roof NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 4 of 1833

GENERAL INFORMATIONSECTION

GI

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL ........................................8

HOW TO READ WIRING DIAGRAMS ..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL .......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................22 Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES ..................................................................25

CONSULT-II CHECKING SYSTEM ...............................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............26

Checking Equipment..................................................26

IDENTIFICATION INFORMATION .................................27

Model Variation ..........................................................27

Identification Number .................................................28

Dimensions ................................................................30

Wheels and Tires .......................................................30

LIFTING POINTS AND TOW TRUCK TOWING ...........31

Garage Jack and Safety Stand .................................31

Screw Jack ................................................................31

4-pole Lift ...................................................................32

Tow Truck Towing ......................................................32

ISO 15031-2 TERMINOLOGY LIST ..............................34

ISO 15031-2 Terminology List ...................................34

TIGHTENING TORQUE OF STANDARD BOLTS ........37

http://vnx.su/

Page 22 of 1833

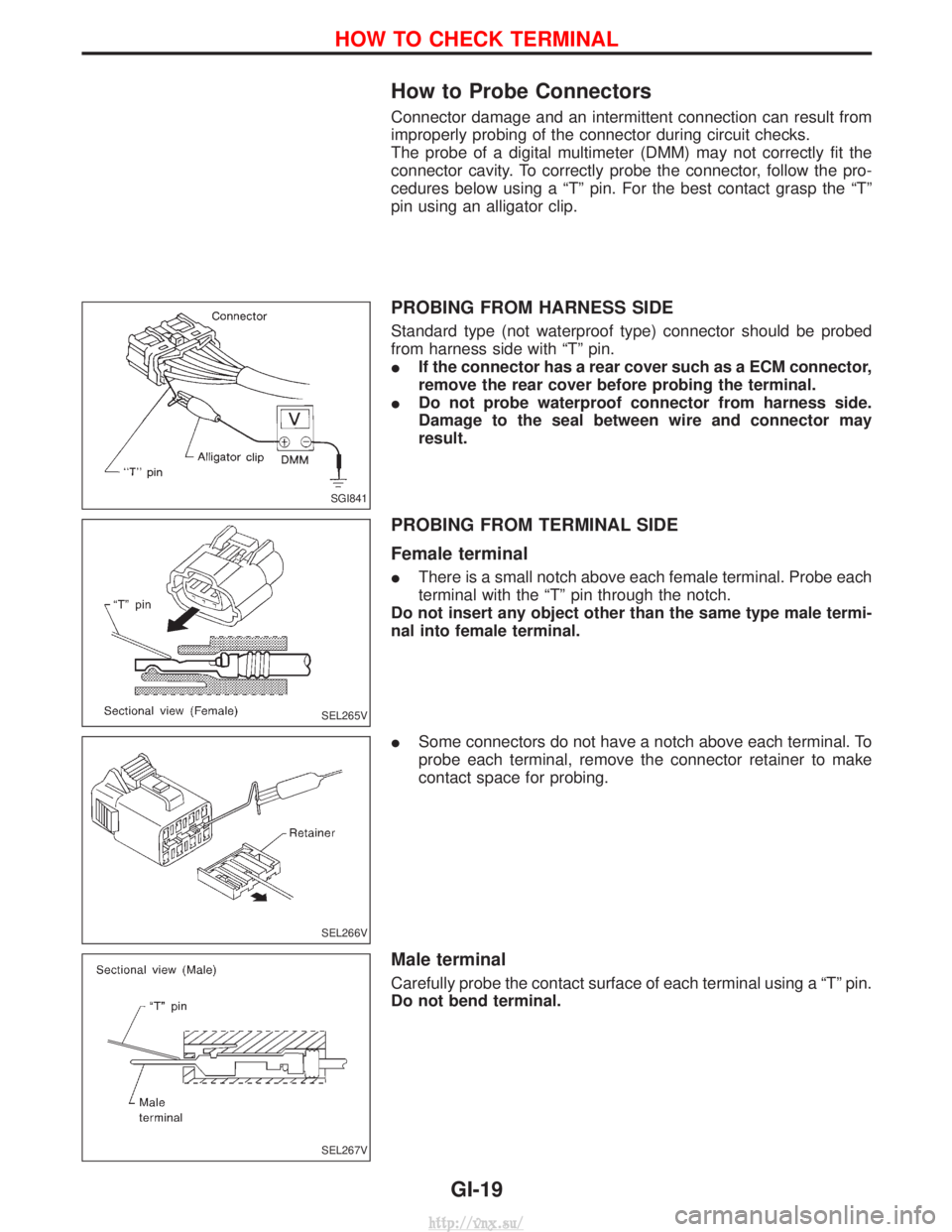

How to Probe Connectors

Connector damage and an intermittent connection can result from

improperly probing of the connector during circuit checks.

