steering NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 2 of 1833

Edition: February 2004

Release: February 2004 (01)

Publication No.: SM4E00-1R20E0E

Reference No.: 7711347141

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

STARTING & CHARGING SYSTEMSSC

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

TERRANO

MODEL R20 SERIES

NISSAN EUROPE S.A.S.

2004 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

http://vnx.su/

Page 6 of 1833

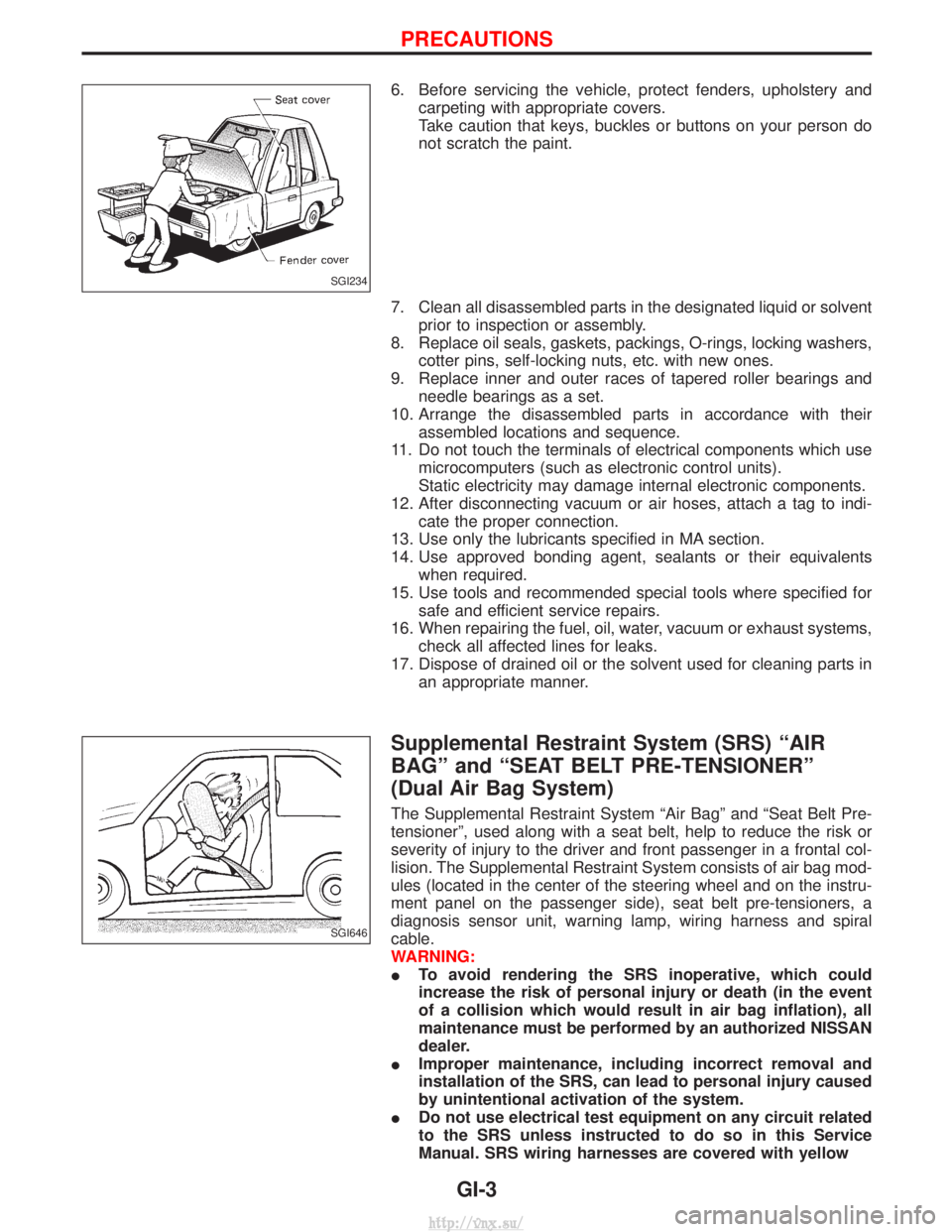

6. Before servicing the vehicle, protect fenders, upholstery andcarpeting with appropriate covers.

Take caution that keys, buckles or buttons on your person do

not scratch the paint.

7. Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

8. Replace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new ones.

9. Replace inner and outer races of tapered roller bearings and needle bearings as a set.

10. Arrange the disassembled parts in accordance with their assembled locations and sequence.

11. Do not touch the terminals of electrical components which use microcomputers (such as electronic control units).

Static electricity may damage internal electronic components.

12. After disconnecting vacuum or air hoses, attach a tag to indi- cate the proper connection.

13. Use only the lubricants specified in MA section.

14. Use approved bonding agent, sealants or their equivalents when required.

15. Use tools and recommended special tools where specified for safe and efficient service repairs.

16. When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

17. Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

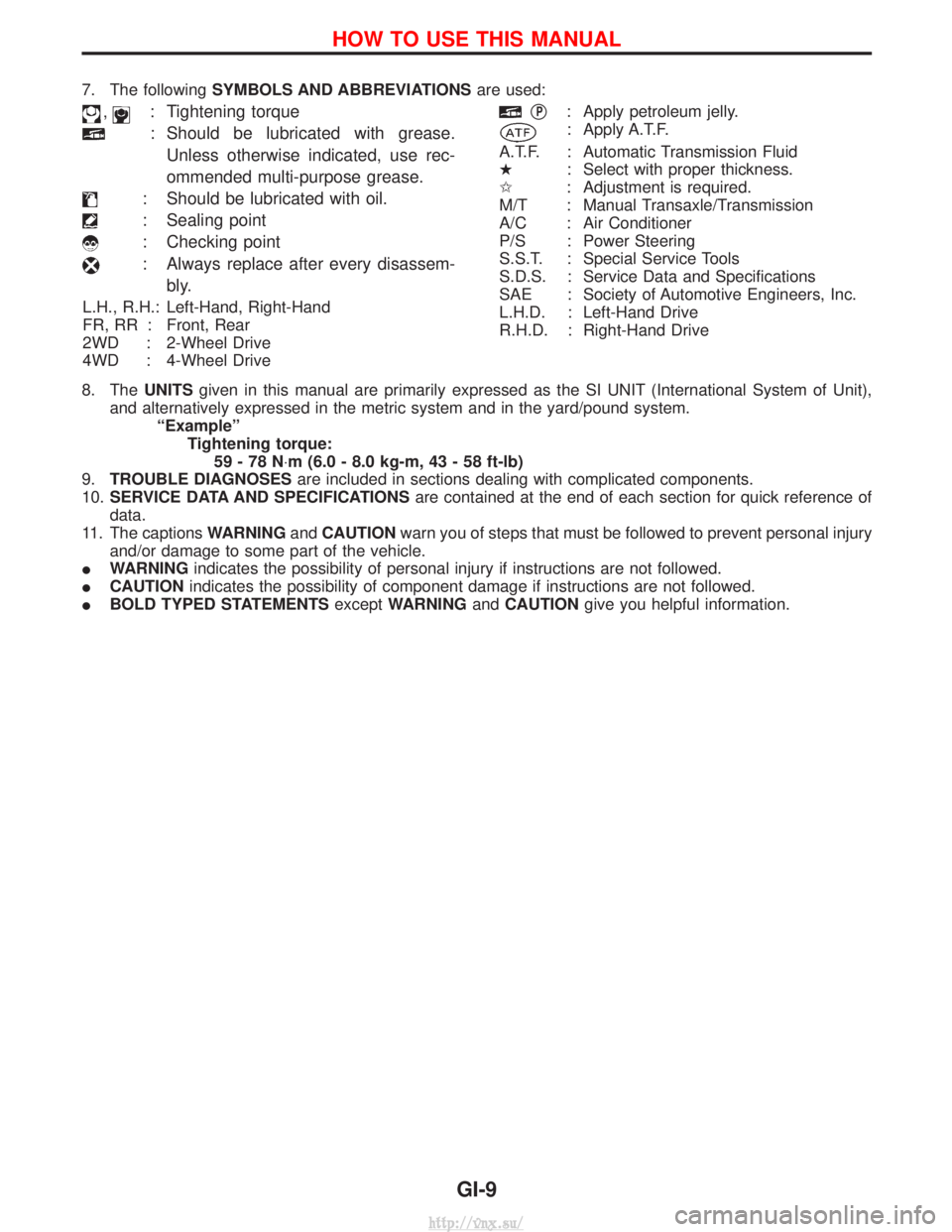

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

(Dual Air Bag System)

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-

tensionerº, used along with a seat belt, help to reduce the risk or

severity of injury to the driver and front passenger in a frontal col-

lision. The Supplemental Restraint System consists of air bag mod-

ules (located in the center of the steering wheel and on the instru-

ment panel on the passenger side), seat belt pre-tensioners, a

diagnosis sensor unit, warning lamp, wiring harness and spiral

cable.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death (in the event

of a collision which would result in air bag inflation), all

maintenance must be performed by an authorized NISSAN

dealer.

I Improper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related

to the SRS unless instructed to do so in this Service

Manual. SRS wiring harnesses are covered with yellow

SGI234

SGI646

PRECAUTIONS

GI-3

http://vnx.su/

Page 12 of 1833

7. The followingSYMBOLS AND ABBREVIATIONS are used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem- bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H : Select with proper thickness.

I : Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. The UNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system. ªExampleºTightening torque:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9. TROUBLE DIAGNOSES are included in sections dealing with complicated components.

10. SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

11. The captions WARNINGandCAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

I WARNING indicates the possibility of personal injury if instructions are not followed.

I CAUTION indicates the possibility of component damage if instructions are not followed.

I BOLD TYPED STATEMENTS exceptWARNING andCAUTION give you helpful information.

HOW TO USE THIS MANUAL

GI-9

http://vnx.su/

Page 35 of 1833

4-pole Lift

WARNING:

Do not use a 2-pole lift.

Due to weight balance of the vehicle and shape of underbody,

lift arms can not be attached in a safe way. Therefore it is rec-

ommended to use a 4-pole lift only.

Tow Truck Towing

CAUTION:

IAll applicable local laws regarding the towing operation

must be obeyed.

I It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

I Attach safety chains for all towing.

I When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

I When towing with the front wheels on the ground:

Move both the gearshift and transfer levers to neutral (ªNº

position).

Turn the ignition key to the ªOFFº position and secure the

steering wheel in a straightahead position with a rope or

similar device. Never place the ignition key in the ªLOCKº

position. This will result in damage to the steering lock

mechanism.

I When towing with the rear wheels on the ground, release

the parking brake and move both the gearshift and trans-

fer levers to neutral (ªNº position).

I Never tow vehicle from the rear (i.e., backward) with four

wheels on the ground as this may cause serious and

expensive damage to the transmission.

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

http://vnx.su/

Page 42 of 1833

MAINTENANCE

SECTION

MA

CONTENTS

PRE-DELIVERY INSPECTION ITEMS ............................3

GENERAL MAINTENANCE ............................................4

PERIODIC MAINTENANCE ............................................5

Maintenance Schedule for Diesel Engine Models

(annual mileage < 30,000 km/year) ............................5

Maintenance Schedule for Diesel Engine Models

(annual mileage > 30,000 km/year) ............................8

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) .......................... 11

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) ..........................14

