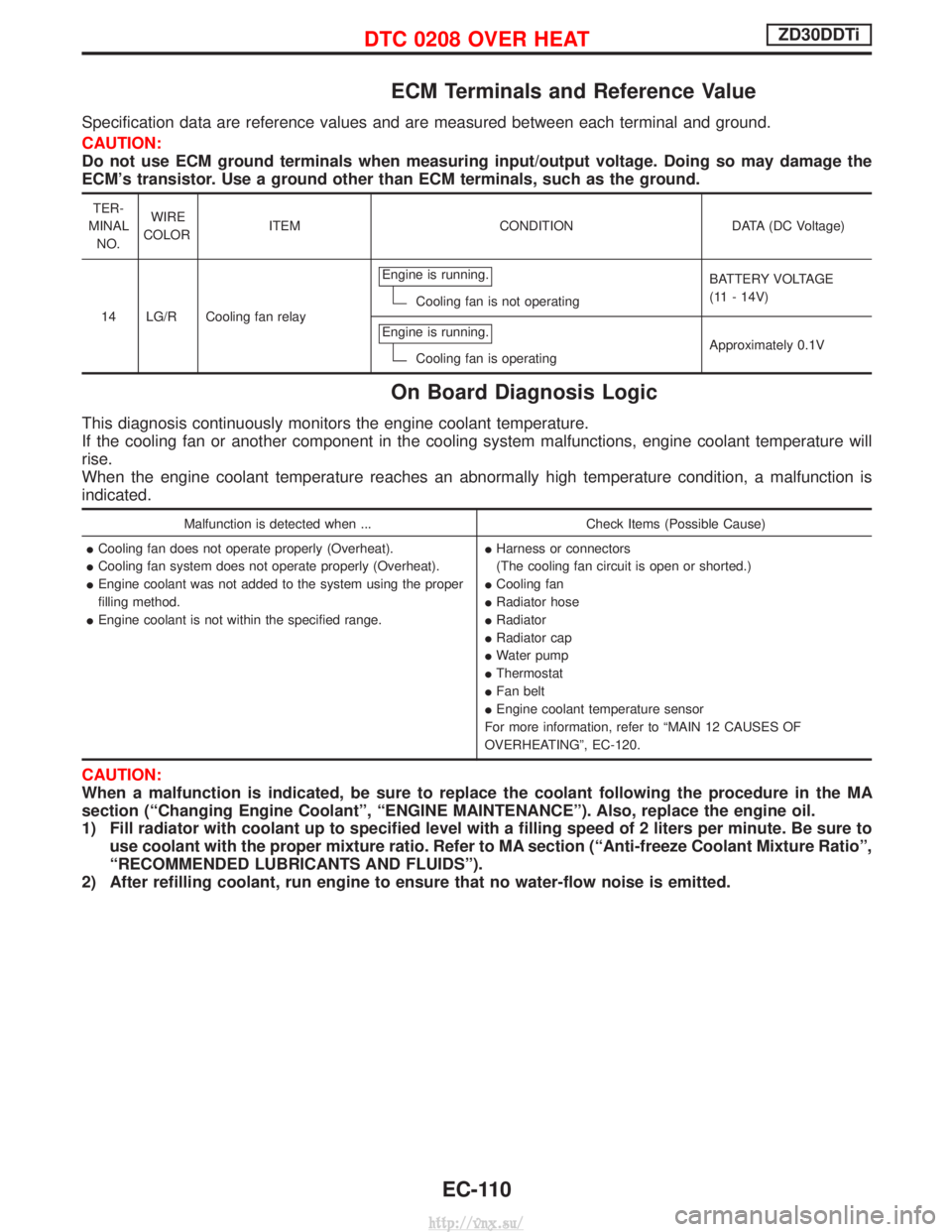

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

14 LG/R Cooling fan relay Engine is running.

Cooling fan is not operating

BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operating Approximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ...

Check Items (Possible Cause)

I Cooling fan does not operate properly (Overheat).

I Cooling fan system does not operate properly (Overheat).

I Engine coolant was not added to the system using the proper

filling method.

I Engine coolant is not within the specified range. I

Harness or connectors

(The cooling fan circuit is open or shorted.)