The probe of a digital multimeter (DMM) may not correctly fit the

connector cavity. To correctly probe the connector, follow the pro-

cedures below using a ªTº pin. For the best contact grasp the ªTº

pin using an alligator clip.

PROBING FROM HARNESS SIDE

Standard type (not waterproof type) connector should be probed

from harness side with ªTº pin.

IIf the connector has a rear cover such as a ECM connector,

remove the rear cover before probing the terminal.

I Do not probe waterproof connector from harness side.

Damage to the seal between wire and connector may

result.

PROBING FROM TERMINAL SIDE

Female terminal

IThere is a small notch above each female terminal. Probe each

terminal with the ªTº pin through the notch.

Do not insert any object other than the same type male termi-

nal into female terminal.

I Some connectors do not have a notch above each terminal. To

probe each terminal, remove the connector retainer to make

contact space for probing.

Male terminal

Carefully probe the contact surface of each terminal using a ªTº pin.

Do not bend terminal.

SGI841

SEL265V

SEL266V

SEL267V

HOW TO CHECK TERMINAL

GI-19

http://vnx.su/

Page 24 of 1833

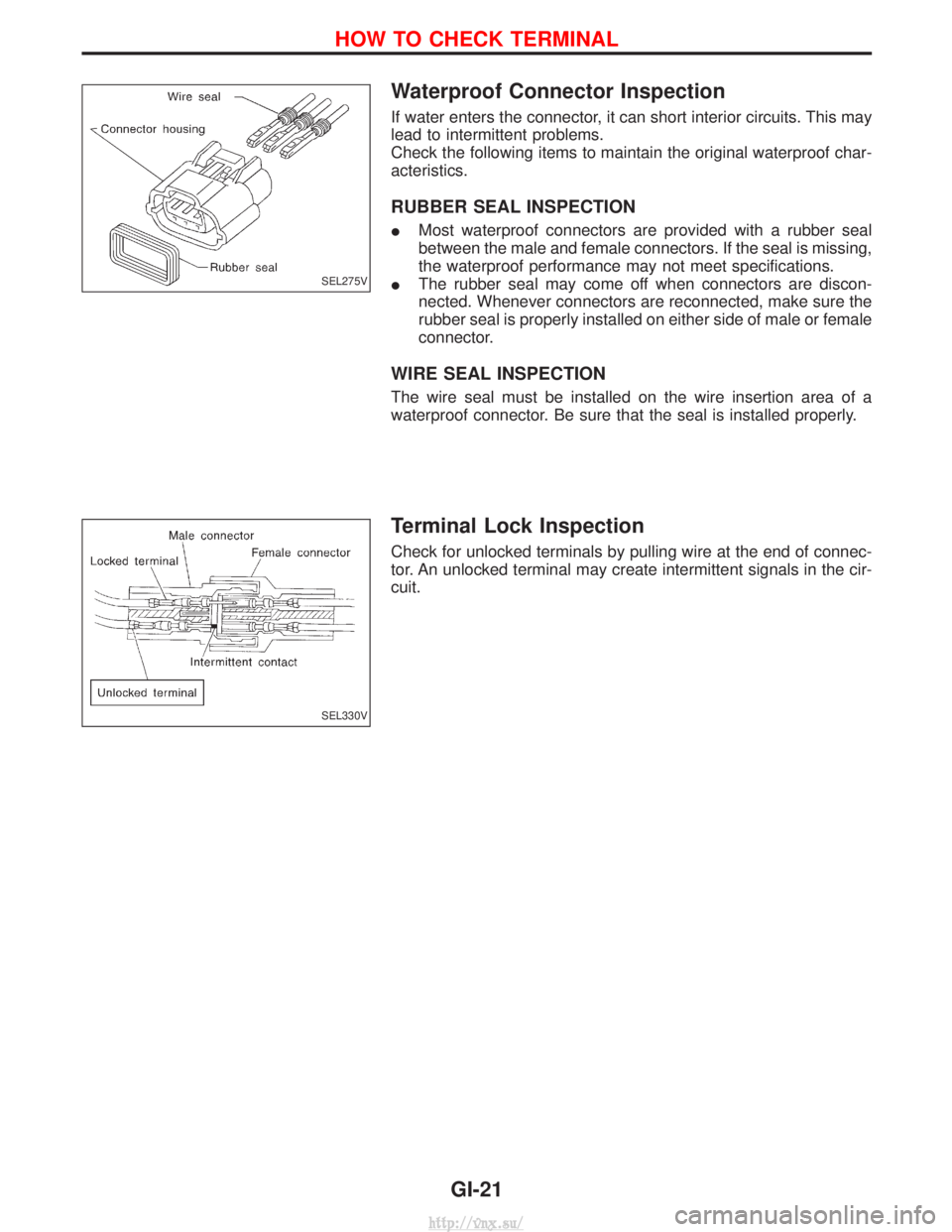

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may

lead to intermittent problems.

Check the following items to maintain the original waterproof char-

acteristics.

RUBBER SEAL INSPECTION

IMost waterproof connectors are provided with a rubber seal

between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

I The rubber seal may come off when connectors are discon-

nected. Whenever connectors are reconnected, make sure the

rubber seal is properly installed on either side of male or female