RECOMMENDED FLUIDS AND LUBRICANTS ...........17

Fluids and Lubricants ................................................17

SAE Viscosity Number ..............................................18

Engine Coolant Mixture Ratio....................................19

TD

ENGINE MAINTENANCE ..............................................20

Retightening Manifold Bolts and Nuts .......................20

Adjusting Intake and Exhaust Valve Clearance ........20

Drive Belt Inspection..................................................20

Changing Engine Oil..................................................21

Changing Oil Filter .....................................................21

Changing Engine Coolant..........................................22

Checking Cooling System .........................................23

Checking and Replacing fuel filter and Draining

Water ........................................................................\

.23

Cleaning and Replacing Air Cleaner Filter (Dry

paper type).................................................................24

Checking Injection Nozzle .........................................25

Checking Idle Speed .................................................26

ZD

ENGINE MAINTENANCE ..............................................28

Checking Tightening Torque ......................................28

Adjusting Intake and Exhaust Valve Clearance ........28

Checking Drive Belt ...................................................28

Removal .....................................................................29 Installation ..................................................................29

Changing Engine Oil..................................................29

Changing Engine Oil Filter ........................................30

Changing Engine Coolant..........................................31

Checking Cooling System .........................................32

Checking and Replacing Fuel Filter and Draining

Water ........................................................................\

.33

Checking Fuel Lines ..................................................34

Cleaning and Replacing Air Cleaner Filter ................35

CHASSIS AND BODY MAINTENANCE .......................36

Checking Exhaust System.........................................36

Checking Clutch Operation........................................36

Checking Clutch Fluid Level and Leaks ....................36

Checking Clutch System ...........................................36

Checking M/T Oil .......................................................36

Changing M/T Oil.......................................................37

Checking Water Entry ................................................37

Checking Transfer Oil ................................................37

Changing Transfer Oil................................................38

Checking Propeller Shaft ...........................................38

Checking Differential Gear Oil ...................................38

Changing Differential Gear Oil ..................................39

Checking Front Wheel Bearing Grease ....................39

Repacking Front Wheel Bearing Grease ..................39

Checking Free-running Hub Grease .........................40

Checking Brake Fluid Level and Leaks.....................40

Checking Brake System ............................................40

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................40

Checking Disc Brake .................................................40

Checking Drum Brake ...............................................41

Checking Foot Brake Pedal Operation......................42

Checking Parking Brake ............................................42

Changing Brake Fluid ................................................43

Balancing Wheels ......................................................43

Tire Rotation ..............................................................43

Checking Steering Gear and Linkage .......................43

Checking Fluid Level and Leaks (Power steering) ...44

http://vnx.su/

Page 43 of 1833

Greasing Steering Linkage ........................................44

Ventilation Air Filter ....................................................44

Body ........................................................................\

...45

Checking Body Corrosion ..........................................47SERVICE AND SPECIFICATIONS (SDS)

.....................48

Engine Maintenance ..................................................48

Chassis and Body Maintenance ................................49

CONTENTS(Cont'd)

MA-2

http://vnx.su/

Page 44 of 1833

Shown below are Pre-delivery Inspection items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

lRadiator coolant level and coolant hose connections for leaks

l Battery fluid level, specific gravity and conditions of battery terminals

l Drive belts tension

l Fuel filter for water or dust, and fuel lines and connections for leaks

l Engine oil level and oil leaks

l Brake and clutch reservoirs fluid level and fluid lines for leaks

l Windshield and rear window washer and headlamp cleaner reservoir fluid level

l Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

lRemove front spring/strut spacer (if applicable)

l Operation of all instruments, gauges, lights and accessories

l Operation of horn(s), wiper and washer

l Steering lock for operation

l Check air conditioner for gas leaks

l Front and rear seats, and seat belts for operation

l All moldings, trims and fittings for fit and alignment

l All windows for operation and alignment

l Hood, tailgate, door panels for fit and alignment

l Latches, keys and locks for operation

l Weatherstrips for adhesion and fit

l Headlamp aiming

l Tighten wheel nuts (Inc. inner nuts if applicable)

l Tire pressure (Inc. spare tire)

l Check front wheels for toe-in

l Install clock/voltmeter/room lamp fuse (if applicable)

l Install deodorizing filter to air conditioner (if applicable)

l Remove wiper blade protectors (if applicable)