I Cooling fan

I Radiator hose

I Radiator

I Radiator cap

I Water pump

I Thermostat

I Fan belt

I Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-120.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-110

http://vnx.su/

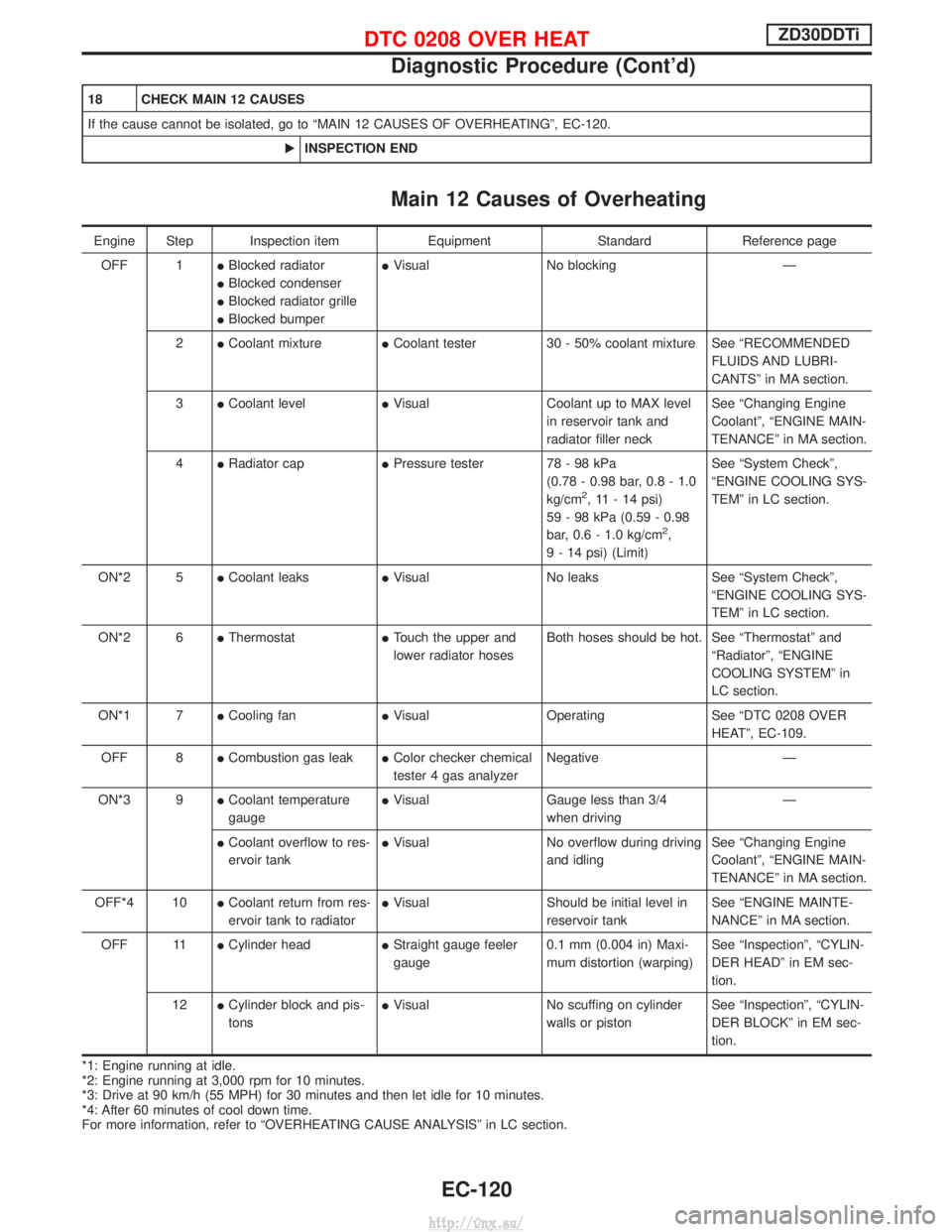

Page 395 of 1833

18 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-120.EINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item EquipmentStandardReference page

OFF 1 IBlocked radiator

I Blocked condenser

I Blocked radiator grille

I Blocked bumper I

Visual No blocking Ð

2 ICoolant mixture ICoolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3 ICoolant level IVisual Coolant up to MAX level

in reservoir tank and

radiator filler neck See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

4 IRadiator cap IPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit) See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5 ICoolant leaks IVisual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6 IThermostat ITouch the upper and

lower radiator hoses Both hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7 ICooling fan IVisual Operating See ªDTC 0208 OVER

HEATº, EC-109.

OFF 8 ICombustion gas leak IColor checker chemical

tester 4 gas analyzer Negative Ð

ON*3 9 ICoolant temperature

gauge I

Visual Gauge less than 3/4

when driving Ð

I Coolant overflow to res-

ervoir tank I

Visual No overflow during driving

and idling See ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA section.

OFF*4 10 ICoolant return from res-

ervoir tank to radiator I

Visual Should be initial level in

reservoir tank See ªENGINE MAINTE-

NANCEº in MA section.