connector.

WIRE SEAL INSPECTION

The wire seal must be installed on the wire insertion area of a

waterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connec-

tor. An unlocked terminal may create intermittent signals in the cir-

cuit.

SEL275V

SEL330V

HOW TO CHECK TERMINAL

GI-21

http://vnx.su/

Page 88 of 1833

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut lower in engine

compartment, etc.

Panel edge

Back door lid opening, sun roof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel,

etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-47

http://vnx.su/

Page 758 of 1833

WARNING:

When replacing fuel line parts, be sure to observe the following:

IDisplay a ªCAUTION: INFLAMMABLEº sign in workshop.

I Be sure to furnish workshop with a CO

2fire extinguisher service.

I Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

I Be sure to disconnect battery ground cable before conducting operations.

I Pour drained fuel into an explosion-proof container, then ensure container lid is installed securely.

CAUTION:

I For ECM models, release fuel pressure from fuel line. Refer to EC section (ªFuel Pressure Releaseº,

ªBASIC SERVICE PROCEDUREº).

I Do not disconnect any fuel line unless absolutely necessary.

I Plug hose and pipe openings to prevent entry of dust or dirt.

I Always replace top lid seal and hose clamps with new ones.

I Do not kink or twist hoses and tubes during installation.

I Do not tighten hose clamps excessively because this could cause damage to the hose.

I Ensure fuel check valve is installed in the correct orientation.

I Refer to EC section (ªFUEL CHECK VALVEº, ªEVAPORATIVE EMISSION SYSTEMº).

I After installation, run engine and check for fuel leaks at connections.