UNDER BODY

lManual transmission/transaxle, transfer and differential gear oil level

l Brake and fuel lines and oil/fluid reservoirs for leaks

l Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

l Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

lClutch operation

l Parking brake operation

l Service brake operation

l Automatic transmission/transaxle shift timing and kickdown (if applicable)

l Steering control and returnability

l Engine performance

l Squeaks and rattles

ENGINE OPERATING AND HOT

lAdjust idle speed

l Automatic transmission/transaxle fluid level (if applicable)

l Engine idling and stop knob operation

FINAL INSPECTION

lInstall necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

l Inspect for interior and exterior metal and paint damage

l Check for spare tire, jack, tools (wheel check) and literature

l Wash, clean interior and exterior

PRE-DELIVERY INSPECTION ITEMS

MA-3

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/

Page 48 of 1833

![NISSAN TERRANO 2004 Service Repair Manual Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTE NISSAN TERRANO 2004 Service Repair Manual Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTE](/img/5/57394/w960_57394-47.png)

Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten[ ] = At the specified mileage only

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Refer-ence

page

Perform on a kilometer basis, but on

a semi-annual basis when driving

less than 20,000 km (12,000 miles)

per year. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Months 6 12 18 24 30 36 42 48 54 50 66 72

Underhood and under vehicle

Headlamp aiming

IIIIII EL-41

Wheel alignment (if necessary, rotate & balance wheels) IIIIII MA-43

Brake pads, discs & other components* IIIIII MA-40

Brake linings, drums & other components* IIIIII MA-41

Foot brake, parking brake & clutch (for free play, stroke &

operation) IIIIII

MA-42

Brake booster vacuum hoses, connections, check valve I I I MA-40

Brake & clutch, systems and fluid (for level and leaks) IIIIII MA-36/

MA-40

Brake fluid* R R R MA-43

Power steering fluid and lines (for level and leaks) IIIIII MA-44

Air bag system See NOTE (1) RS-17

Ventilation air filter* RRRRMA-44

Transfer and standard differential gear oil* I I R I I R MA-37/

MA-38

Manual transmission oil I I I [R] I I MA-36

LSD gear oil (for level and leaks)* I I R I I R MA-38

Steering gear & linkage, axle & suspension parts, propeller

shaft and exhaust system* IIIIII MA-43/

FA-4/

RA-4/

MA-38/ MA-36

Greasing points of steering gear linkage,

propeller shaft and suspension* See NOTE (2)

LLLLLL MA-44/

MA-38

Drive shafts* IIIIIIF A-13

Front wheel bearing grease* IRIRIR MA-39

Free running hub grease* IIIIII MA-40

Body mounting bolts and nuts TTTTTTBT-48

Body corrosion See NOTE (3) MA-47

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) Inspect once per year.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe drivingconditionsº.

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

(Cont'd)