OFF 11 ICylinder head IStraight gauge feeler

gauge 0.1 mm (0.004 in) Maxi-

mum distortion (warping) See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12 ICylinder block and pis-

tons I

Visual No scuffing on cylinder

walls or piston See ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-120

http://vnx.su/

Page 519 of 1833

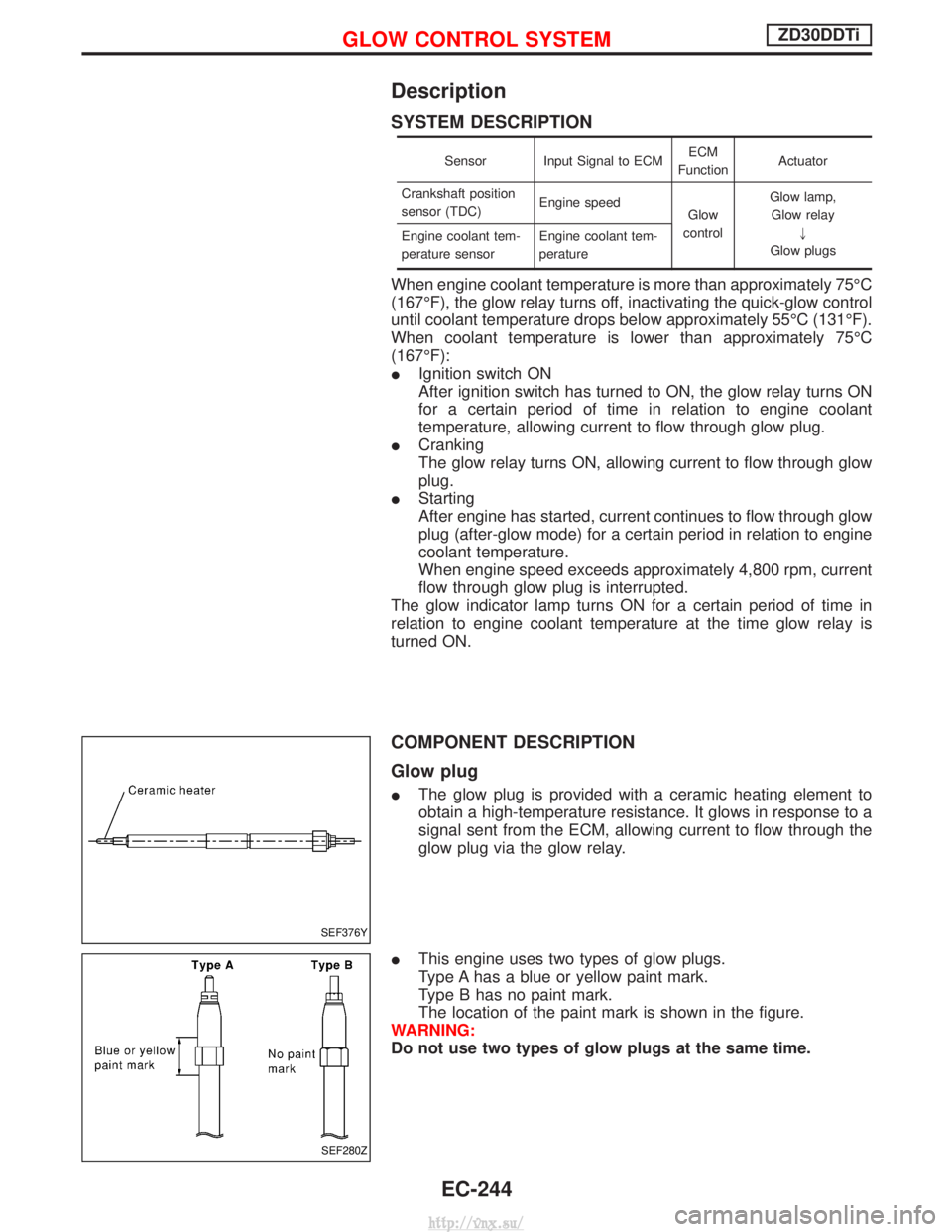

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

Function Actuator

Crankshaft position

sensor (TDC) Engine speed

Glow

control Glow lamp,

Glow relay "

Glow plugs

Engine coolant tem-

perature sensor Engine coolant tem-

perature

When engine coolant temperature is more than approximately 75ÉC

(167ÉF), the glow relay turns off, inactivating the quick-glow control

until coolant temperature drops below approximately 55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

I

Ignition switch ON

After ignition switch has turned to ON, the glow relay turns ON

for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

I Cranking

The glow relay turns ON, allowing current to flow through glow

plug.

I Starting

After engine has started, current continues to flow through glow

plug (after-glow mode) for a certain period in relation to engine

coolant temperature.

When engine speed exceeds approximately 4,800 rpm, current

flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

COMPONENT DESCRIPTION

Glow plug

I The glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to a

signal sent from the ECM, allowing current to flow through the

glow plug via the glow relay.

I This engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-244

http://vnx.su/

Page 527 of 1833

![NISSAN TERRANO 2004 Service Repair Manual 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped NISSAN TERRANO 2004 Service Repair Manual 17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped](/img/5/57394/w960_57394-526.png)

17 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

MEC005EResistance: Approx. 0.5W[at 20ÉC (68ÉF)]

NOTE:

I Do not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

I If glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

I If glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

I Hand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

:15-20N ×m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

OK or NG

OK EGO TO 18.