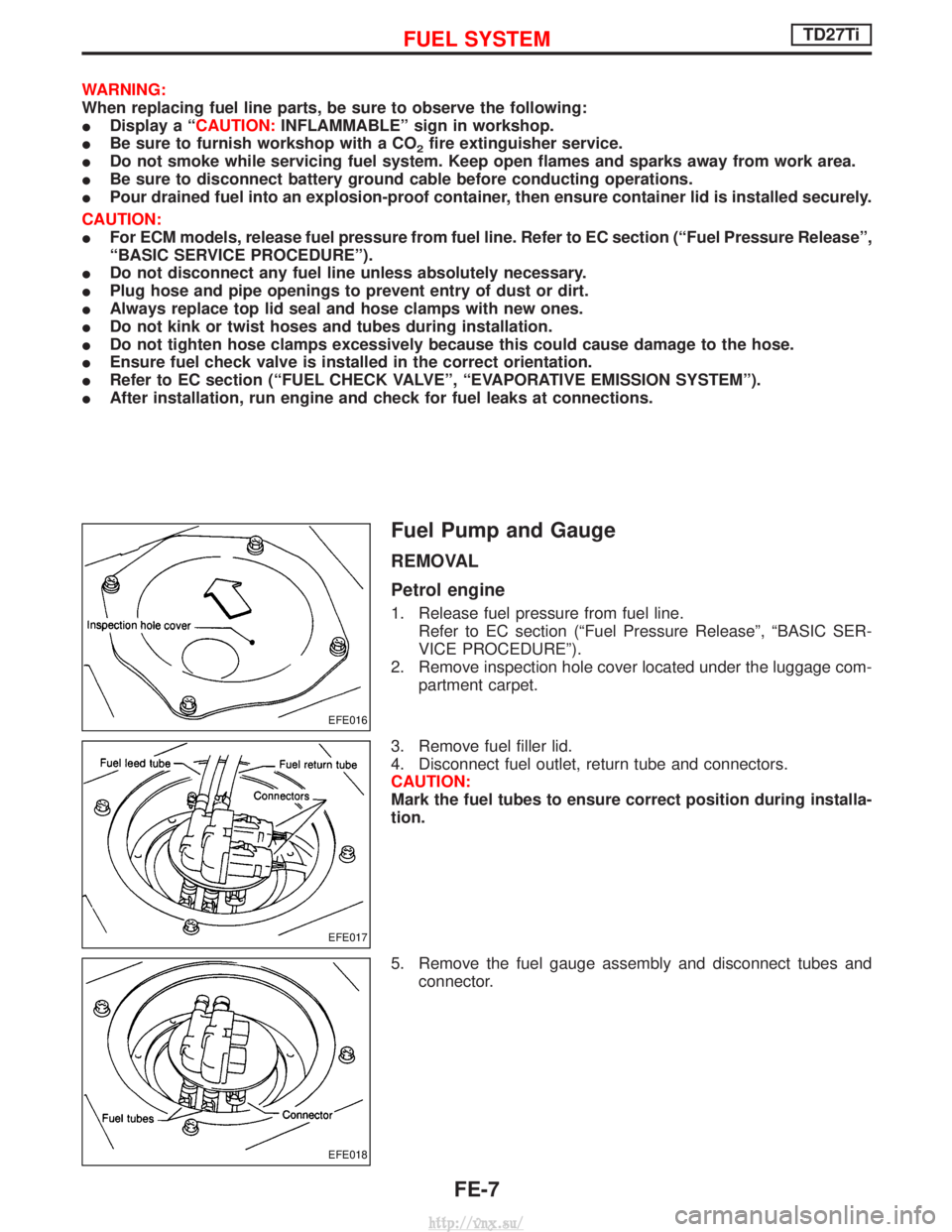

Fuel Pump and Gauge

REMOVAL

Petrol engine

1. Release fuel pressure from fuel line.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

2. Remove inspection hole cover located under the luggage com- partment carpet.