MA-7

http://vnx.su/

Page 51 of 1833

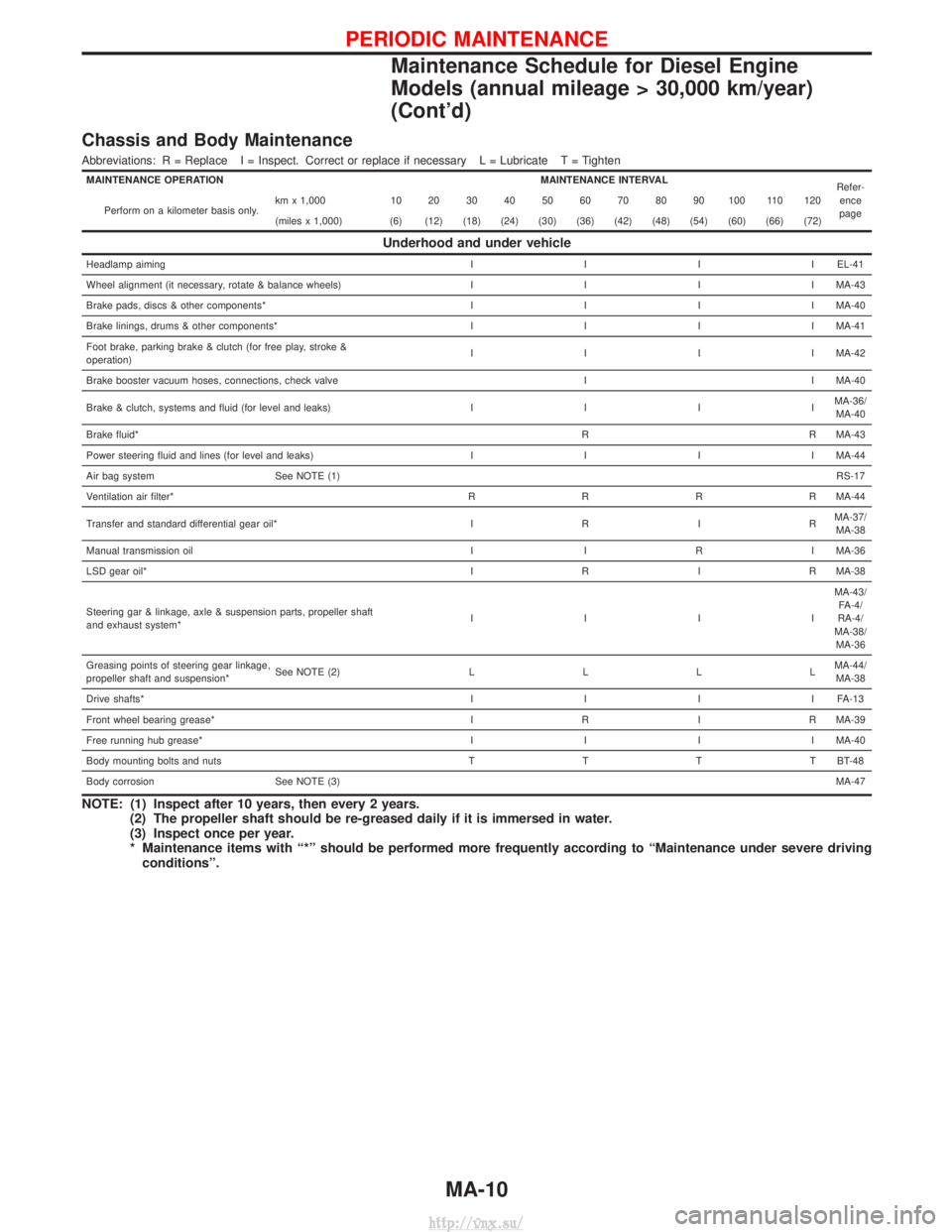

Chassis and Body Maintenance

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary L = Lubricate T = Tighten

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page

Perform on a kilometer basis only. km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Underhood and under vehicle

Headlamp aiming

IIIIEL-41

Wheel alignment (it necessary, rotate & balance wheels) IIIIMA-43

Brake pads, discs & other components* IIIIMA-40

Brake linings, drums & other components* IIIIMA-41

Foot brake, parking brake & clutch (for free play, stroke &

operation) IIII

MA-42

Brake booster vacuum hoses, connections, check valve I I MA-40

Brake & clutch, systems and fluid (for level and leaks) IIIIMA-36/

MA-40

Brake fluid* R R MA-43

Power steering fluid and lines (for level and leaks) IIIIMA-44

Air bag system See NOTE (1) RS-17

Ventilation air filter* RRRRMA-44

Transfer and standard differential gear oil* IRIRMA-37/

MA-38

Manual transmission oil I I R I MA-36

LSD gear oil* IRIRMA-38

Steering gar & linkage, axle & suspension parts, propeller shaft

and exhaust system* IIIIMA-43/

FA-4/

RA-4/

MA-38/ MA-36

Greasing points of steering gear linkage,

propeller shaft and suspension* See NOTE (2)

LLLL MA-44/

MA-38

Drive shafts* IIIIFA-13

Front wheel bearing grease* IRIRMA-39

Free running hub grease* IIIIMA-40

Body mounting bolts and nuts TTTTBT-48

Body corrosion See NOTE (3) MA-47

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) Inspect once per year.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe drivingconditionsº.

PERIODIC MAINTENANCE

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

(Cont'd)

MA-10

http://vnx.su/