NG EReplace glow plug.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-252

http://vnx.su/

Page 688 of 1833

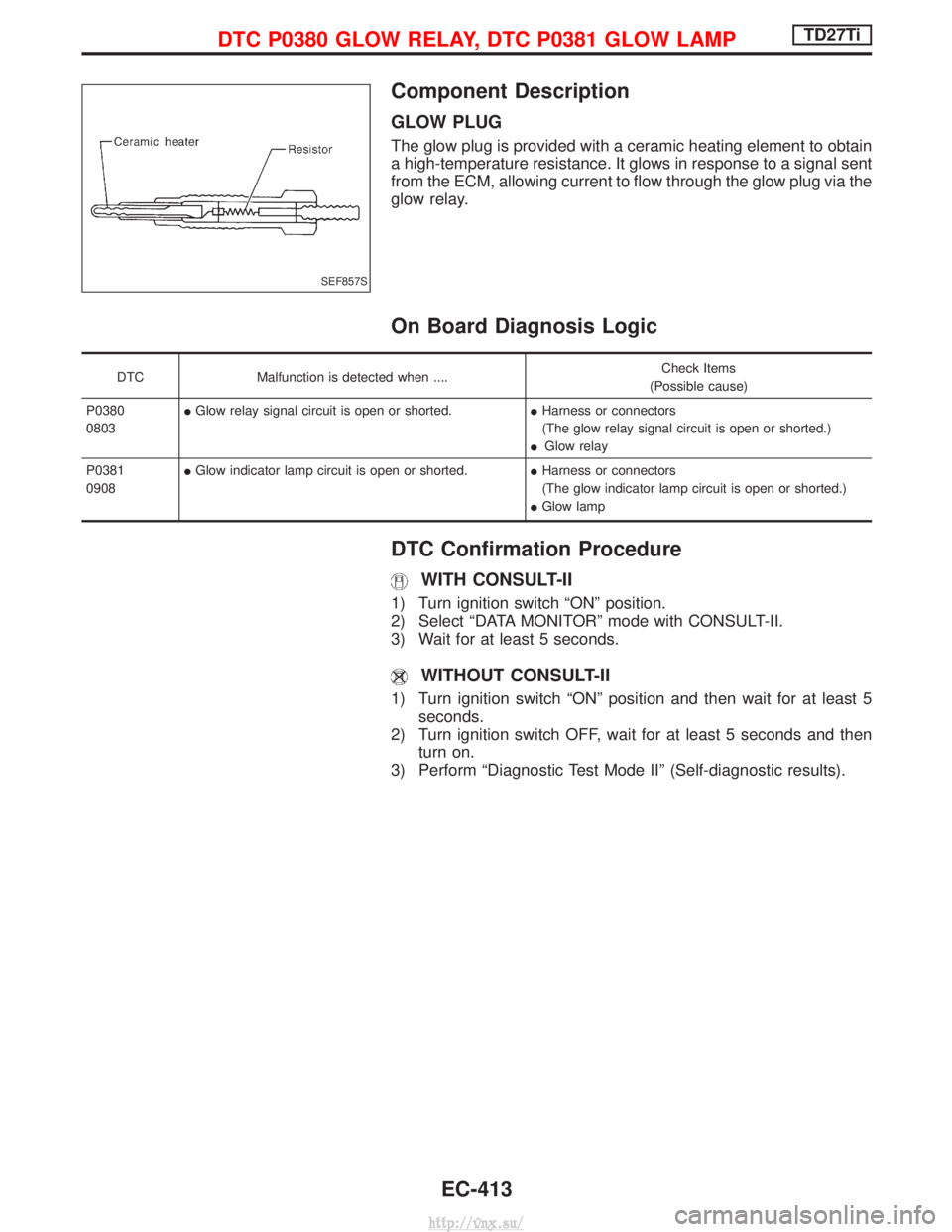

Component Description

GLOW PLUG

The glow plug is provided with a ceramic heating element to obtain

a high-temperature resistance. It glows in response to a signal sent

from the ECM, allowing current to flow through the glow plug via the

glow relay.

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items

(Possible cause)

P0380

0803 I

Glow relay signal circuit is open or shorted. IHarness or connectors

(The glow relay signal circuit is open or shorted.)

I Glow relay

P0381

0908 I

Glow indicator lamp circuit is open or shorted. IHarness or connectors

(The glow indicator lamp circuit is open or shorted.)

I Glow lamp

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait for at least 5 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº position and then wait for at least 5

seconds.

2) Turn ignition switch OFF, wait for at least 5 seconds and then turn on.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF857S

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-413

http://vnx.su/