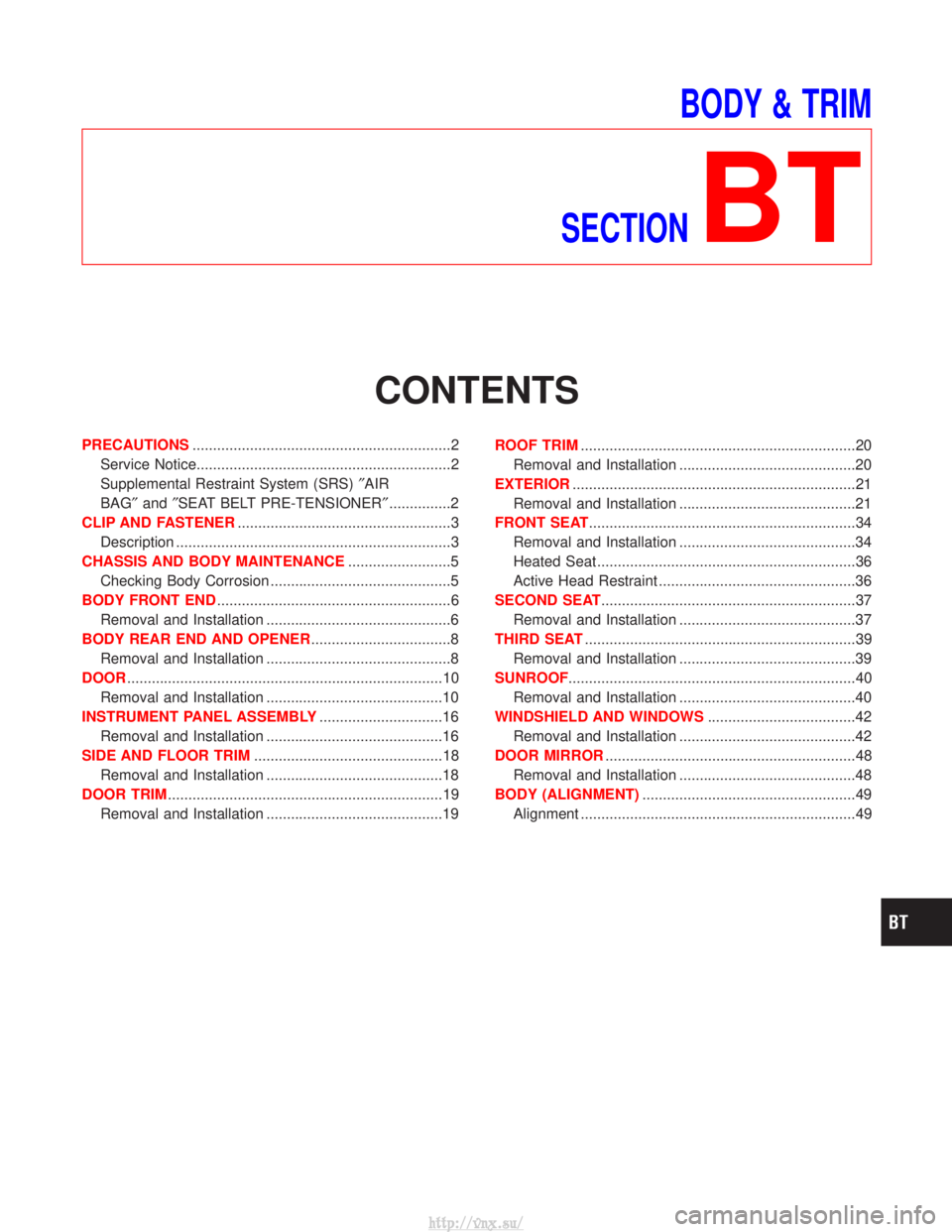

3. Remove fuel filler lid.

4. Disconnect fuel outlet, return tube and connectors.

CAUTION:

Mark the fuel tubes to ensure correct position during installa-

tion.

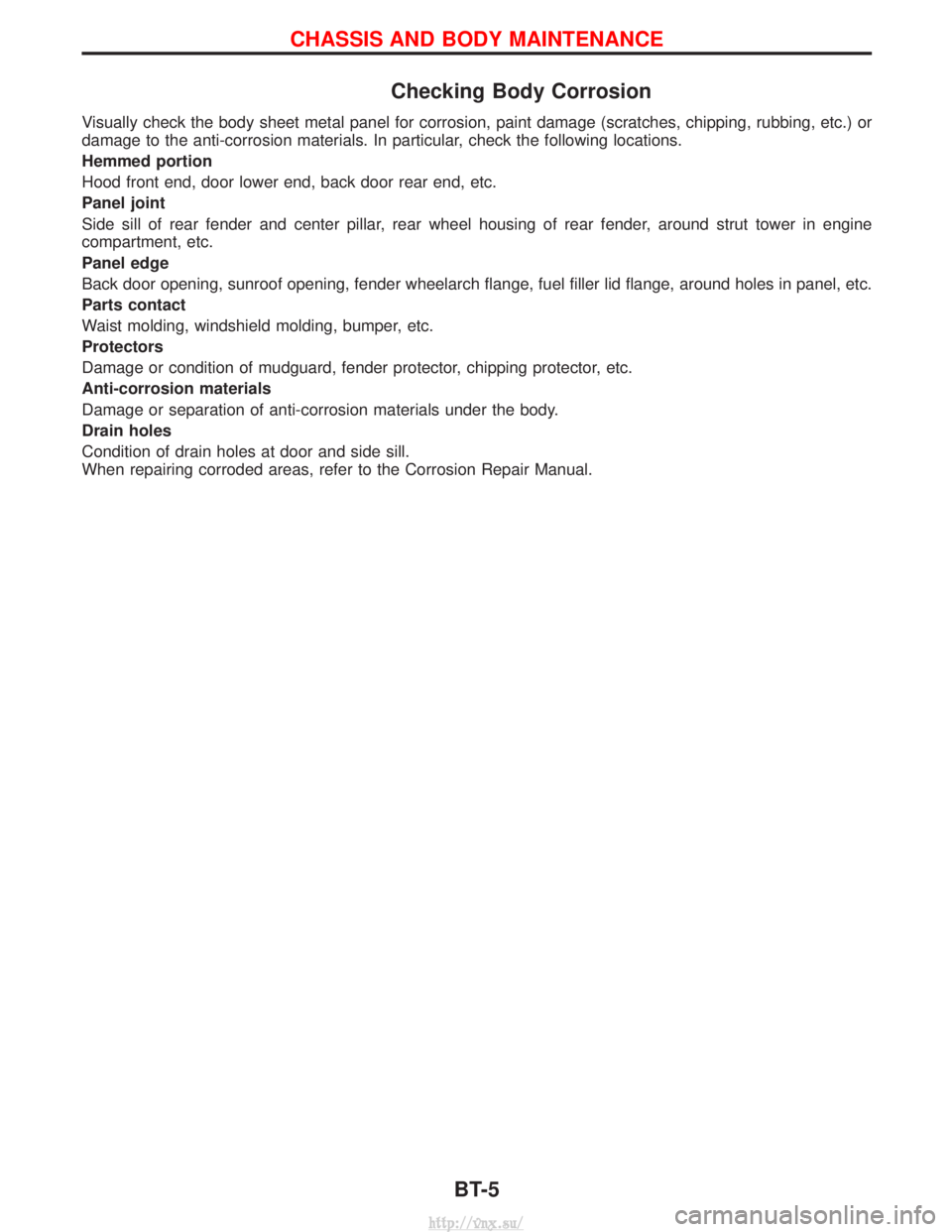

5. Remove the fuel gauge assembly and disconnect tubes and connector.

EFE016

EFE017

EFE018

FUEL SYSTEMTD27Ti

FE-7

http://vnx.su/

Page 1338 of 1833

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS ...............................................................2

Service Notice..............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............2

CLIP AND FASTENER ....................................................3

Description ...................................................................3

CHASSIS AND BODY MAINTENANCE .........................5

Checking Body Corrosion ............................................5

BODY FRONT END .........................................................6

Removal and Installation .............................................6

BODY REAR END AND OPENER ..................................8

Removal and Installation .............................................8

DOOR ........................................................................\

.....10

Removal and Installation ...........................................10

INSTRUMENT PANEL ASSEMBLY ..............................16

Removal and Installation ...........................................16

SIDE AND FLOOR TRIM ..............................................18

Removal and Installation ...........................................18

DOOR TRIM ...................................................................19

Removal and Installation ...........................................19 ROOF TRIM

...................................................................20

Removal and Installation ...........................................20

EXTERIOR .....................................................................21

Removal and Installation ...........................................21

FRONT SEAT .................................................................34

Removal and Installation ...........................................34

Heated Seat ...............................................................36

Active Head Restraint ................................................36

SECOND SEAT ..............................................................37

Removal and Installation ...........................................37

THIRD SEAT ..................................................................39

Removal and Installation ...........................................39

SUNROOF ......................................................................40

Removal and Installation ...........................................40

WINDSHIELD AND WINDOWS ....................................42

Removal and Installation ...........................................42

DOOR MIRROR .............................................................48

Removal and Installation ...........................................48

BODY (ALIGNMENT) ....................................................49

Alignment ...................................................................49

http://vnx.su/

Page 1342 of 1833

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, back door rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Back door opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

BT-5

http://vnx.su/

Page 1357 of 1833

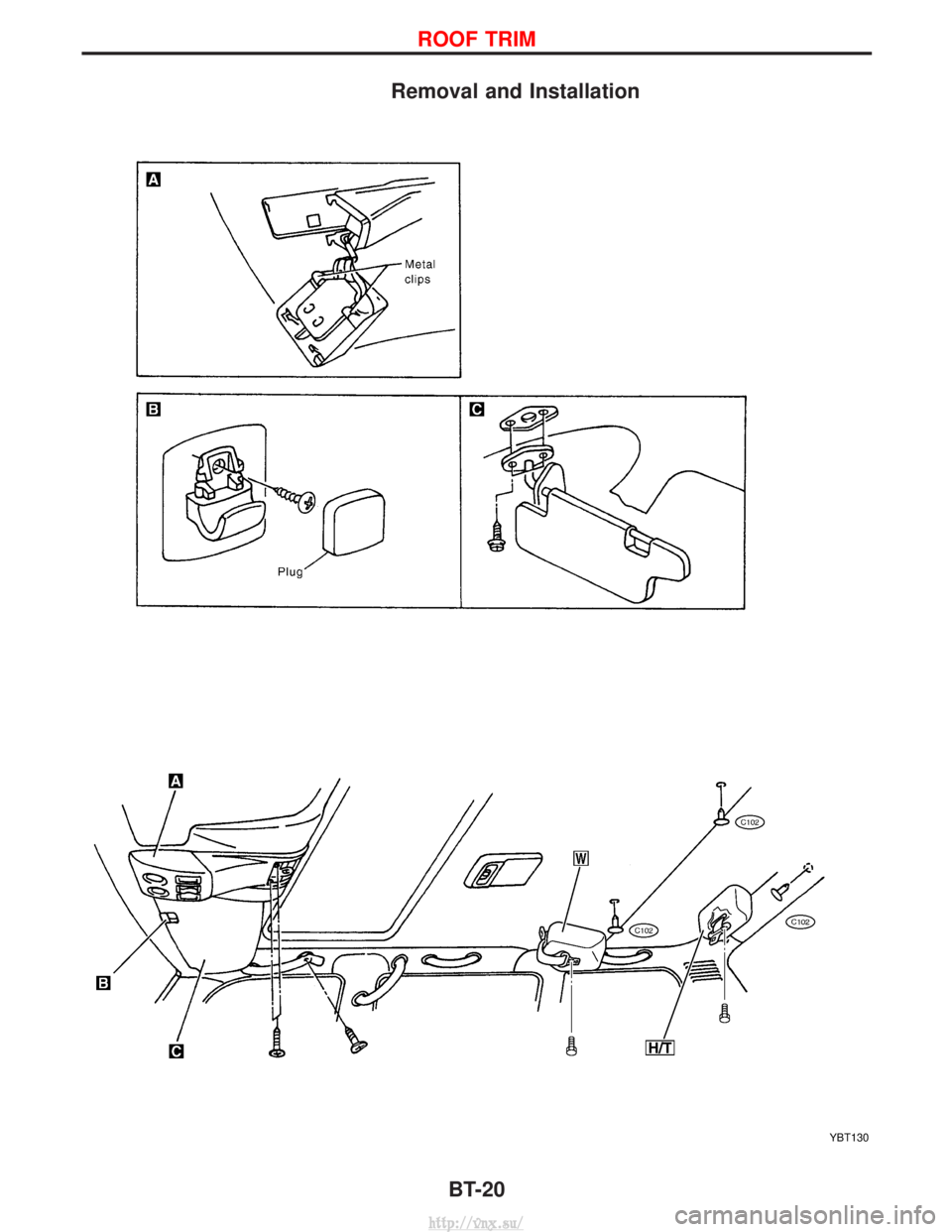

Removal and Installation

YBT130

ROOF TRIM

BT-20

http://vnx.su/

Page 1377 of 1833

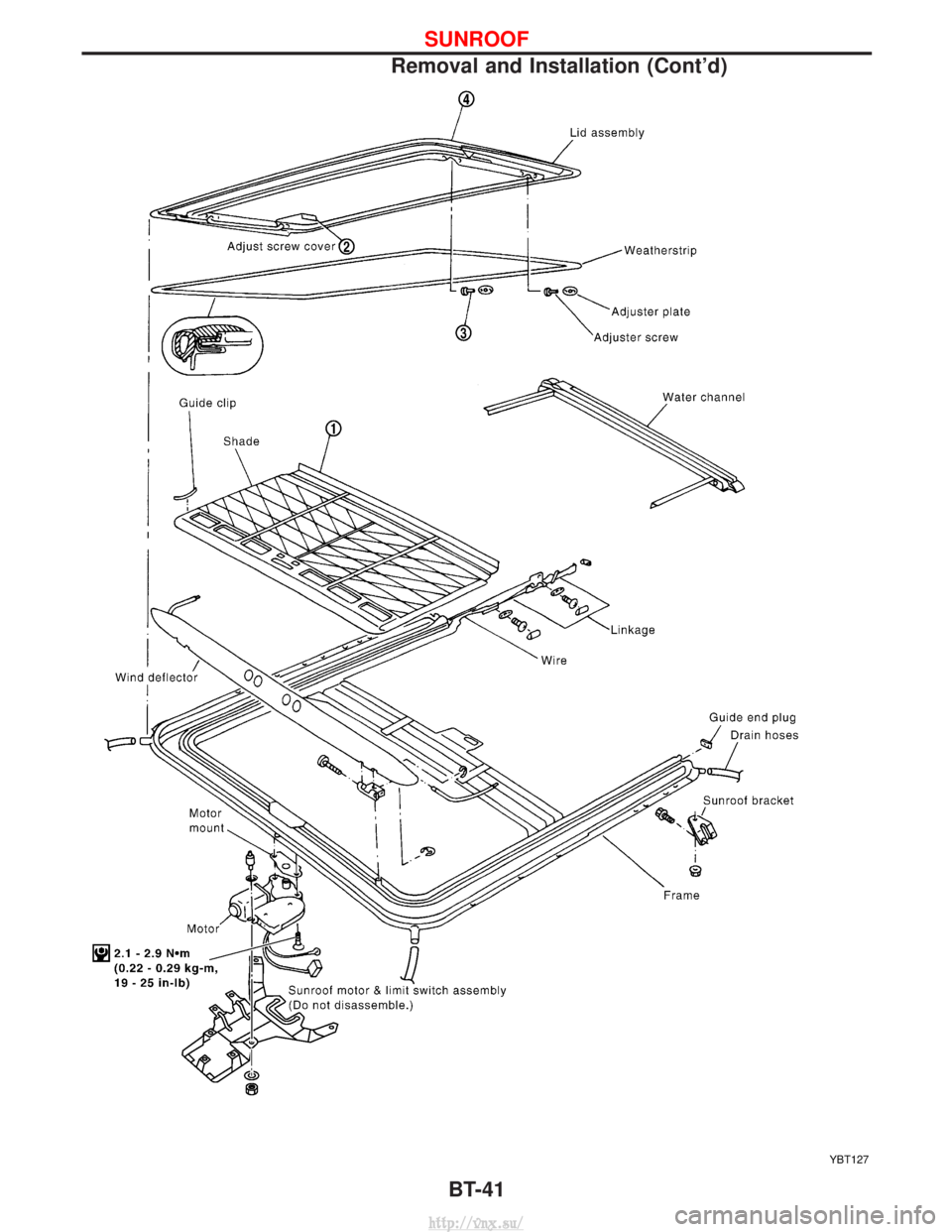

Removal and Installation

IAfter any adjustment, check sunroof operation and lid alignment.

I Handle finisher plate and glass lid with care so not to cause damage.

I It is desirable for easy installation to mark each point before removal.

CAUTION:

I Always work with a helper.

I Remove sunroof frame rear door opening.

SUNROOF LID ASSEMBLY

q1Open sunroof shade.

q

2Close sunroof lid, and remove adjustment screw covers.

q

3Remove the four adjuster screws

q

4Remove sunroof lid assembly.

SUNROOF ASSEMBLY

1. Remove headlining. For details, refer to ªROOF TRIMº, BT-20.

2. Disconnect interior lamp harness.

3. Disconnect front and rear drain hoses.

4. Remove nuts and bolts securing sunroof frame and motor to roof.

5. Remove sunroof assembly.

SUNROOF

BT-40

http://vnx.su/

Page 1378 of 1833

YBT127

SUNROOF

Removal and Installation (Cont'd)BT-41

http://vnx.su/